Patents

Literature

147results about How to "Increase production profit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

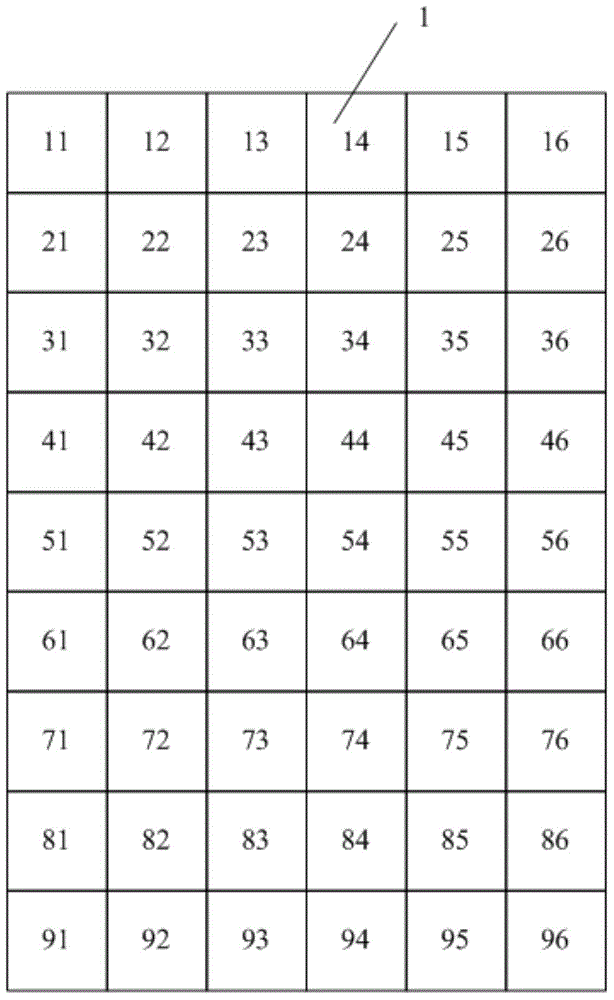

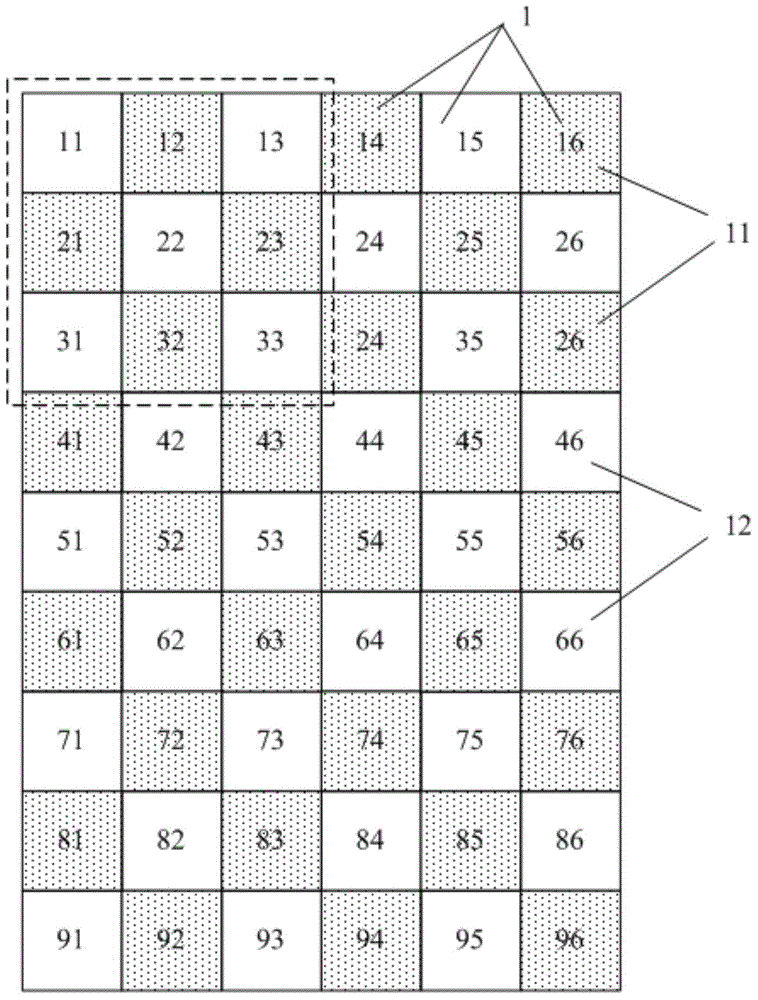

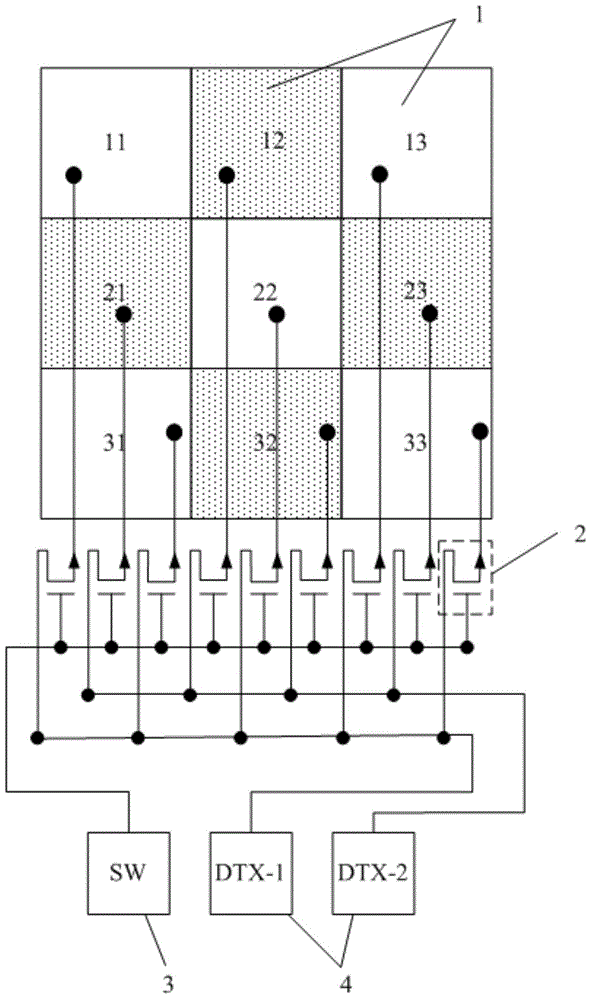

Display substrate and testing method and display device thereof

ActiveCN105093593AImprove yieldImprove bad detection rateStatic indicating devicesNon-linear opticsDisplay deviceComputer science

The invention belongs to the technical field of display, and particularly relates to a display substrate and a testing method and display device thereof. The display substrate comprises a plurality of pixel regions arranged in a matrix mode and a testing unit. Each pixel region is provided with a first electrode. The testing unit comprises at least two subsidiary testing units. The corresponding first electrodes of the pixel regions adjacent in position are classified into one electrode block. All the electrode blocks are electrically isolated. The electrode blocks are divided into at least two testing sets with the number the same as that of the subsidiary testing units according to set positions. The electrode blocks belonging to the same testing set are arranged in an intersecting and staggered mode in the row and column directions. The electrode blocks in the same testing set are connected with one subsidiary testing unit. The testing unit can accurately test open circuit and short circuit defects of a touch display panel during the display stage or the touch stage, the testing accuracy is improved, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

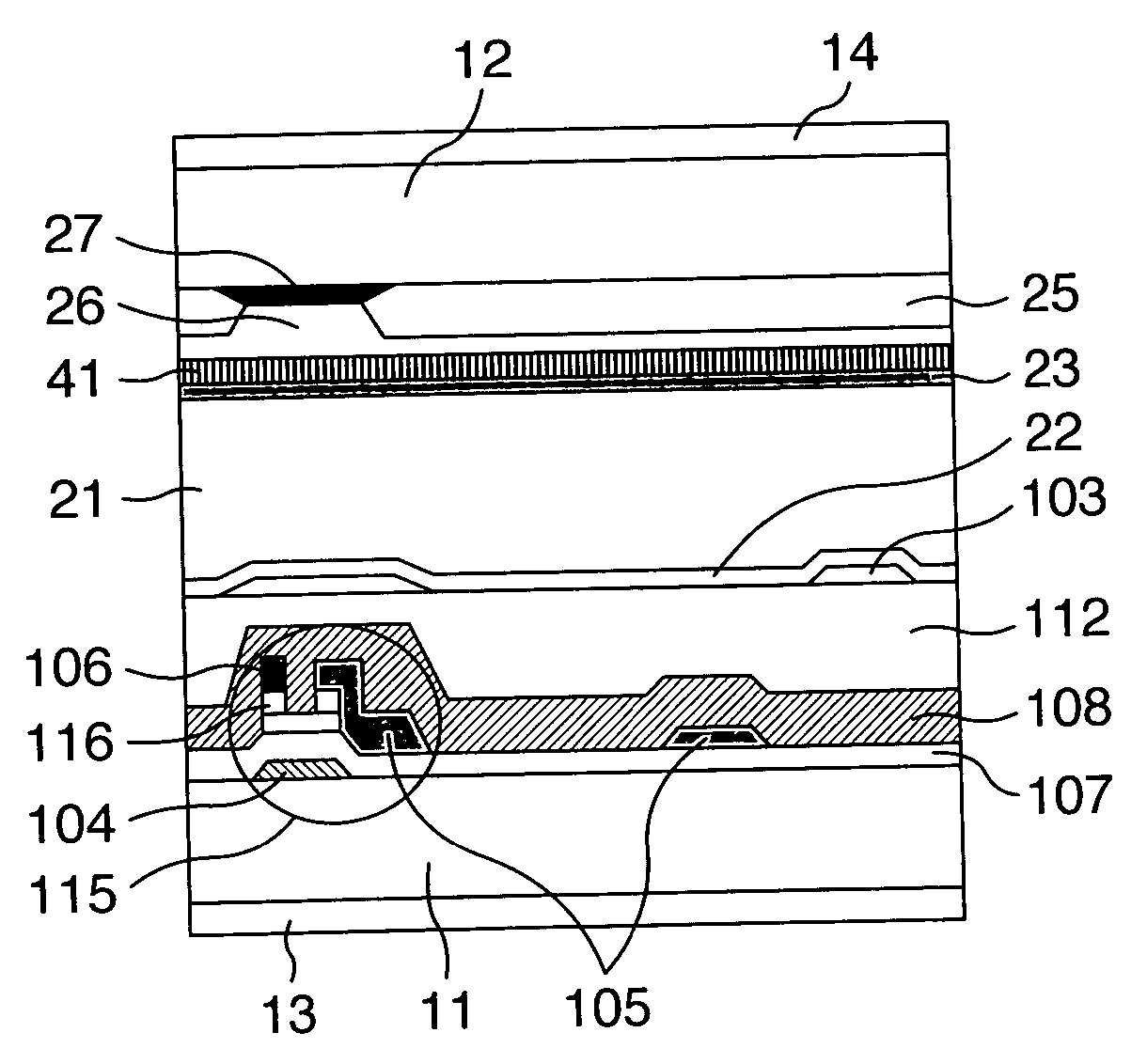

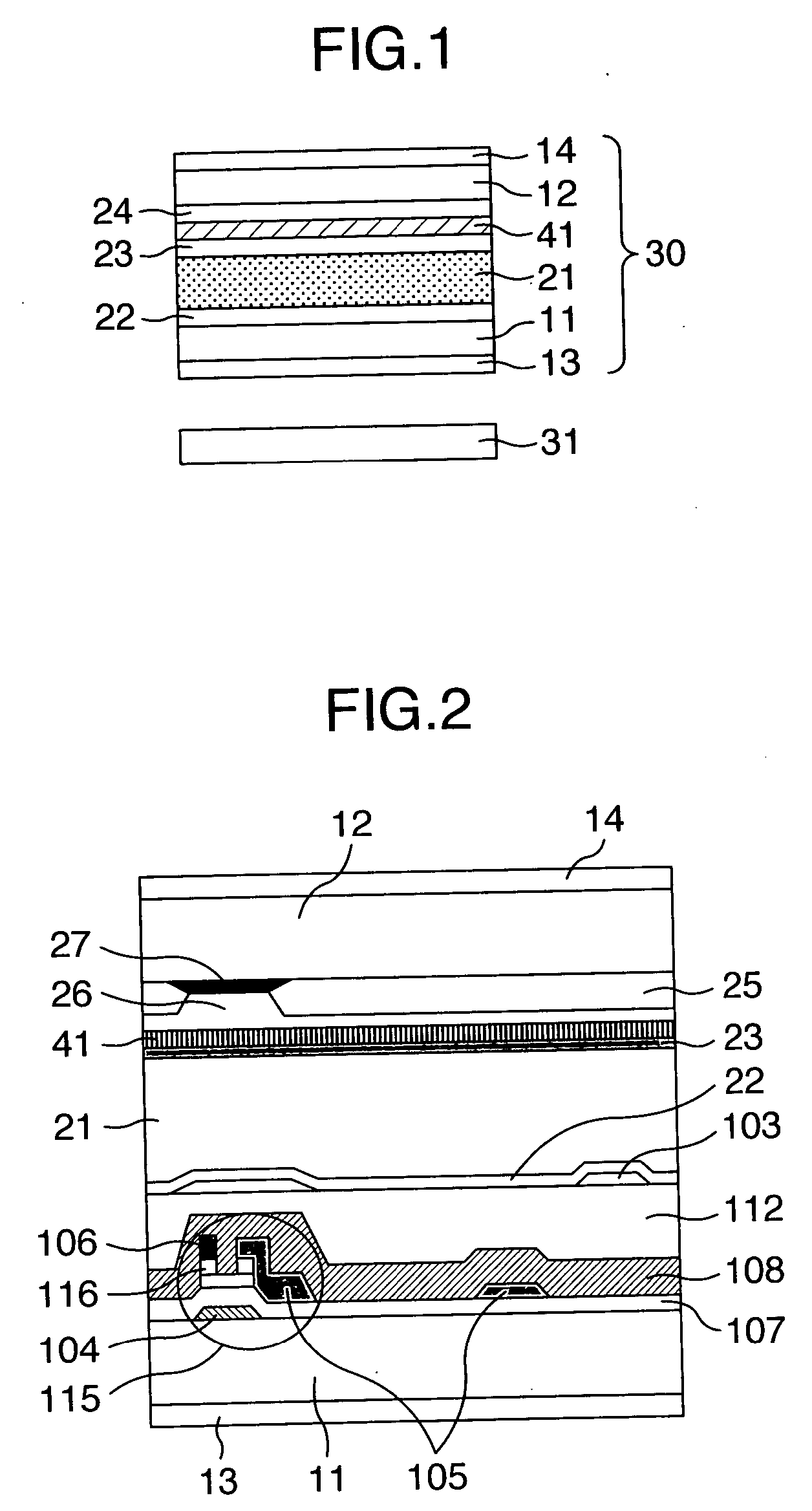

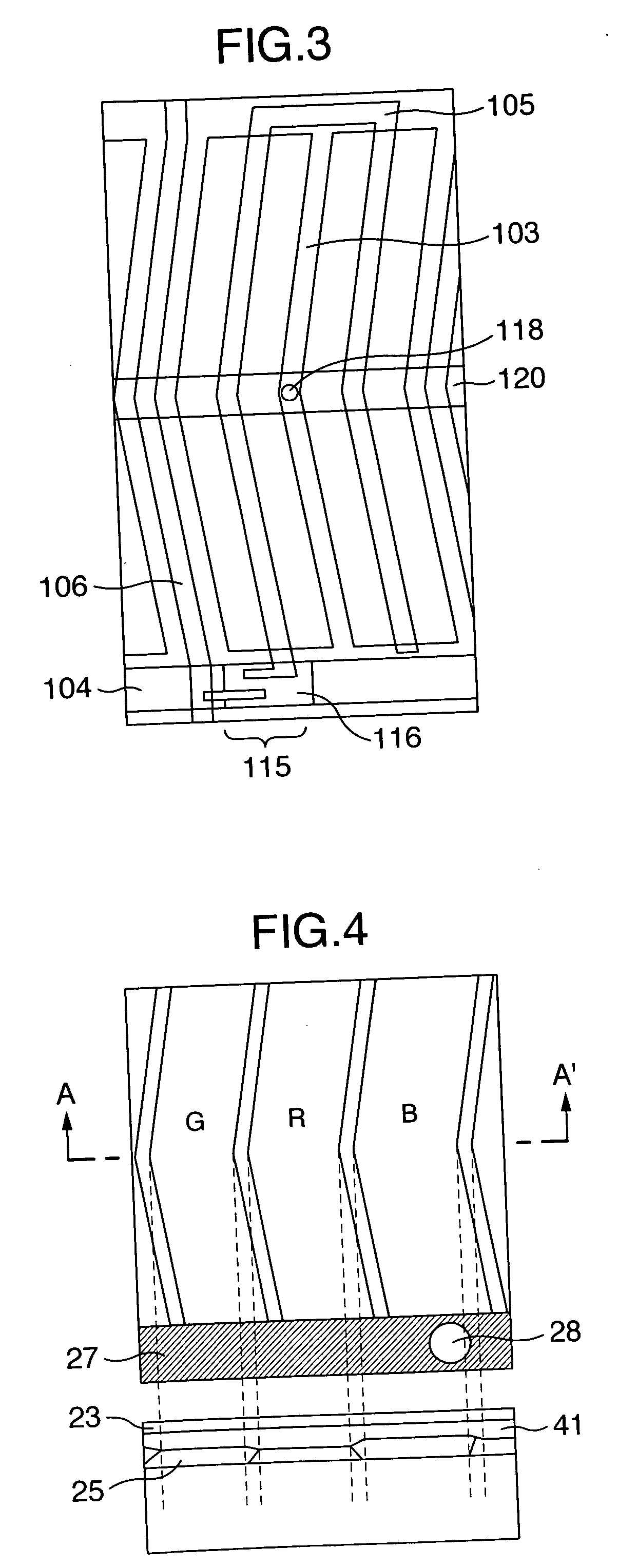

Liquid crystal display apparatus

InactiveUS20060066788A1Black luminance is reducedIncrease contrastNon-linear opticsLiquid-crystal displayContrast ratio

A liquid crystal display apparatus including one pair of substrates, at least one of said substrates being transparent, one pair of polarizing plates arranged on the paired substrates respectively, a liquid crystal layer sandwiched by the paired substrates, a liquid crystal display panel in which an electrode group is formed on at least one of the paired substrates and is to apply an electric field to the liquid crystal layer, and a light source unit arranged on a rear surface of the liquid crystal display panel, a monoaxial absorption anisotropic layer provided between the paired polarizing plates. In such apparatus, a high contrast ratio can be achieved due to suppression of black luminance. Also, better display qualities can be achieved by reducing a blue changing phenomenon of black representation.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

