Patents

Literature

510 results about "Dyeing hair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The dyeing of hair is an ancient art that involves treatment of the hair with various chemical compounds. In ancient times, the dyes were obtained from plants. Some of the most well known are henna (Lawsonia inermis), indigo, Cassia obovata, senna, turmeric and amla.

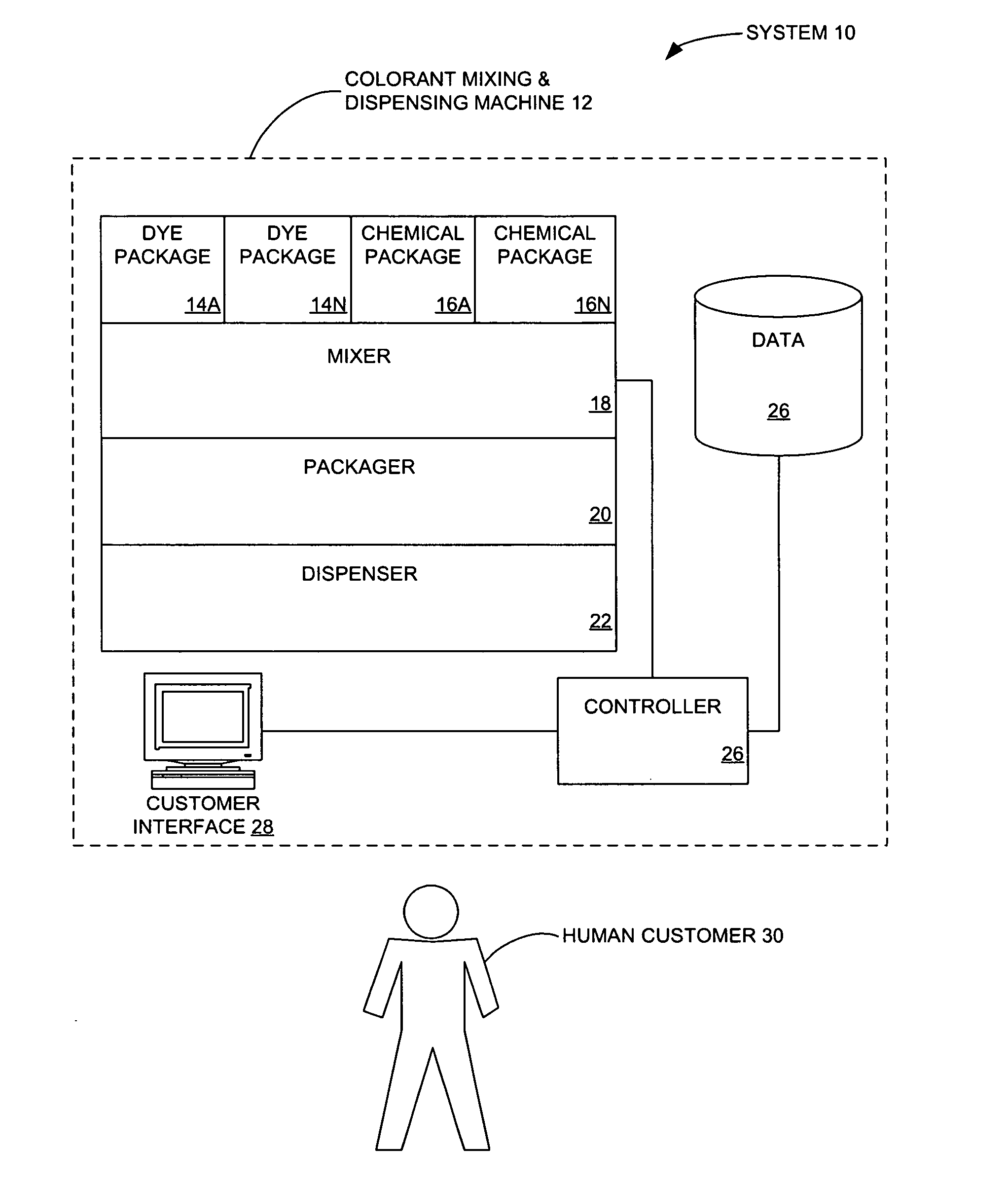

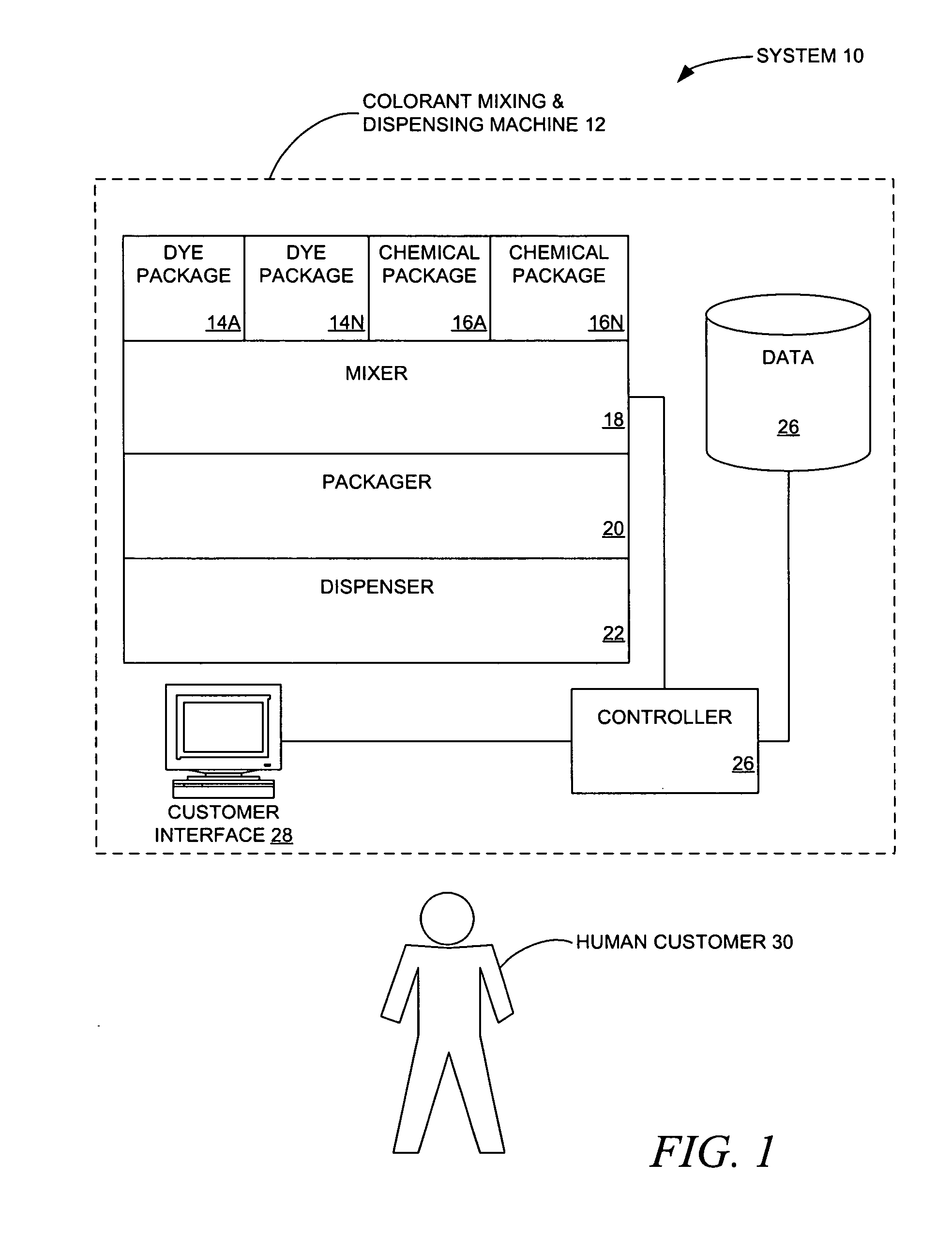

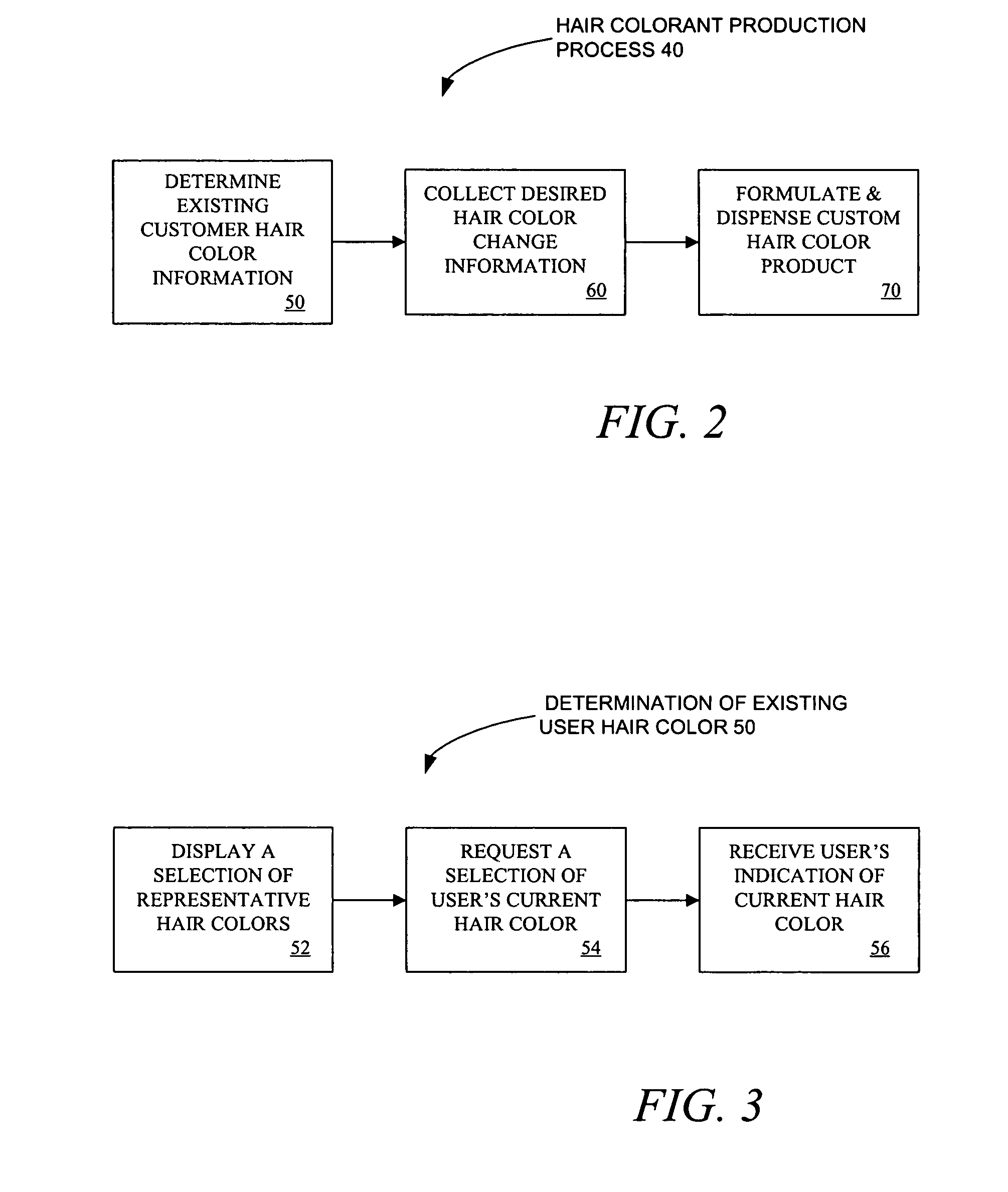

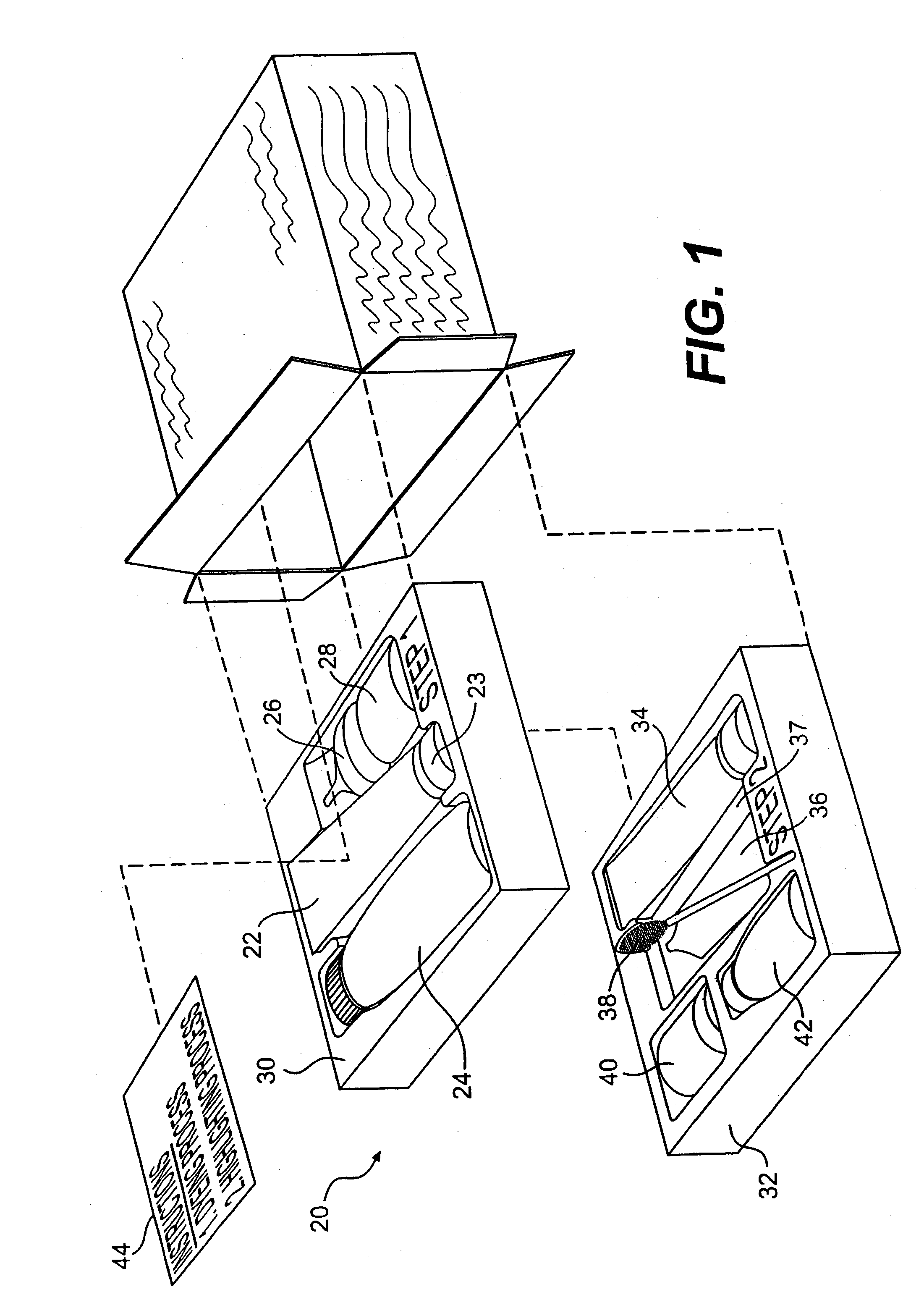

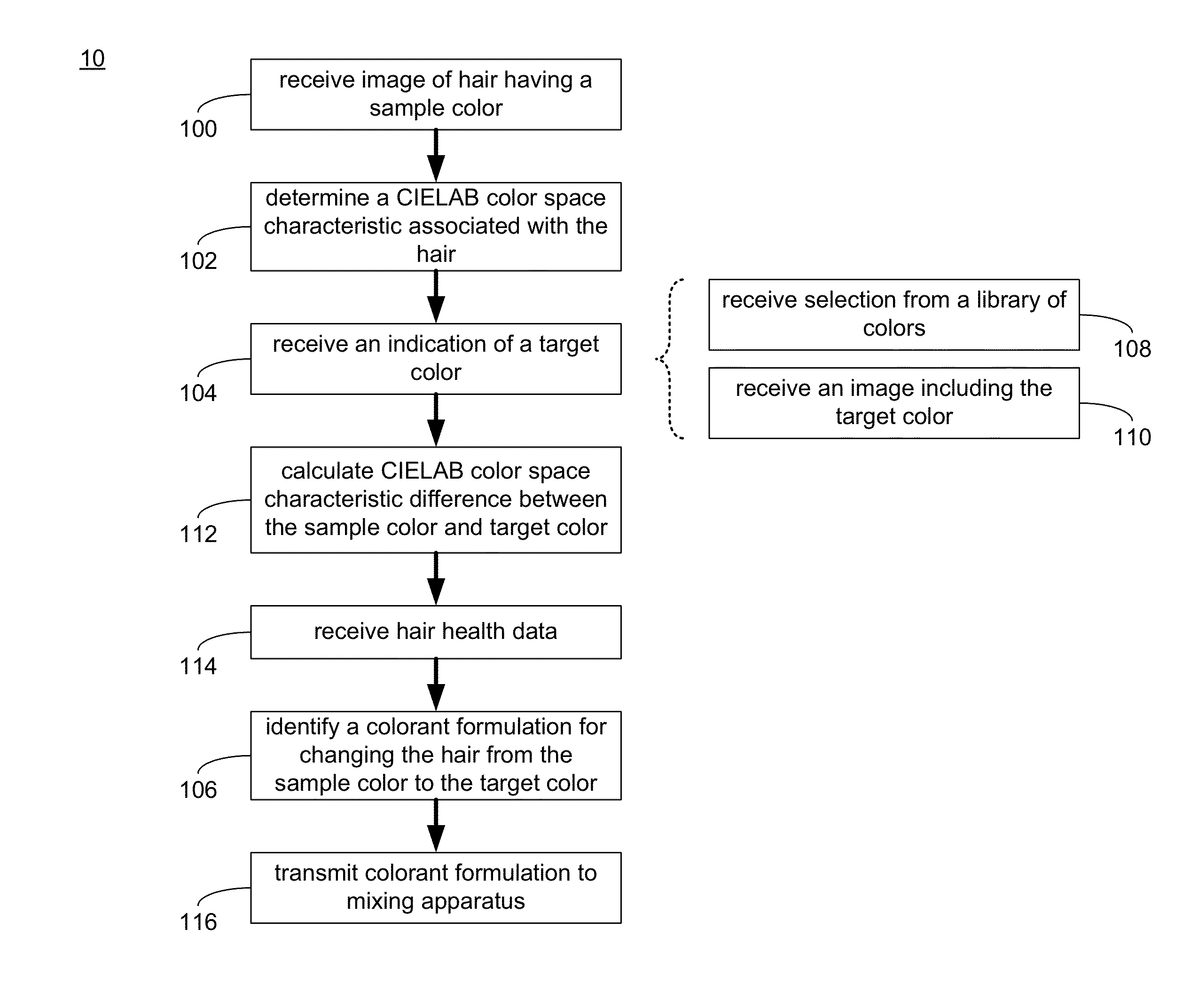

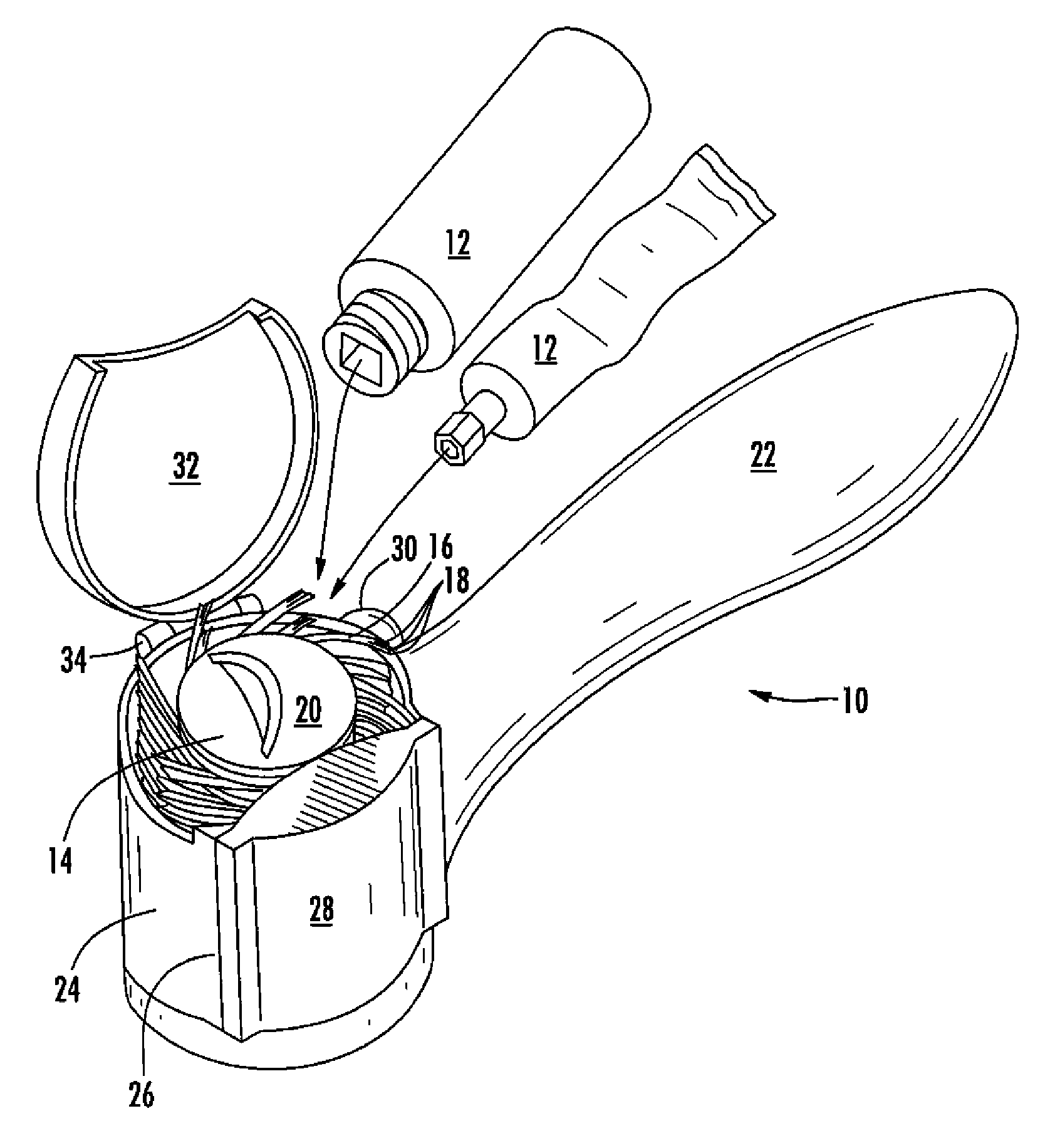

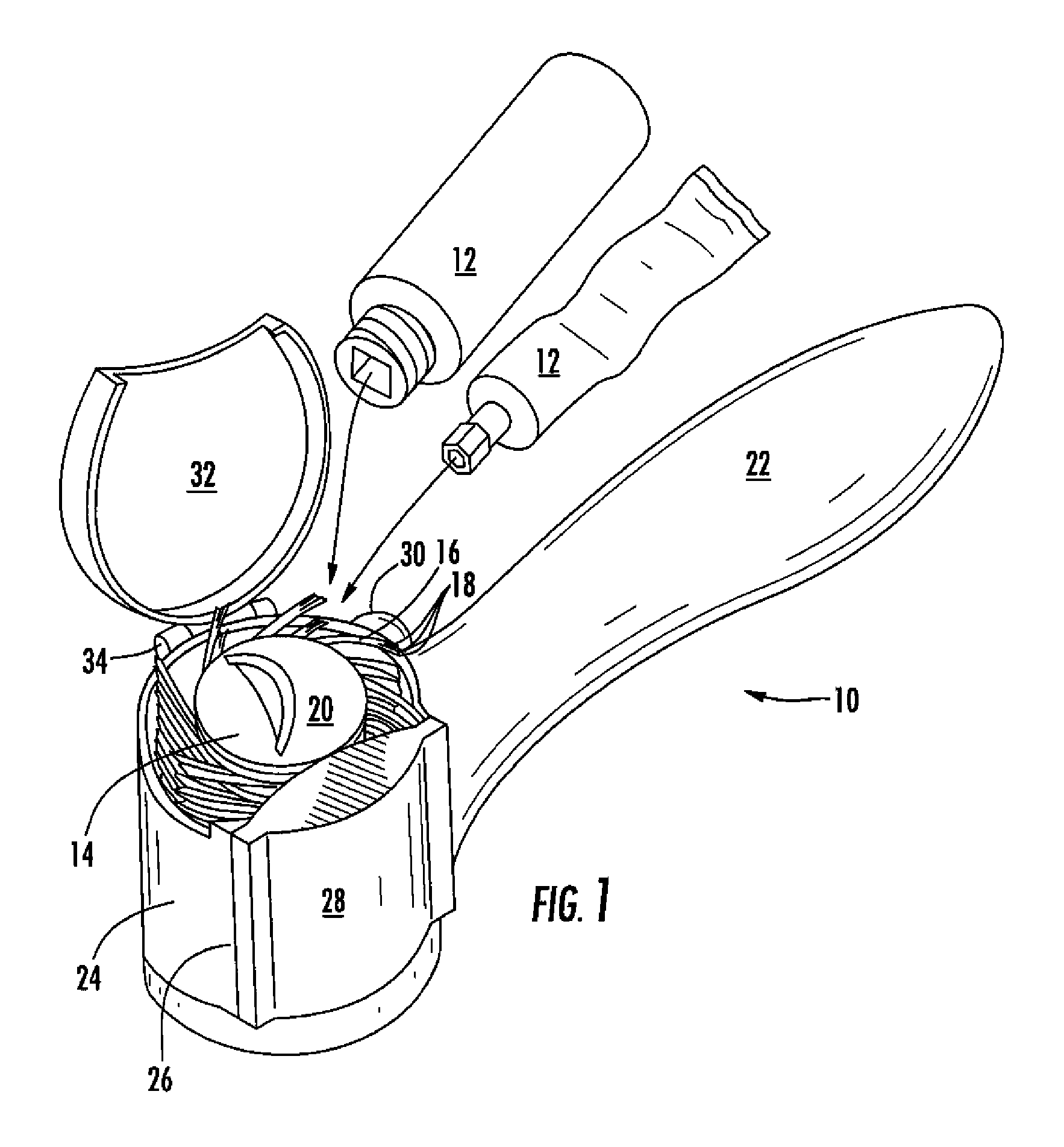

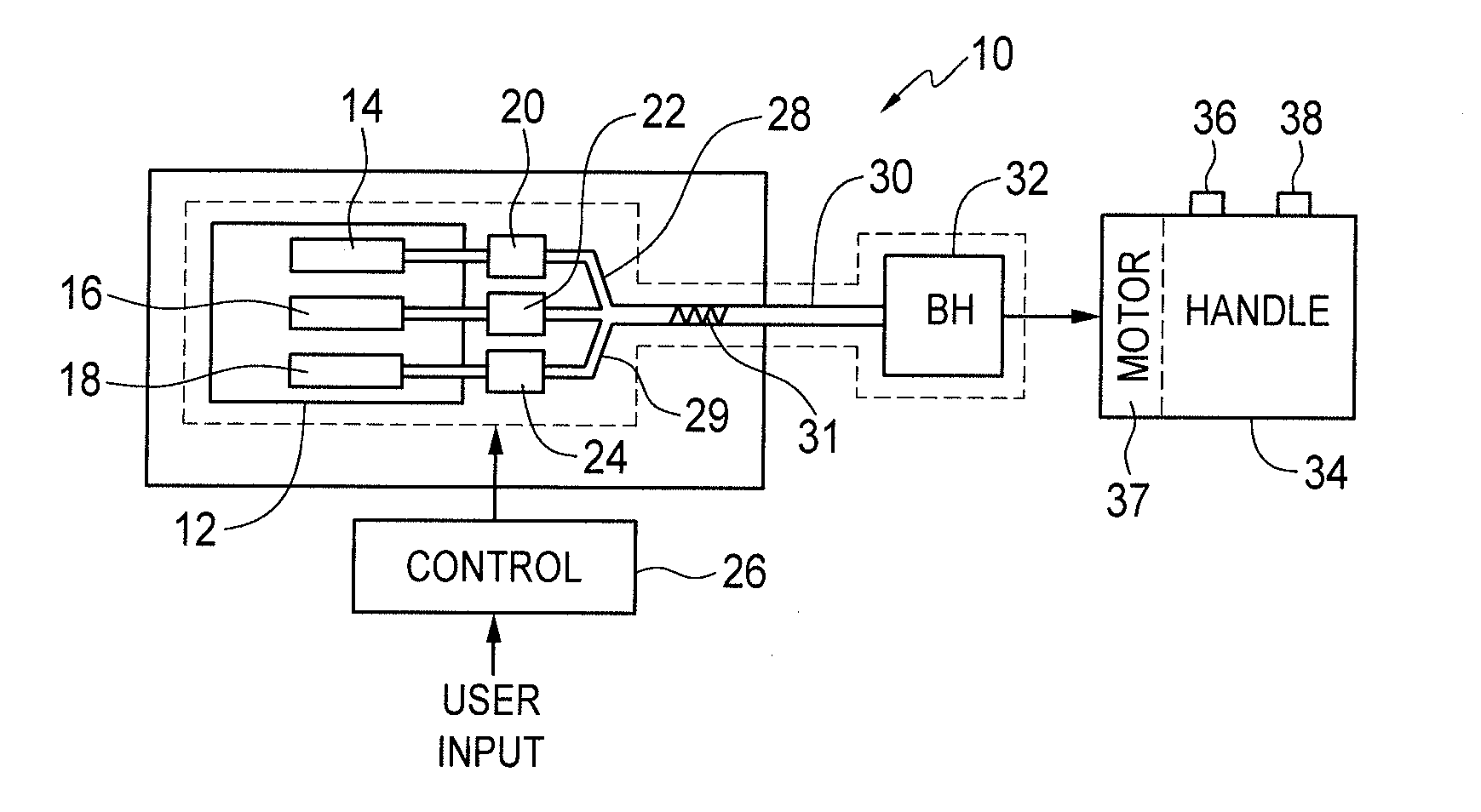

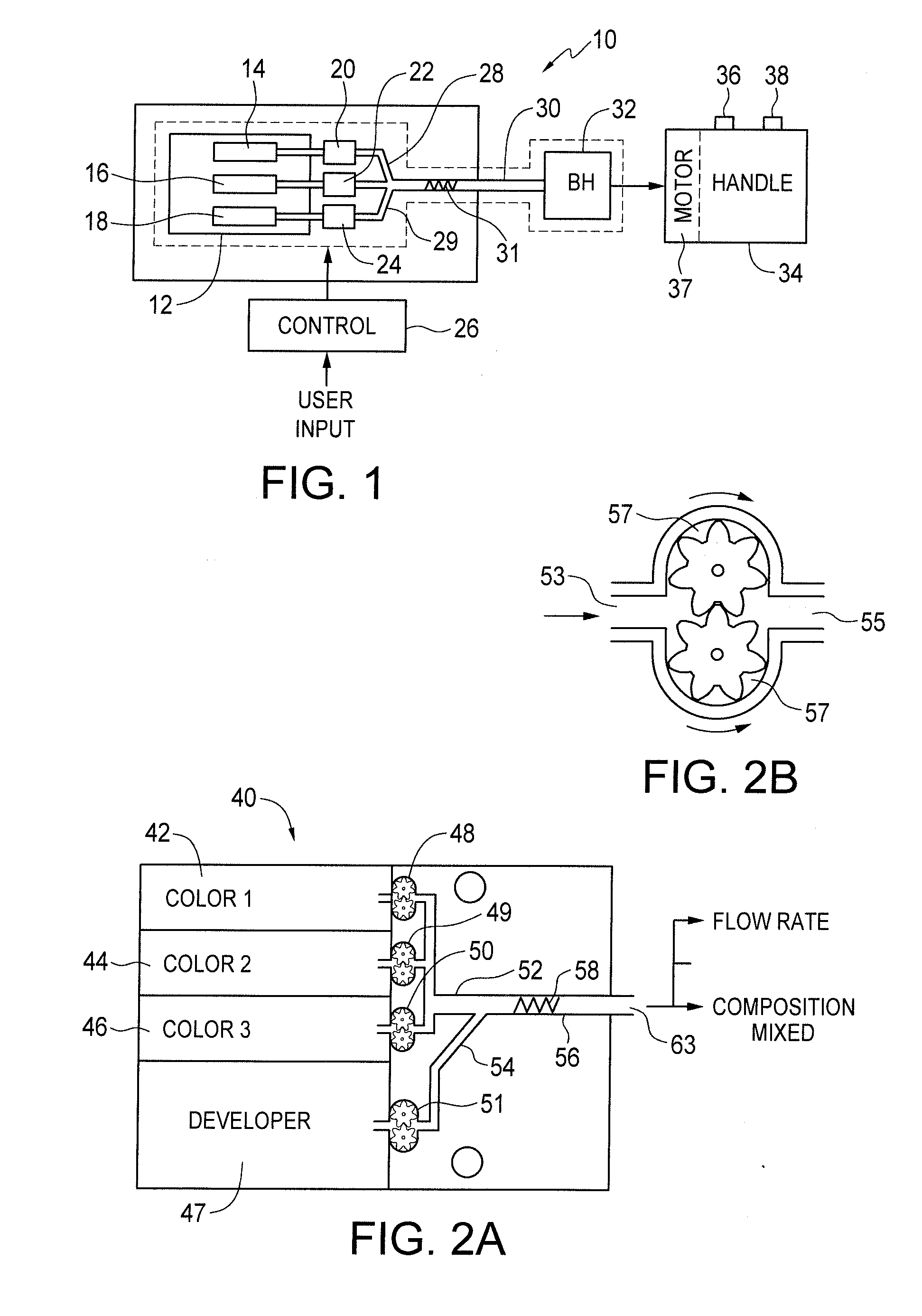

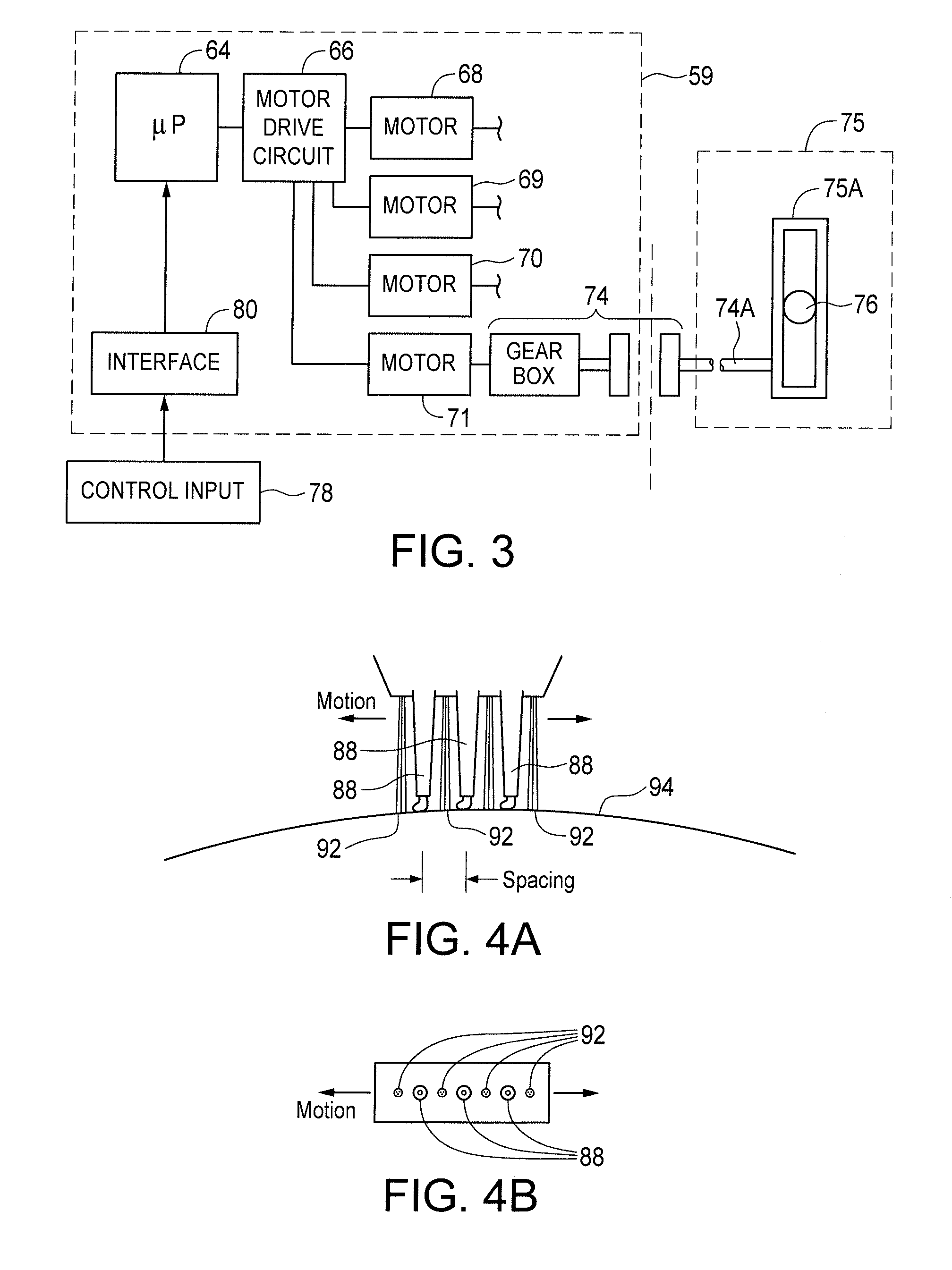

Apparatus and methods for selecting, formulating, mixing & dispensing custom hair coloring products for a user

InactiveUS20050165705A1Space minimizationReduce areaHair cosmeticsMixer accessoriesHair dyesCompound (substance)

Graphical interfaces are provided to a customer enabling her to identify her existing hair color and to select a desired change to that hair color, based upon which there is produced hair dyes and / or intensive toners in which the intermediates (developer and coupler) and the direct dyes are dissolved in liquid or creamy carrier masses that are mixed together by a computer-controlled device based on recipes stored in a computer. Using packaged dyes and chemicals, there is formulated, mixed, packaged and dispensed to the customer a custom hair colorant.

Owner:HCD

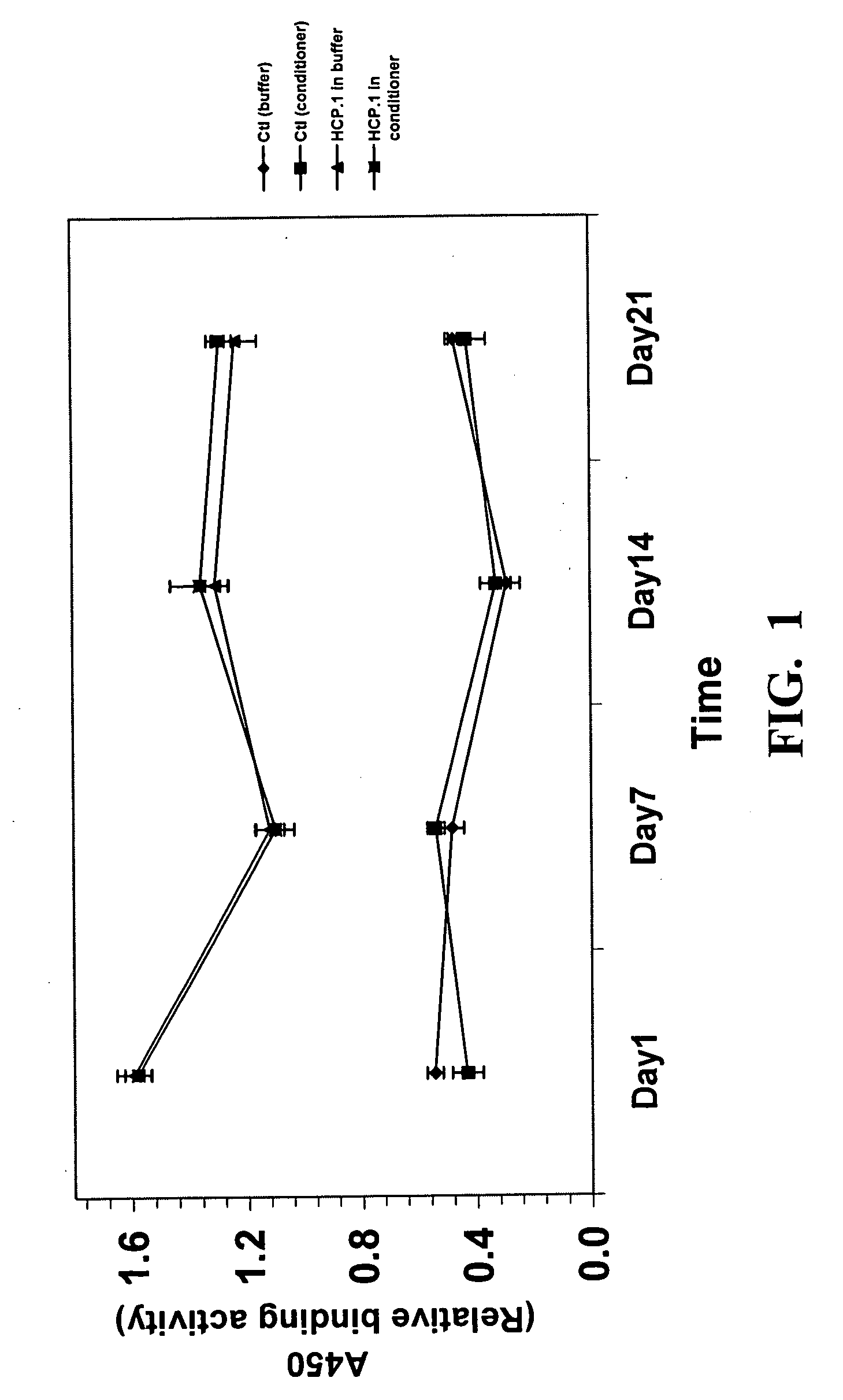

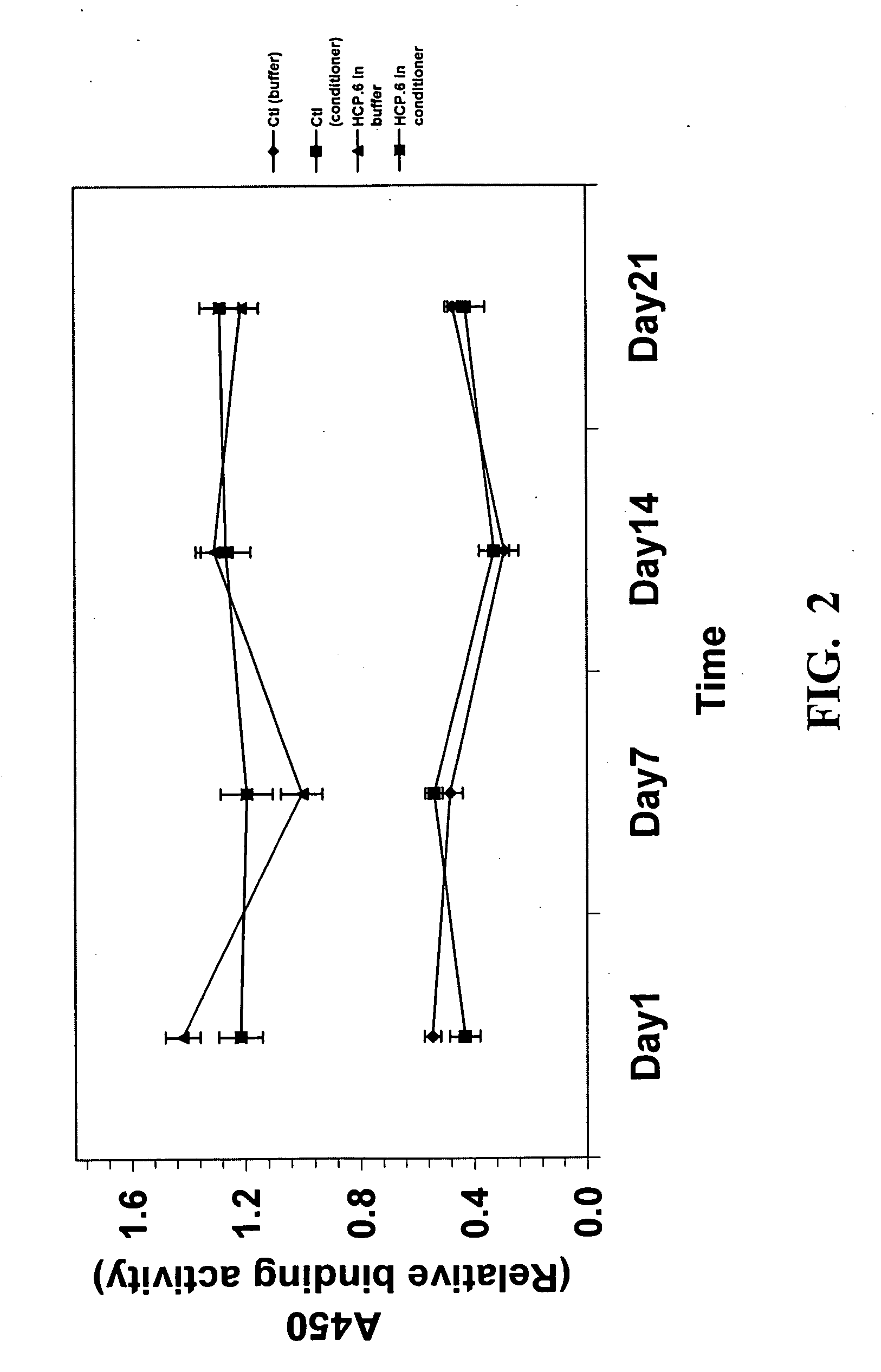

