Display substrate and testing method and display device thereof

A technology for displaying substrates and testing methods, applied to static indicators, instruments, calculations, etc., can solve problems such as failure to detect poor short circuit of touch sensor units, failure to ensure poor open circuit of touch sensors, loss of polarizer POL, etc., to achieve Improve the defect detection rate, ensure effective utilization, and improve the effect of production profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

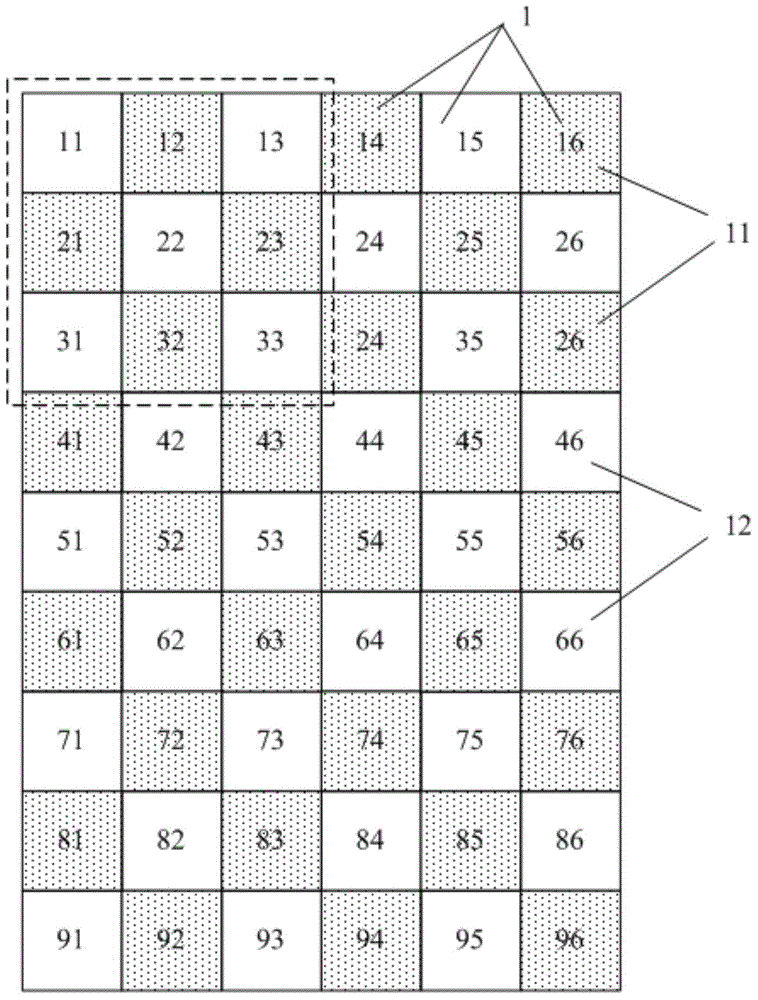

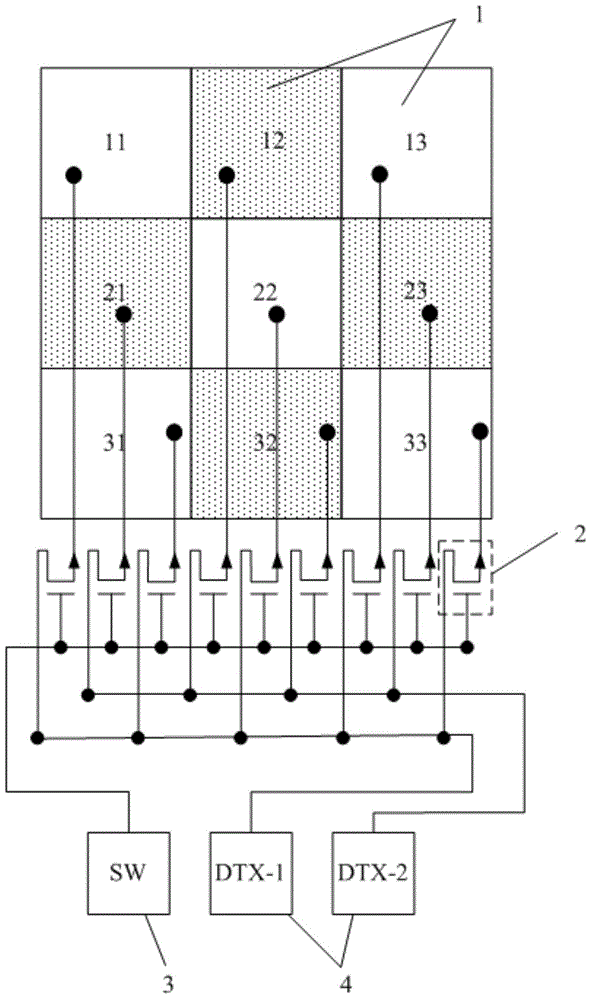

[0038] This embodiment provides a display substrate, the display substrate is provided with a test unit, and the test unit is used to test the electrical performance of the display substrate during the display process and the electrical performance of the formed self-capacitive touch electrodes. The test unit can accurately test the open circuit or short circuit of the touch display panel in the display stage or the touch stage, so as to improve the test accuracy and reduce the production cost.