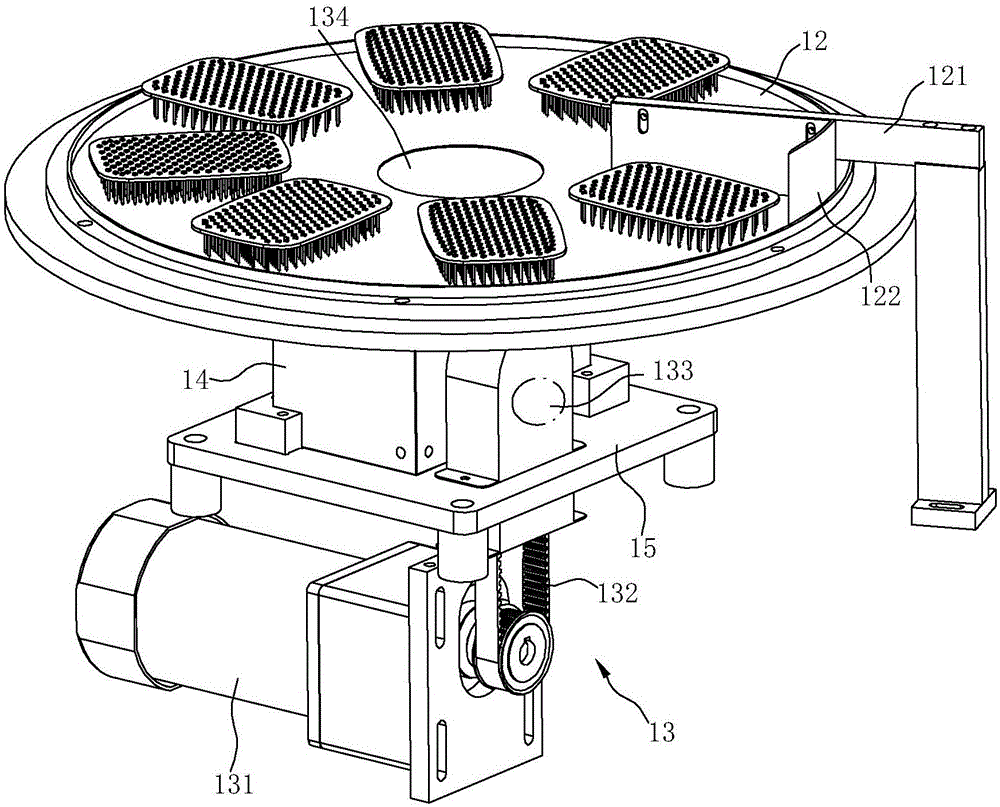

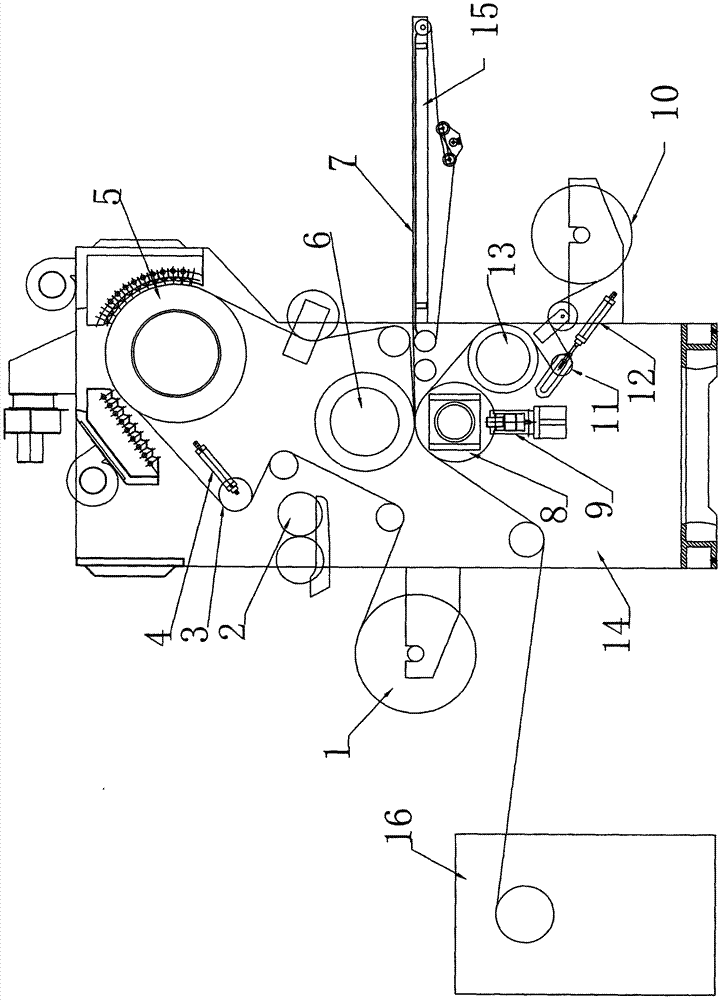

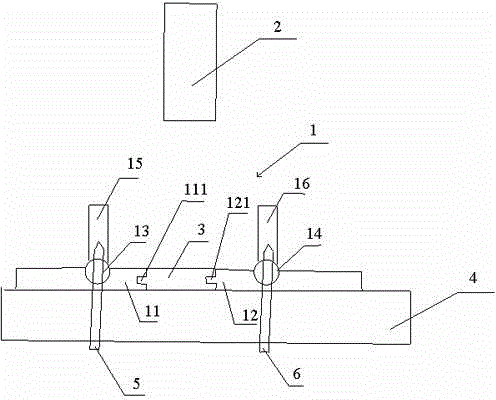

Automatic hair dyeing machine for comb teeth

The invention relates to an automatic hair dyeing machine for comb teeth. The automatic hair dyeing machine comprises a hair dyeing mechanism and a comb body transferring and taking mechanism. The hair dyeing mechanism at least comprises a rotatable oil disc used for placing hair oil for dyeing hair. The comb body transferring and taking mechanism comprises a first transferring and taking mechanism capable of transferring comb bodies to be subjected to hair dyeing into the oil disc and a second transferring and taking mechanism capable of transferring the comb bodies obtained after hair dyeing is finished out of the hair dyeing mechanism. The first transferring and taking mechanism and the second transferring and taking mechanism are arranged on the two sides of the oil disc respectively. When the automatic hair dyeing machine is used, the first transferring and taking mechanism can move the comb bodies to the subjected to hair dyeing into the oil disc; and due to the fact that the oil disc rotates all the time, the comb bodies obtained after hair dyeing is finished are transferred to the second transferring and taking mechanism along with rotating of the oil disc. The second transferring and taking mechanism takes the comb bodies obtained after hair dyeing is finished out. Meanwhile, the oil disc without the comb bodies rotates continuously to the first transferring and taking mechanism to bear new comb bodies to the subjected to hair dyeing, and the process is repeated till the automatic hair dyeing work of the comb teeth is finished. The automatic hair dyeing machine is convenient to use, working efficiency is improved, and the production cost of combs is lowered.

Owner:NINGBO RAVO IND GRP CO LTD

Automatic terminal screw assembling machine with material rejecting function

ActiveCN102303238AImplement automatic assemblySave human effortMetal working apparatusEngineeringMechanical engineering

The invention relates to an automatic terminal screw assembling machine with a material rejecting function, which comprises a terminal vibration disk, a first terminal positioning index plate, a screw vibration disk, a screw positioning index disk, a first electric screw driver, a second terminal positioning index plate and a fourth electric screw driver, wherein the edge of the first terminal positioning index plate is provided with a plurality of first grooves, terminals sent by the terminal vibration disk sequentially fall in the first grooves, the lateral side of the screw positioning index plate is provided with a plurality of notches, screws sent by the screw vibration disk sequentially enter the notches, the first grooves have one first longitudinal coincidence position with the notches, the first electric screw driver is positioned above the first longitudinal coincidence position, the edge of the second terminal positioning index plate is provided with a plurality of second grooves, the first grooves have one second longitudinal coincidence position with the second grooves, and the fourth electric screw driver is positioned above the second groove behind the second longitudinal coincidence position. The automatic terminal screw assembling machine has the advantages of high safety, high production efficiency and stable quality, and has the material rejecting function.

Owner:徐圣宇

Tender and crisp fish ball and making method thereof

The invention discloses a tender and crisp fish ball. The tender and crisp fish ball comprises the following components in parts by weight: 45-60 parts of minced fillet of frozen nemipterus virgatus, 0.5-2 parts of tender and crisp agent, 3-8 parts of pig fat, 20-30 parts of ice water, 0.1-0.5 part of composite phosphate, 1-3 parts of table salt, 0.1-1.0 part of aginomoto, 0.1-1.0 part of glucose, 0.1-1.0 part of seafood flavor and 5-20 parts of accessories. The invention also relates to a method for making the fish balls; the method has the following advantages: (1) the high-quality minced fillet of nemipterus virgatus is adopted so that the protein content is rich, the accessories of the product are simple, and the water binding capacity and freezing resistance of the product can be guaranteed without any starch and colloid; (2) the tender and crisp agent comprises protein as a major component, and is nutritive, healthy and harmless to a human body, and capable of keeping better tender and crisp taste of the product while supplementing the protein; and (3) a simple steaming process is adopted, so that the production cost of an enterprise is saved and the productive profit of the enterprise is increased.

Owner:SHANDONG HUIFA FOODS

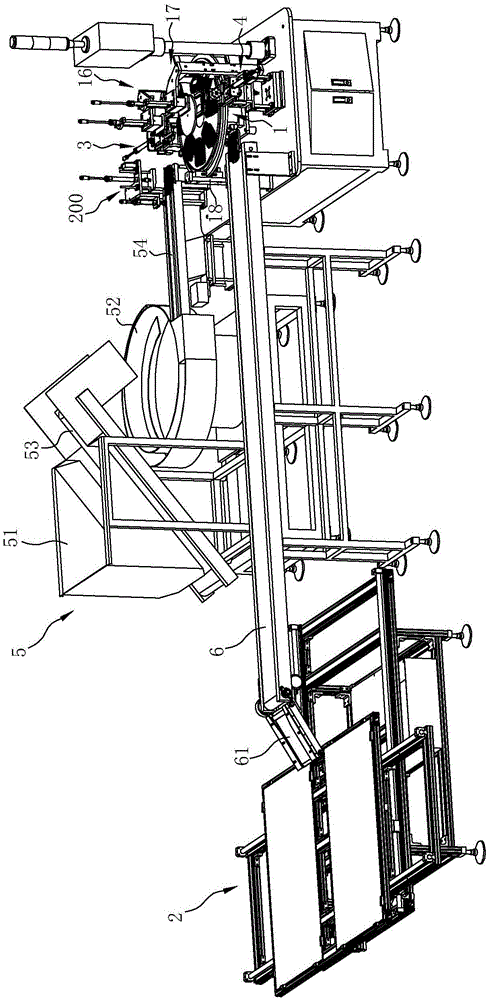

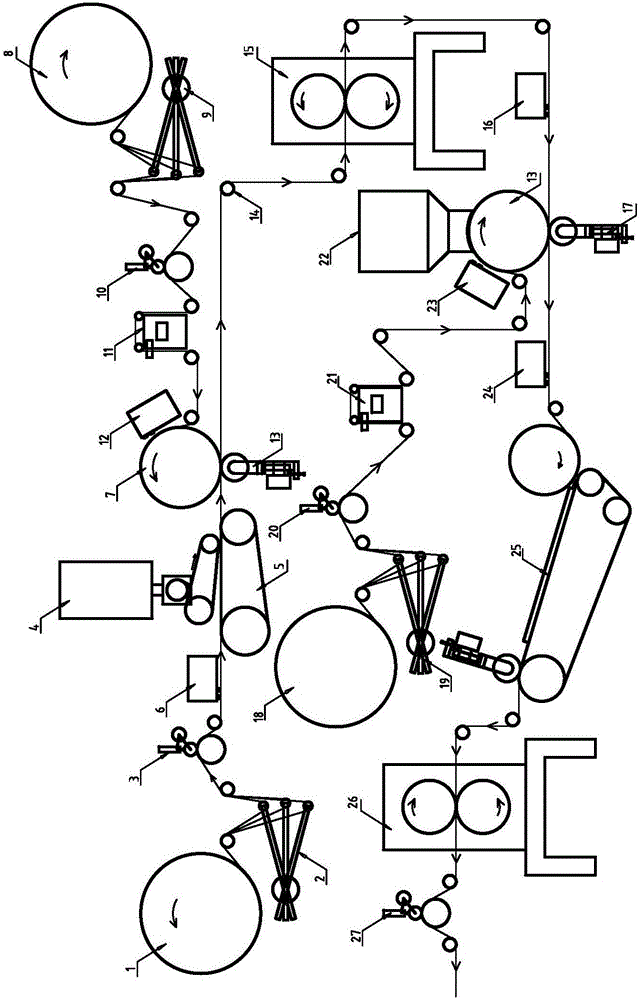

Multi-purpose type double-sided film laminating system

InactiveCN107160852AAvoid wrinklesFully warmed upLamination ancillary operationsLaminationMechanical engineeringEnergy conservation

The invention discloses a multi-purpose type double-sided film laminating system applied to a film laminating machine. The multi-purpose type double-sided film laminating system comprises a rack (14), an upper film roller (1) and a hot-pressing mechanism, wherein a gluing mechanism and a drying mechanism (5) are installed in sequence on the rack and above the hot-pressing mechanism, and a preheating roller (13) and a lower film roller (10) are installed in sequence on the rack and below the hot-pressing mechanism. An extension roller (11) is installed on the rack and between the preheating roller and the lower film roller, and the extension roller is connected with an extension power source (12).According to the multi-purpose type double-sided film laminating system, instant coating or precoating can be flexibly selected, so that the convenience is provided for the next processing procedure after a film is laminated on paper, the film can be effectively prevented from generating wrinkles during operation, a big enough wrap angle between the film and the preheating roller is guaranteed so as to be fully preheated, and the film laminating quality is high. The multi-purpose type double-sided film laminating system has the advantages of reasonable structure, simplicity in operation, energy conservation, environmental friendliness and high heat utilization rate, multiple purposes of one machine are realized, and the multi-purpose type double-sided film laminating system can be widely used for various paper materials.