Method for identifying hair conditioner-resistant hair-binding peptides and hair benefit agents therefrom

A method for identifying hair conditioner-resistant hair-binding peptides is described. The hair conditioner-resistant hair-binding peptides bind strongly to hair from a hair conditioner matrix and are stable therein. Peptide-based benefit agents, such as hair conditioners and hair colorants, based on the hair conditioner-resistant hair binding peptides are described. The peptide-based hair conditioners and hair colorants consist of a hair conditioner-resistant hair-binding peptide coupled to a hair conditioning agent or a coloring agent, either directly or through an optional spacer. Hair care and hair coloring product compositions comprising these peptide-based hair conditioners and colorants are also described.

Owner:EI DU PONT DE NEMOURS & CO

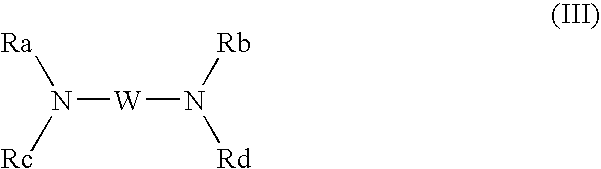

Method for identifying shampoo-resistant hair-binding peptides and hair benefit agents therefrom

A method for identifying shampoo-resistant hair-binding peptides is described. The shampoo-resistant hair-binding peptides bind strongly to hair from a shampoo matrix and are stable therein. Peptide-based benefit agents, such as peptide-based hair conditioners and hair colorants, based on the shampoo-resistant hair binding peptides are described. The peptide-based hair conditioners and hair colorants consist of a shampoo-resistant hair-binding peptide coupled to a hair conditioning agent or a coloring agent, respectively. Hair care and hair coloring product compositions comprising these peptide-based hair conditioners and colorants are also described.