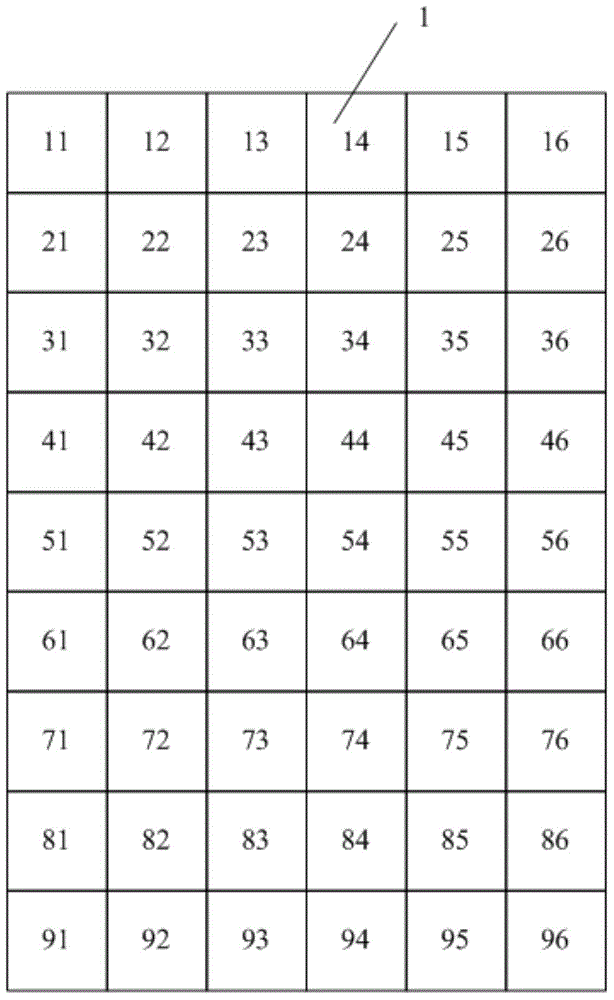

[0039] The display substrate includes a plurality of pixel regions arranged in a matrix and a test unit, each pixel region is provided with a first electrode, wherein the test unit includes at least two sub-test units, and the plurality of adjacent pixel regions correspond to the first electrode. The electrodes are divided into an electrode block, and the electrode blocks are electrically isolated from each other. The electrode blocks are divided into at least two test groups with the ...

Embodiment 2

[0071] This embodiment provides a display device, which includes the display substrate in Embodiment 1, and uses a corresponding test method to test its display function and touch electrical performance.

[0072] Since the display device adopts the above-mentioned high-yield display substrate, it has better display and touch effects and more stable performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com