Owner:RUIAN GREAT PRINTING & PACKAGING MACHINERY

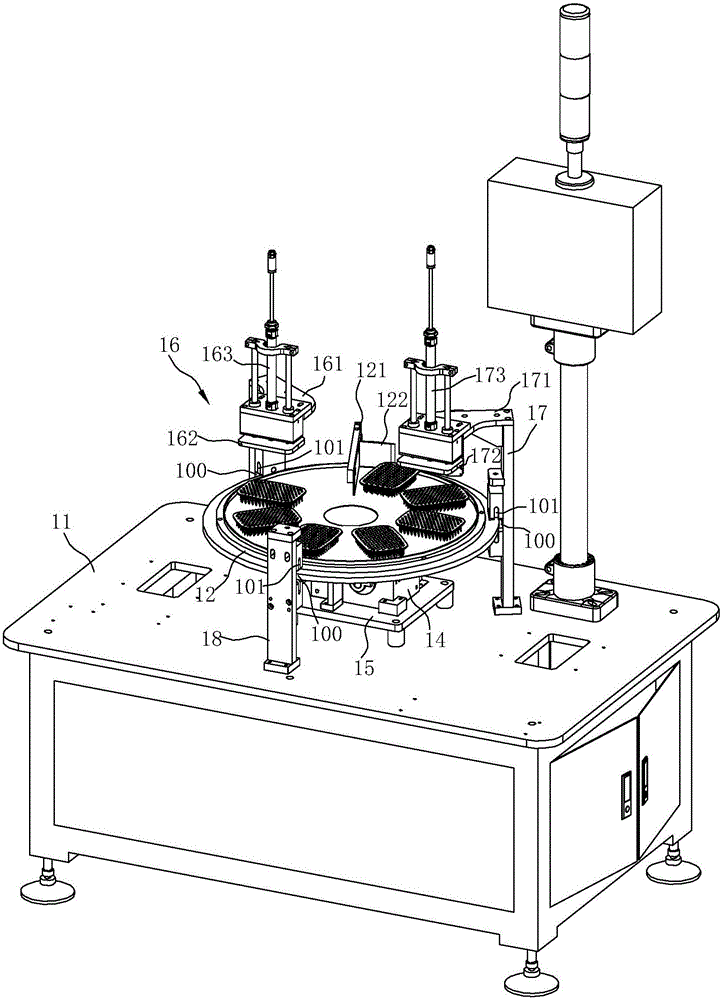

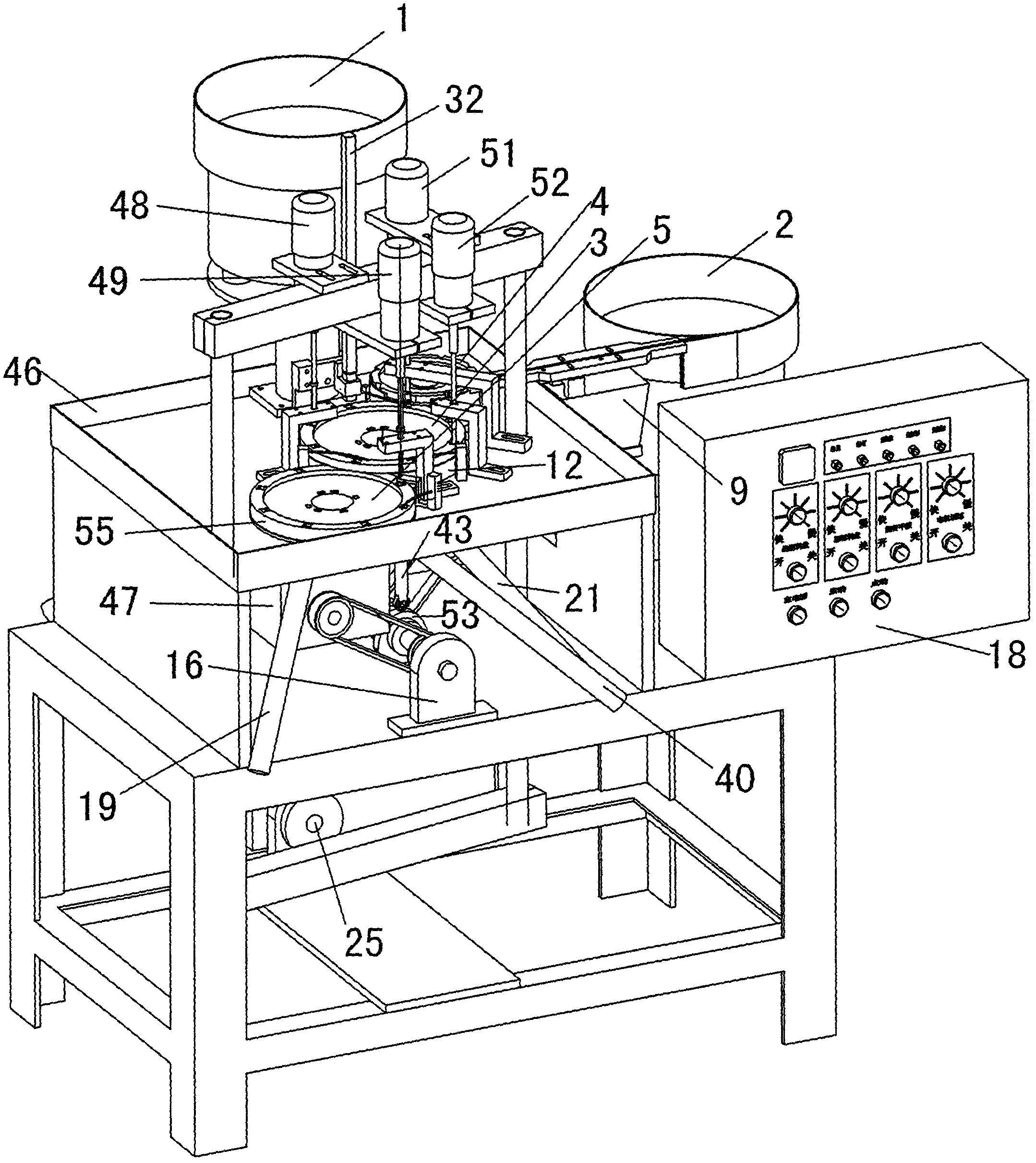

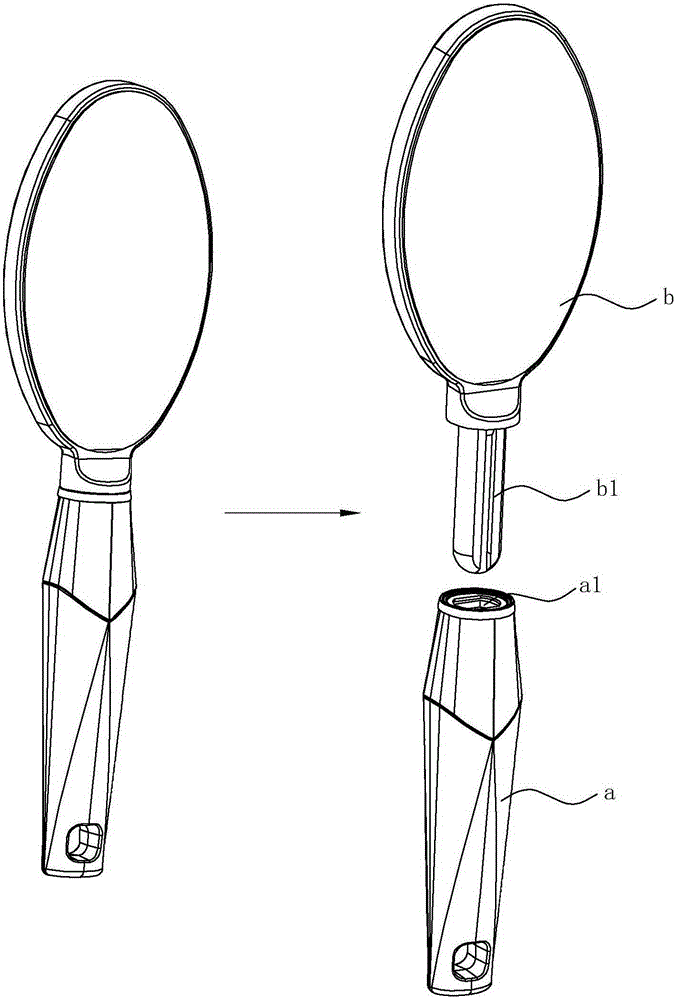

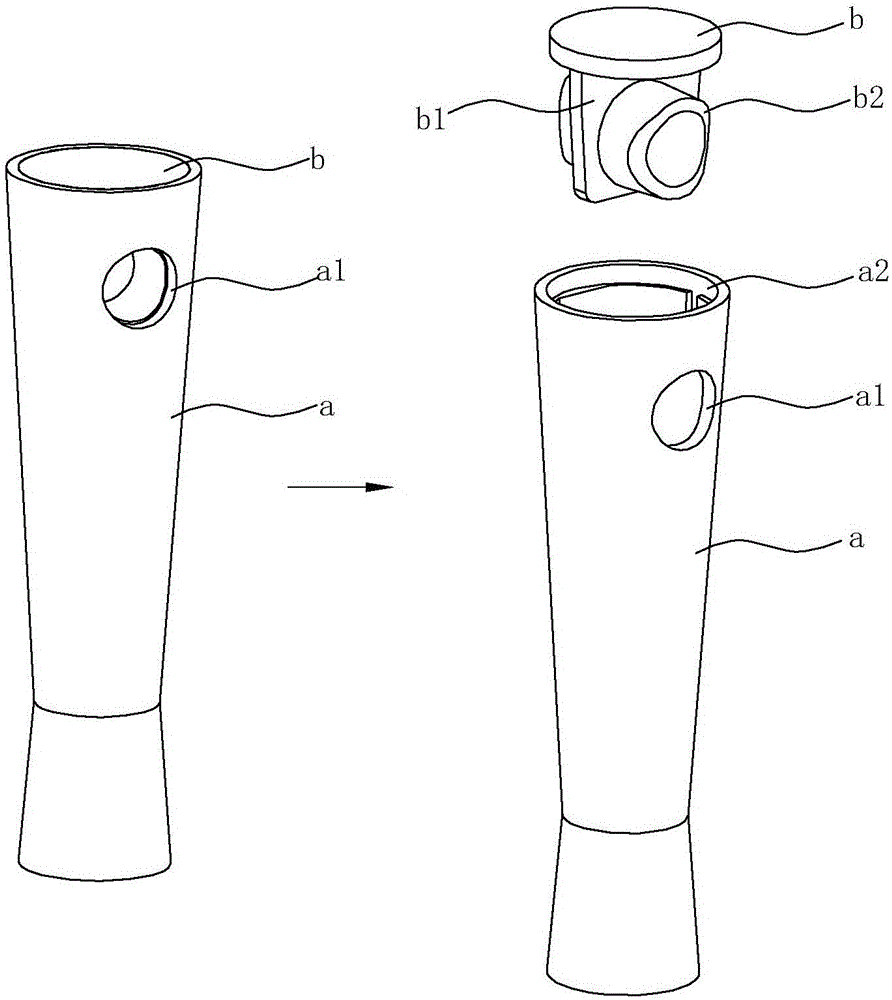

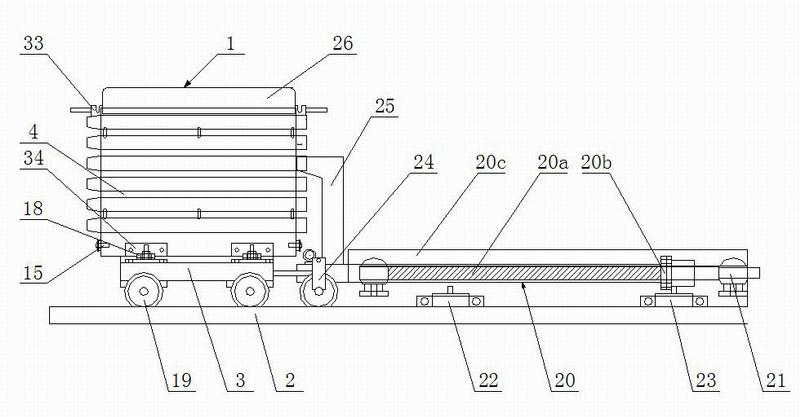

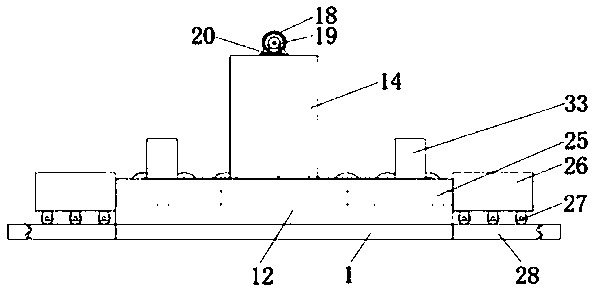

Semi-automatic comb assembler

InactiveCN105215682AImprove assembly efficiencyImprove quality stabilityMaterial gluingOther manufacturing equipments/toolsSemi automaticAssembly machine

The invention relates to a semi-automatic comb assembler. The semi-automatic comb assembler comprises an assembly platform, a turntable, a first driving mechanism, a dispensing mechanism, a pressing mechanism and a finished product shift-out mechanism; in use, a comb handle is manually inserted in a comb handle positioning mechanism at the upstream of the dispensing mechanism; then, the dispensing mechanism drips quantitative glue in a slot of the comb handle; operators inserts a comb body in the slot having the glue at the downstream of the dispensing mechanism; the pressing mechanism at a next station totally presses an insertion column of the comb body in the slot of the comb handle for tight insertion; and finally, the assembled comb is shifted out by the finished product shift-out mechanism for continuous reciprocating of the process to perform semi-automatic comb assembly. Compared with a manual assembly process in the prior art, the semi-automatic comb assembler is convenient for use, greatly improves the comb assembly efficiency, reduces the manual factor influence, enables combs produced in the same batches to have higher quality stability, and reduces the comb production cost to a greater extent.

Owner:NINGBO RAVO IND GRP CO LTD

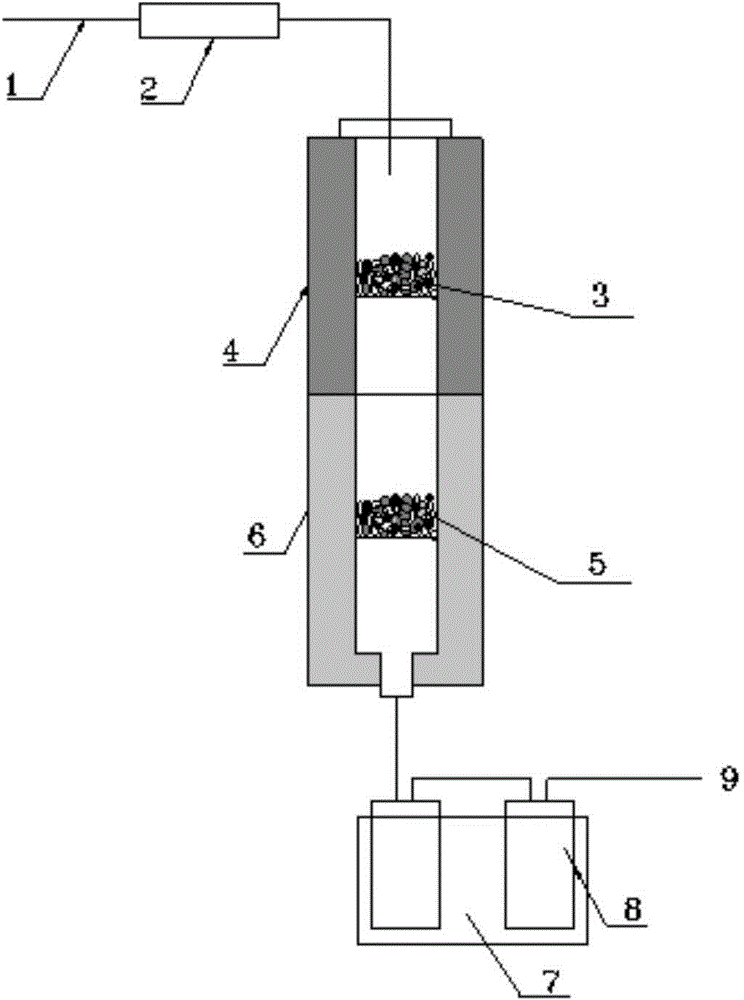

Catalytic pyrolysis method of biomass and/or coal

InactiveCN106147817AIncrease contentReduce contentLiquid hydrocarbon mixture productionCatalytic pyrolysisTemperature control

The invention relates to a catalytic pyrolysis method of biomass and coal. The method comprises steps as follows: biomass and / or coal and a catalyst are placed in a temperature-constant area of a fixed bed reactor, the catalyst is placed in the downstream position of the biomass and / or coal, a catalyst bed layer is formed, a gaseous product produced in a pyrolytic reaction of the biomass and / or coal, at the temperature higher than or equal to 400 DEG C flows through the catalyst bed layer to be subjected to a catalytic reaction, and a gaseous product and an aqueous product are obtained through condensation and separation of a product of the catalytic reaction. The biomass and / or coal and the catalyst are placed in different temperature control areas (or the same temperature control area) of the fixed bed reactor, the efficient catalyst is adopted, the catalytic pyrolysis reaction is performed, the content of alkylphenol in tar can be significantly increased, and the content of alkoxy phenol can be significantly decreased; the component composition of phenols in tar obtained through pyrolysis of the biomass and / or coal is simplified, optimization of downstream reaction conversion conditions with tar or phenol oil used as raw materials is facilitated, and the quality of products with tar or phenol oil used as raw materials is further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