Owner:EI DU PONT DE NEMOURS & CO

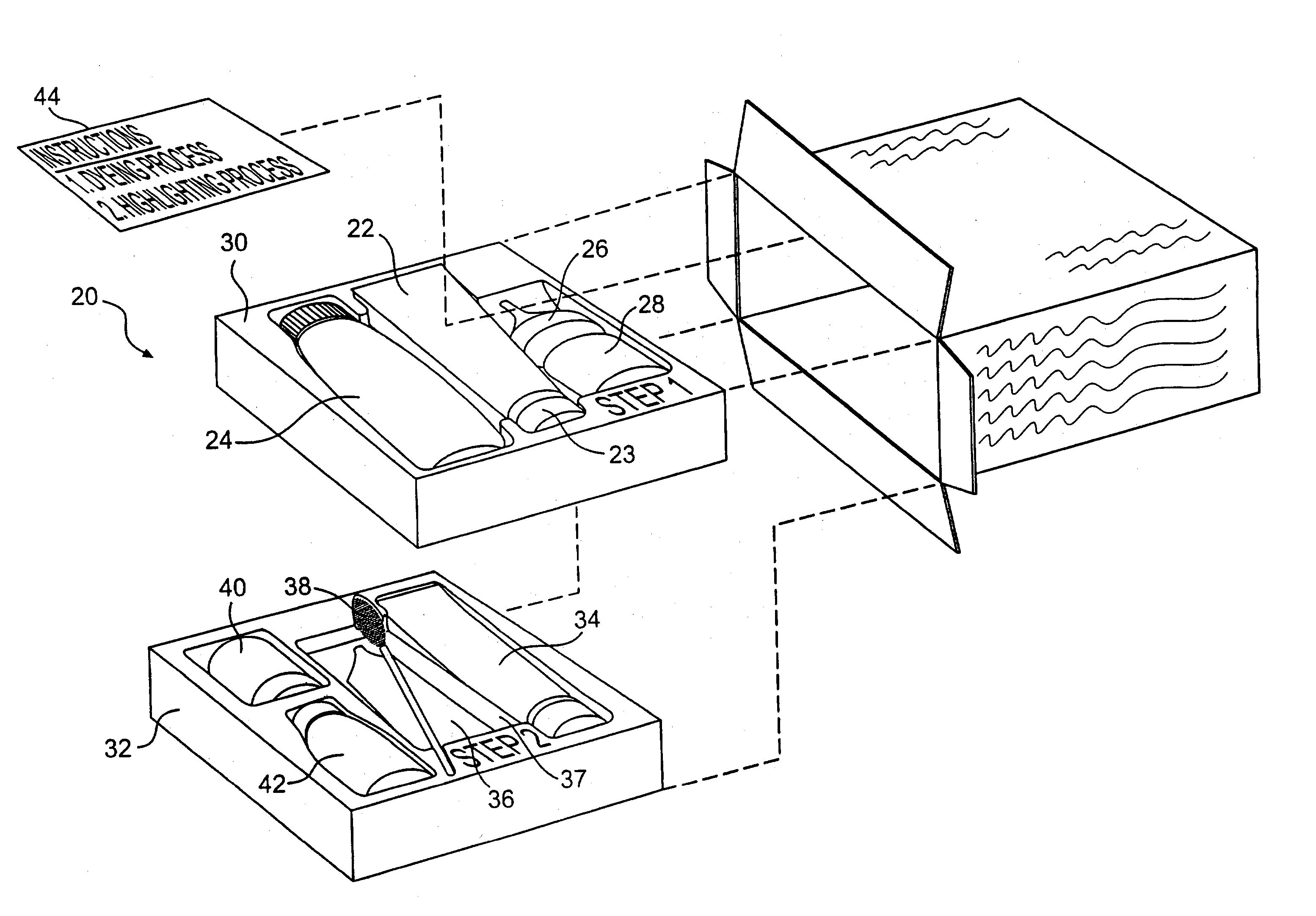

Methods and systems for hair coloring and highlighting

InactiveUS20040089316A1Improved hair treatment systemSimple processCosmetic preparationsHair cosmeticsHair dyesBright spot

Various methods, systems and structures relating to hair treatment are disclosed. They include a kit made up of a hair dye and a hair highlight. The kit may contain instructions to apply the highlight while the hair remains moist. A bristled applicator may be included in the kit for use in applying highlight to the hair. Corresponding methods of use and marketing are also disclosed.

Owner:LOREAL SA

Methods for fixing hair and skin

ActiveUS9095518B2Good benefitImprove dry strengthCosmetic preparationsHair cosmeticsHair straighteningCompound (substance)

Compositions, kits, and methods for repairing bonds, for example, disulfide bonds, in hair or on the skin are disclosed. The compositions provide improved conditioning benefit for dry hair or moisturize the skin. The compositions also provide a long lasting moisturized feel and smooth feel to the skin or hair, without feeling greasy. The compositions contain one or more compounds that covalently bind at least two thiol groups in the hair or on the skin. Use of the binding compositions prevents reversion of the repaired bonds to their free thiol state, for at least one week or one month, or more, after a single application of the composition. Improved methods of styling hair, for example permanent hair waving, hair curling, hair coloring or highlighting, and hair straightening, are also provided.

