Automatic hair dyeing machine for comb teeth

A dyeing and automatic technology, applied in the direction of coating, etc., can solve the problems of inconsistent size of the round head at the tip of the comb, the decline of the overall pass rate of the comb, and the instability of human factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

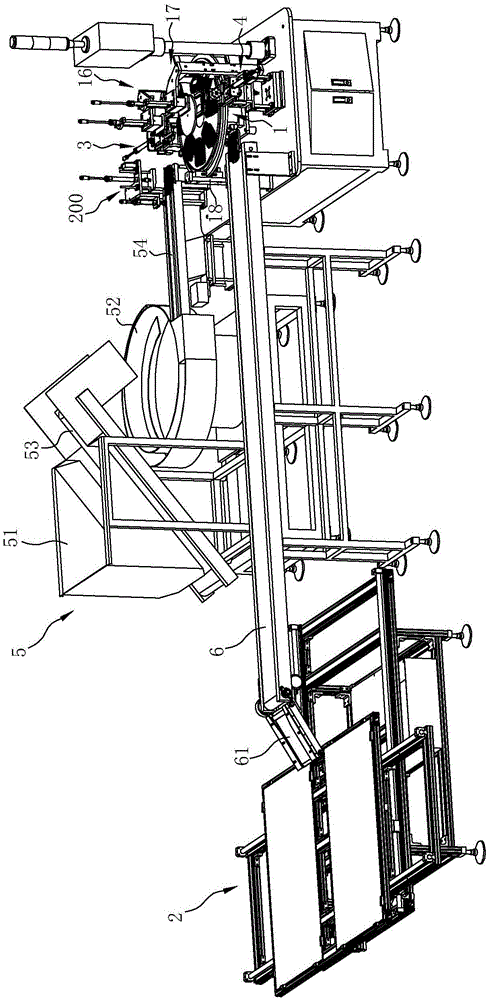

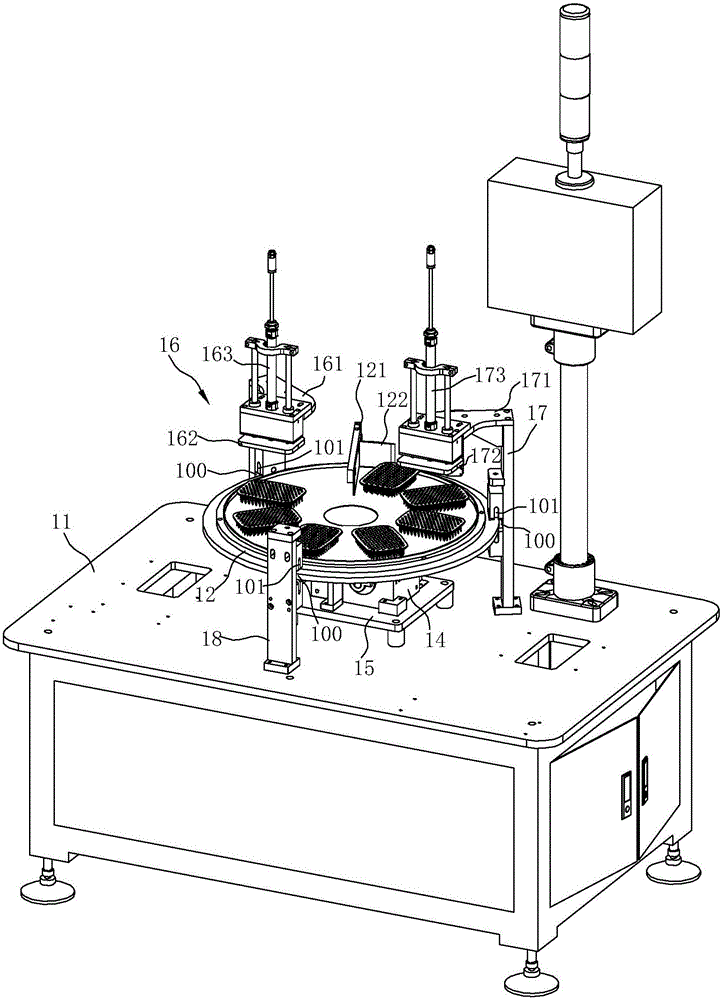

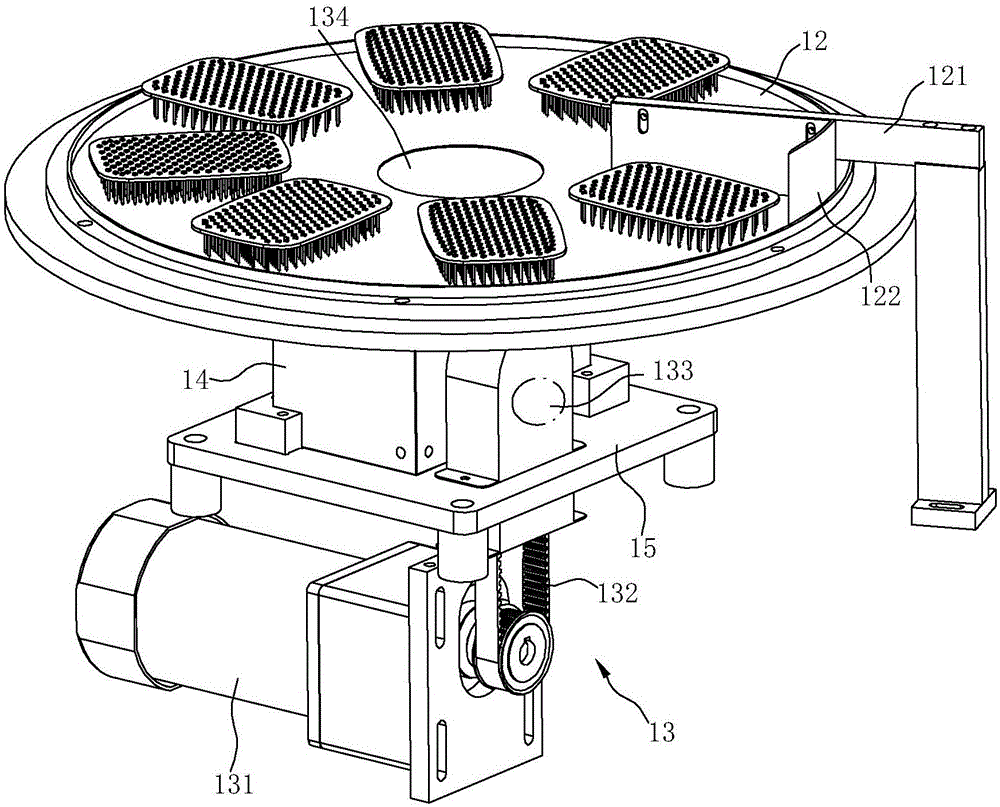

[0047] Such as Figure 1-14 As shown, the comb needle automatic hair dyeing machine of the present embodiment includes a comb body providing mechanism 5 for the hair to be dyed, a comb body removing mechanism, a hair dyeing mechanism 1, a comb body output mechanism 6 and a comb body discharge mechanism 2, except for the comb body discharge mechanism 2. Mechanism 2. The comb needle automatic hair dyeing machine of this embodiment is controlled by a total control system. The comb removal mechanism in this embodiment includes a first removal mechanism 3 and a second removal mechanism 4, and the comb supply mechanism 5 transports the comb body to be dyed to the vicinity of the first comb removal mechanism 3. The comb body removal mechanism 3 grabs the comb body to be dyed and places it in the hair dyeing mechanism 1 for dyeing hair, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com