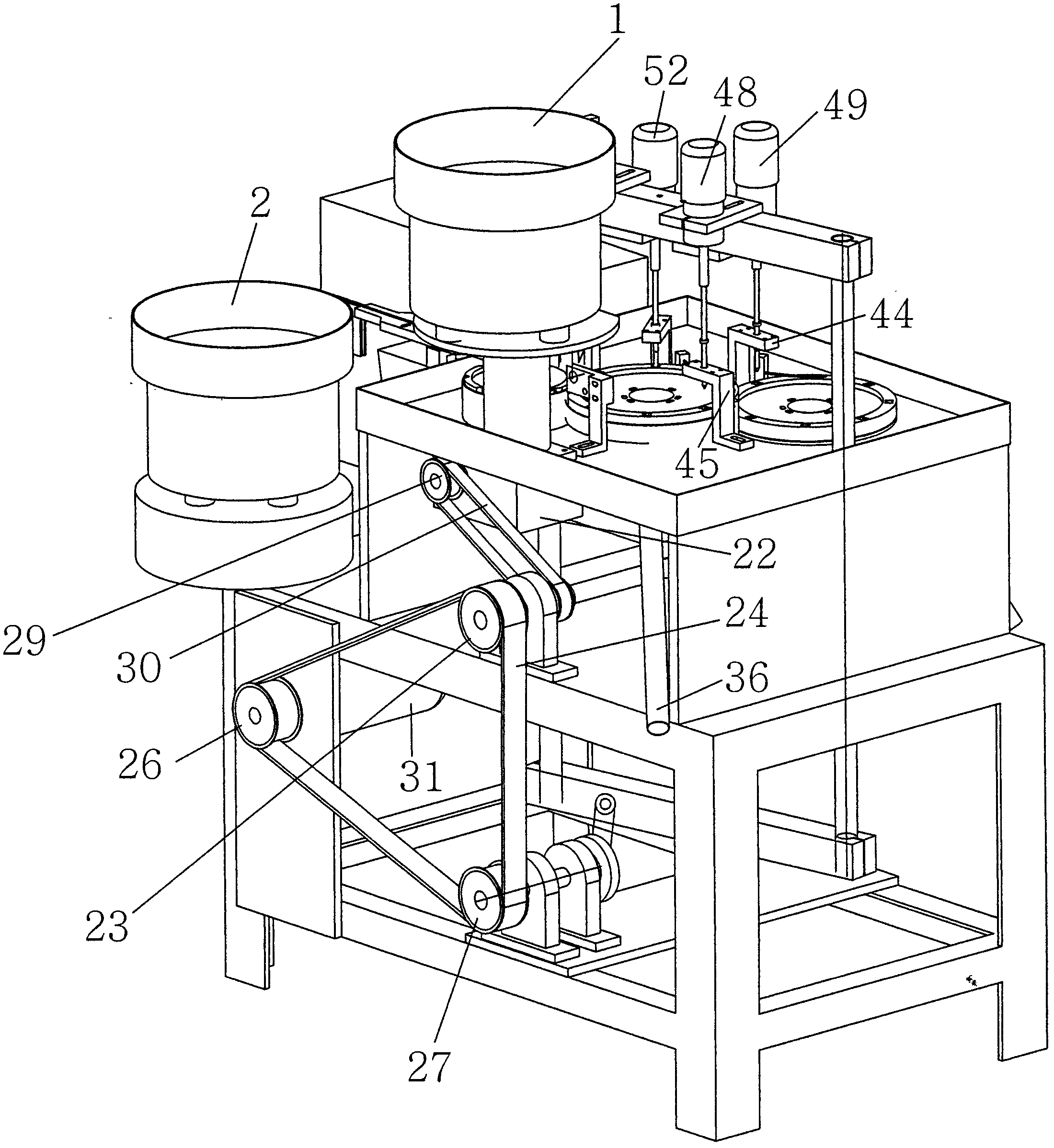

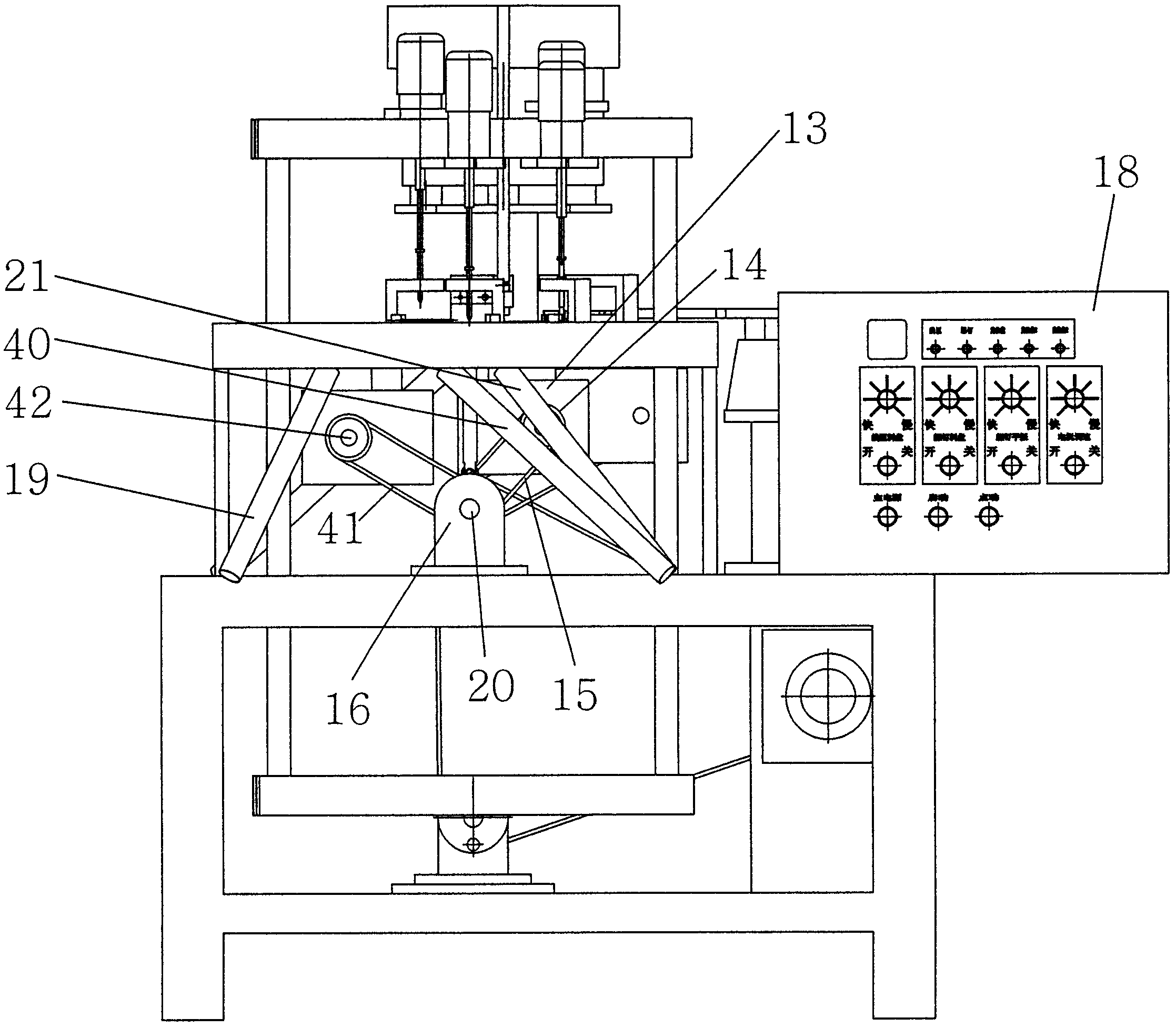

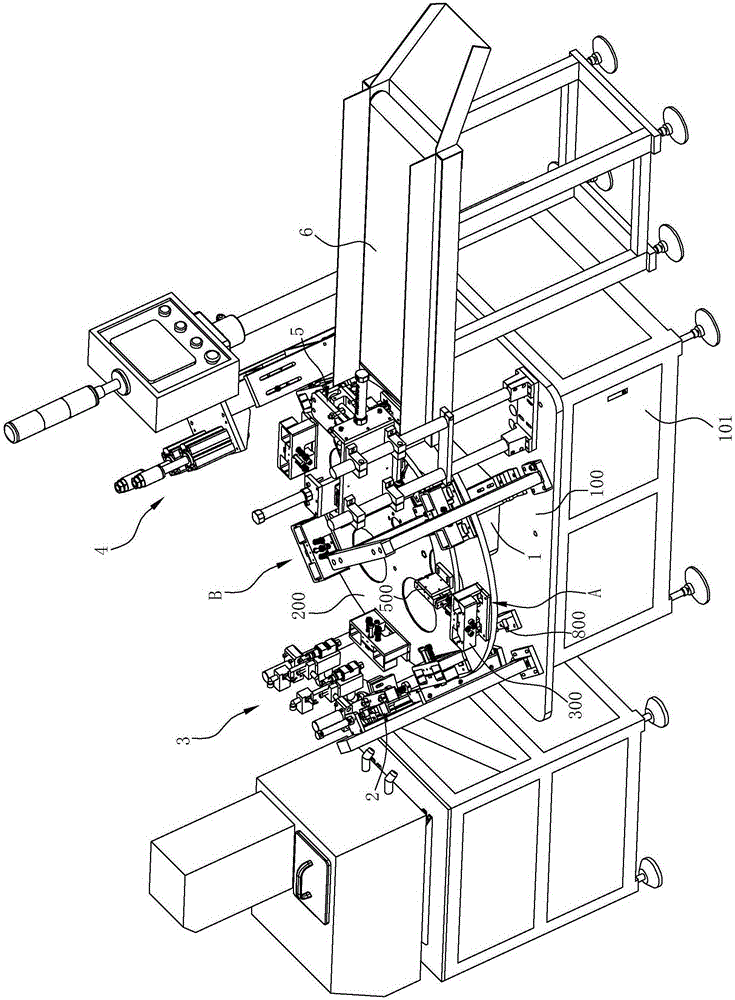

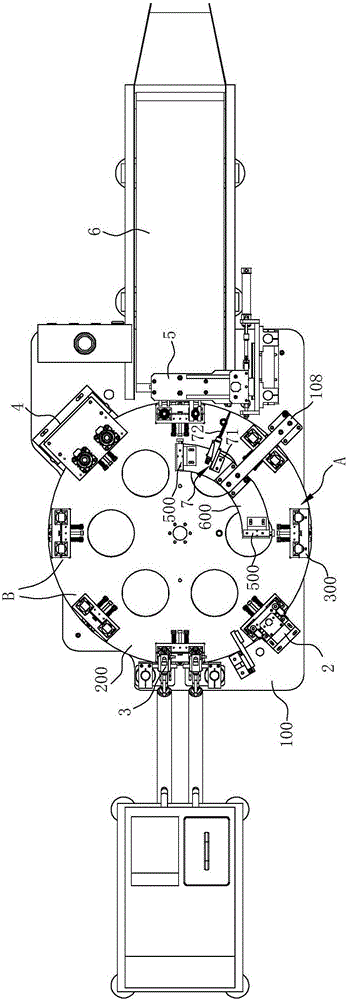

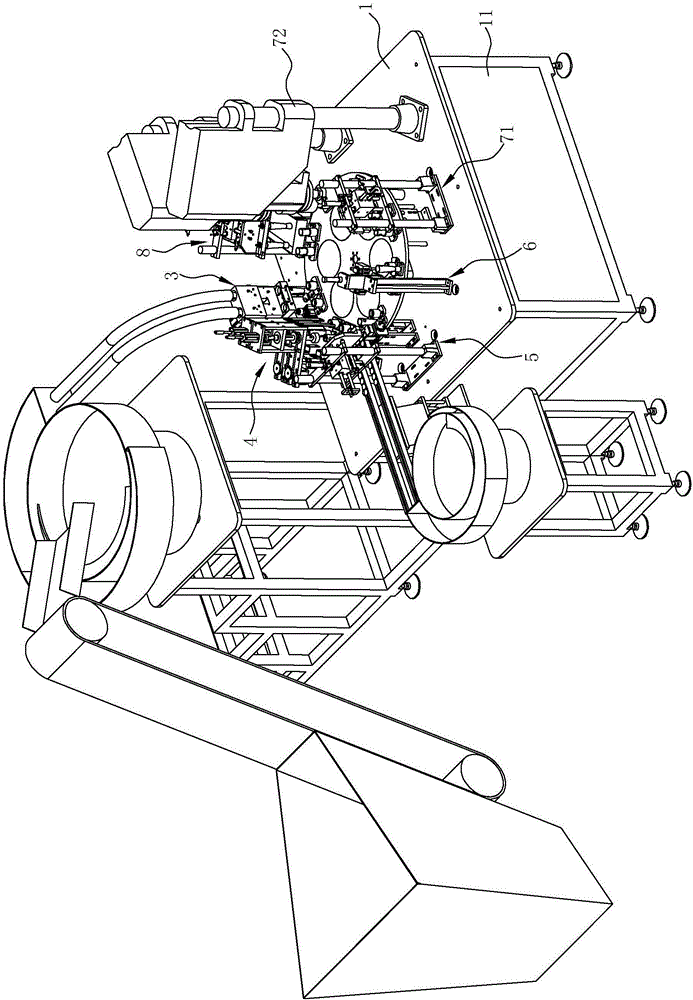

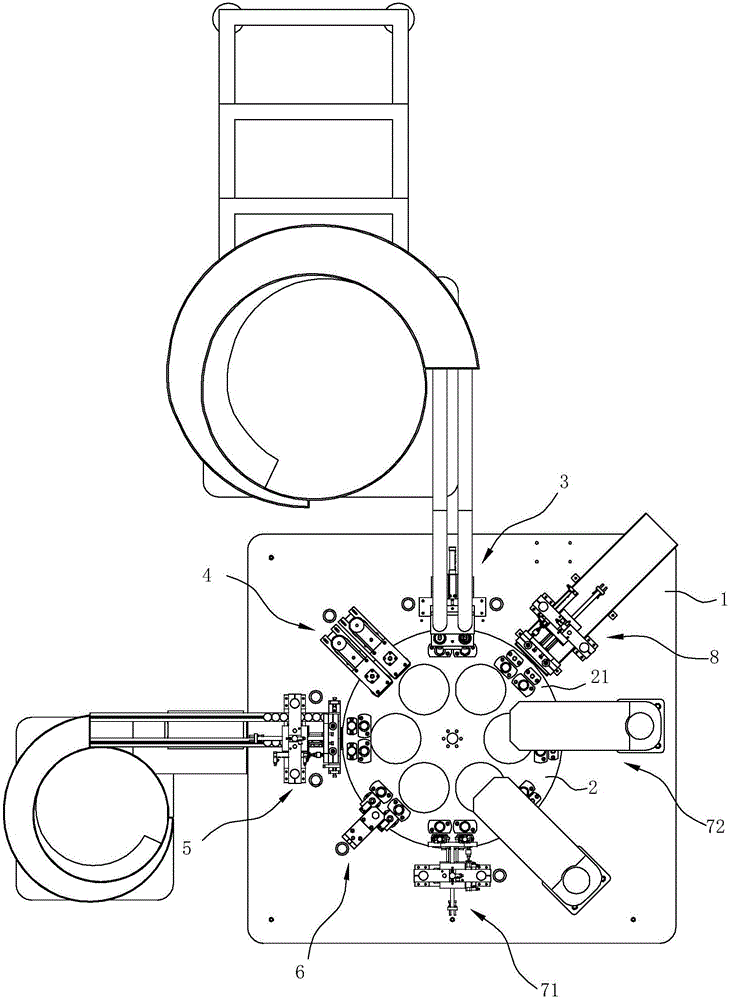

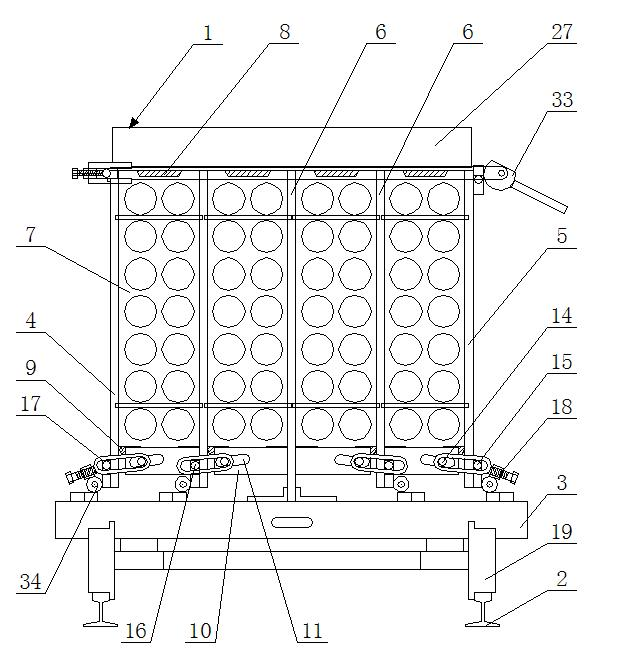

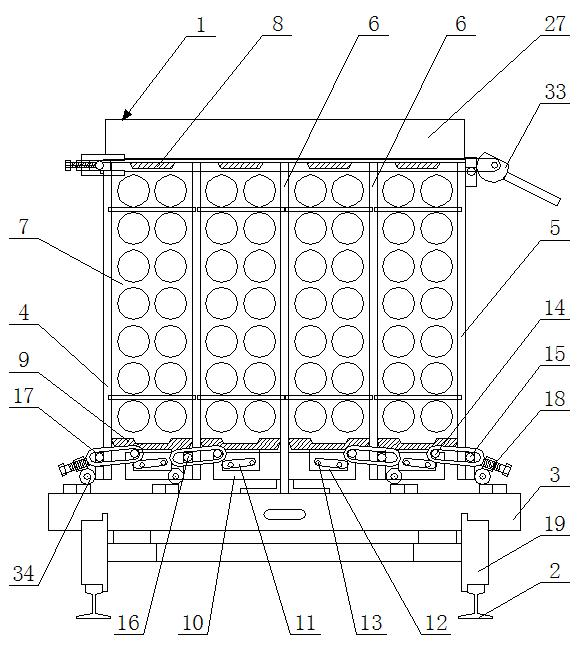

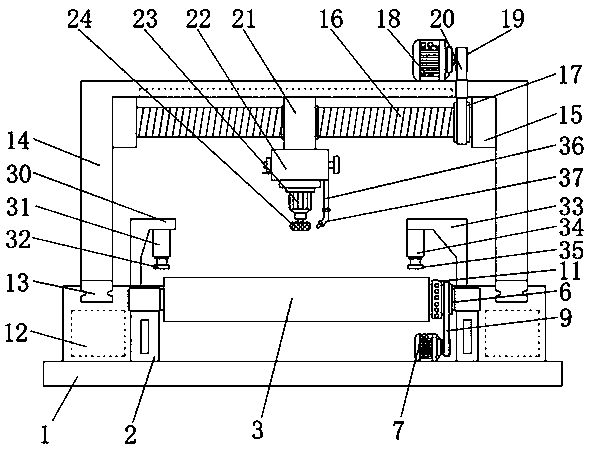

Automatic comb handle assembling and welding machine

ActiveCN105710525AImprove assembly efficiencyImprove quality stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to an automatic comb handle assembling and welding machine which comprises an assembling platform, a rotary disc, a first drive mechanism, a handle moving and taking mechanism, a bottom cover moving and taking mechanism, a handle locating mechanism, a welding mechanism and a finished product output mechanism. The handle moving and taking mechanism is used for moving and taking handles to mold seats on the edge of the rotary disc. The handle locating mechanism is used for rotating the handles into the state that through holes in the upper ends of the handles are aligned with tubular bodies on bottom covers. The bottom cover moving and taking mechanism is used for moving and taking the bottom covers to the positions above the mold seats and arranging the bottom covers in upper ports of the handles. The welding mechanism is used for ultrasonically welding the bottom covers and the handles. Compared with a manual assembling process in the prior art, the automatic comb handle assembling and welding machine is convenient to use, and the assembling efficiency of the comb handles is greatly improved; due to the fact that the whole process is automatically operated and controlled for operation through a master control program, influences caused by manual factors are reduced, the handles and the bottom covers are accurately aligned, welding is firm, the comb handles produced in the same batch are high in quality stability, the production cost of the comb handles is reduced to a great extent, and the productive profit of an enterprise is improved.

Owner:NINGBO RAVO IND GRP CO LTD

Tomentosa cherry planting method

InactiveCN105103906APromote growthAvoid erosionSeed and root treatmentPlant cultivationCerasus tomentosaSpore germination

The invention discloses a tomentosa cherry planting method which includes the steps of (1) soil preparation, (2) seed collection and processing, (3) seed germination accelerating and sowing, (4) seedling management and transplanting and (5) management after transplanting. By reasonably processing a seedling cultivating field, a good foundation is laid for the seedling cultivation environment of tomentosa cherries, and it is guaranteed that seedlings smoothly grow. By means of germination accelerating processing of tomentosa cherry seeds before sowing, the emergency period of the tomentosa cherries is shortened, the problem that the tomentosa cherries grow slowly in the common environment is further alleviated, the cultivation period of the tomentosa cherries is shortened, and planting cost of the tomentosa cherries is reduced. Besides, by processing the tomentosa cherry seedlings, the transplanting survival rate of the tomentosa cherry seedlings is increased to a larger extent. Meanwhile, the cultivation time of the seedling stage is also shortened by 1-2 months, production profits of the tomentosa cherries are further improved, planting enthusiasm of planters is stimulated, and conditions are provided for large-area large-scale tomentosa cherry planting and production.

Owner:GUZHEN COUNTY LVHE FAMILY FARMS

Cotton core forming process

InactiveCN107174407AStable absorption effect is goodIncrease contentAbsorbent padsBaby linensProduction lineMetallurgy

The invention relates to the field of manufacturing of sanitation supplies and provides a cotton core forming process. The process comprises the following steps: (1) applying a composite polymer layer to the lower surface of an intermediate fluffy non-woven fabric layer and feeding the composite polymer layer to a material transfer composite roller; (2) conveying a bottom fluffy non-woven fabric, performing edge correction, spraying glue, and feeding to the material transfer composite roller; (3) gluing the composite intermediate fluffy non-woven fabric layer and the upper surface of the intermediate fluffy non-woven fabric of the composite bottom fluffy non-woven fabric layer, and feeding to a second firm pressing mechanism; (4) performing massive discontinuous glue spraying on the upper fluffy non-woven fabric, discontinuously arranging the polymer layer and fixedly laminating with the intermediate fluffy non-woven fabric and the bottom fluffy non-woven fabric, and completing compounding of the three layers; and (5) folding, covering, compacting and reinforcing excessive parts of the bottom fluffy non-woven fabric compared with two sides of the intermediate fluffy non-woven fabric and the upper non-woven fabric, thereby obtaining the formed cotton core. According to the process disclosed by the invention, the problems that the conventional cotton core is high in forming cost, complicated in process and long in production line are solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

Method for catalytically converting tar

ActiveCN108339547ALow costAvoid security issuesMolecular sieve catalystsHydrocarbon oil crackingMethanolChemistry

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Block making machine

ActiveCN102528896AReduce scrap rateIncrease production profitCeramic shaping apparatusMolding machineRejection rate

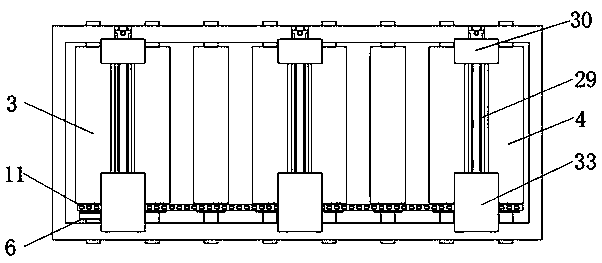

The invention discloses a block making machine. Bottom mold pins (14) are arranged at the bottom of a bottom mold (9), bottom mold blocks (10) are disposed on outer sides of two ends of the bottom mold (9), strip-shaped sliding guide holes (11) are arranged on the bottom mold blocks (10), and two ends of each bottom mold pin (14) penetrate through the corresponding strip-shaped sliding guide holes (11) to extend out of the corresponding bottom mold blocks (10). In another scheme of the block making machine, bottom mold blocks (10) are disposed below a bottom mold (9), strip-shaped sliding guide holes (11) are disposed on the bottom mold blocks (10), sliding pins (13) are fixedly arranged at the bottom of the bottom mold (9), ends of the sliding pins (13) extend into the strip-shaped sliding guide holes (11), bottom mold pins (14) are further disposed at the bottom of the bottom mold (9), and one end of each bottom mold pin (14) extends out of the bottom mold (9). Rejection rate is reduced due to the movable bottom mold and change of the shape of the bottom mold, and the block making machine has the advantages of ingenious design, simple structure, easiness in manufacture and the like.

Owner:JIANGSU RAINPAT DATA SERVICE

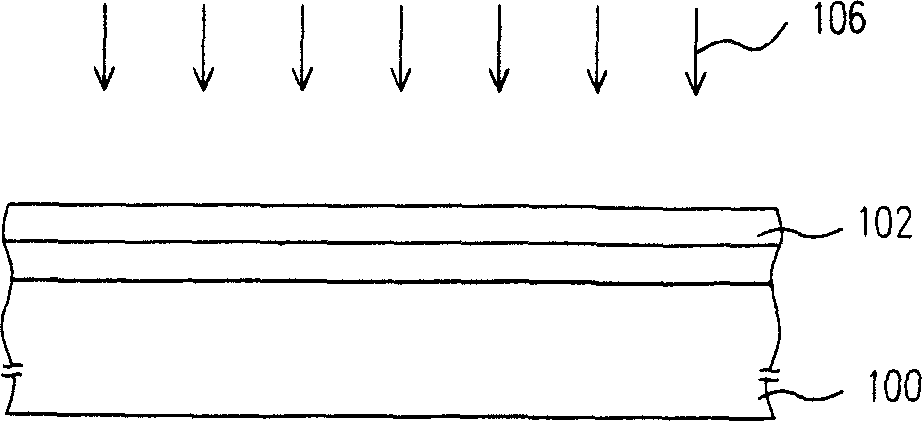

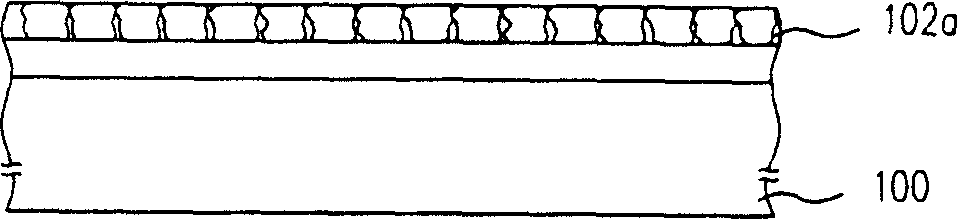

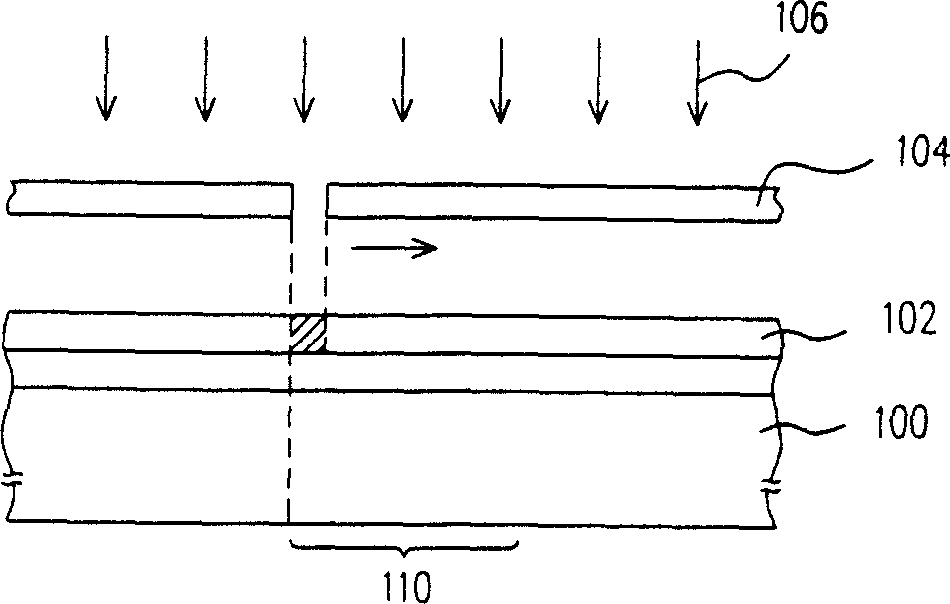

Low-temperature polysilicon thin film transistor and method for manufacturing its channel layer

InactiveCN1722467AIncrease drive currentReduce leakage currentTransistorSemiconductor/solid-state device manufacturingEngineeringGrain boundary

This invention relates to a polysilicon film transistor at low temperature, mainly composed of top cover layer, polysilicon and lock end, wherein, the top cover layer is located on the base plate, and leaves a space away from the base plate, the polysilicon is located on the top cover layer and separated into channel region on top of the space and drain region on the two sides of the channel region, and the lock end is located on the channel region. The silicon atom needs longer recrystallization time, which can reduce the grain boundary plane in the channel region and improve the transistor working efficiency.