Owner:LIQWD

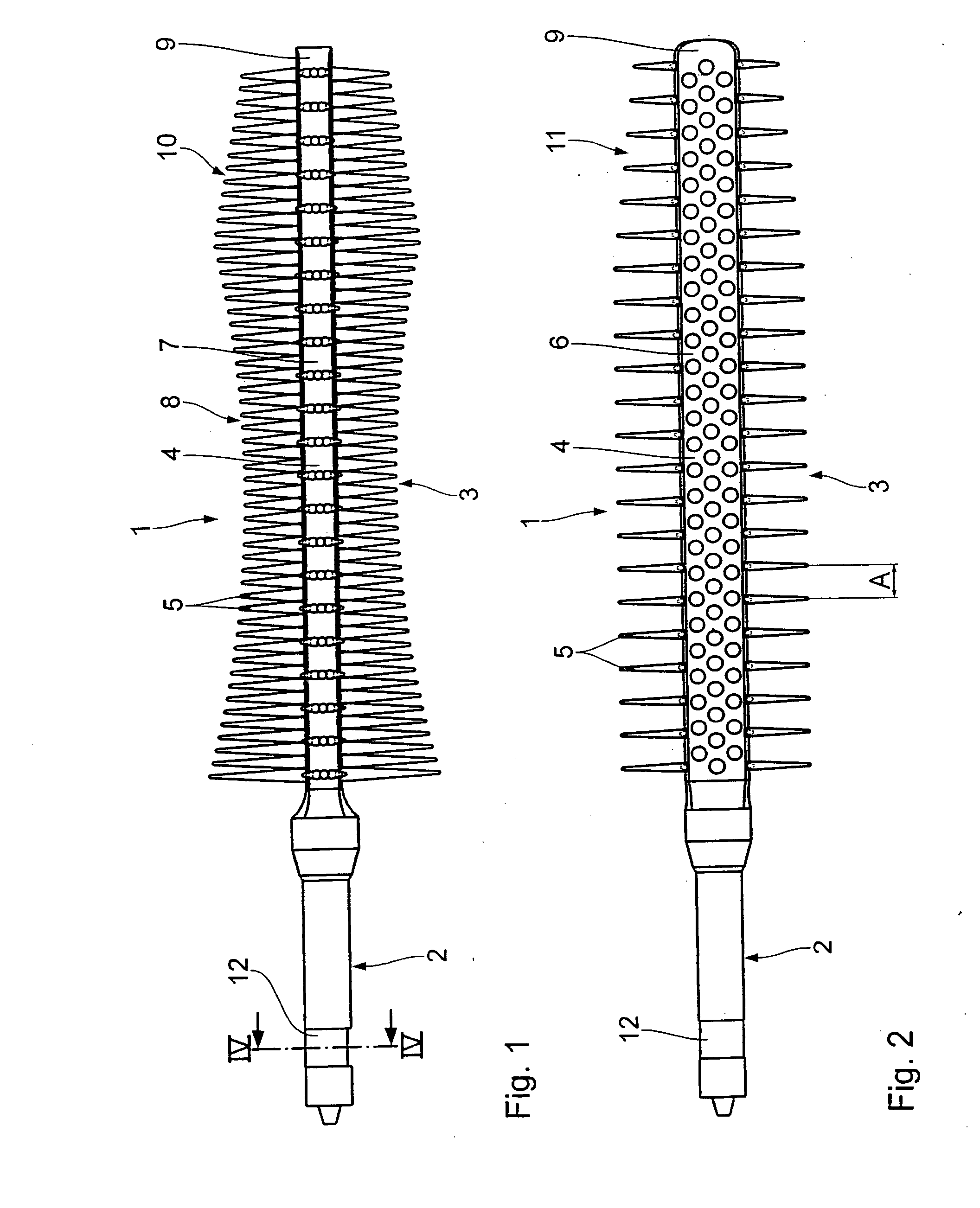

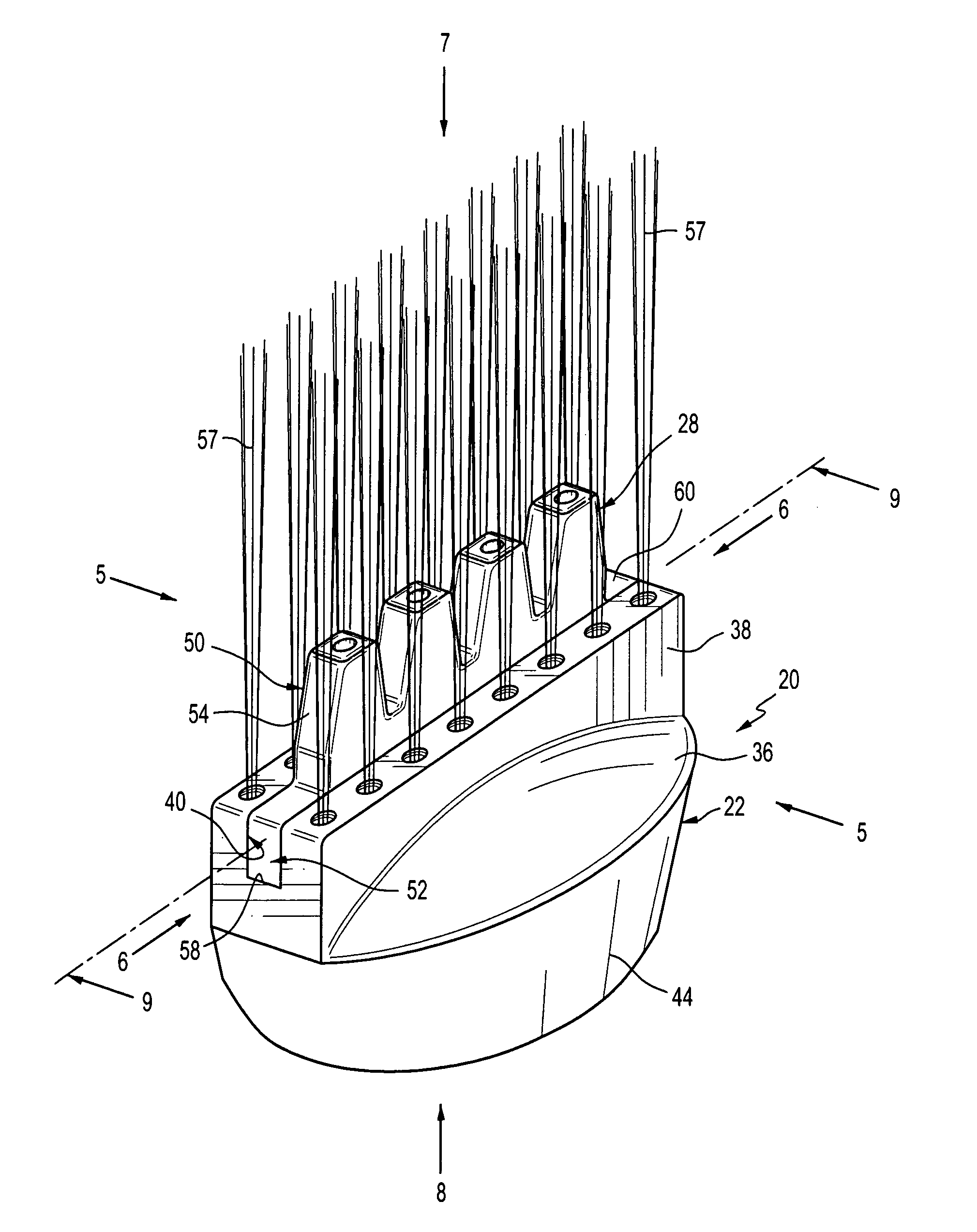

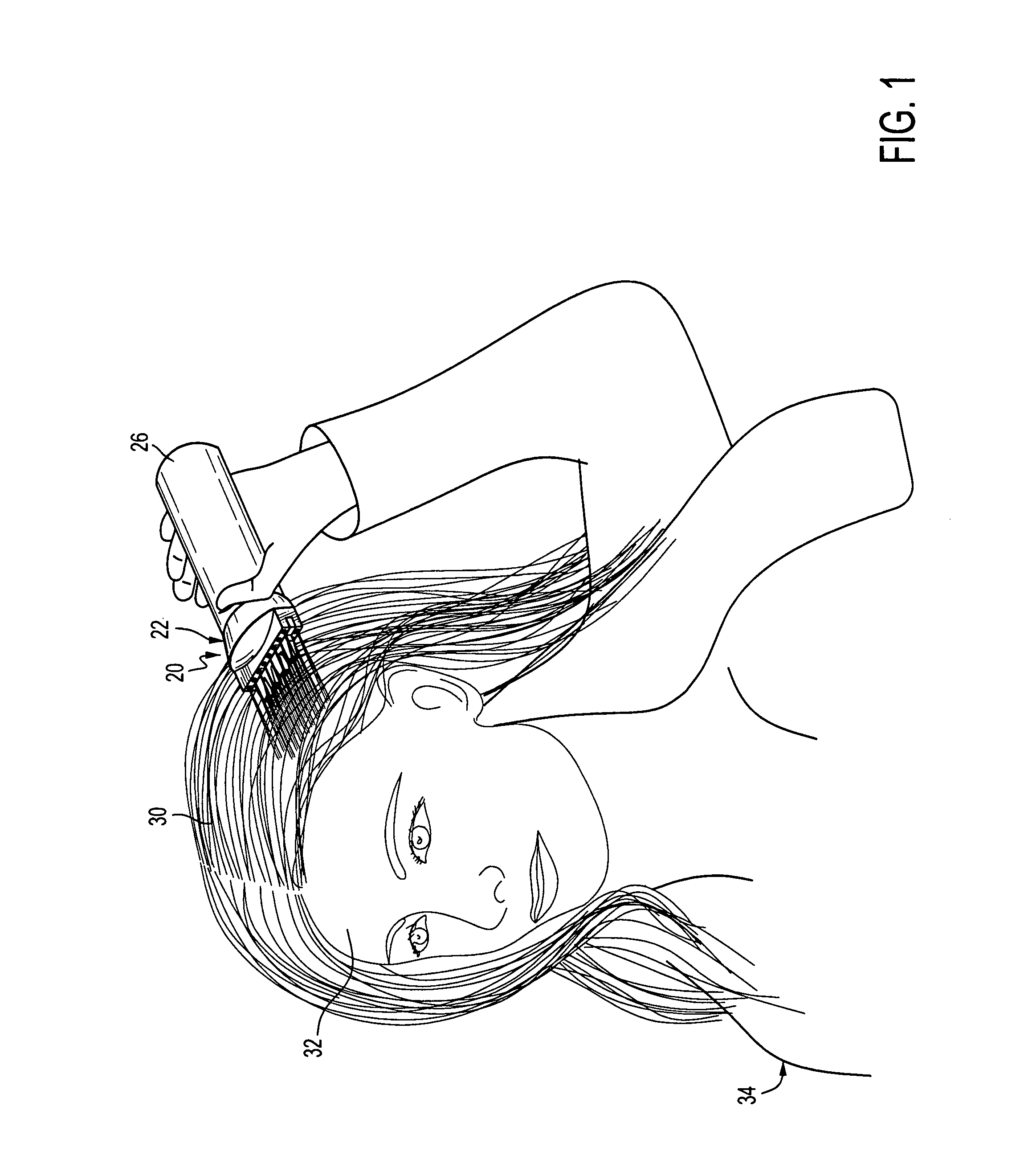

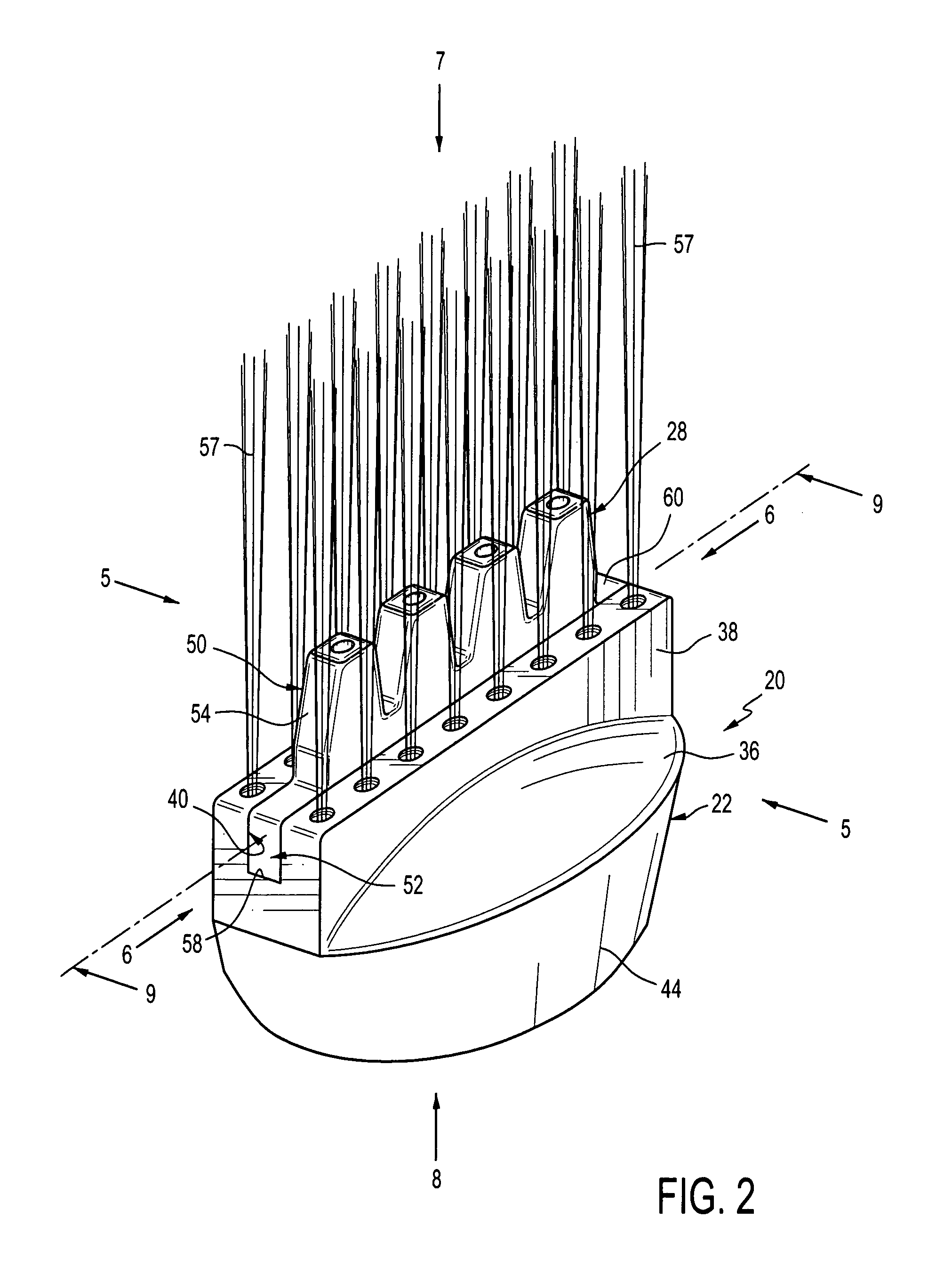

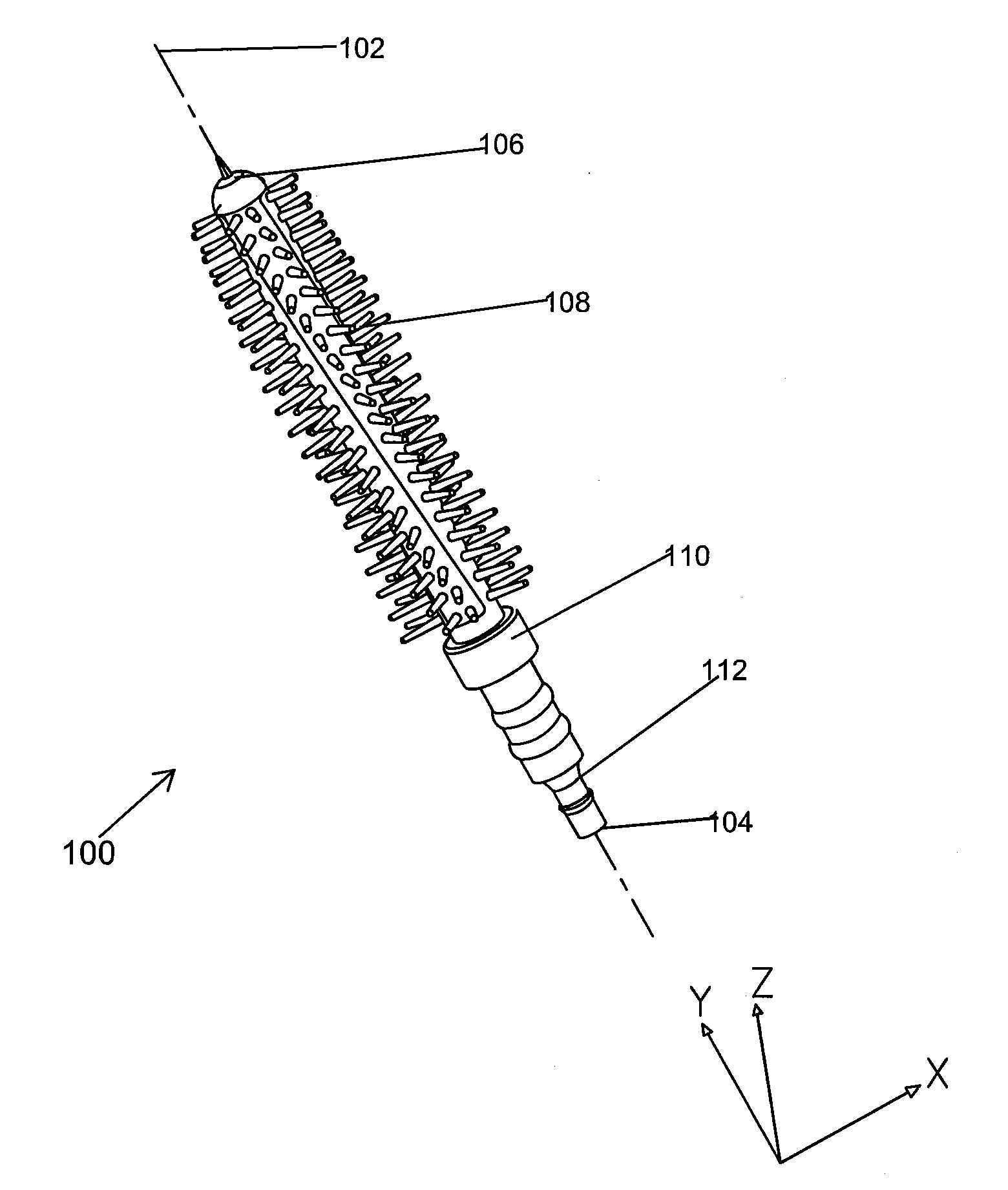

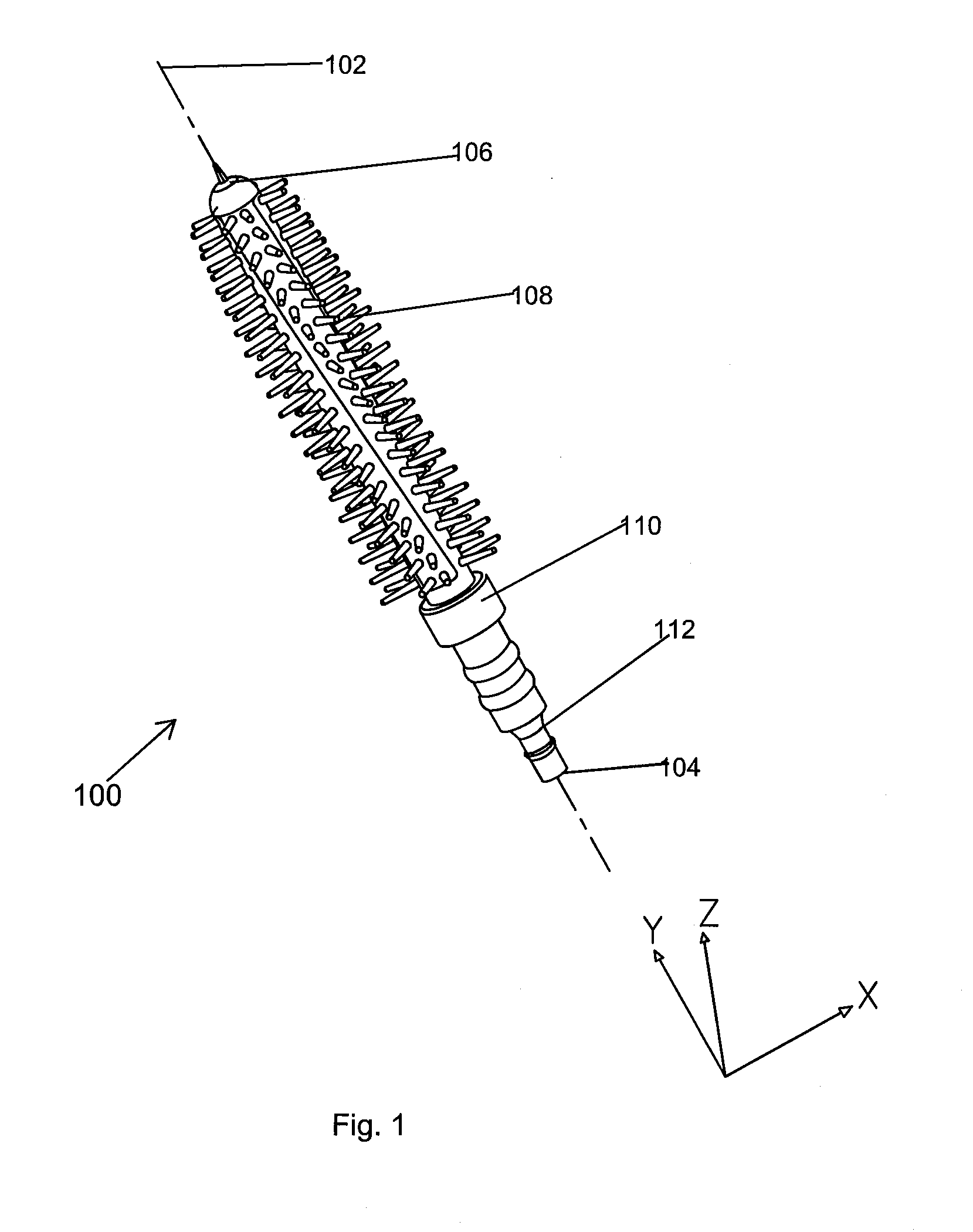

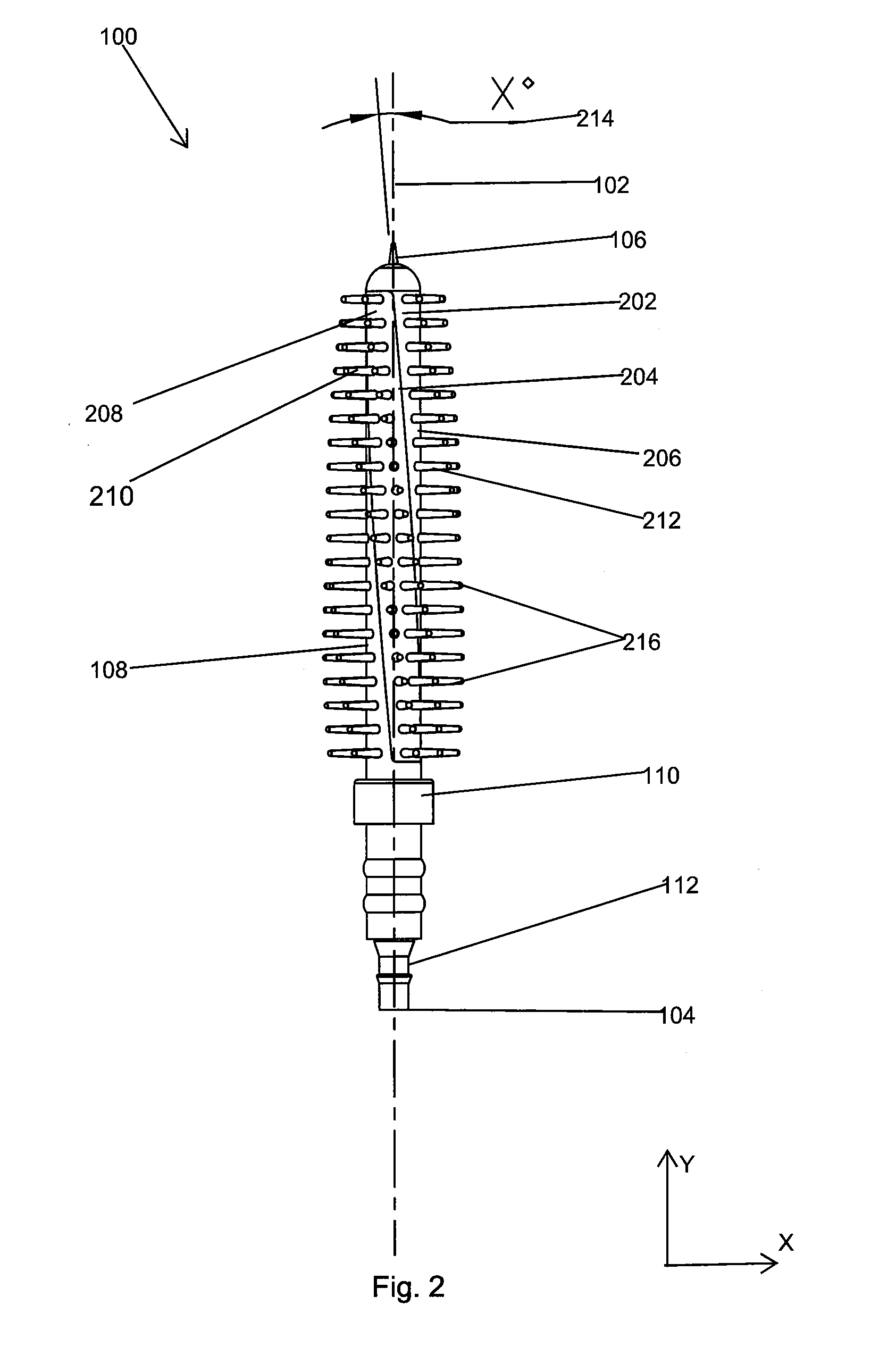

Brush for applying cosmetic substances

ActiveUS20070033759A1Broaden applicationOptimal combing propertyBrush bodiesBristleBristleEngineering

In a brush for applying cosmetic substances, especially a mascara brush or hair coloring brush, which is injection-molded from plastic as one piece and comprises a first section for connection to a rod and a second section, said second section having a main body from which a plurality of bristles protrude radially outward, provision is made for the main body to be designed as a polygon in cross section.

Owner:GEKA

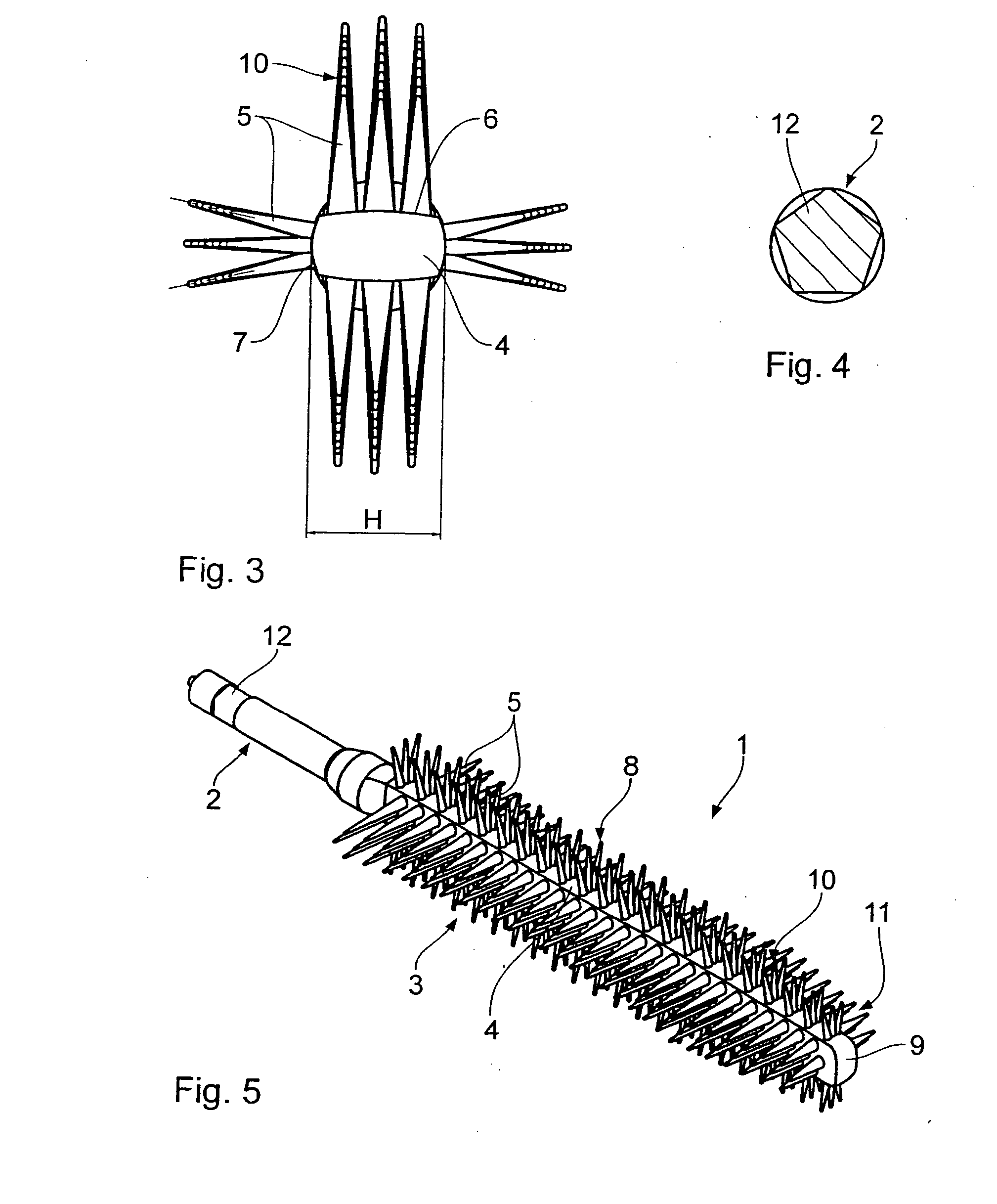

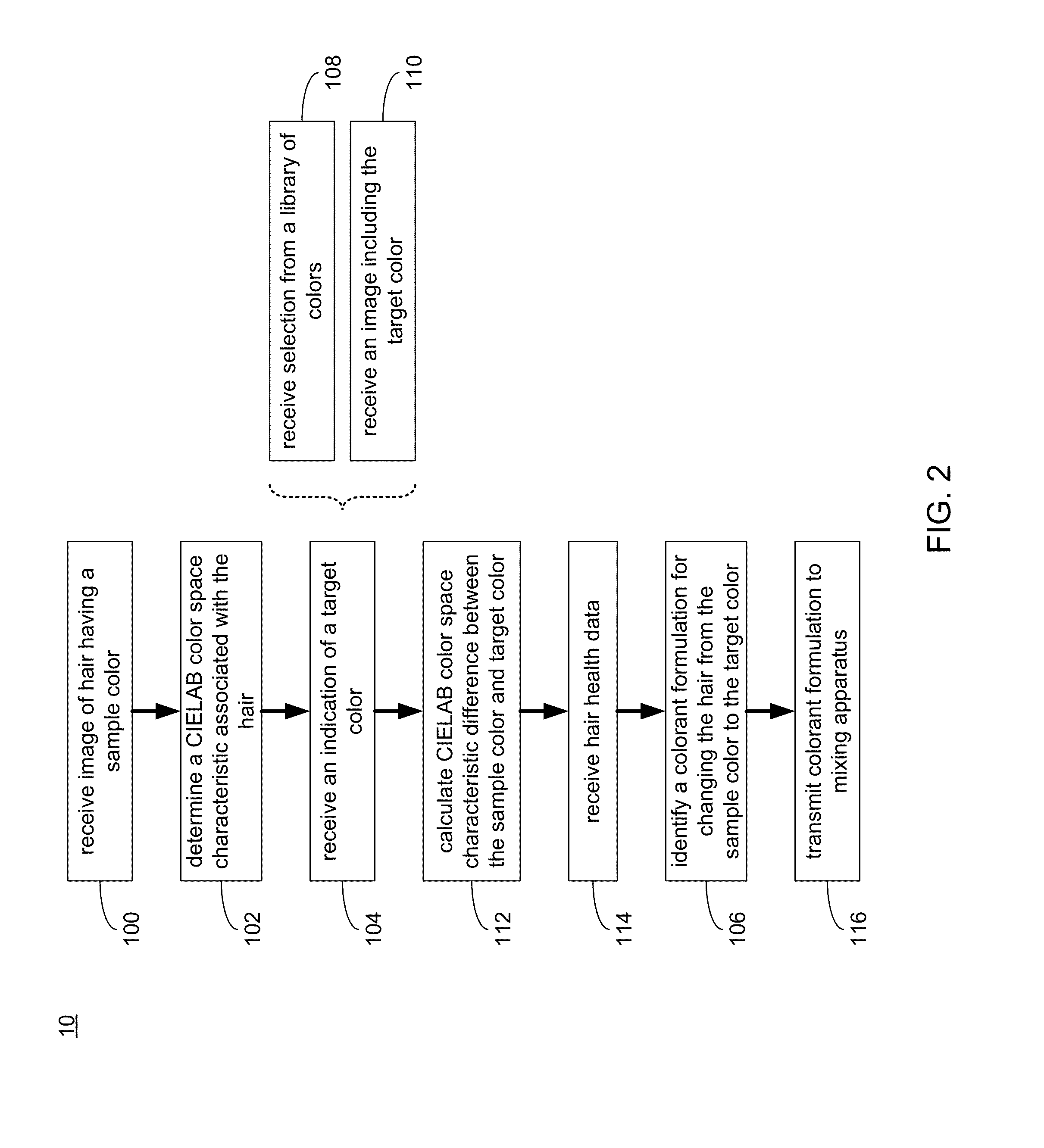

Hair colorant system and method

A system and method for improving the outcome and consistency of hair coloring is provided. In an example method, an image of hair having a sample color may be received. A color space characteristic associated with the hair sample may be determined. An indication of a target color may be received. A colorant formulation may be identified for changing the hair from the sample color to the target color.

Owner:CONTI AARON JAMES +4

Emulsified compositions for bleaching or dyeing the hair and method of bleaching or dyeing the hair using these emulsified compostions

InactiveUS20060042023A1Reduced irritating odorReduce an irritating odor of ammoniaCosmetic preparationsHair cosmeticsIrritationBleach

It becomes possible to provide ammonia-containing hair bleaches or hairdyes which are highly safe and cause less hair damage, skin inflammation and irritation, and have no or reduced irritating odor of ammonia, and a method for bleaching or dyeing hair with the use of the hair bleaches or hairdyes by decreasing an average diameter of emulsified particles of emulsified compositions of ammonia-containing hair bleaches or hairdyes enough to reduce an irritating odor of ammonia.

Owner:ARIMINO

Composition for blending to hair treating agents and a hair treating agent

The present invention is provide compositions for blending in hair treating agents which can prepare hair conditioners, hair colorings, waving agents, finishing agents, additives that increase the feeling effects, aromatic material dispersants, refreshers or thickening agents used on preparing hair treating agents easily and by lower cost. Further the present invention provides hair treating agents which are excellent in the features of hair treating agents such as moist feel, slippery feel, rustle feeling, wet look, luster, smooth feel, soft feel, suppleness, good feel, slightly oily feel, bounce, smoothness, less damage of hair, no hardness and no squeak and smooth combing, and which are excellent in functionalities such as easy appliance, well spread, thickening ability and gelling ability of hair colorings, decolorizing ability of decolorizing agents, setting ability of finishing agents, and dispersibility and dissolving ability to aromatic materials and azulenes by containing alcohols.

Owner:SANEI KAGAKU KK

Hair highlighting applicator nozzle

InactiveUS8220469B1Avoid disadvantagesSimple and inexpensive to manufactureBrush bodiesHair combsSpray nozzleHair streams

A hair highlighting applicator nozzle comprises a cap adapted to be removably mounted to an open end of a flexible container for holding a hair coloring fluid therein. A mechanism is for distributing the hair coloring fluid onto the hair. The distributing mechanism is retained to the cap and is in fluid communication with the flexible container. When the flexible container is squeezed the hair coloring fluid will be forced through the distributing mechanism and applied onto the hair.