Owner:AU OPTRONICS CORP

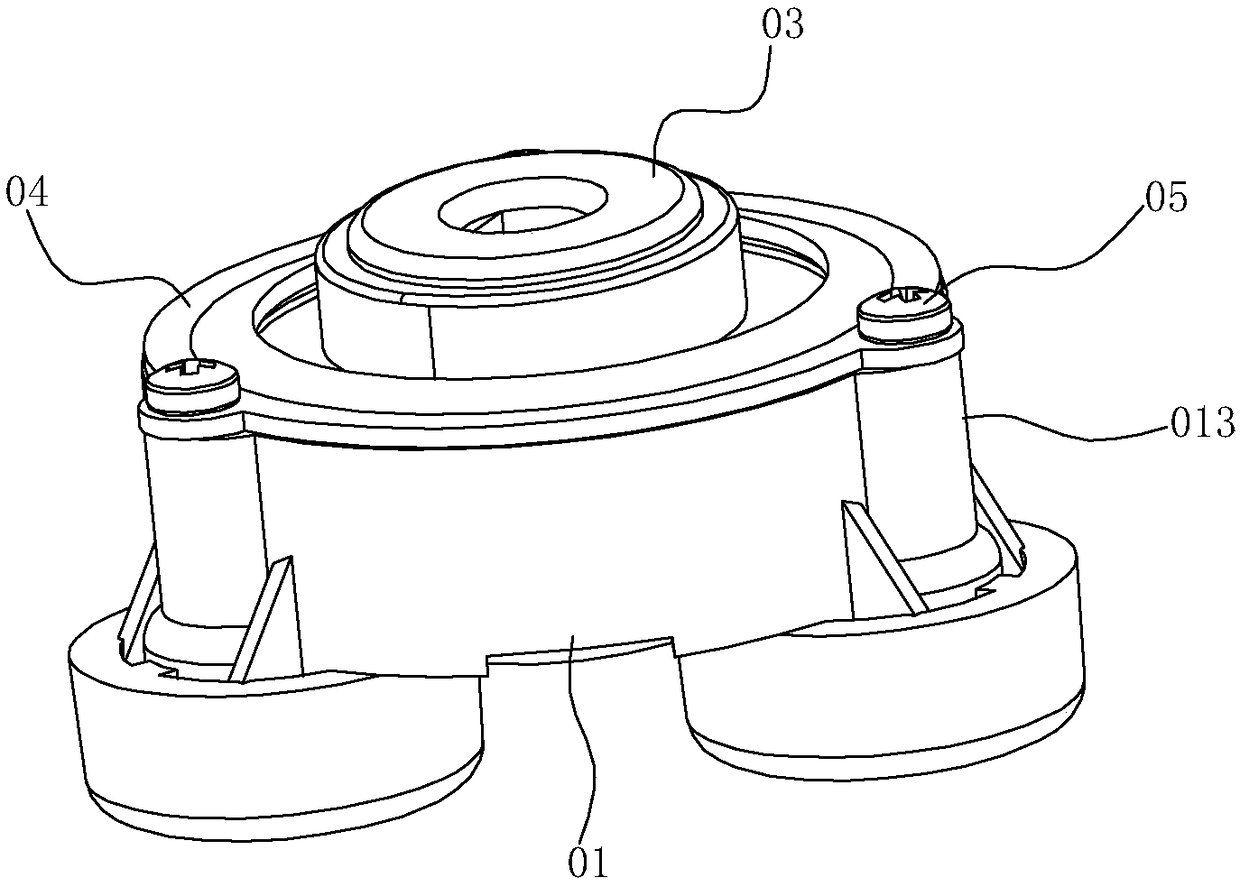

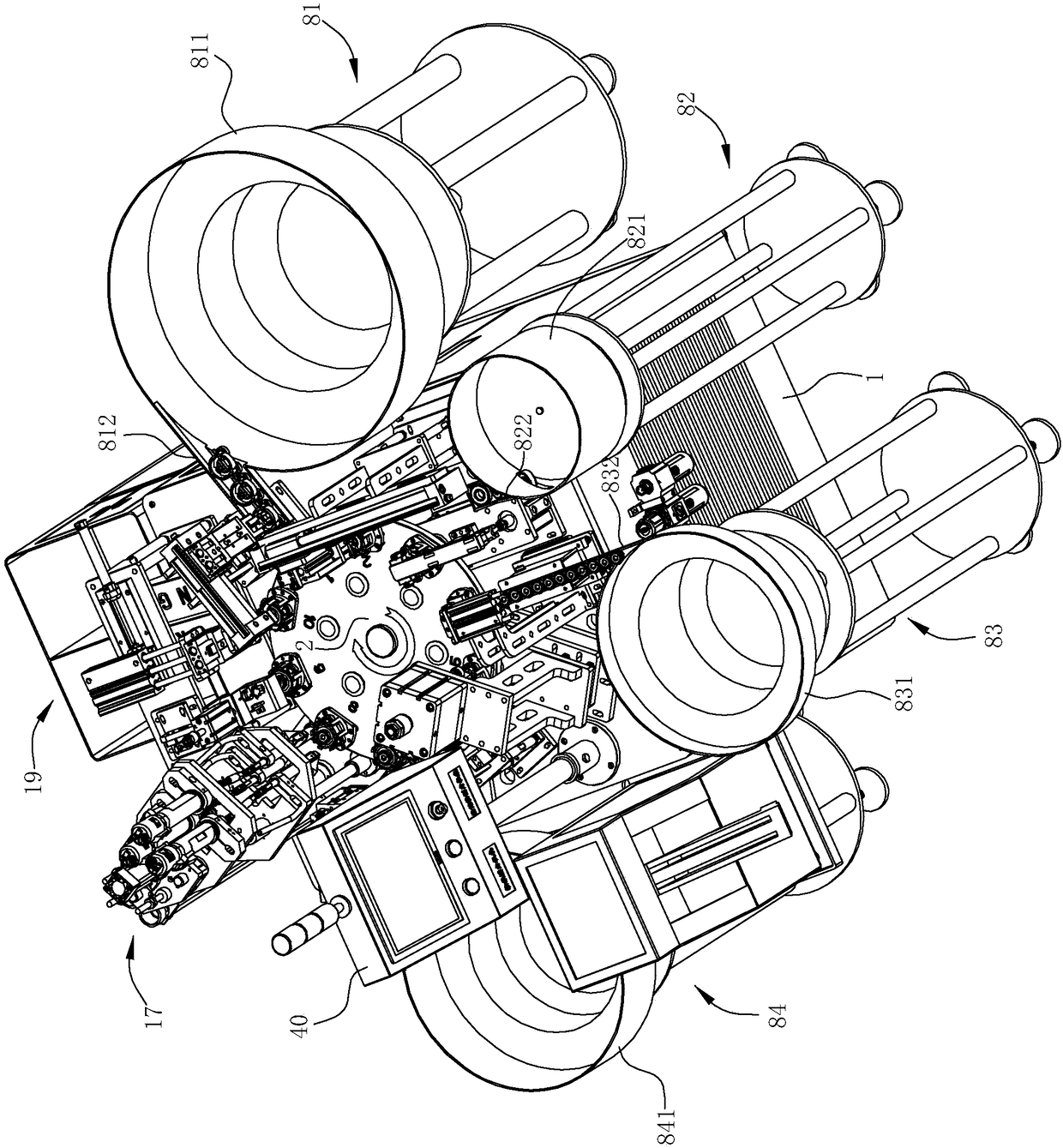

Automatic assembling method for water pump piston frame assembly

ActiveCN109079490AGuaranteed fit toleranceHigh degree of automationAssembly machinesEngineeringClockwise

The invention relates to an automatic assembling method for a water pump piston frame assembly. The water pump piston frame assembly is assembled through an automatic assembling device. The automaticassembling device comprises a controller and an assembling platform; a rotating disc is arranged on the assembling platform; a plurality of operation stations are arranged on the positions, adjacent to the edge, of the rotating disc in the clockwise direction; each operation station is provided with a clamp used for clamping the piston fixing frame assembly correspondingly; and a plurality of working mechanisms are sequentially arranged on the positions, close to the edge of the rotating disc, of the assembling platform in the clockwise direction, and each working mechanism is arranged corresponding to the corresponding clamp. According to the automatic assembling method, assembling of the piston fixing frame assembly can be circularly conducted in a reciprocating mode, the automation degree is high, and the assembling efficiency is improved.

Owner:浙江理工大学瓯海研究院有限公司

Method for planting mountain mushroom in second crop of asafelida mushroom from farming shed

InactiveCN1759654AEasy to masterPromote decompositionHorticultureEcological environmentPollution soil

A culture method for second harvesting of asafetida mushroom in big plastic-film shed includes such steps as peeling the fungal rods, removing small mushroom buds, digging beds, disinfecting with calcium lime, vertically arranging the treated fungal rods in the bed, covering them with non-pollution soil, second generation of mushroom at 5-8 deg.C and ordinary-temp culture. Its mushroom output rate can reach more than 96%.

Owner:玛纳斯县科技服务中心

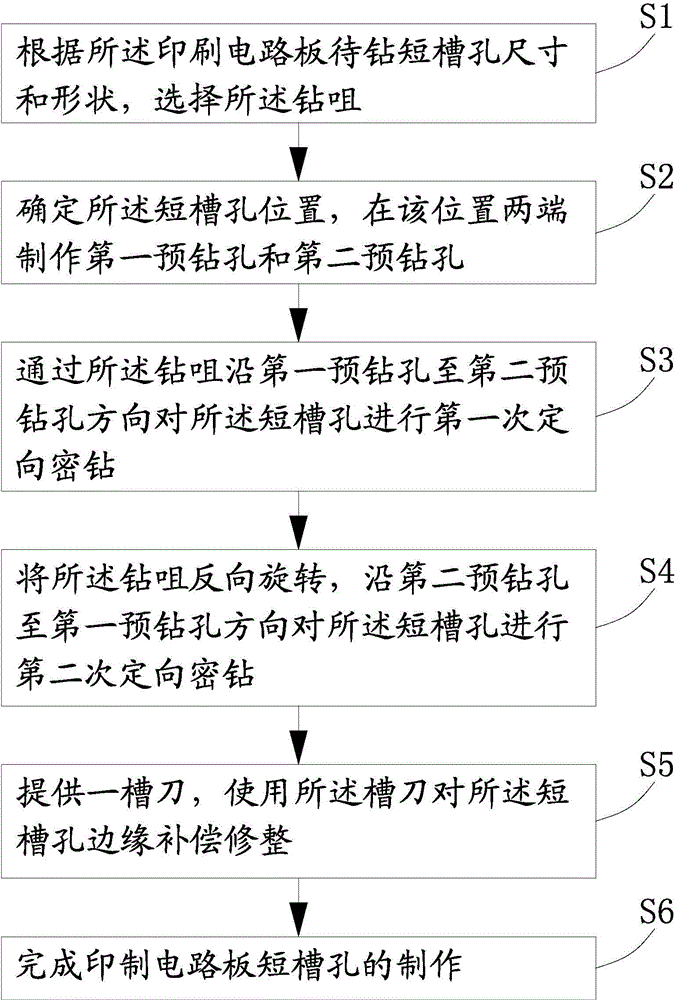

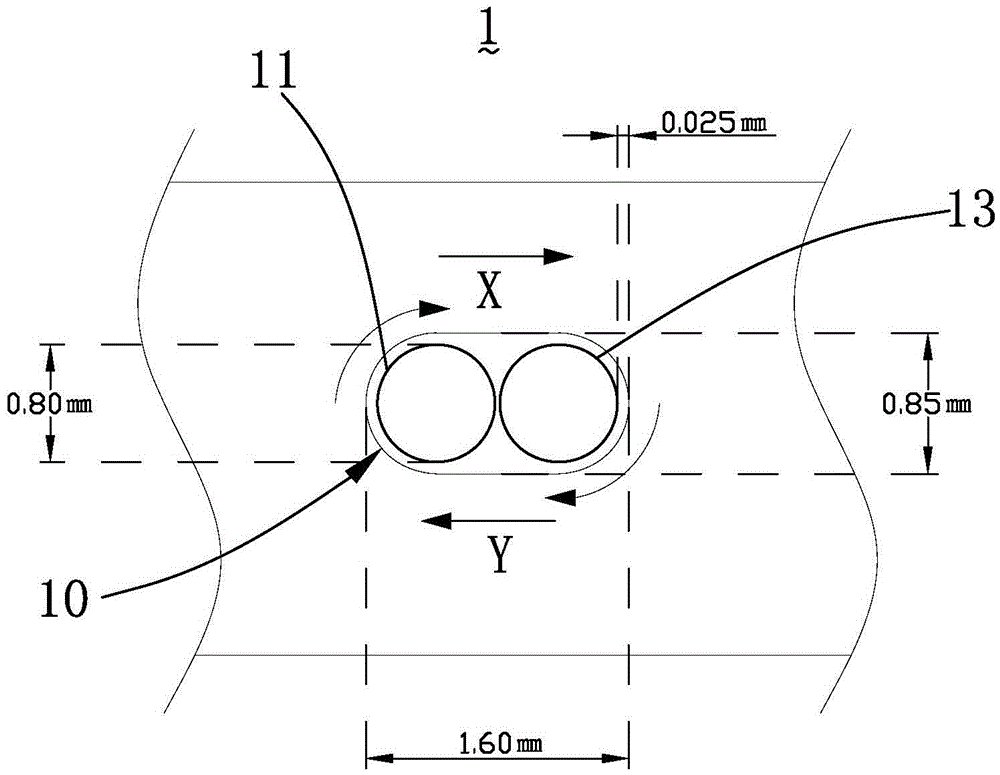

Manufacturing method of slot of printed-circuit board

ActiveCN104476616AReduce qualityIncrease production profitMetal working apparatusEngineeringPrinted circuit board

The invention provides a manufacturing method of a slot of a printed-circuit board. The manufacturing method includes the following steps: selecting a drill bit according to the size and shape of the to-be-drilled short slot of the printed-circuit board; determining the position of the short slot, and drilling a first pre-drill hole and a second pre-drill hole at two ends of the determined position; conducting first orientated dense drilling on the short slot along the first pre-drill hole towards the second pre-drill hole by aid of the drill bit; reversely rotating the drill bit, and then conducting second orientated dense drilling on the short slot along the second pre-drill hole towards the first pre-drill hole; providing a slot cutter and conducting compensatory finishing on the edge of the short slot. Compared with the prior art, the manufacturing method of the slot of the printed-circuit board makes different cutter compensation according to the slot width, and can fundamentally solve the quality problem of short slot processing for circuit board manufacturers.

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

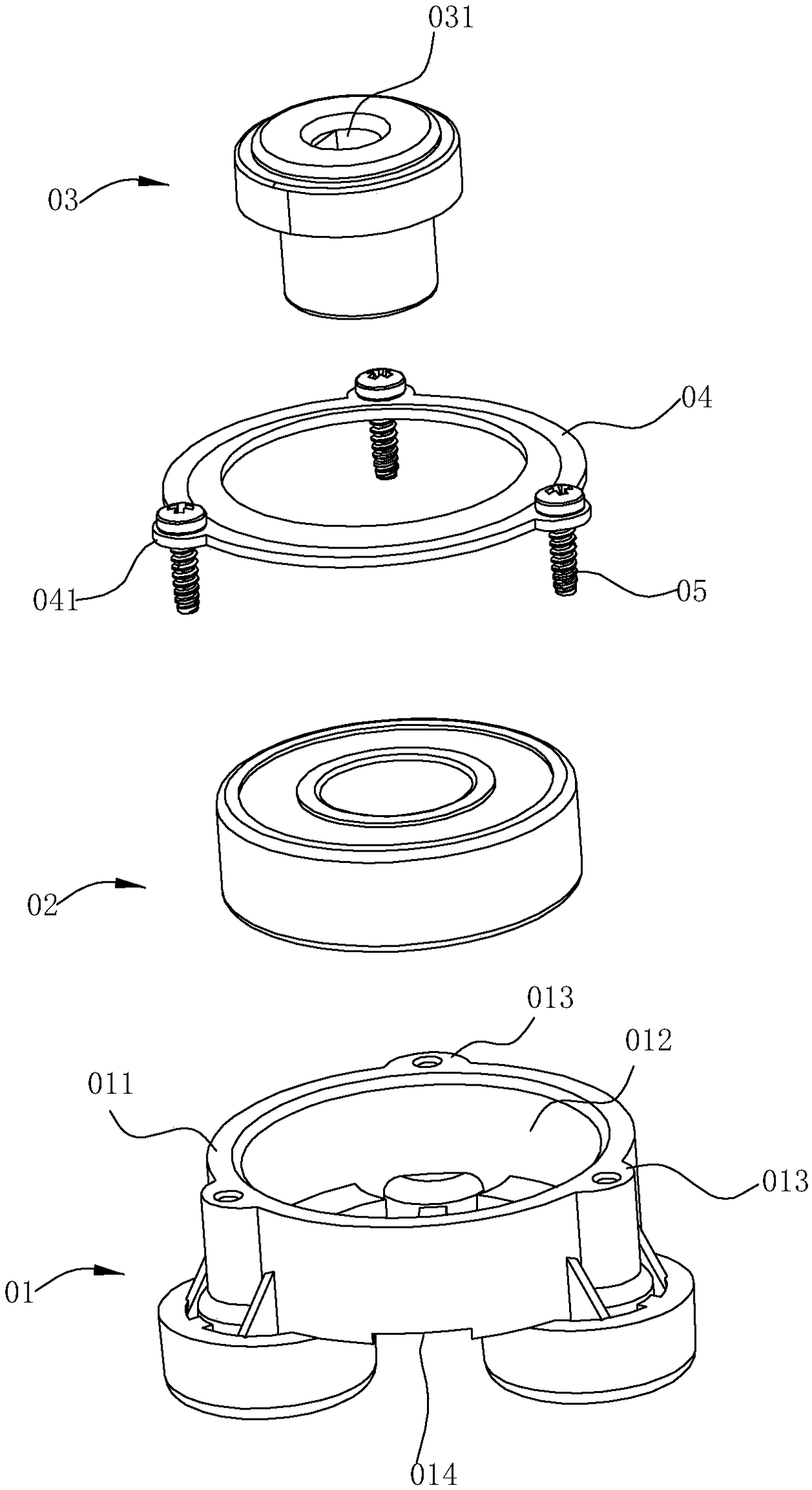

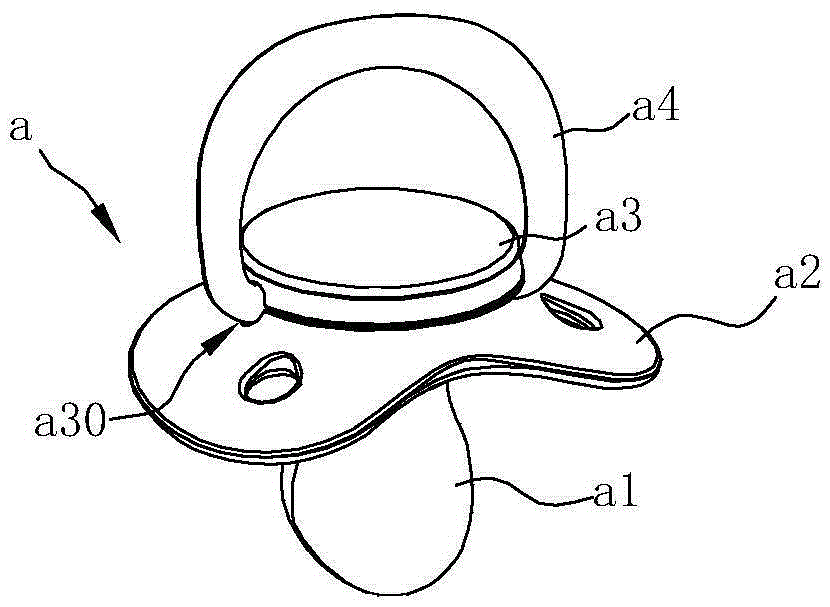

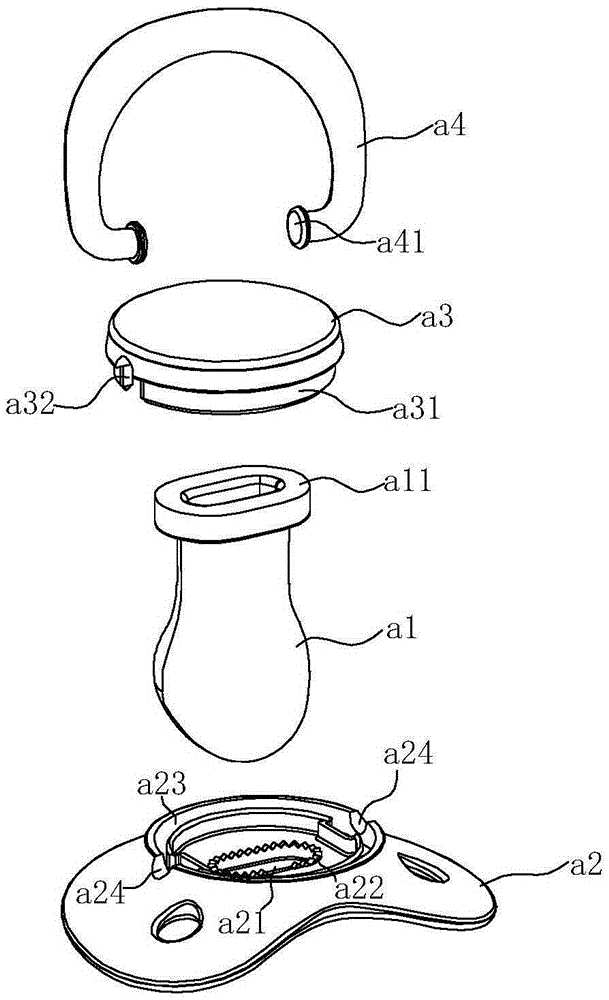

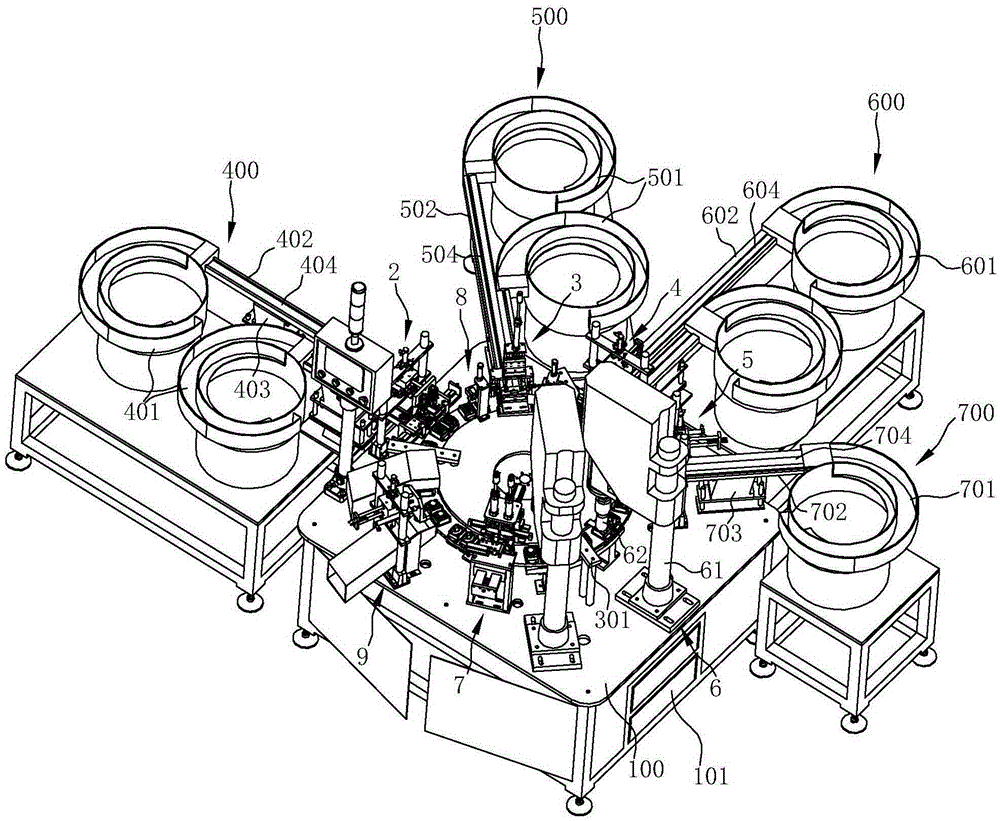

Automatic assembling machine for pacifying nipple

ActiveCN105269314AImprove assembly efficiencyImprove quality stabilityAssembly machinesEngineeringNozzle

The invention relates to an automatic assembling machine for a pacifying nipple. The automatic assembling machine comprises an assembling platform, a rotary disc, a first drive mechanism, a first moving and taking mechanism, a nipple head assembling mechanism and a third moving and taking mechanism. The rotary disc is in a disc shape and is rotationally arranged on the assembling platform. The first drive mechanism is used for driving the rotary disc to rotate. The edge, close to the rotary disc, of the first moving and taking mechanism is arranged on the assembling platform, and the first moving and taking mechanism is used for moving and taking a baffle of the pacifying nipple to operation stations of the rotary disc. The nipple head assembling mechanism is used for pressing the nipple head into an assembling opening of the baffle. The third moving and taking mechanism is used for moving and assembling an upper cover of the pacifying nipple in an inserting groove in the upper portion of the baffle. Compared with the manual assembling process, using is convenient, and the assembling efficiency of the pacifying nozzle is greatly improved. The whole process is automatically operated to proceed through a master control program, the influence of the artificial factor is reduced, and pacifying nipples produced in the same batch have high quality and stability. The production cost of the pacifying nipple is reduced to a large degree, and the production profit of enterprises is increased.

Owner:NINGBO LONGWELL BABY PROD LTD

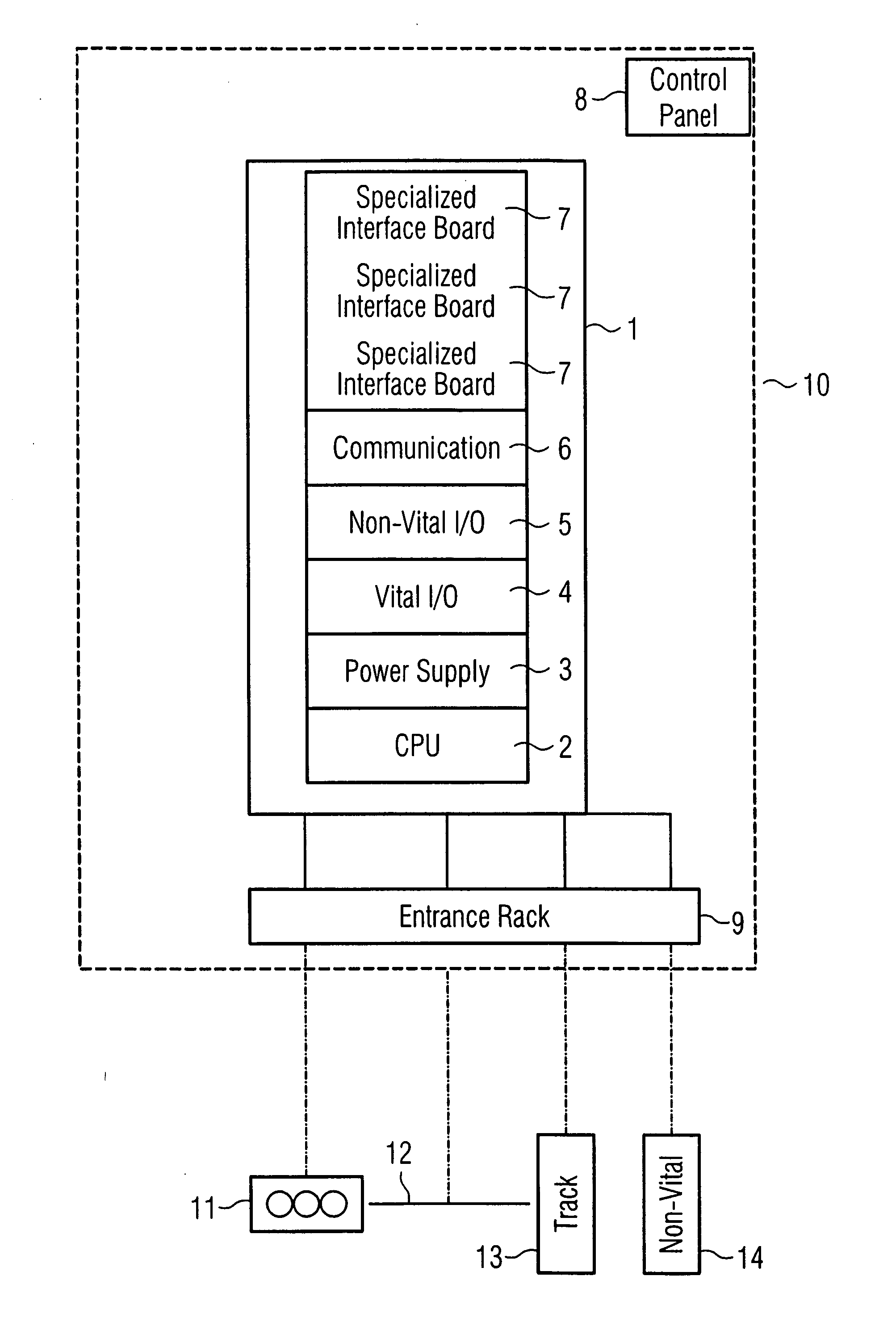

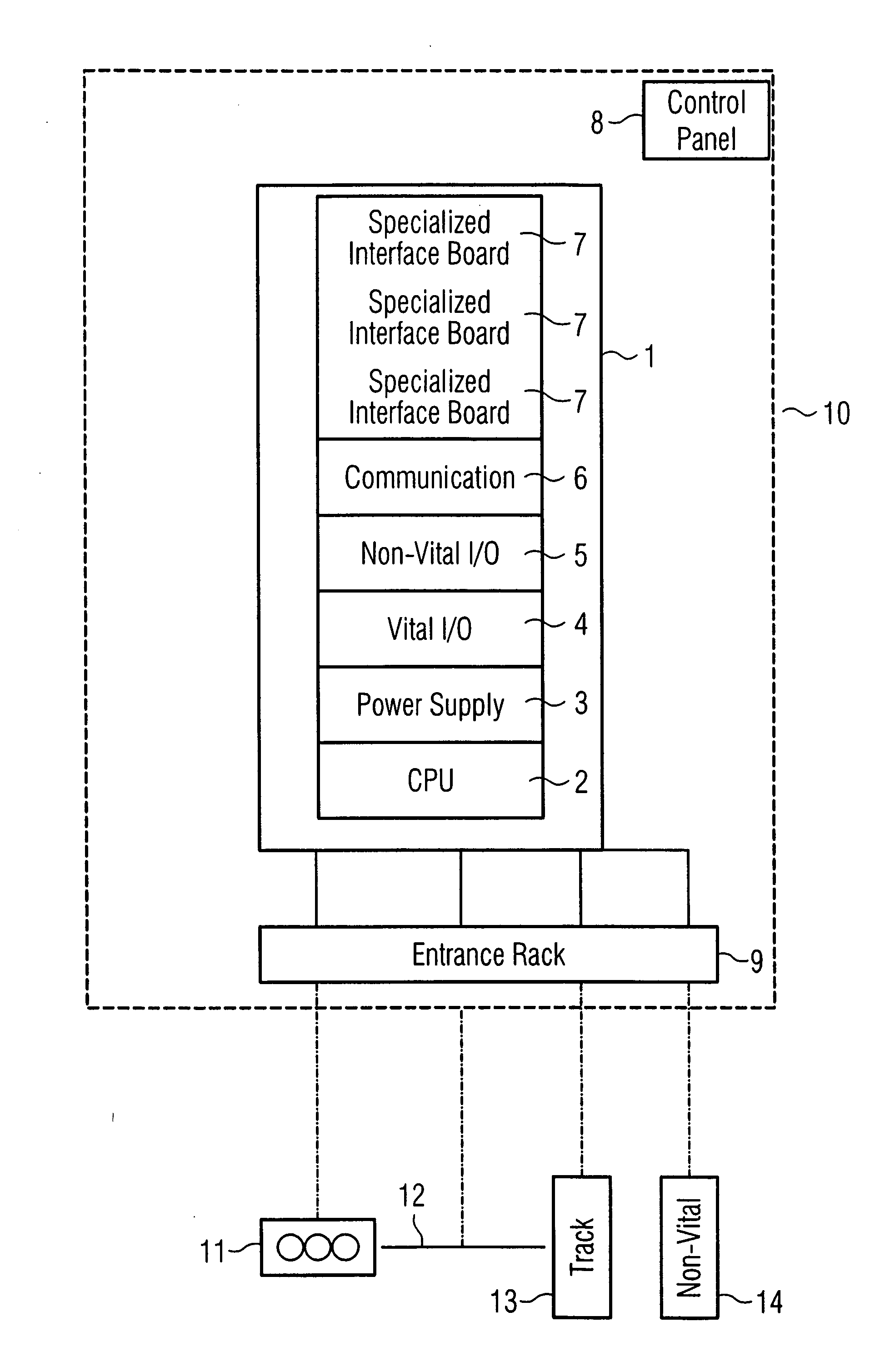

System architecture for controlling and monitoring components of a railroad safety installation

InactiveUS20070073453A1High degree of standardizationImprove usabilityDigital data processing detailsTrack side maintainancePassenger information systemHigh availability

The invention relates to a system architecture for controlling and monitoring components, in particular light signals, switches, rail circuits, rail junctions, passenger information systems, of a railroad safety installation. In order to improve the availability and the adaptability to changing environmental conditions, the invention provides that an automation platform which comprises a plurality of modules, in particular a CPU, a power supply, a module for safety-relevant signal processing, a module for non-safety-relevant signal processing and a communication module is connected via specific interfaces to safety-relevant and non-safety-relevant components of the railroad safety installation.