Owner:SPAGNUOLO ROSE

Composition for dyeing keratin fibers and a method of dyeing hair using same

Owner:ADVANCED COSMETIC TECH

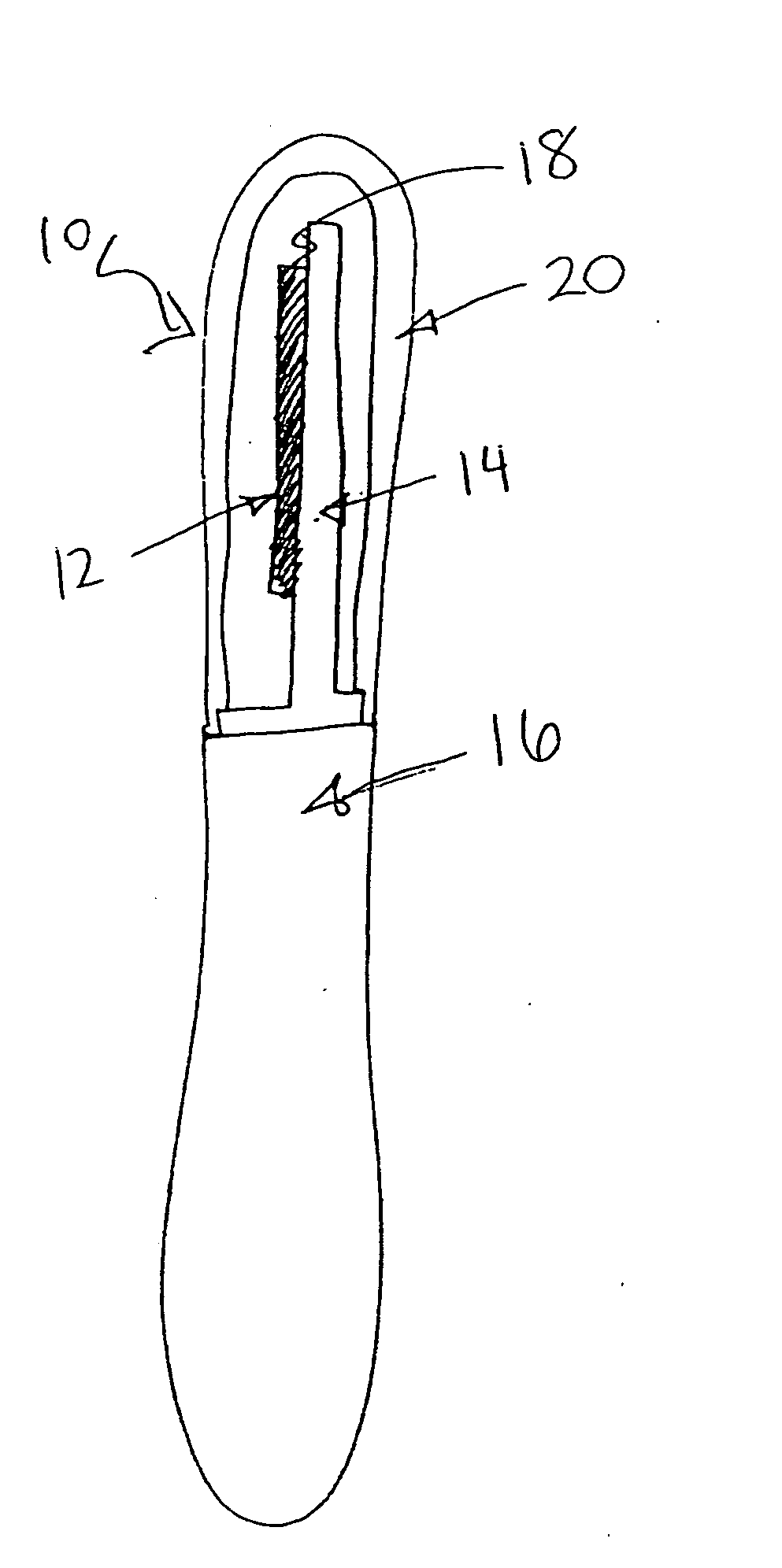

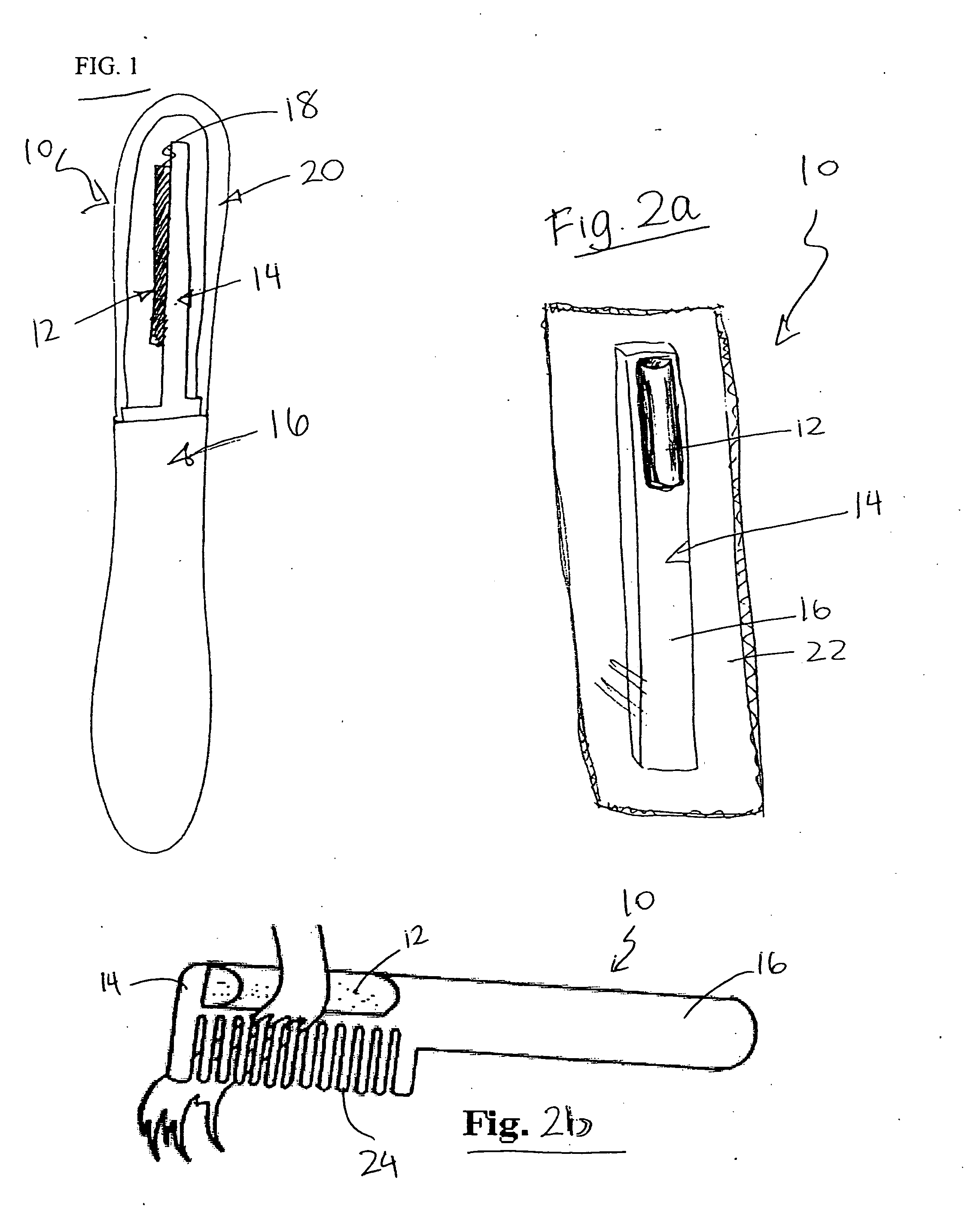

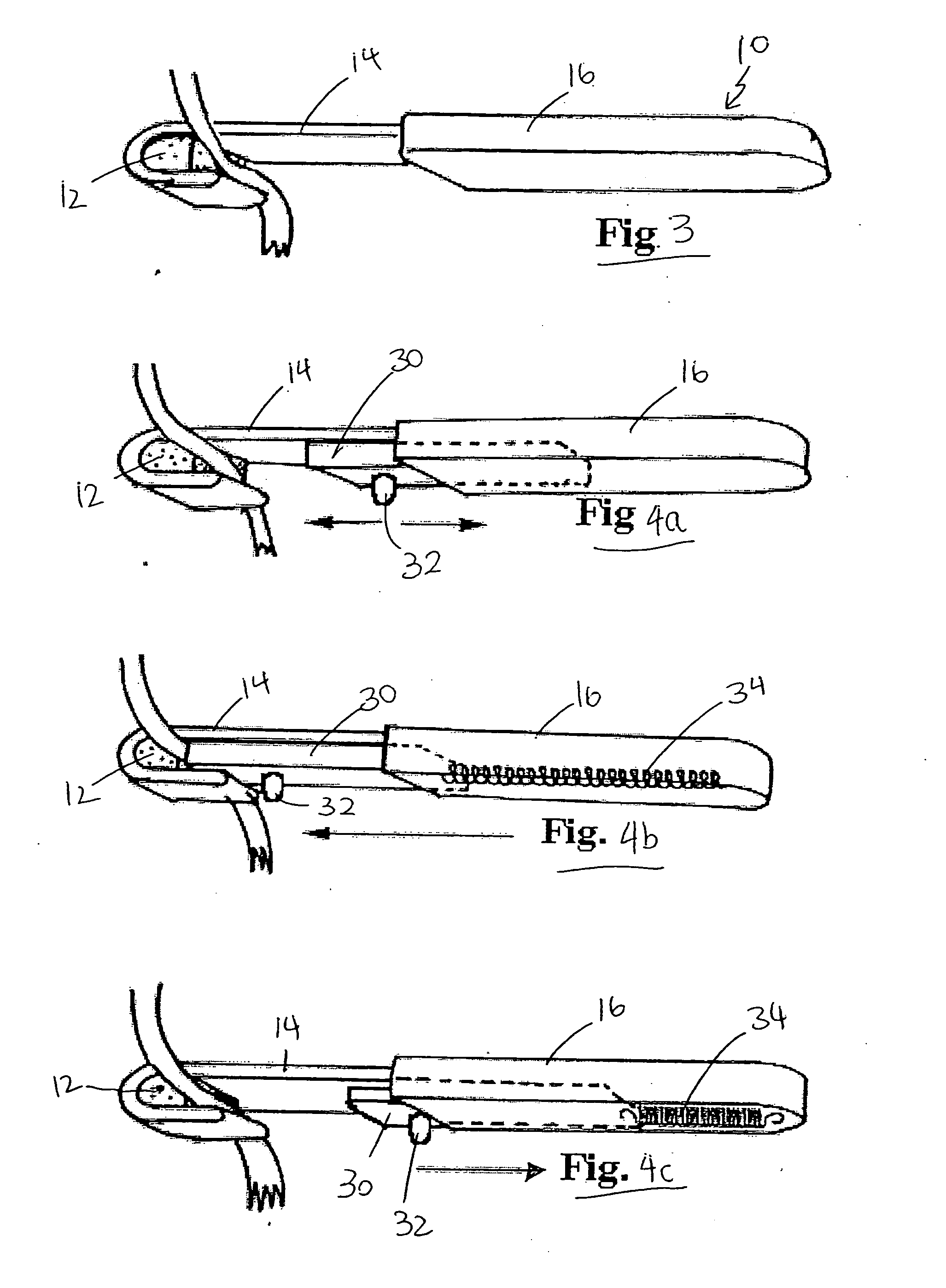

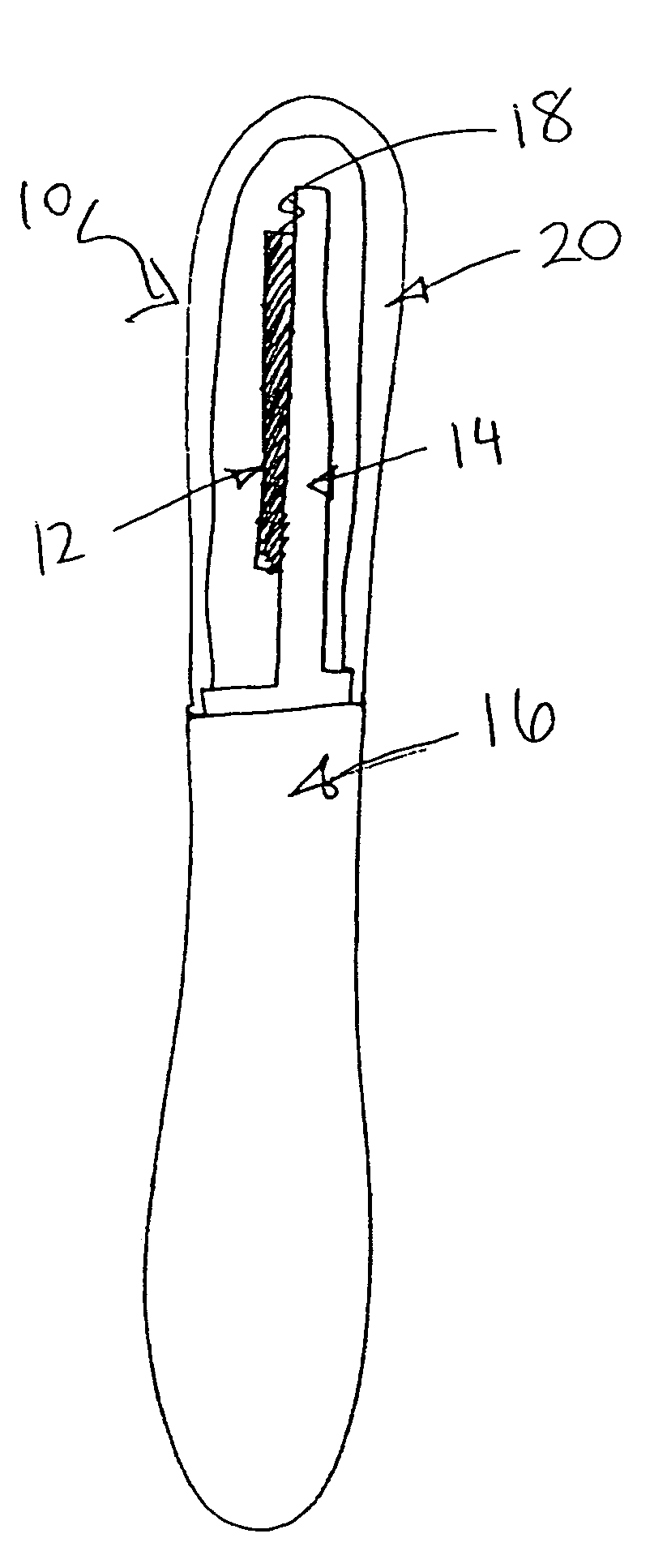

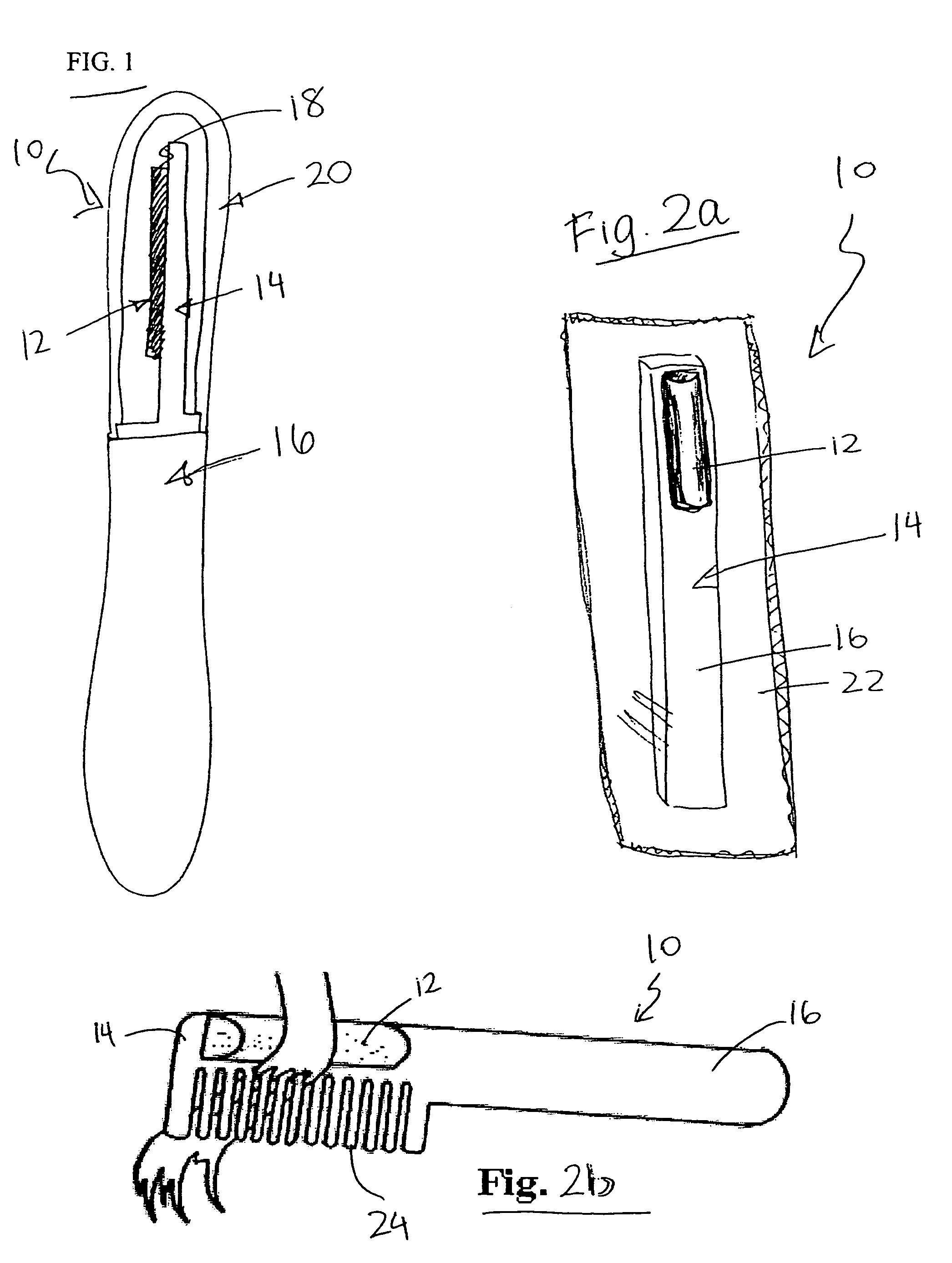

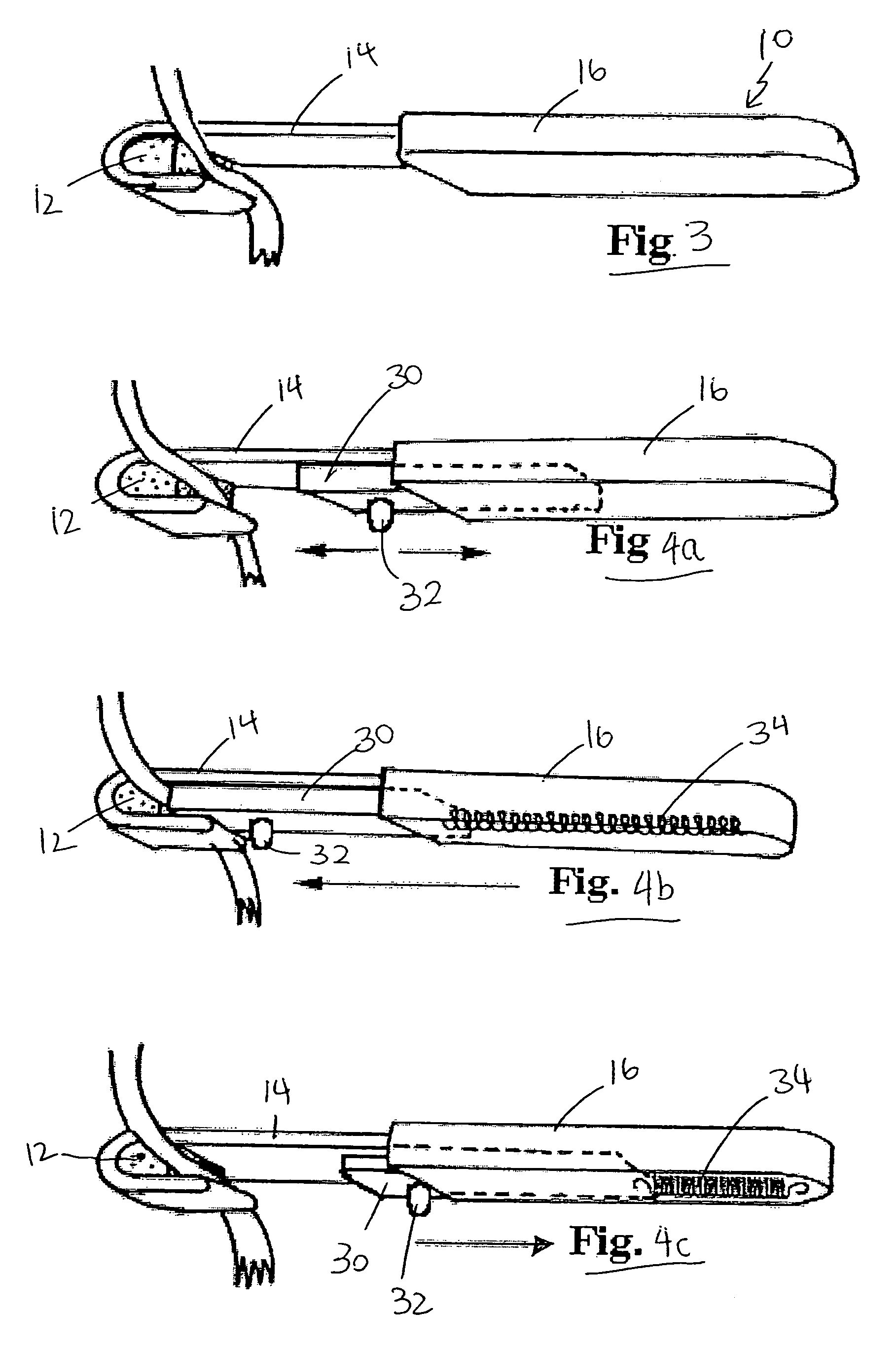

Hair coloring device

Devices configured to permit the application of color to hair from a solid or semi-solid hair coloring composition and methods relating to use of such devices are disclosed. The device includes a support, and a solid or semi-solid hair coloring composition fixedly disposed on the support. The solid or semi-solid hair coloring composition includes a soap gelling agent such that the hair coloring composition retains its shape, and can be provided as a block having a predefined shape. These devices are not attendant with dripping as has been associated with prior art hair color applicators.

Owner:SPECTRUM ASSOC LLC +2

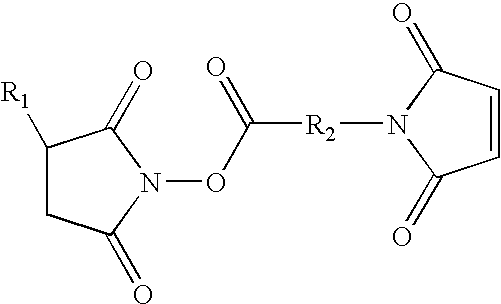

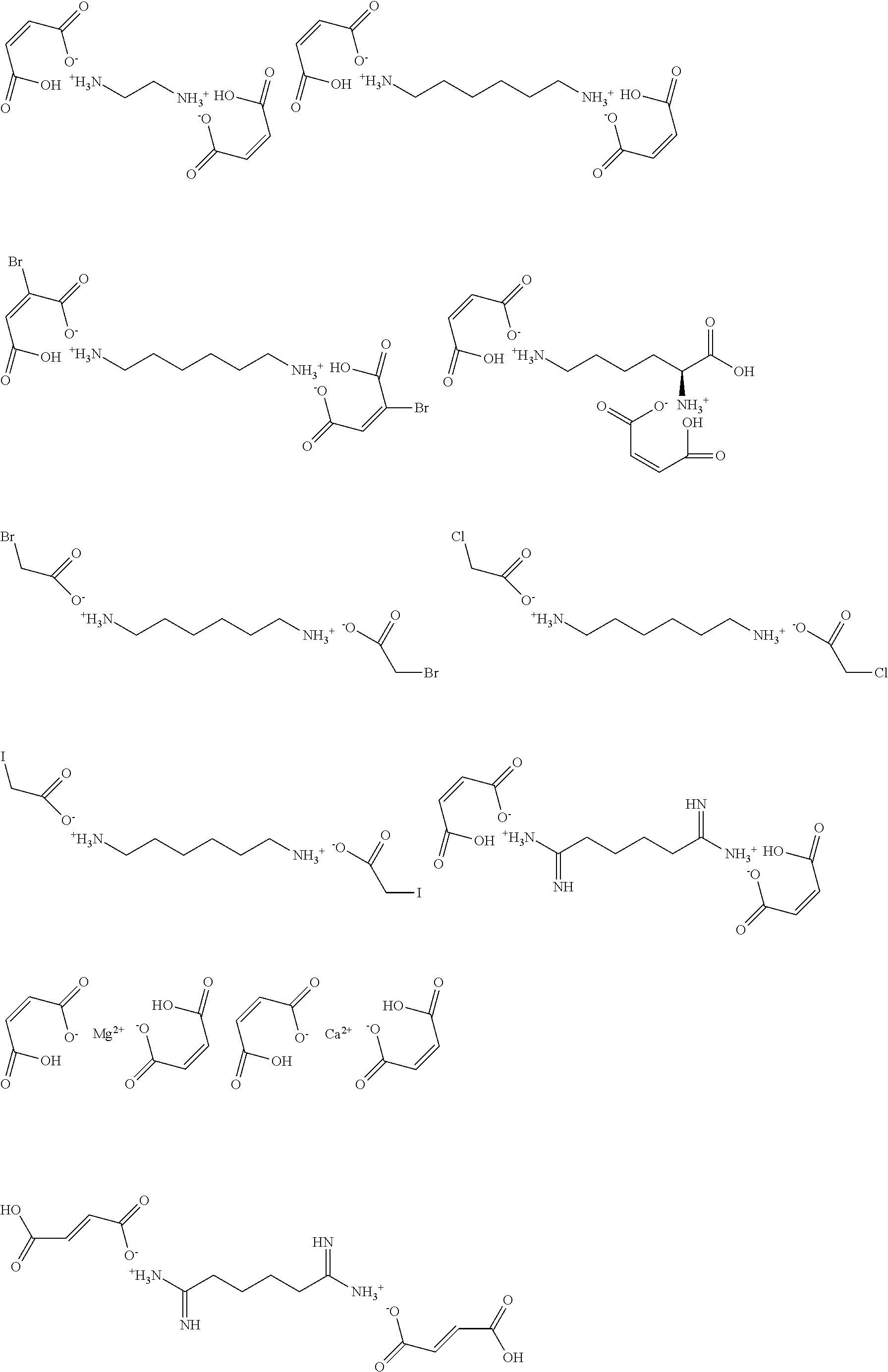

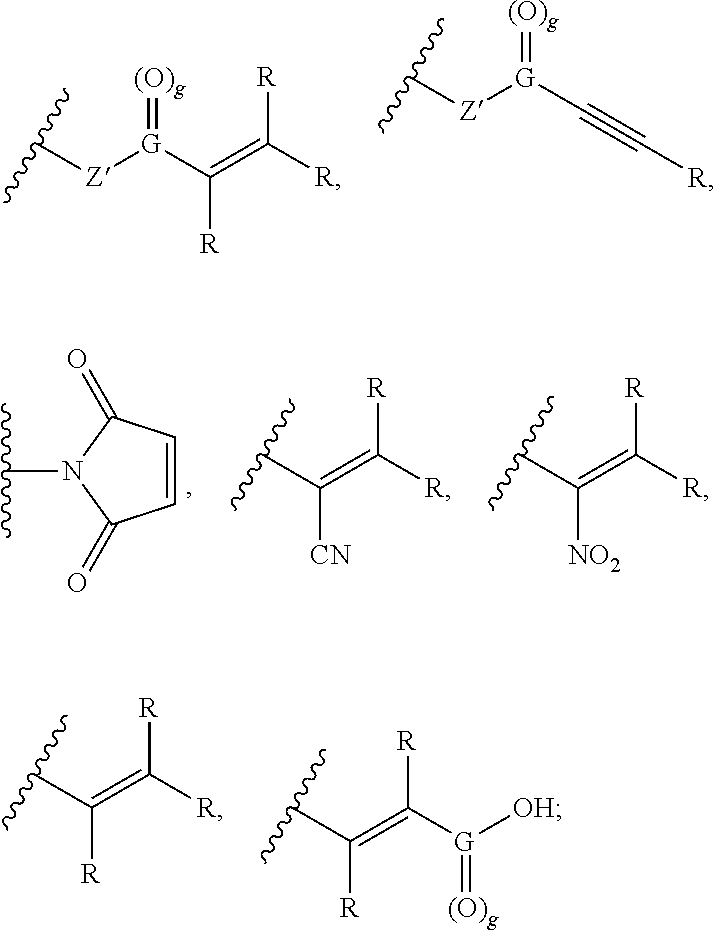

Keratin Treatment Formulations and Methods

ActiveUS20150328102A1Simple methodReducing treatmentCosmetic preparationsHair removalReduction treatmentActive agent

Formulations, kits, and methods for rebuilding the disulfide bonds in keratin found in hair, skin, or nails. Hair that is damaged due to a hair coloring treatment and / or other reducing treatment, such as during a permanent wave, can be treated with the formulations containing one or more active agents. The formulations may be applied subsequent to a hair coloring treatment or simultaneously with a hair coloring treatment. Use of the active agent formulations during a permanent wave treatment prevents the reversion of the hair to its previous state, for at least one week, preferably at least three months, more preferably at least one year, most preferably greater than one year, after one or more than one application of the formulation. Application of the active agent formulation to skin or nails can help repair damaged disulfide bonds due to natural wear and tear or natural aging.

Owner:LIQWD

Keratin treatment formulations and methods

Formulations, kits, and methods for rebuilding the disulfide bonds in keratin found in hair, skin, or nails. Hair that is damaged due to a hair coloring treatment and / or other reducing treatment, such as during a permanent wave, can be treated with the formulations containing one or more active agents. The formulations may be applied subsequent to a hair coloring treatment or simultaneously with a hair coloring treatment. Use of the active agent formulations during a permanent wave treatment prevents the reversion of the hair to its previous state, for at least one week, preferably at least three months, more preferably at least one year, most preferably greater than one year, after one or more than one application of the formulation. Application of the active agent formulation to skin or nails can help repair damaged disulfide bonds due to natural wear and tear or natural aging.

Owner:LIQWD

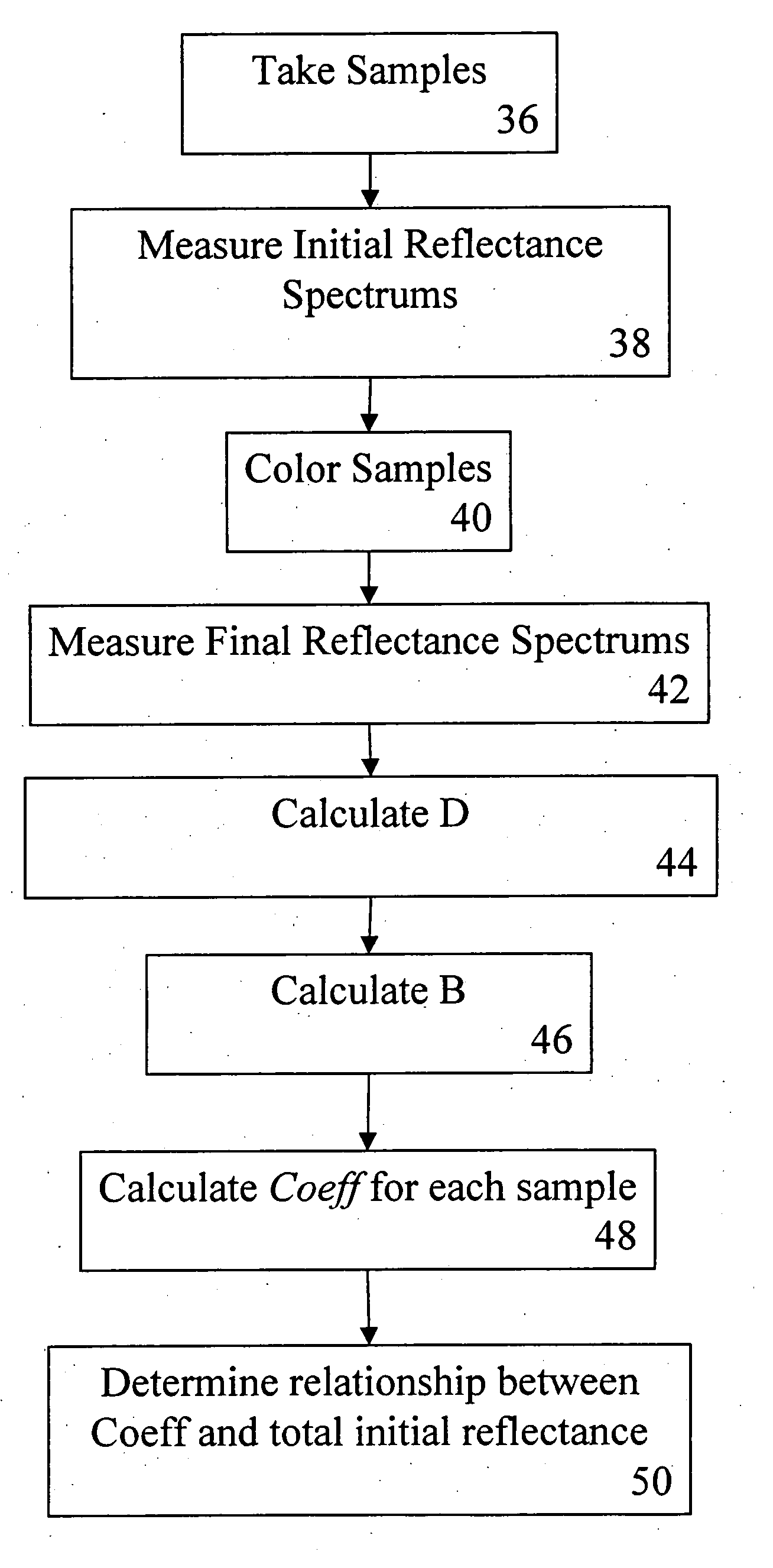

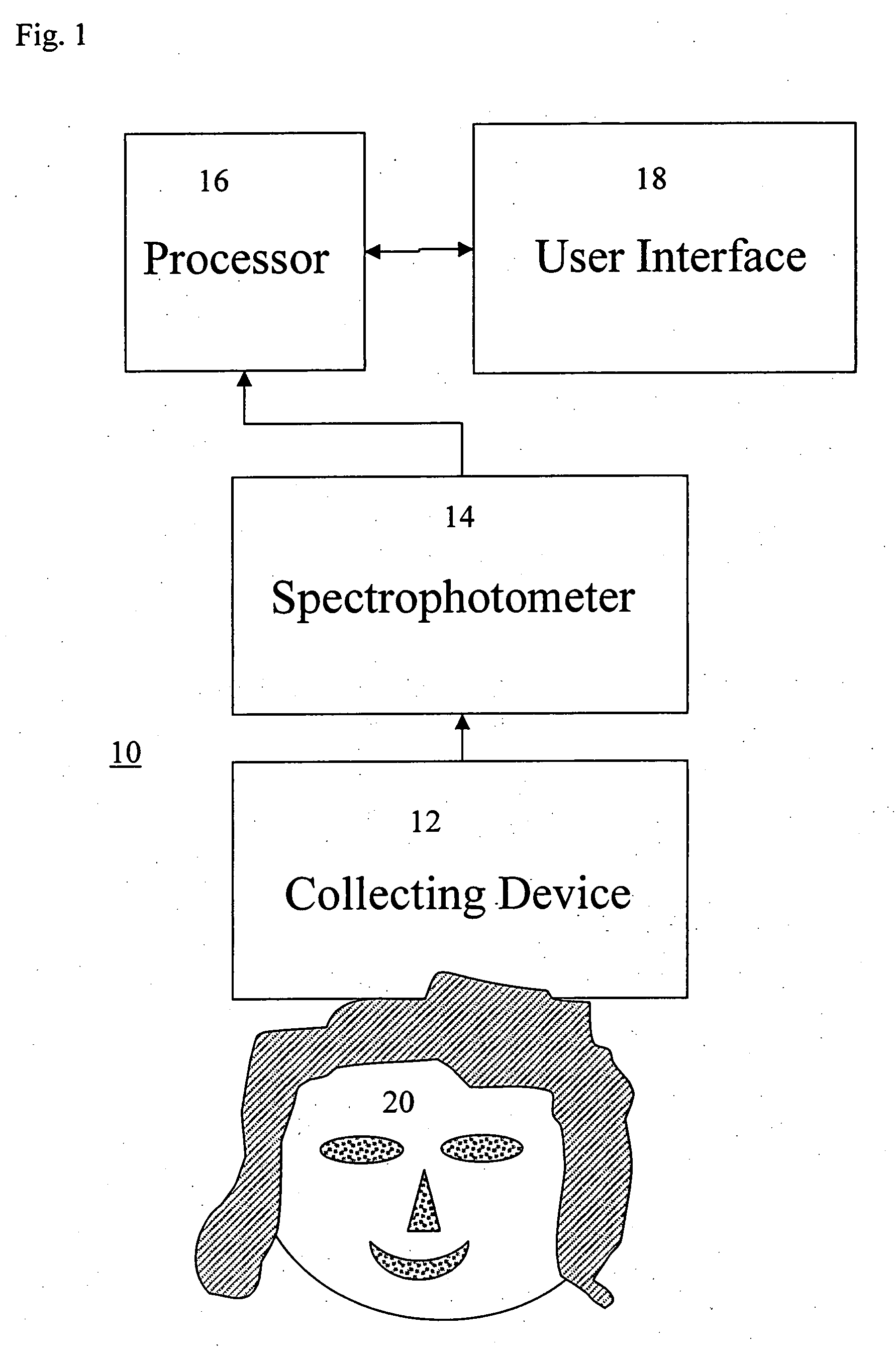

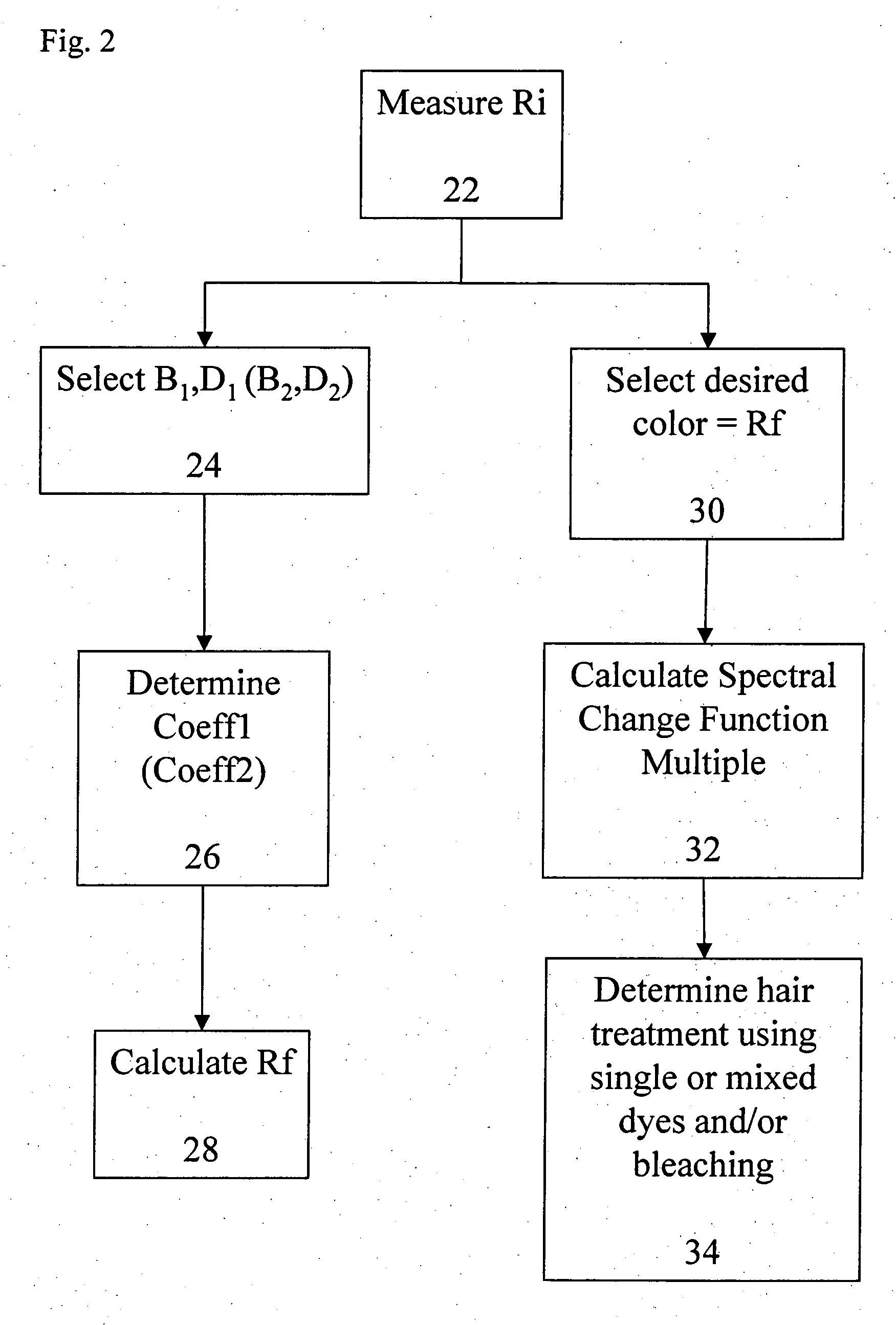

Hair coloring system

A system for determining hair color treatment, including a processor. The processor is configured for: receiving as input an initial spectrum of a sample of hair, the initial spectrum having a wavelength range; calculating a new spectrum of the hair due to a hypothetical hair color treatment as a direct function of the initial spectrum; and outputting data to a device, the data being based upon the step of calculating. The system also includes a spectrum analyzer configured for producing the initial spectrum and a display device configured for displaying a color and hair color treatment instructions based on the data. An alternate embodiment of the invention includes a color mixing device configured for dispensing a hair color treatment based on the data.

Owner:COLORIGHT

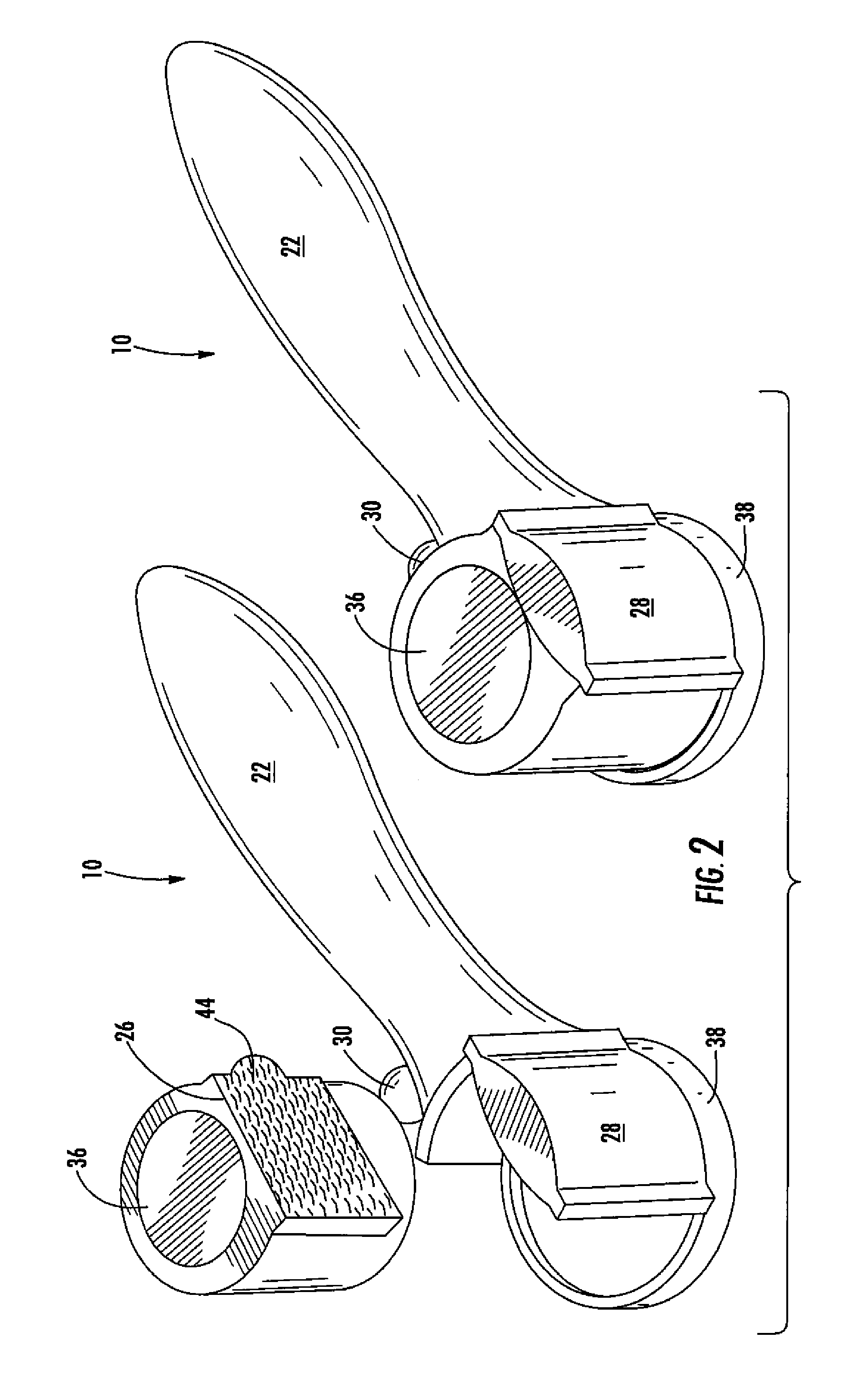

Hair Colorant Applicator and Methods

A hair coloring applicator including a body forming a handle, a brush which rotates relative to the body, a housing wherein the brush is rotatable within the housing. The brush may be designed as a plurality of flexible squeegee arms. The housing is designed to receive a liquid hair colorant such that the brush contacts the hair colorant within the housing. The housing includes at least one opening for receiving at least one strand of hair and placing the at least one strand of hair in contact with the brush. The hair colorant and / or the brush may be provided in a disposable cartridge.

Owner:KENNEDY MELVIN L +2

Composition For Dyeing Keratin Fibers and A Method of Dyeing Hair Using Same

A composition for dyeing keratin fibers that contains 0.1 to 30 percent of at least one substantially pure plant dye material obtained using solvent or supercritical CO2 extraction, combined with 0.01 to 5 percent of active metal in a metal or mineral salt capable of acting as a mordant as a two-part hair color system.

Owner:ADVANCED COSMETIC TECH

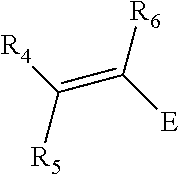

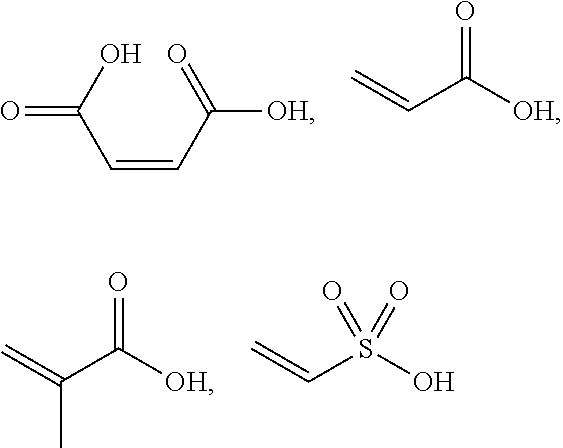

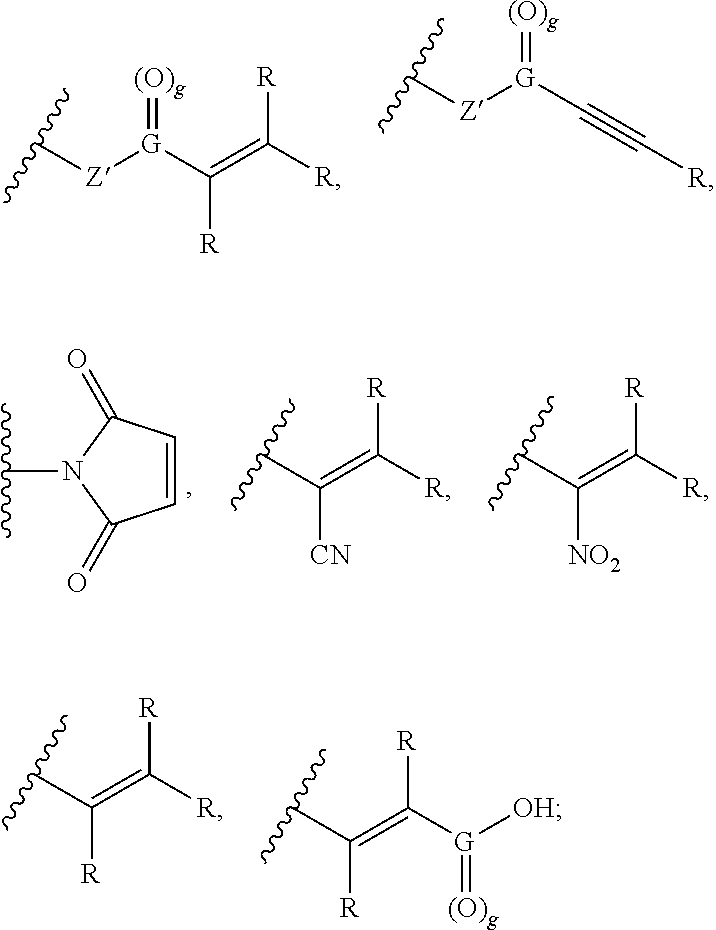

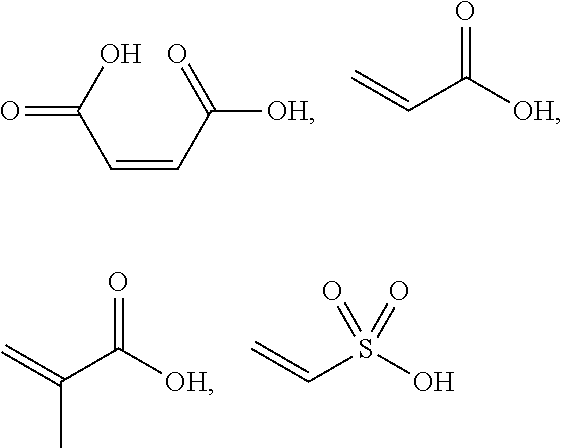

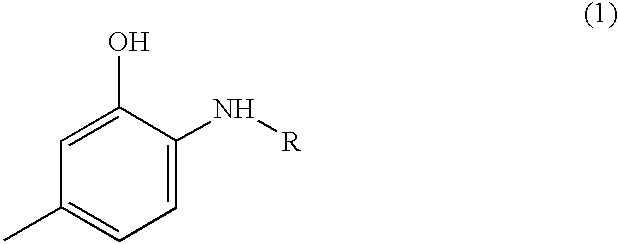

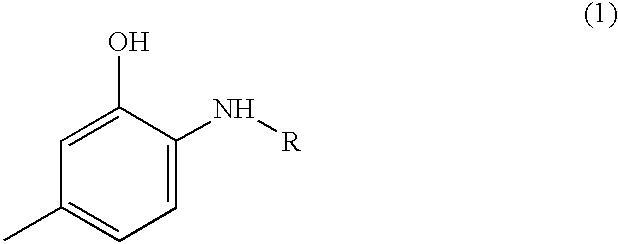

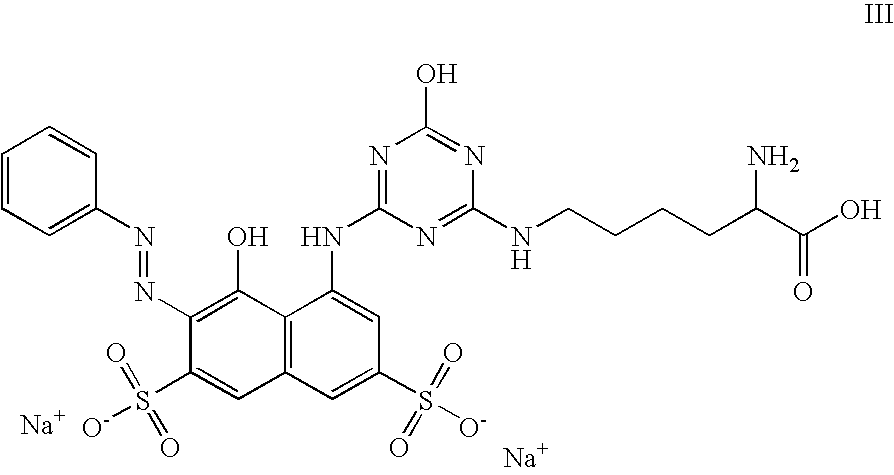

Primary intermediates for oxidative coloration of hair

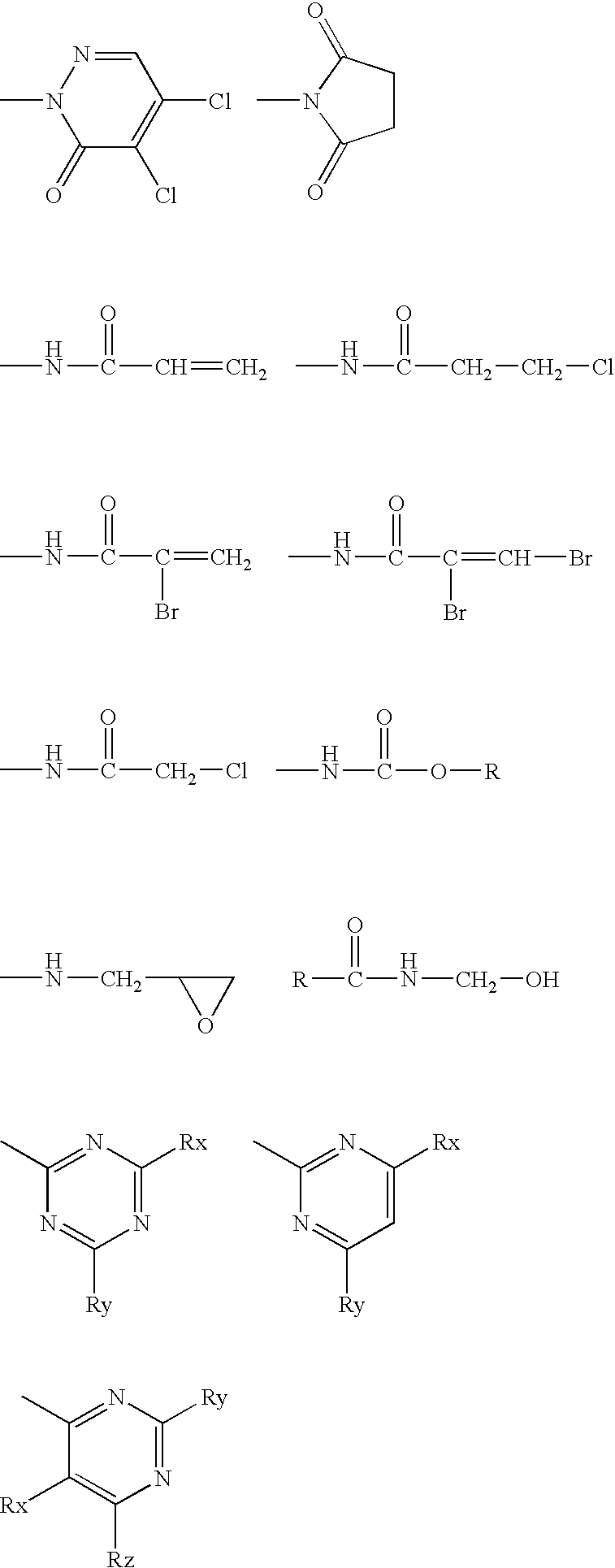

InactiveUS6774244B2Good oxidative coloration of hairAcceptable light fastnessCosmetic preparationsHair cosmeticsHydroxy groupPhotochemistry