Owner:SIEMENS AG

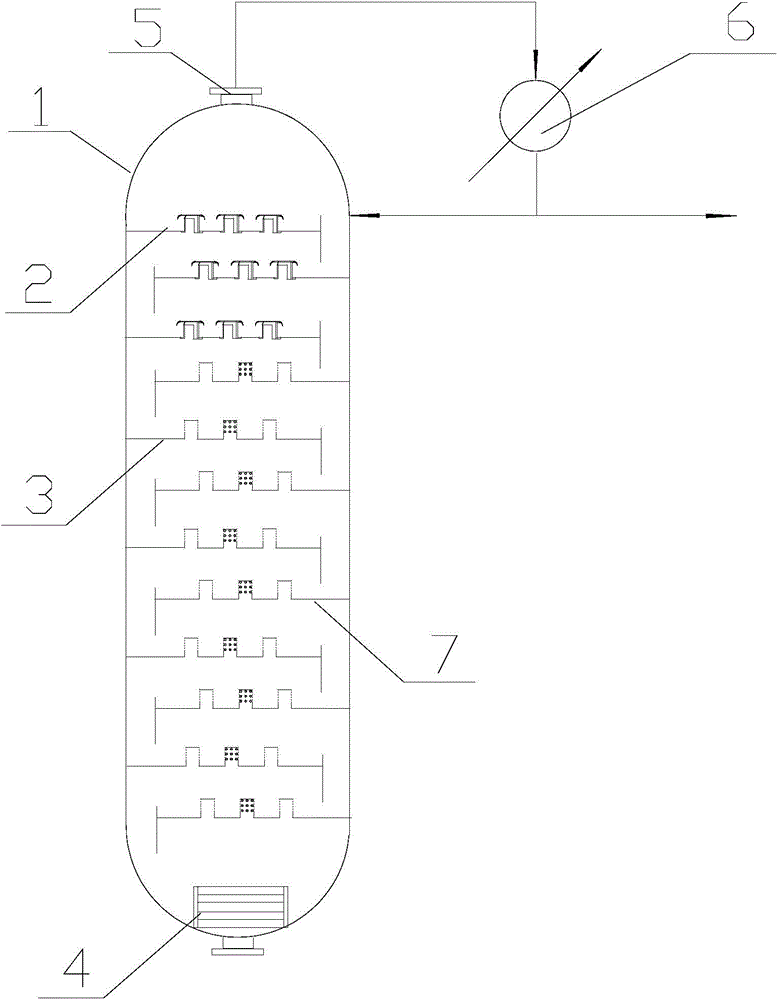

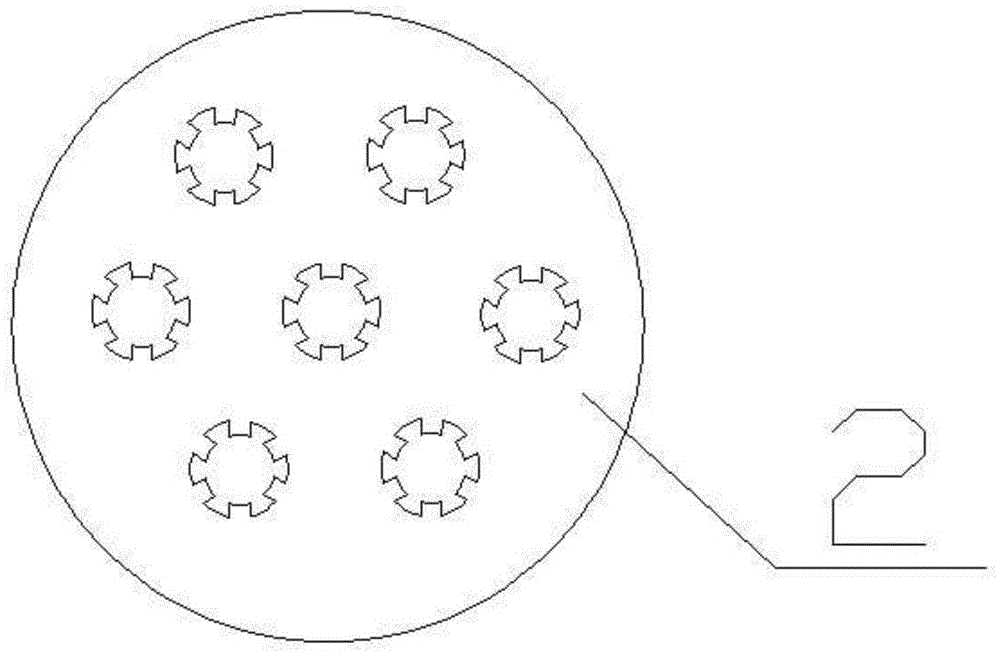

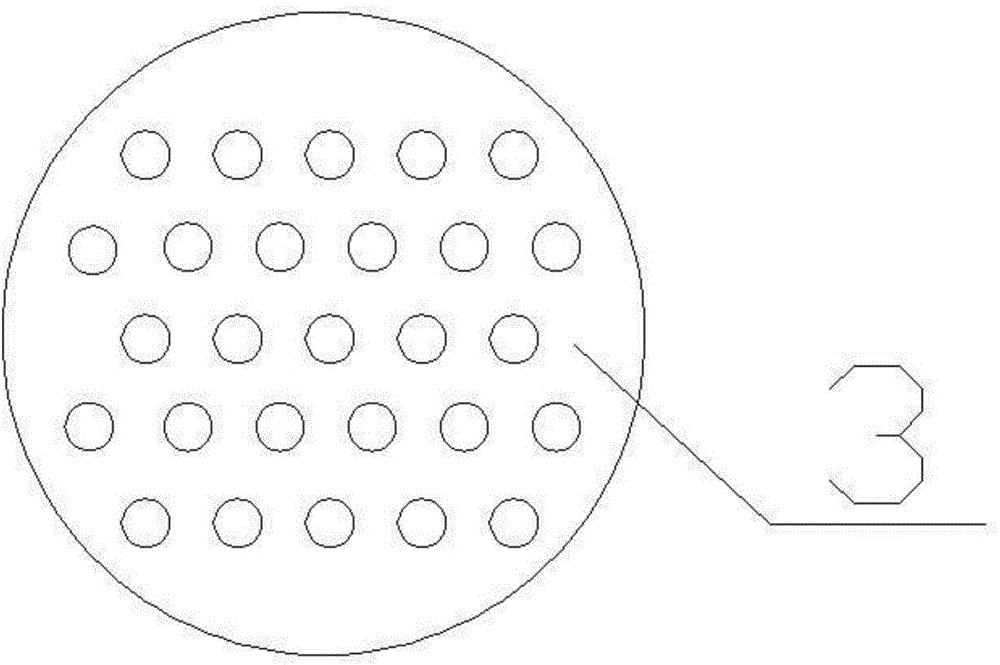

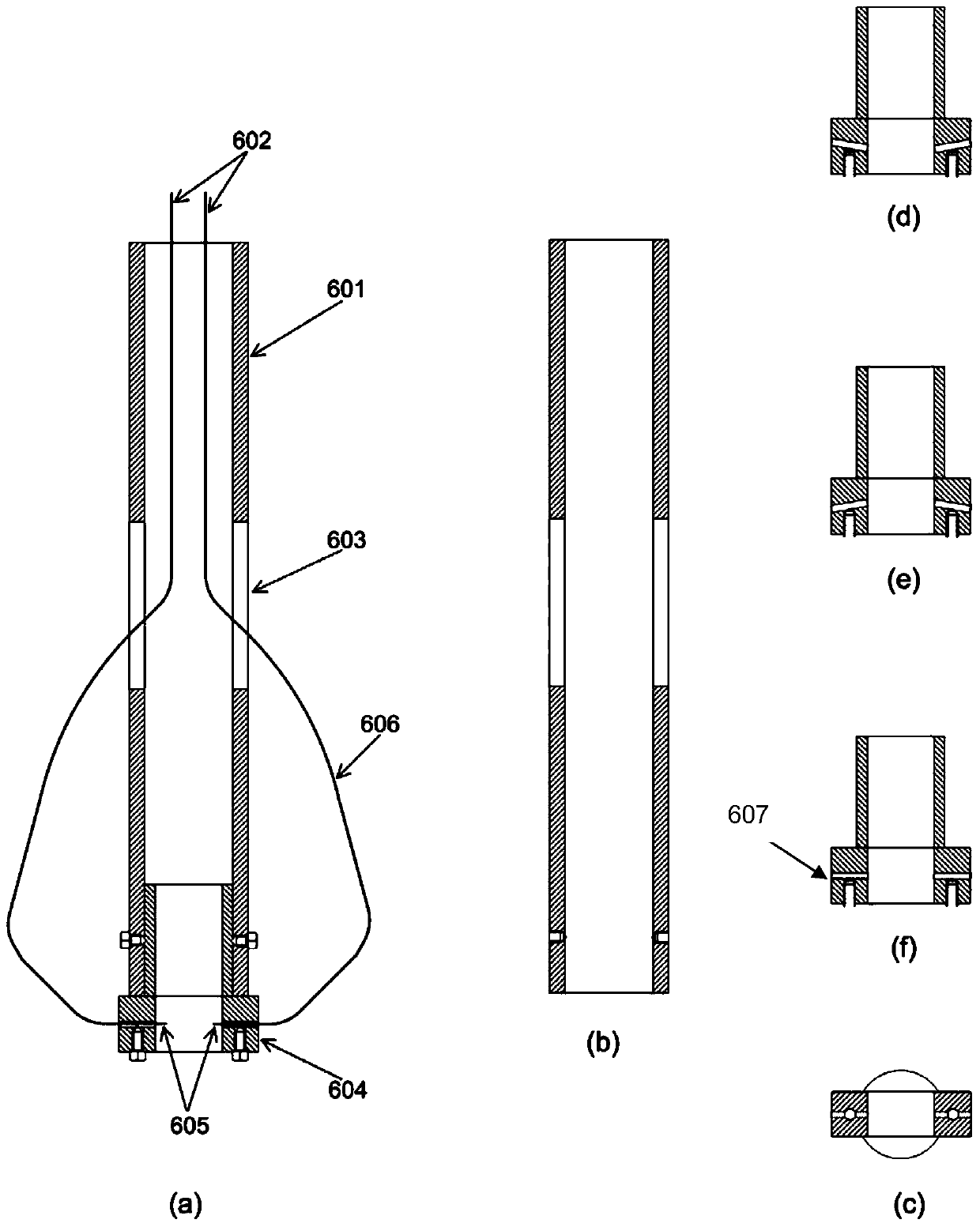

Novel tower plate-structure rectifying tower for maleic anhydride refining

InactiveCN104689590ASmall fluxReduce dosageOrganic chemistryFractional distillationCurrent limitingEngineering

The invention provides a novel tower plate-structure rectifying tower for maleic anhydride refining. The novel tower plate-structure rectifying tower for maleic anhydride refining comprises a tower body, a float valve tower plate unit and a sieve tower plate unit, the bottom of the tower body is provided with a tower bottom heater, the top of the tower body is provided with a tower top outlet, the tower top outlet is fixedly connected to a condenser by a pipe, the float valve tower plate unit and the sieve tower plate unit are arranged between two side inner walls of the tower body, the float valve tower plate unit comprises several float valve tower plates, the sieve tower plate unit comprises several sieve tower plates, the novel tower plate-structure rectifying tower is used in maleic anhydride rectification purification, the float valve tower plates and eight sieve tower plates are arranged in the tower body. Through reasonable design of the number and positions of the float valve tower plates and the sieve tower plates and current limiting effects of the float valve tower plates, gas flux is partly reduced and a steam use amount is reduced. The novel tower plate-structure rectifying tower effectively utilizes the advantage of a high vertical sieve plate production capacity and improves production efficiency.

Owner:TIANJIN BOHUA ZHONGHE CHEM

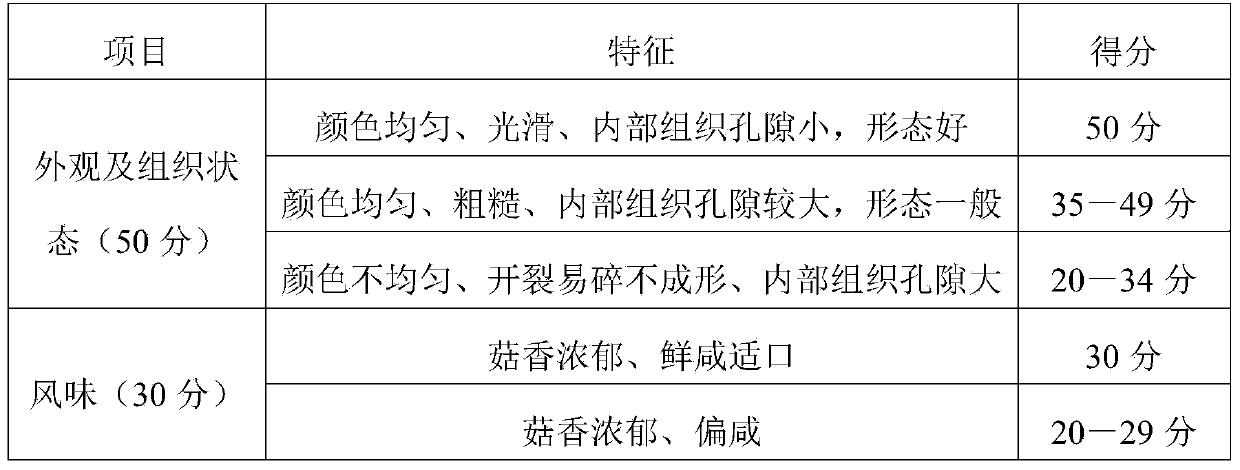

Salty fresh edible fungi aromatic rice fruit and preparation method thereof

The invention discloses a salty fresh edible fungi aromatic rice fruit and a preparation method thereof. The raw materials comprise the following components in percentage by weight: 5-15% of mushroom substances, 70-80% of starch grains, 5-12% of water and 2-5% of seasoning substances, wherein the starch grains are 50-60-mesh powder, the mushroom substances which comprise mushrooms and / or pleurotus eryngii are 60-120-mesh powder. The preparation method comprises the following steps: uniformly mixing and extruding the raw materials; shaping and cutting; cooling and drying to obtain extruded fruits; and spraying oil and seasoning by seasoners, and cooling, wherein the extruding condition is that a main machine is pre-heated to 50 DEG C in an area I, 150 DEG C in an area II and 160-170 DEG C in an area III; then, a main motor is started, the extruding temperature is controlled at 160-180 DEG C, and the rotary speed of the main motor is 1200r / min; the seasoners are salty fresh seasoners. The salty fresh edible fungi aromatic rice fruit is abundant in nutrition and delicious in taste.

Owner:上海大山合菌物科技股份有限公司

Planting method for black walnuts

InactiveCN105052663APromote growthAvoid erosionSeed and root treatmentCultivating equipmentsObserved SurvivalGermination

The invention discloses a planting method for black walnuts. The method comprises the steps of 1 land preparing; 2 seed collecting and processing; 3 seed germinating accelerating and sowing; 4 seedling managing and transplanting; 5 managing after transplanting. The planting method for the black walnuts has the advantages that reasonable processing is performed on seedling raising land, therefore, a good foundation is laid for the seedling raising environment of the black walnuts, and the smooth growth of seedlings is guaranteed; germination accelerating processing is performed on black walnut seeds before sowing is performed, therefore, the seedling emergence cycle of the black walnuts is shortened, the problem that the growth speed of the black walnuts is low in the general environment is further solved, the cultivation cycle of the black walnuts is shortened, and the planting cost of the black walnuts is lowered; in addition, the black walnut seedlings are processed, therefore, the transplanting survival rate of the black walnut seedlings is improved to a greater extent, the cultivation time of the seedling stage is shortened by one to two months, the productive profit of the black walnuts is further improved, the planting passion of farmer households is inspired, and conditions are supplied for large-area large-scale planting production of the black walnuts.

Owner:GUZHEN COUNTY LVHE FAMILY FARMS

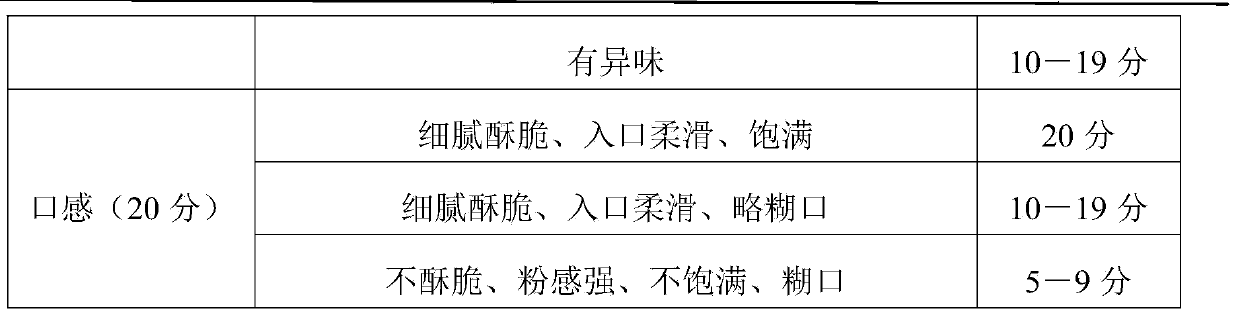

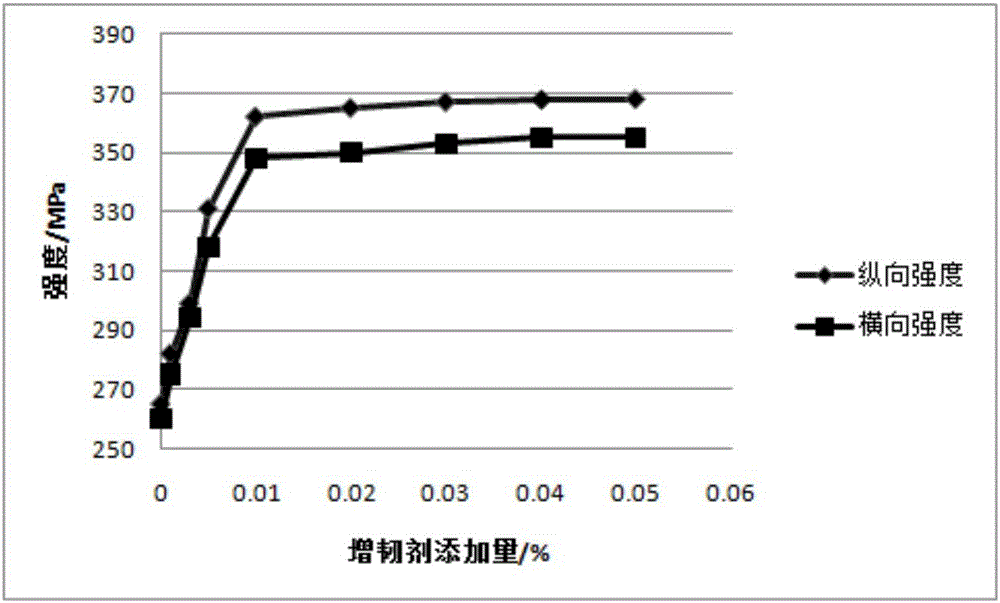

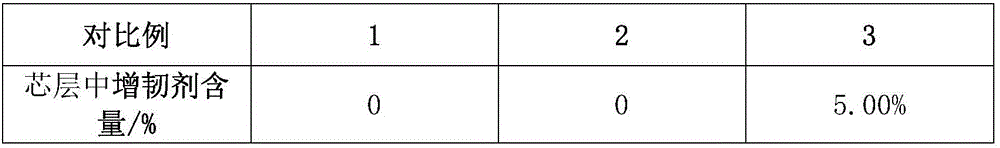

High-strength and two-way-stretching PEN film and preparation method thereof

ActiveCN106626679AAccelerated corrosionImprove thermal stabilitySynthetic resin layered productsSurface layerShrinkage rate

The invention discloses a high-strength and two-way-stretching PEN film and a preparation method thereof. The film is composed of an upper surface layer, a core layer and a lower surface layer, wherein the thickness of the film is 20-50 microns, the tensile strength is 350 Mpa or above, the hydrolysis resisting performance is up to 200 h or above, and the longitudinal and horizontal heat shrinkage rate is 0.4% or below under the conditions of the temperature of 150 DEG C and the time of 30 minutes. The core layer consists of a toughening agent and a polyethylene naphthalate slice, wherein the toughening agent content is 0.01-5% by weight. The upper surface layer and the lower surface layer are composed of polyethylene naphthalate slices and an anti-sticking agent, wherein the anti-sticking agent content is 0.01-5% by weight. The high-strength and two-way-stretching PEN film prepared by adopting a three-layer co-extrusion and two-way stretching process has the advantages of being large in tensile strength, resistant to hydrolysis and corrosion, high in thermal stability and the like.

Owner:ANHUI GUOFENG PLASTIC

Bending machine mold

The invention discloses a bending machine mold, which comprises a lower mold and an upper mold placed on an operating table; the lower mold comprises a first horizontal iron block and a second horizontal iron block; one side face of the first horizontal iron block is provided with a groove; one side face of the second horizontal iron block is provided with a lug matched with the groove; a plurality of splicing iron blocks which are connected with the first horizontal iron block and the second horizontal iron block simultaneously in a clamping manner are arranged between the first horizontal iron block and the second horizontal iron block; a first idler wheel is arranged on the first horizontal iron block; a second idler wheel is arranged on the second horizontal iron block; a first longitudinal iron block is connected to the first idler wheel; and a second longitudinal iron block is connected to the second idler wheel. The opening length and the opening angle of the lower mold are adjusted, so that only one group of molds can adapt to various kinds of bending specifications, frequent replacement of the mold is not needed, the integral bending efficiency is improved, the purchasing cost is reduced, and the production profit is improved.

Owner:NANJING BLESSED HYDRAULIC MACHINERY

Stone surface grinding and polishing device

PendingCN108723917AAvoid Difficult Handling ProblemsImprove clamping efficiencyPlane surface grinding machinesEngineeringSurface grinding

The invention discloses a stone surface grinding and polishing device which comprises a base plate. A fixing frame is fixedly connected to the top of the base plate. Driving rollers and driven rollersare sequentially and rotationally connected between the two opposite sides of the inner wall of the fixing frame, movable devices are fixedly connected to the portions, on the two sides of the fixingframe, of the top of the base plate, a sliding base is slidably connected to the tops of the movable devices, a supporting frame is fixedly connected to the top of the sliding base, a first lead screw is rotationally connected to the top of the inner wall of the supporting frame through a first rotating base, a first movable block is in threaded connection with the surface of the first lead screw, a regulating device is fixedly connected to the bottom of the first movable block, a grinding motor is fixedly connected to the bottom of the regulating device, and a grinding tool is fixedly connected to an output shaft of the grinding motor. The invention relates to the technical field of stone processing. The problem that the working efficiency is low due to the fact that marble is heavy andis not convenient to transport is solved, and meanwhile the problem that the production profit is lowered due to selection of outsource processing is solved.

Owner:湖州永昆石材有限公司

Manufacturing method of aluminum profile zipper with colored nonferrous metal

InactiveCN106868561ATake advantage ofIncrease production profitSlide fastenersNonferrous metalBiological activation

The invention relates to the field of zipper manufacturing, and provides a method for manufacturing an aluminum profile zipper with colored nonferrous metals, comprising the following steps: (1) chemically degreasing the teeth of the aluminum profile zipper; (2) cleaning; (3) grinding; (4) cleaning; (5) electroplating nickel layer; (6) cleaning, (7) activation; (8) cleaning, (9) electroplating non-ferrous metal film layer, (10) cleaning to obtain finished aluminum profile zippers with colored non-ferrous metals . The invention solves the problems of high production cost, large consumables, and environmental pollution during production of existing zippers.

Owner:FUJIAN CHUANGYUE ZIPPER SCI&TECH CO LTD

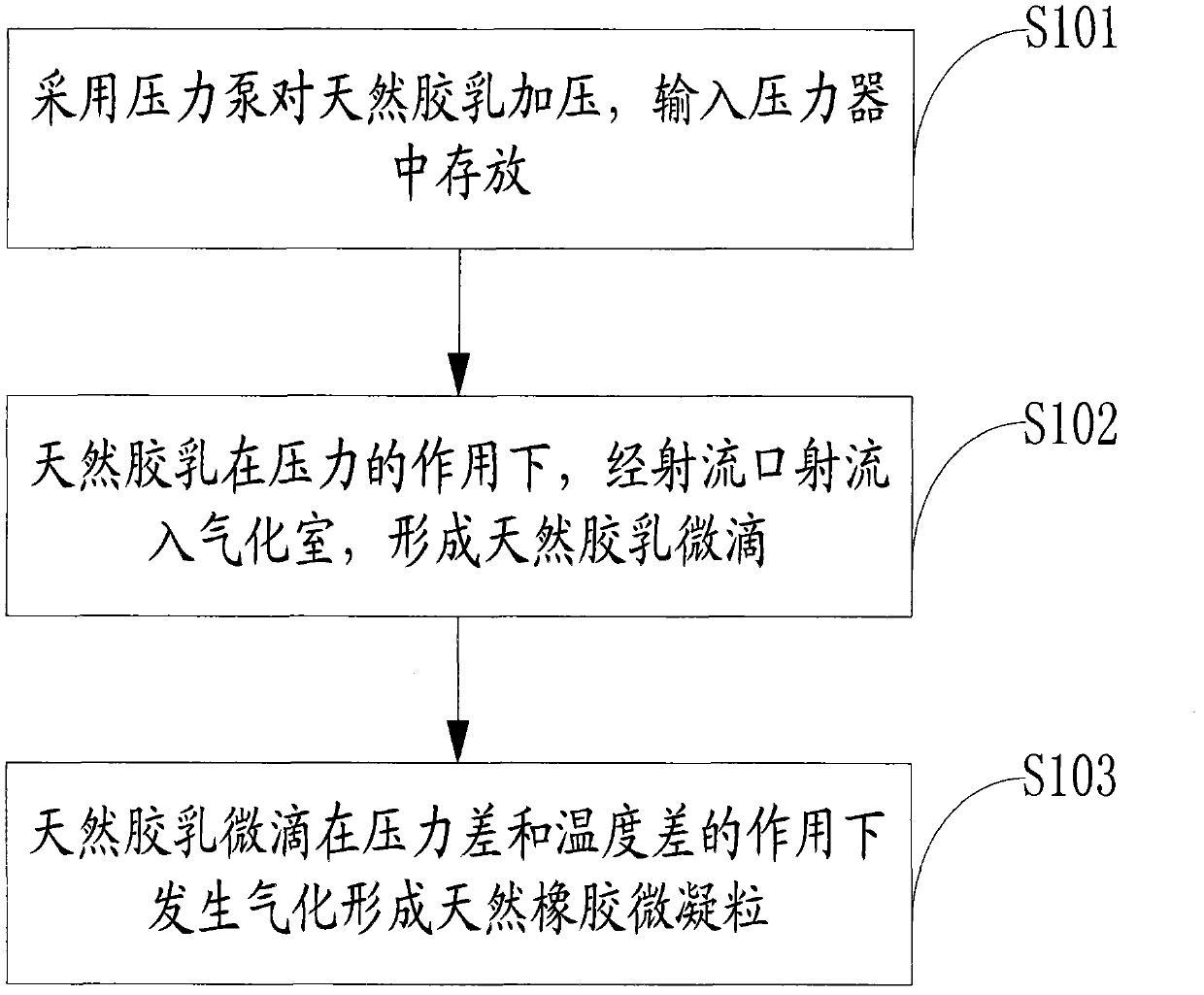

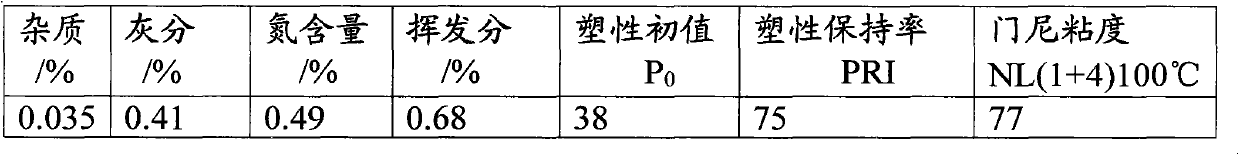

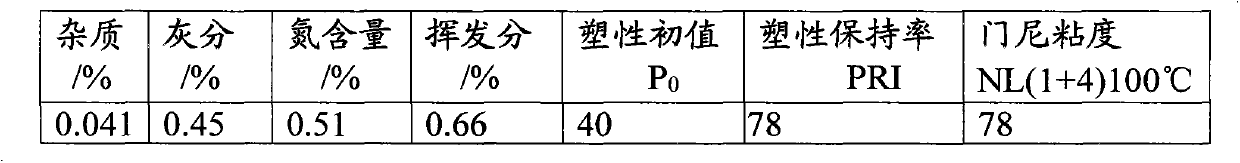

Natural latex jet-flow solidification method

The invention discloses a natural latex jet-flow solidification method which comprises the following steps of: pressurizing the natural latex by using a pressure pump, putting the natural latex into a pressure instrument to be stored up, jetting the natural latex into a gasifying chamber through a jet-flow port under the action of pressure, so as to form natural latex microdroplets; and gasifying the natural latex microdroplets under the action of pressure difference and temperature difference so as to form natural latex solidified grains. The natural latex jet-flow solidification method provided by the invention overcomes the defects that the acid solidification in the conventional production is high in production cost, long in production period, large in environmental pollution and large in body damage to operators, the production cost is greatly lowered, the application and the emission of harmful pollutants are reduced, the production period is shortened, and at the same time the production profits of enterprises are increased, so that the natural latex jet-flow solidification method is non-pollution environment-friendly production, meets the environment-friendly production concept which is proposed by China, and has wide application prospect in future.

Owner:HAINAN UNIVERSITY

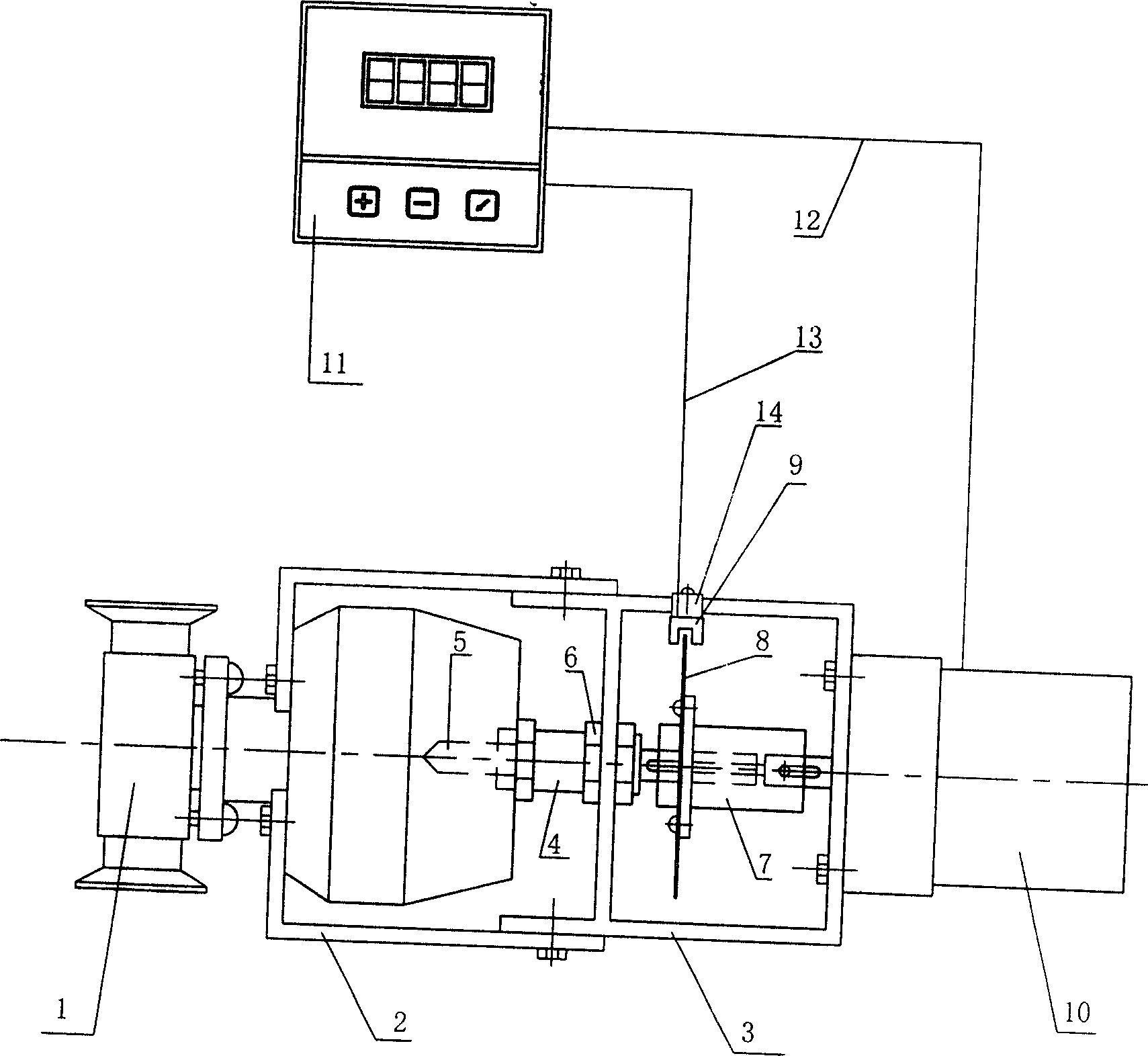

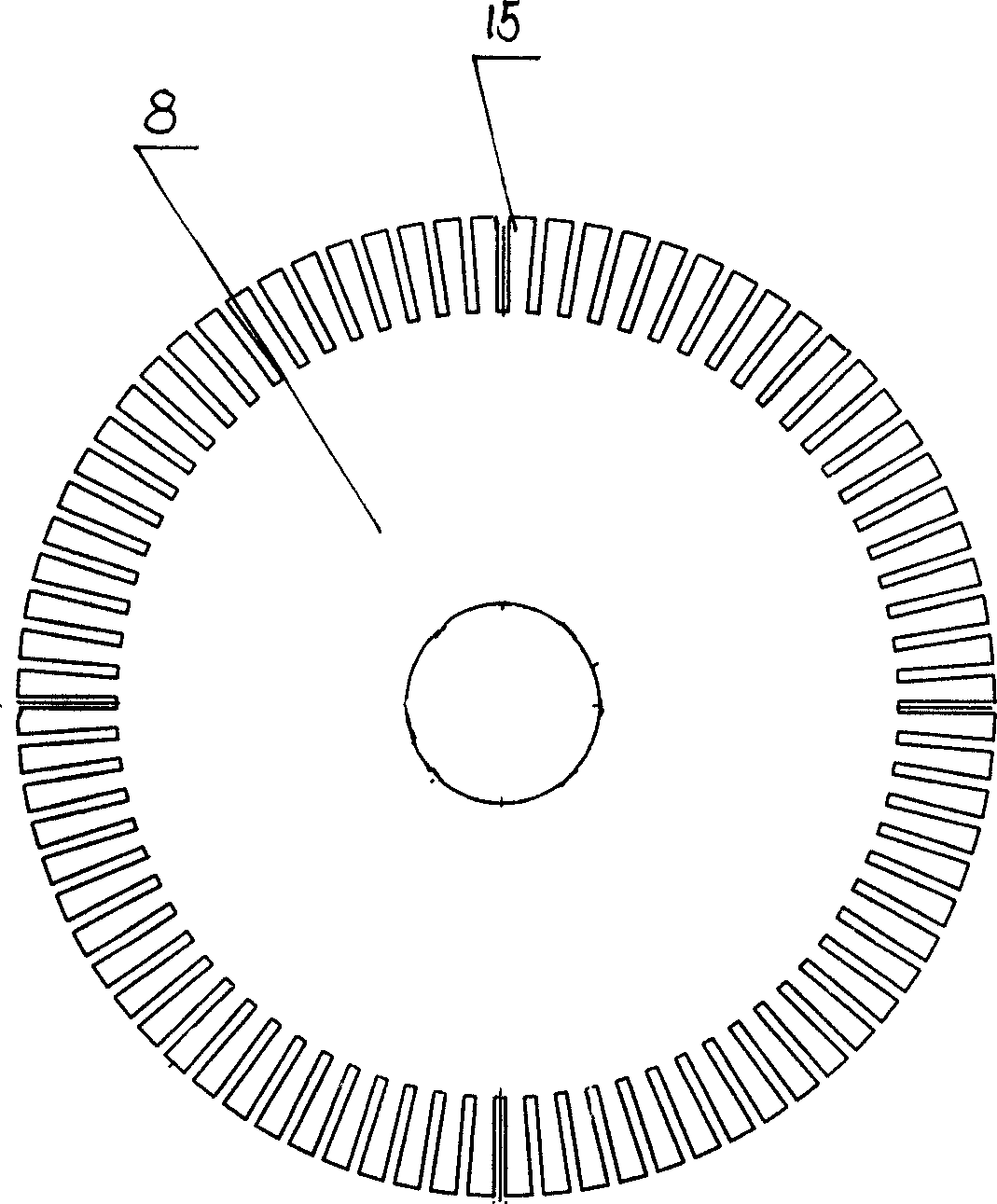

Flow control device for filling liquid

InactiveCN1696015AHigh measurement accuracyCutting costsOperating means/releasing devices for valvesFlow control using electric meansControl systemEngineering

A flow controlling system for filling liquid into the soft packages is composed of a pneumatic diaphragm valve, a regulating motor and a filled quantity control box containing microprocessor control circuit. The regulating screw bolt connected to the output shaft of said regulating motor via a connecting sleeve with a regulating wheel is extended in the limiting screw hole of said pneumatic diaphragm valve. The counting teeth are arranged on the circumference of regulating wheel. The switch for detecting said regulating wheel and the regulating motor are respectively and electrically connected with said microprocessor control circuit.

Owner:刘伯菊 +2

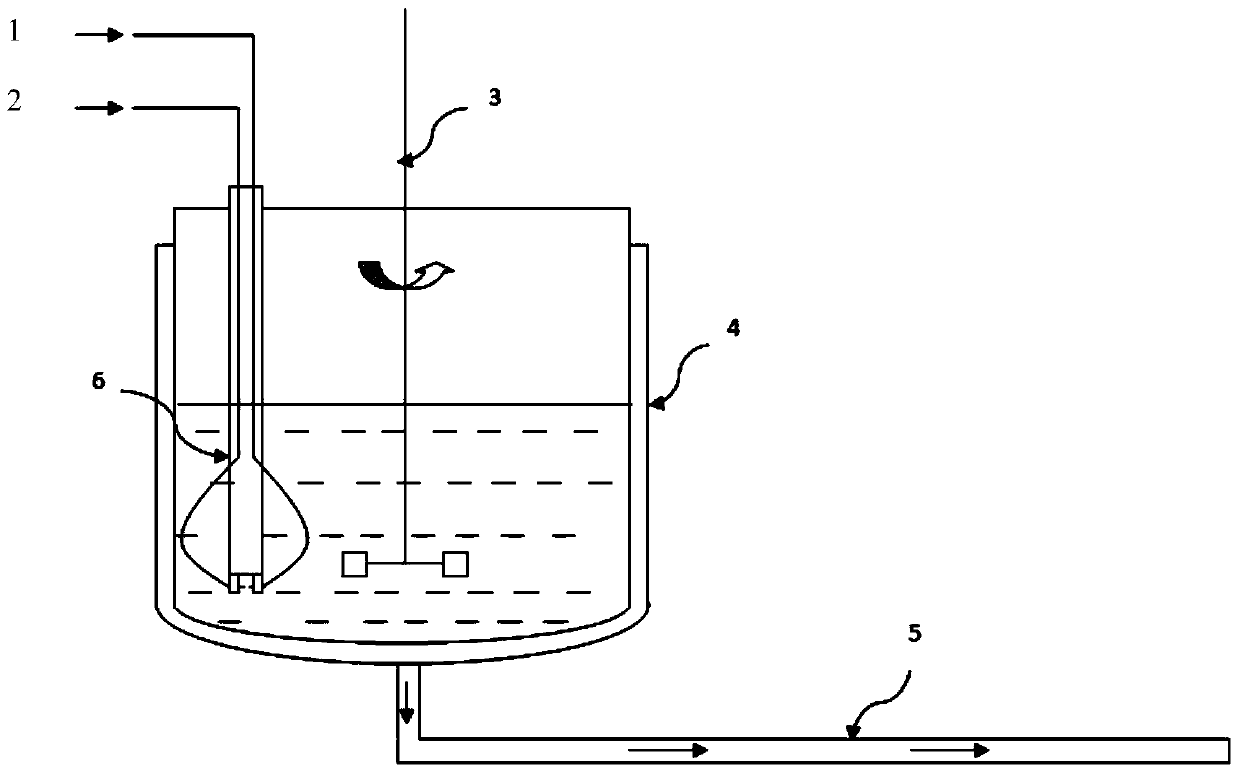

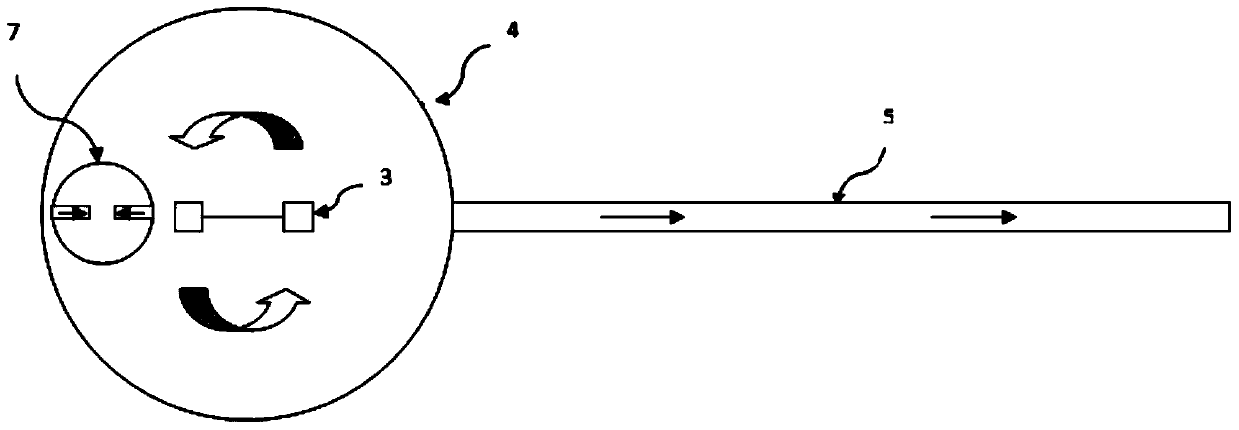

Device and method for improving stability of crystals by using continuous and rapid reactive crystallization

ActiveCN103551100APromotes fast and thorough mixingHigh crystallinityOrganic chemistrySolution crystallizationLiquid jetEngineering

The invention discloses a device and method for improving stability of crystals by using continuous and rapid reactive crystallization. The device comprises a kettle-type reactor and a tubular reactor connected with the kettle-type reactor in series, wherein the kettle-type reactor is internally provided with a liquid jet impacting feeding device; the liquid jet impacting feeding device comprises a hollow pipe and more than two feeding pipes, and the pipe wall of the hollow pipe is provided with a through hole through which the feeding pipes pass; the feeding pipes are inserted from an upper port of the hollow pipe and can go out from the through hole in the pipe wall, discharge openings of the feeding pipes are connected with nozzles, and the discharge opening and / or nozzle of each feeding pipe is fixed at the lower end part of the hollow pipe through a fixing frame; the nozzles are arranged in a specific way to ensure compacting collision, and a feeding pipe section between the through hole in the hollow pipe and the fixing frame is of an arc-shaped structure. The device and the method provided by the invention have the advantages that the average size and granularity of the crystals are uniform, and the purity and stability of a product are greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

Fermentation process capable of degrading organic waste

InactiveCN1966471AImprove metabolic environmental conditionsPrevent volatilizationBio-organic fraction processingOrganic fertiliser preparationEvaporationNitrogen

The invention relates to a preparing technology of a fertilizer, especially a zymotechnique that can degrade organic offal. The disintegrant solution is added in the pre-fermenting process which improves the fermenting effects; the formula of the fermenting material is regulated, the environmental condition for microbial metabolism is improved, the stabilizer is added in the process, all the previous aspects have increased the fermenting efficiency substantially; the stabilizer is sprinkled in the turning over process for oxygen inletting and dehumidifying to prevent the evaporation of the nitrogen and increase the soluble fosforus. The invention can increase the digesting efficiency and it can increase the total nutrients (the major element of N+P2O5+K2O) of the digesting substances to more than 6%.

Owner:杨立刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com