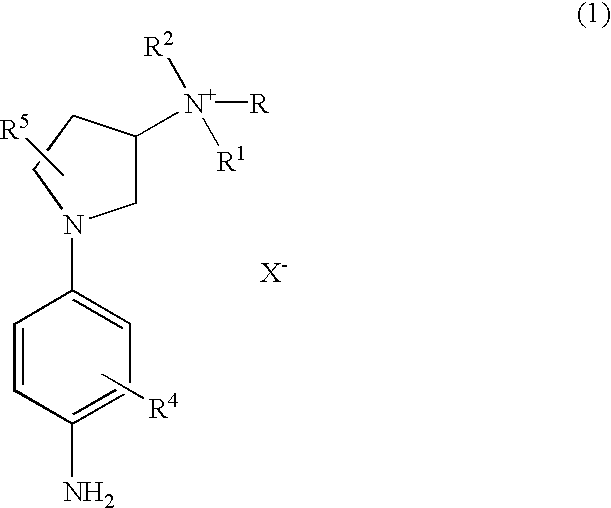

Primary intermediates for hair coloring compositions for oxidative dyeing of hair are compounds of the formula (1):wherein R is selected from C1 to C5 alkyl or hydroxyalkyl, a C3 to C6 cyclic ring containing hetero atoms selected from O, S and N atoms, and -CH2-Ar where Ar is an aromatic ring wherein the aromatic ring may be substituted with one or two hydroxy C1 to C3 alkoxy, or amino groups.

Owner:CLAIROL +1

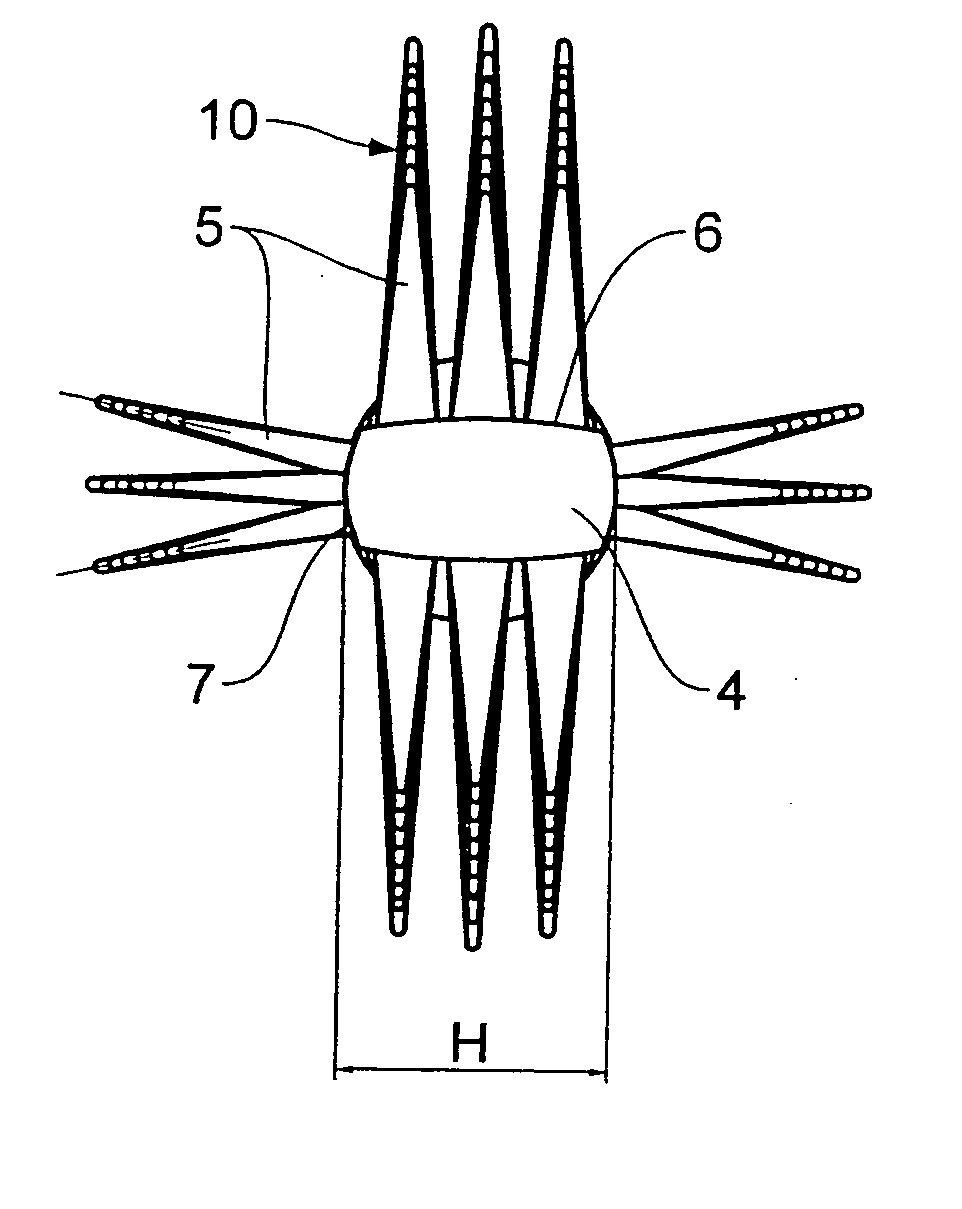

Hair coloring system

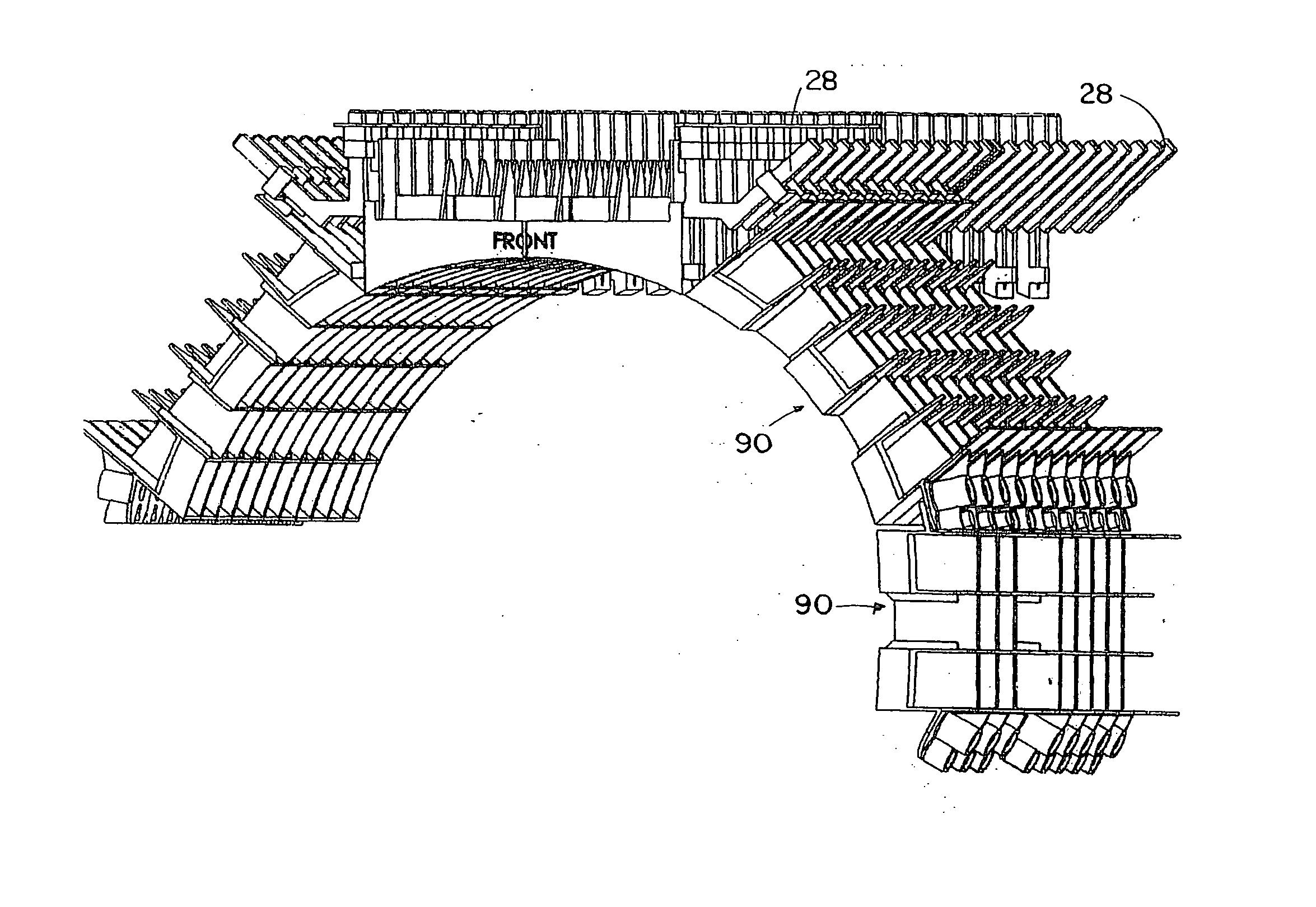

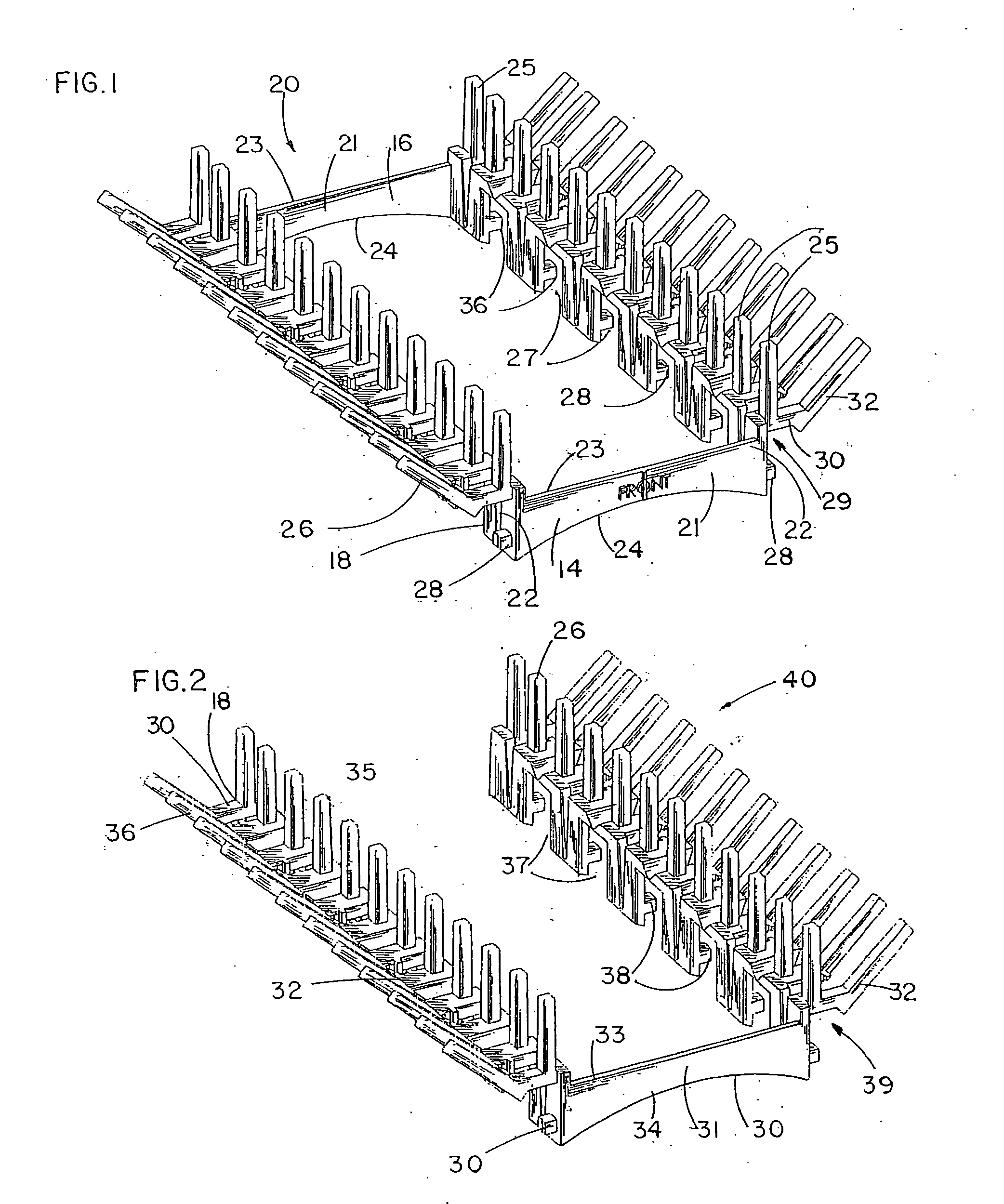

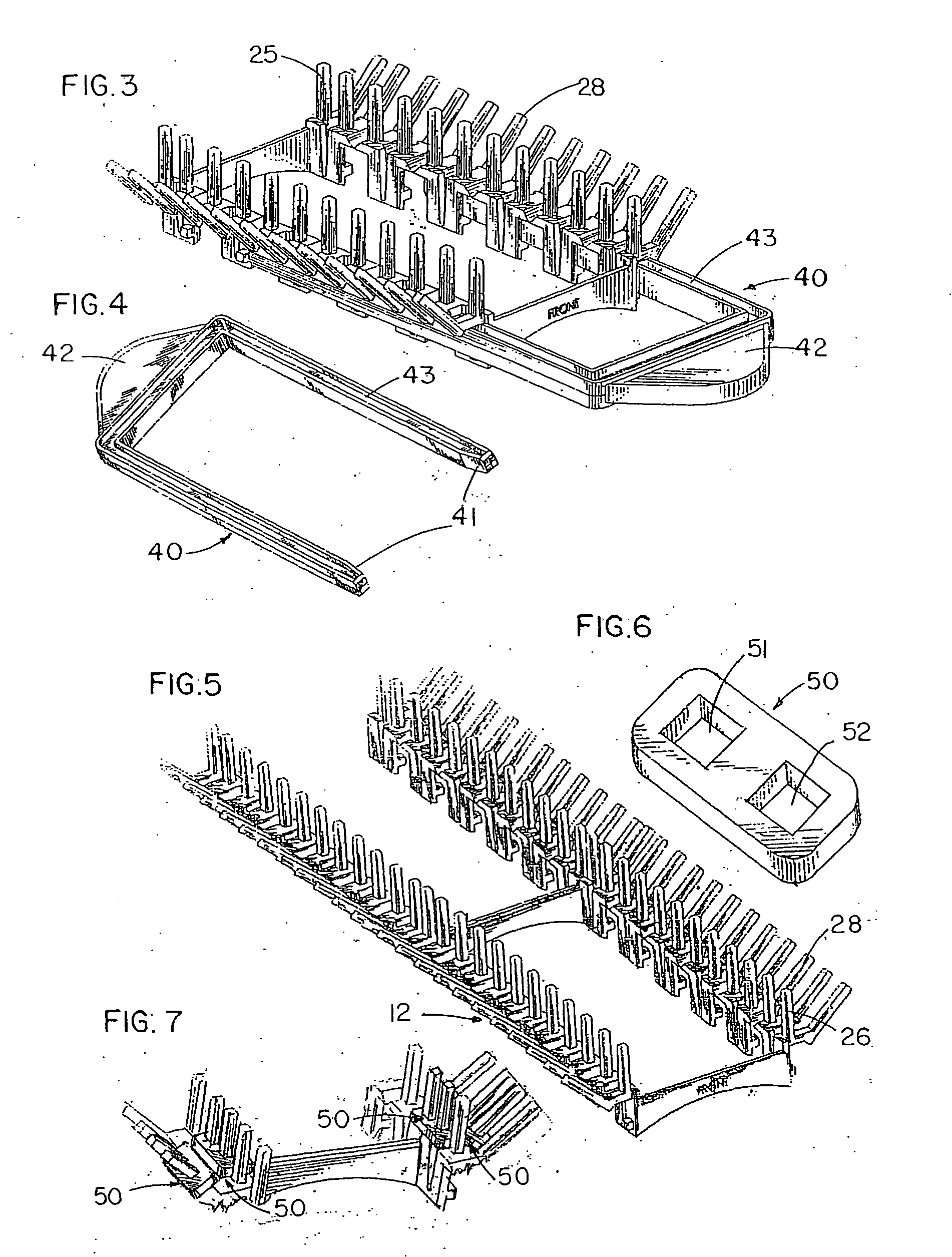

InactiveUS20060144415A1Easy and efficient to manufactureDurable and reliable constructionCurling devicesHair combsEngineeringScalp

A hair coloring system having a grid and associated quads. The quads are held against the scalp with a tie-down tool. Such placement allows the dyeing of hair up to the root structure. A hair manipulating tool enables a user to separate the hair into manageable quantities. The hair manipulating tool also enables the user to efficiently thread the hair strand through the quad structure.

Owner:MAGEE HARVEY

Primary intermediates for oxidative coloration of hair

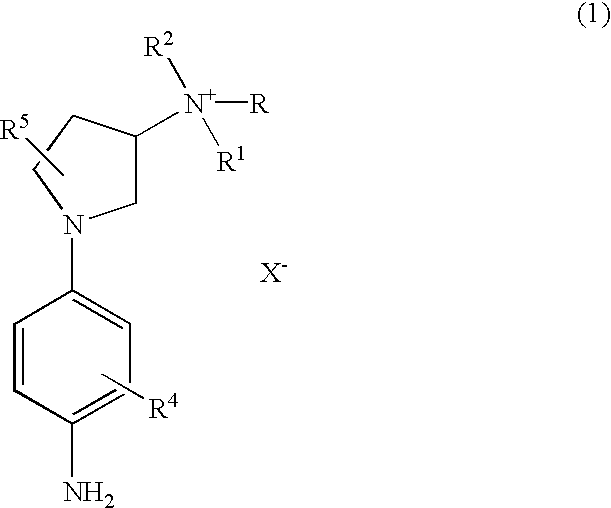

InactiveUS20020106341A1Good oxidative colorationAcceptable light fastness and fastnessCosmetic preparationsHair removalHydrogen atomPyrrolidine

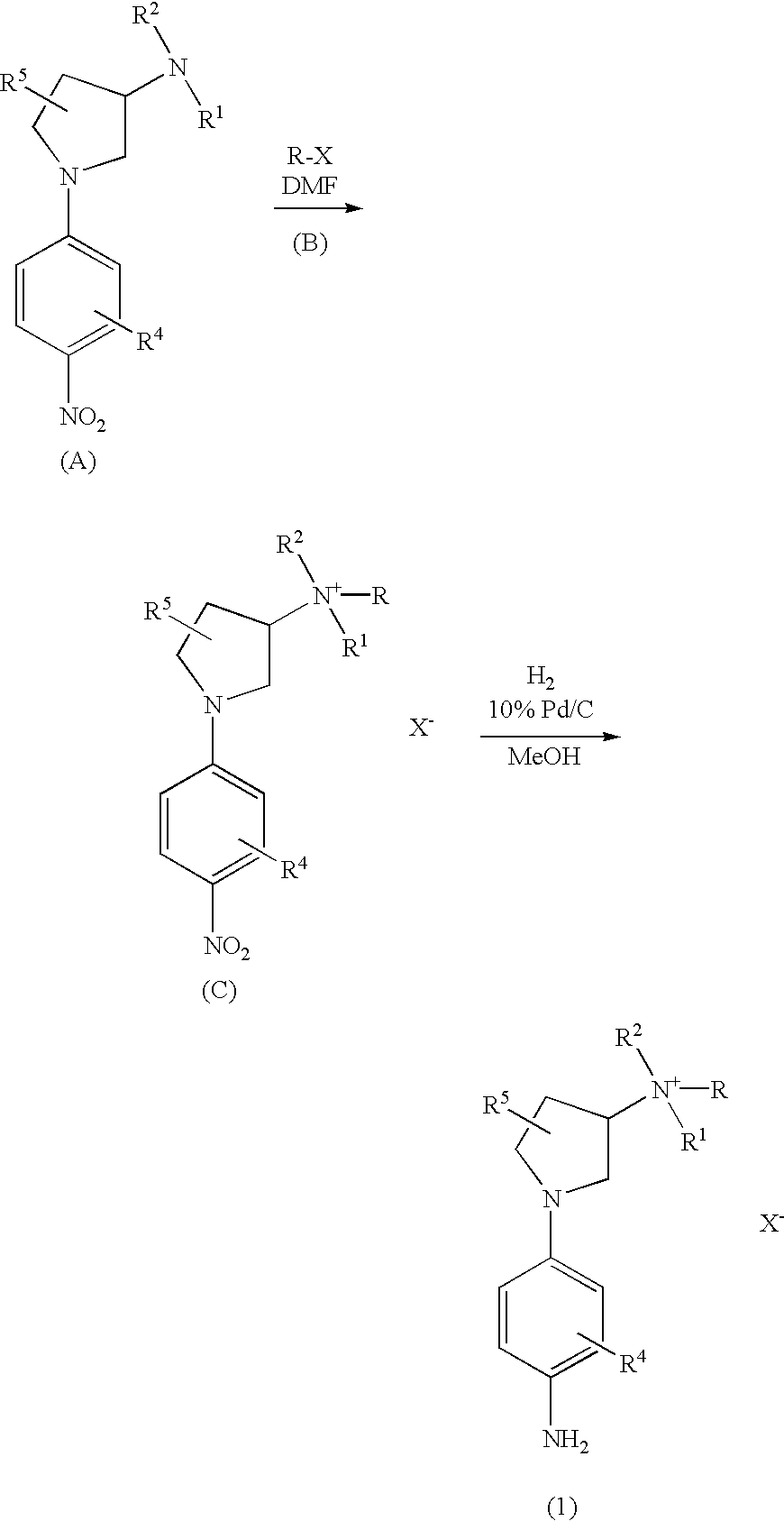

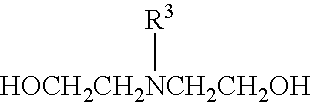

Primary intermediates useful hair coloring systems comprise quaternized pyrrolidine compounds. The invention provides new quaternized pyrrolidine of Formula (1): wherein X is Cl, Br, I, or R3 SO4; R is a C1 to C22 alkyl group or a C1 to C22 mono or dihydroxyalkyl group; R1 and R2 are each independently a C1 to C4 alkyl group; R3 is a C1 to C22 alkyl group or a C1 to C22 mono or dihydroxyalkyl group; R4 is a hydrogen atom, a C1 to C5 alkyl group or such an alkyl group substituted with one or more hydroxy or amino moieties; and R5 is a hydrogen atom or a hydroxy group.

Owner:WELLA OPERATIONS US LLC +1

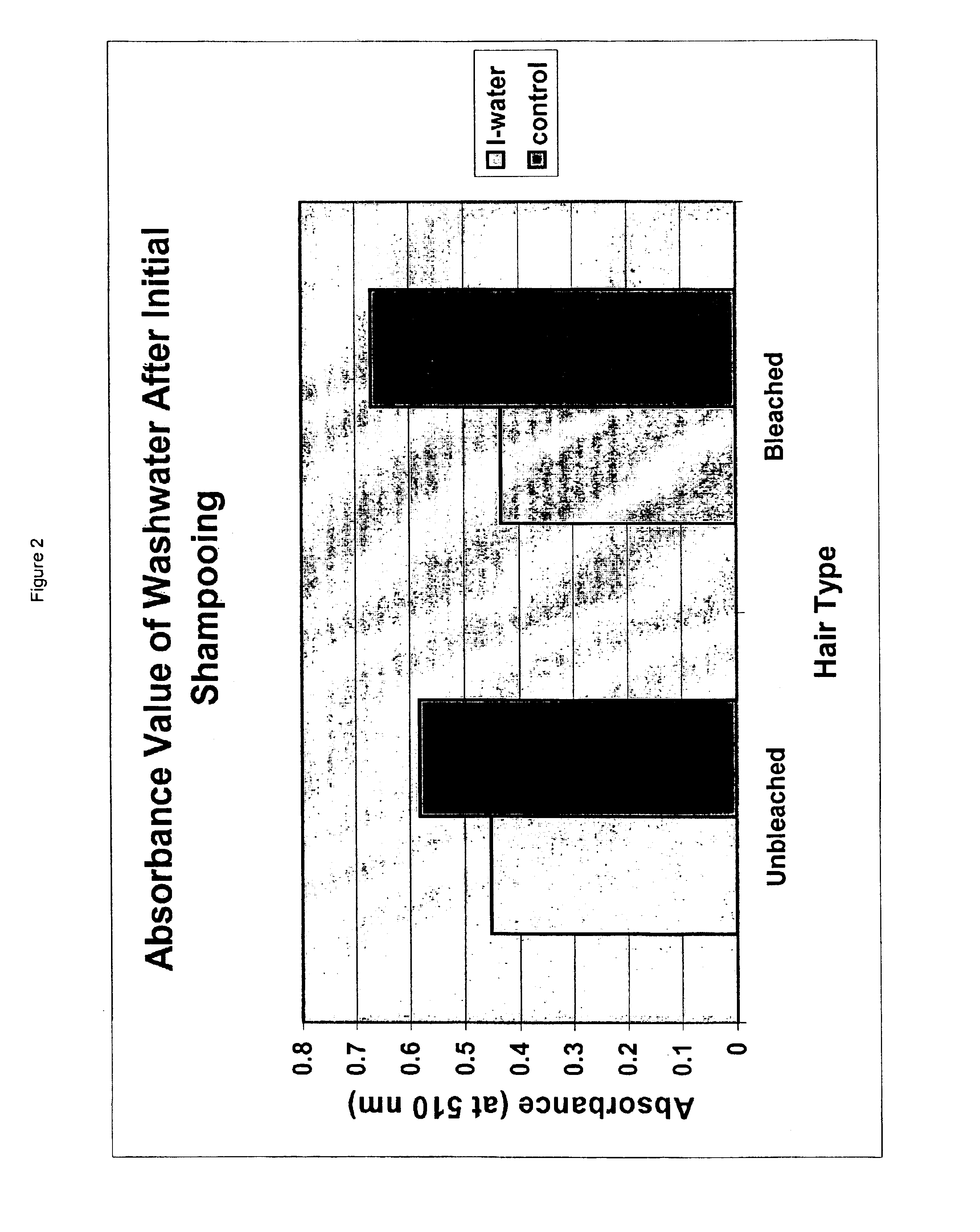

Hair color application using cluster-modified water

InactiveUS6905523B2High color intensityAdd depthCosmetic preparationsHair cosmeticsHair ColorsChemistry

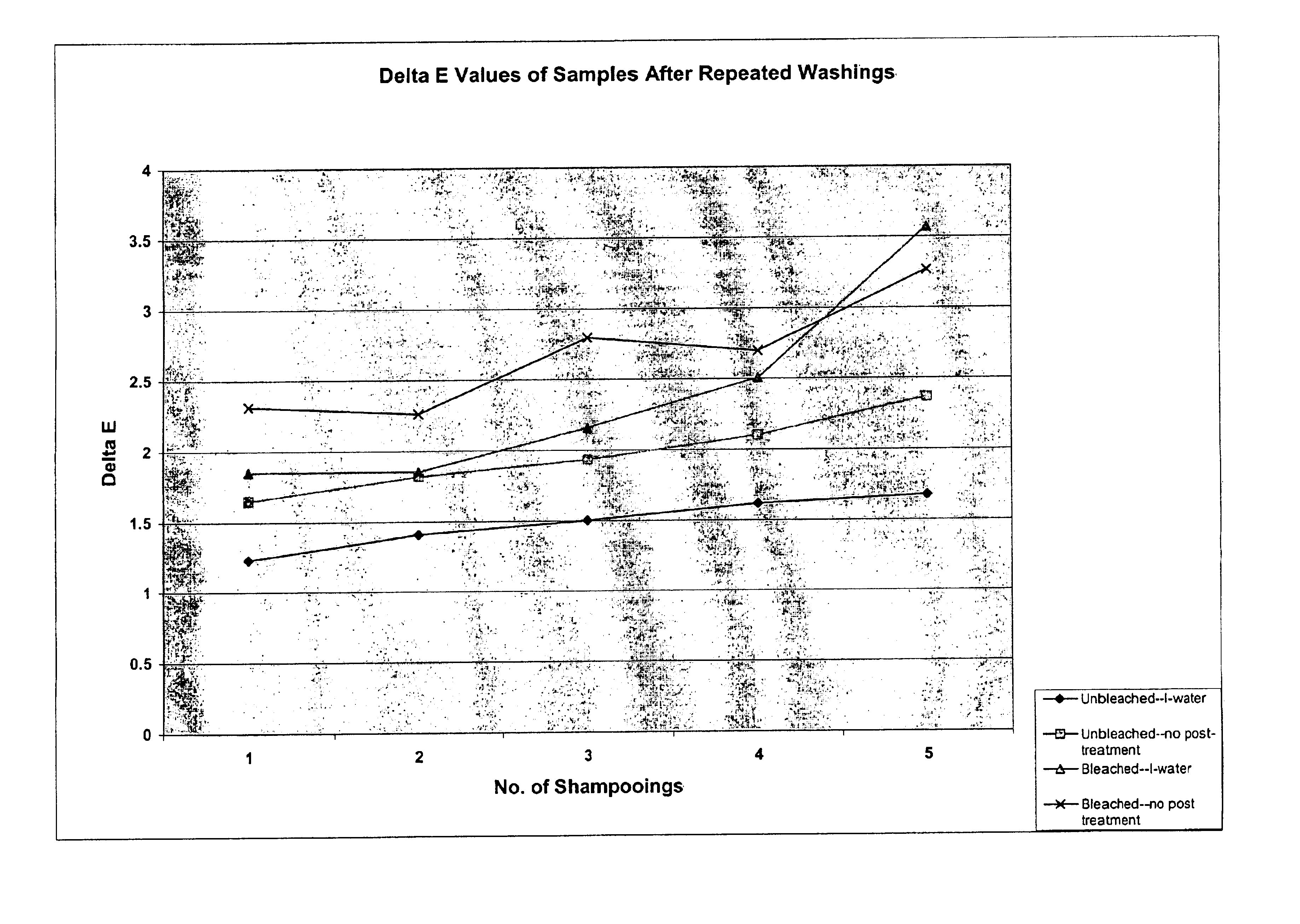

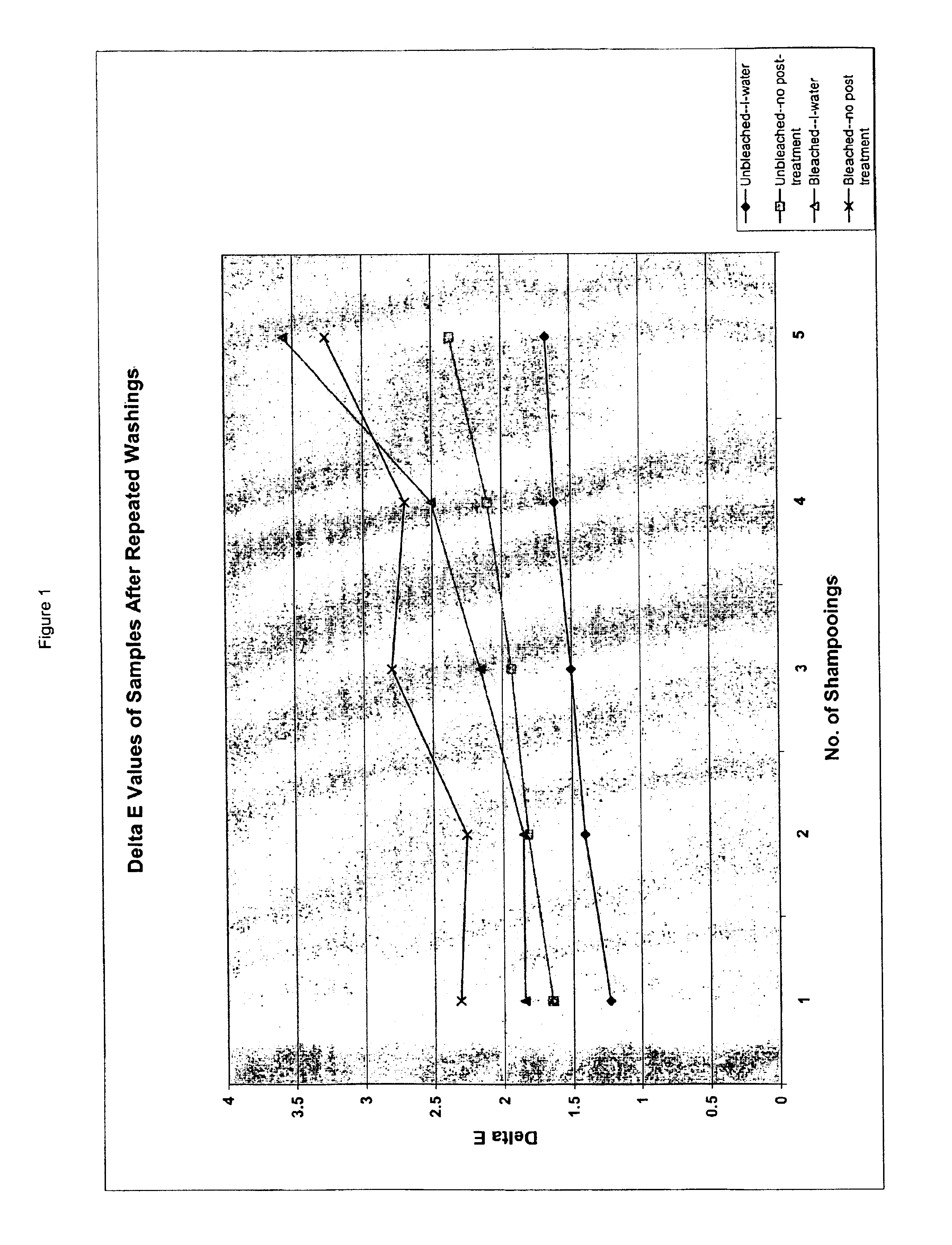

The invention relates to methods of coloring the hair with cluster-modified water and the ability to achieve enhanced color and conditioning for the hair that is color-treated. The cluster-modified water can be ionized water such as alkalinic or acidic water, or structured water such as I or S water. In addition, the cluster-modified water can be applied to the hair as a pre-saturating treatment and / or a post-saturating treatment relative to the hair color treatment process. Additional benefits of the present invention are the ability to minimize the use of harsh chemicals and dyes while still achieving an enriched color, and increased softness and smoothness to the color-treated hair. The present invention can also be used with mordanting salts. The present invention also includes a hair coloring kit including the cluster-modified water for post-saturating and / or pre-saturating the hair.

Owner:A VEDA CORPORATION +1

Hair coloring appliance

The system includes a hair color packet assembly having several individual hair color packets and one developer packet, each packet having a pump for delivering selected amounts of material to a mixing assembly. A control assembly operable in response to a user's input controls each of the pumps to deliver selected amounts of color material and developer material to a mixing assembly which mixes the colors and the developer and delivers it to a brushhead / distributor, which has openings through which the selected hair color formulation is delivered. The brushhead / distributor is mountable in a handle having a motor which drives the brushhead / distributor in a linear oscillating manner.

Owner:LOREAL SA

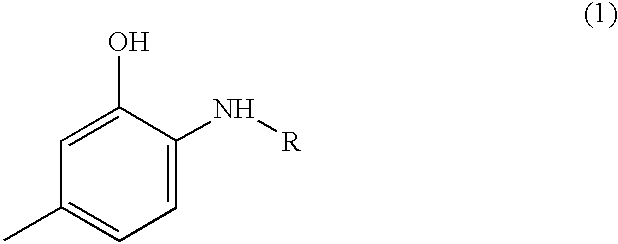

Primary intermediates for oxidative coloration of hair

InactiveUS20020170124A1Good oxidative coloration of hairAcceptable light fastnessCosmetic preparationsHair cosmeticsPhotochemistryAmino radical

Primary intermediates for hair coloring compositions for oxidative dyeing of hair are compounds of the formula (1): wherein R is selected from C1 to C5 alkyl or hydroxyalkyl, a C3 to C6 cyclic ring containing hetero atoms selected from O, S and N atoms, and -CH2-Ar where Ar is an aromatic ring wherein the aromatic ring may be substituted with one or two hydroxy C1 to C3 alkoxy, or amino groups.

Owner:CLAIROL +1

Cosmetic applicator

The present invention generally relates to a cosmetic applicator and in particular, relate to a cosmetic applicator comprising of at least two molded applicator parts that are interlinked such that a non-zero angle is formed at an interface of the at least two molded applicator parts with respect to a centerline of the applicator. The cosmetic applicator of present invention imitates the twirl of the wrist during application and thereby provides a better application. The cosmetic applicator of the present invention may be used for cosmetic and care applications such as mascara application, hair coloring, lip application, etc.

Owner:ZEN DESIGN SOLUTIONS

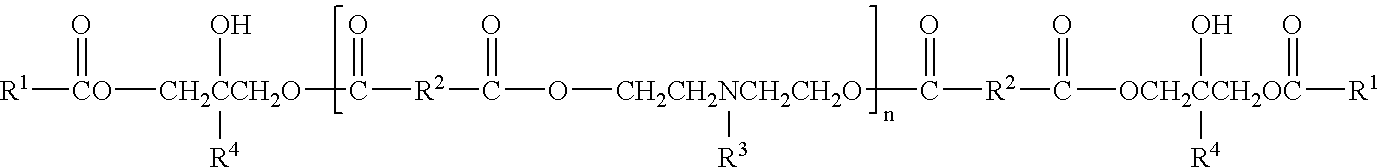

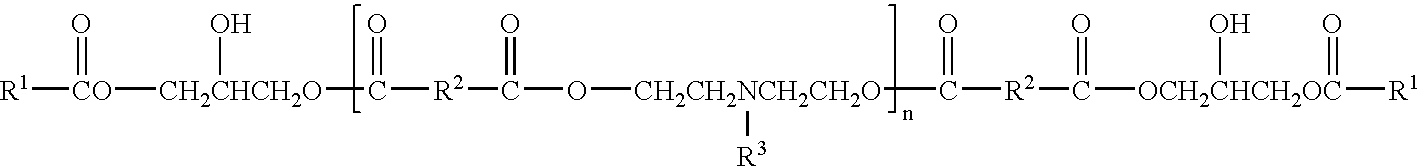

Polyesteramine ingredient and use of same

ActiveUS7101538B1Wet and dry and activityWet and dry chargeCosmetic preparationsHair removalAdditive ingredientBULK ACTIVE INGREDIENT

The present invention provides a polyesteramine, a composition having a polyesteramine according to the present invention as an active ingredient and methods for improving hair detangling, wet and dry combing, shine, gloss, conditioning, surface smoothening, water resistance, film-forming properties, static charge reduction and any combination thereof in various personal care products, such as, hair care, skin care, nail care and cosmetic products. Preferably, the polyesteramine is incorporated into a shampoo, hair conditioner, styling mousse, hair treatment preparation, hair coloring product, semi-perm product, oxidation dye, body wash, liquid soap, skin care preparation, lipstick, mascara, color cosmetic, nail care preparation or any combination thereof.

Owner:INOLEX INVESTMENT CORP

Water-soluble silk proteins in compositions for skin care, hair care or hair coloring

Skin care, hair care and hair coloring compositions comprising a water-soluble silk protein as an active ingredient are described. The water-soluble silk protein deposits onto the skin or the natural hair keratin to provide a smooth and durable film to provide added strength for protection against environmental, chemical, and grooming associated damage. The compositions may be in the form of skin care, skin cleansing, or anti-wrinkle products, shampoos, conditioners, lotions, aerosols, gels, mousses, dyes, or bleaches.

Owner:EI DU PONT DE NEMOURS & CO

Circularly-tanning technology for chrome tanning liquor of sheep garment leather

InactiveCN102586505APure white coatFull coatTanning treatmentPre-tanning chemical treatmentLeather industryFlocculation

The invention discloses a circularly-tanning technology for chrome tanning liquor of sheep garment leather. The circularly-tanning technology comprises the following steps: conditioning, drying, shearing, main-soaking, fleshing, degreasing, pickling, softening, disacidifying, softening, pickling, tanning, wet grinding, retanning, neutralizing, adding grease, retanning, dyeing hair, and dyeing plates. According to the circularly-tanning technology for chrome tanning liquor of sheep garment leather, the formation of hexavalent chromium can be effectively reduced, and the chrome waste liquor flocculation is omitted. According to the test on the chrome content after the chrome tanning liquor is utilized, the chrome waste liquor can be recycled repeatedly by supplementing corresponding chrome powder during next-time recycling, thereby realizing the clean production of tanned leather industry. According to the circularly-tanning technology, the sealed no-emission utilization of a chrome resource can be guaranteed so as to greatly reduce environmental pollution, effectively lower waste water emission and save enterprise waste treatment and production cost. In addition, the quality of the produced leather is consistent with that of the common chrome tanned leather, the shrinkage temperature is above 100DEG C, and a leather body is soft, plump and flexible, is colorful, has pure white hair and has no effect on the dyed hair and the dyed plates.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +2

Hair coloring and conditioning composition

By providing certain quaternary terpolymers as an integral ingredient in hair coloring formulations, substantially improved and enhanced hair conditioning benefits are attained, providing a highly effective, hair coloring composition which also provides conditioning benefits to the hair fibers. In addition, the conditioning benefits and effects are long lasting and capable of being retained by the hair fibers for up to four weeks.

Owner:HENKEL KGAA

Highly affine cosmetic agent

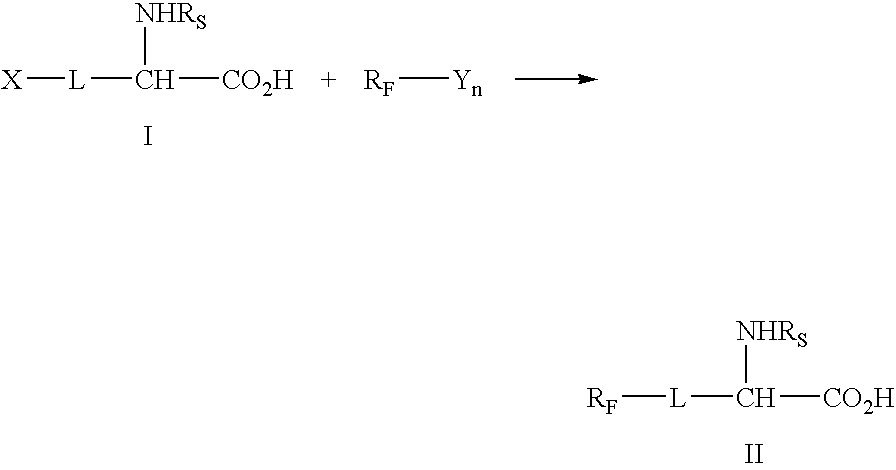

InactiveUS7341604B2Increase variabilityStrong and longer-lasting holdCosmetic preparationsHair removalAdditive ingredientAmino acid

The cosmetic composition for cosmetically treating parts of the body comprising keratin-containing material includes one or more conventional cosmetic auxiliary ingredients and a cosmetically active compound, which is prepared by covalently bonding peptide linker molecules with known organic cosmetic effector molecules. The peptidic linker group is a peptide group, preferably with from 2 to 15 amino acids, which has binding specificity for keratin-containing material. The organic cosmetic effector molecules have dyeing, care-imparting, conditioning, protective, hardening, softening, repairing and / or strengthening properties for keratin-containing material. The method of cosmetically treating parts of the body that include keratin-containing material, for example a method of dyeing hair, includes applying the above-described cosmetic composition to the parts of the body.

Owner:WELLA GMBH

Hair coloring device

Devices configured to permit the application of color to hair from a solid or semi-solid hair coloring composition and methods relating to use of such devices are disclosed. The device includes a support, and a solid or semi-solid hair coloring composition fixedly disposed on the support. The solid or semi-solid hair coloring composition includes a soap gelling agent such that the hair coloring composition retains its shape, and can be provided as a block having a predefined shape. These devices are not attendant with dripping as has been associated with prior art hair color applicators.

Owner:SPECTRUM ASSOC LLC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com