Automatic terminal screw assembling machine with material rejecting function

A terminal and assembly machine technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of unstable terminal quality, hidden dangers, low production efficiency, etc., and achieve labor saving, high safety, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be further explained below in conjunction with the accompanying drawings.

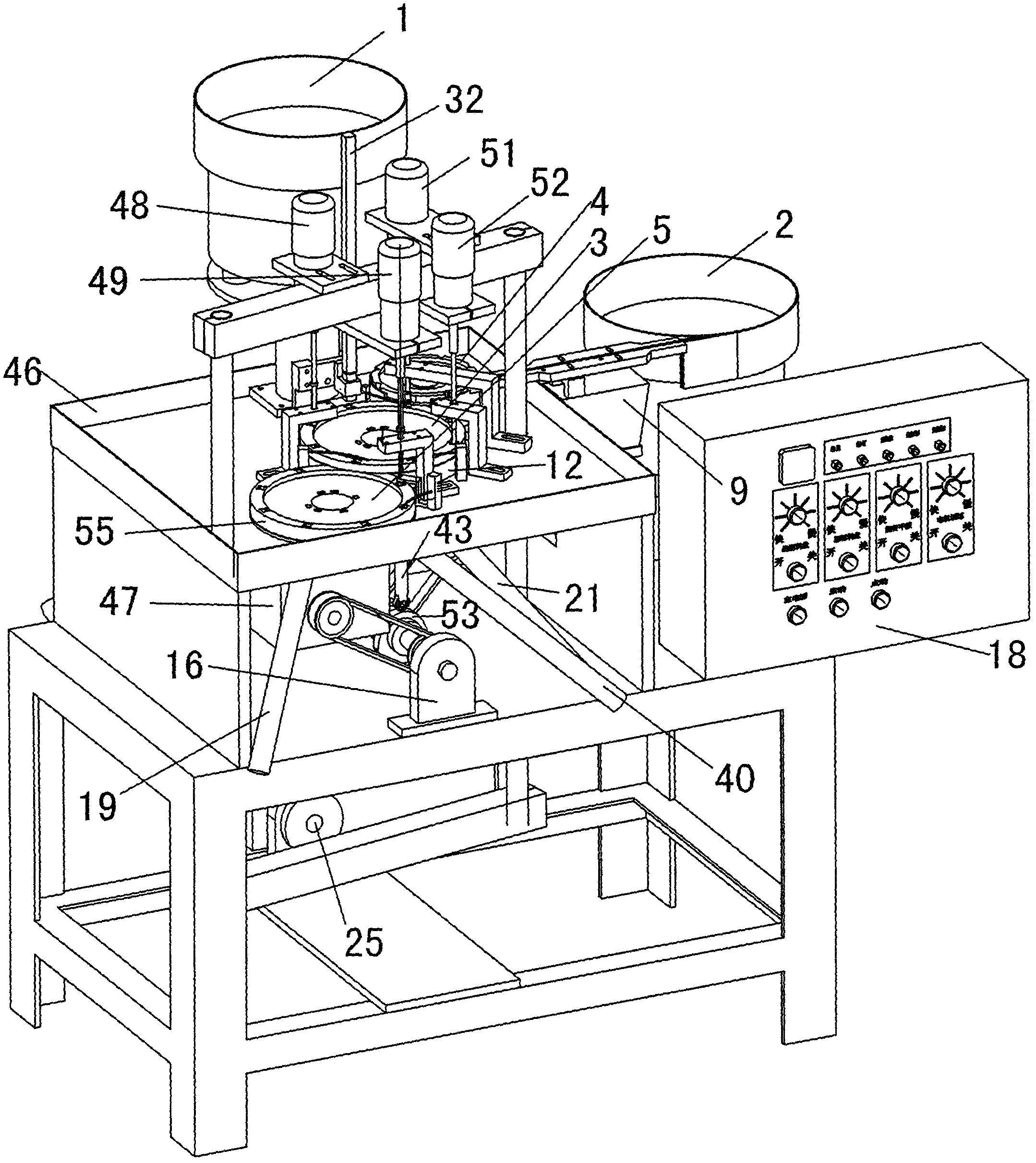

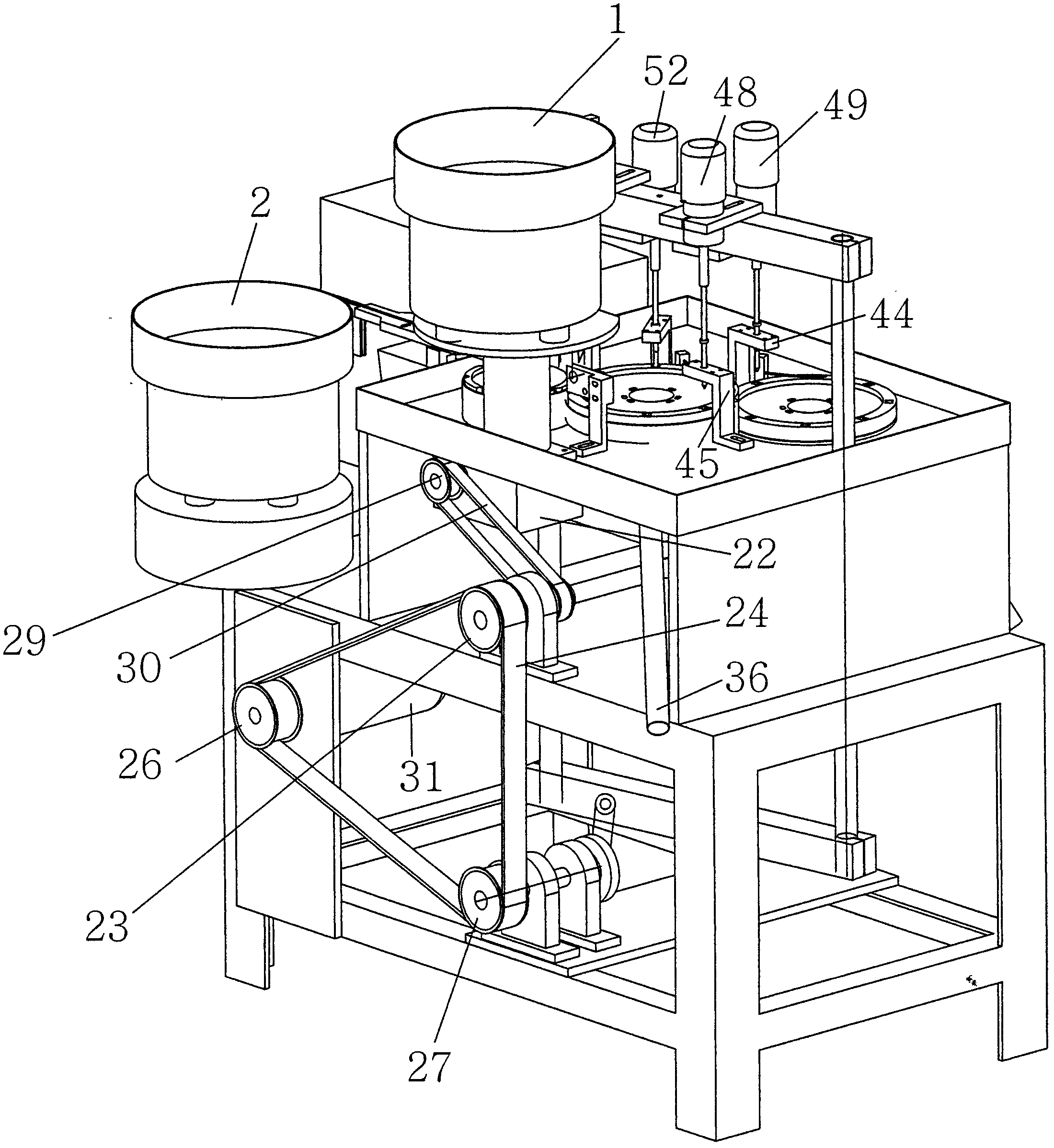

[0036] Such as figure 1 The shown terminal screw automatic assembly machine with the function of returning materials includes the upper part of the workbench area surrounded and limited by the baffle plate 46, and the terminal vibration plate 1, the first terminal positioning index plate 3, the second Two binding posts positioning indexing plate 5, screw vibrating plate 2, screw positioning indexing plate 4, first electric screwdriver 51, second electric screwdriver 52, third electric screwdriver 48, fourth electric screwdriver 49.

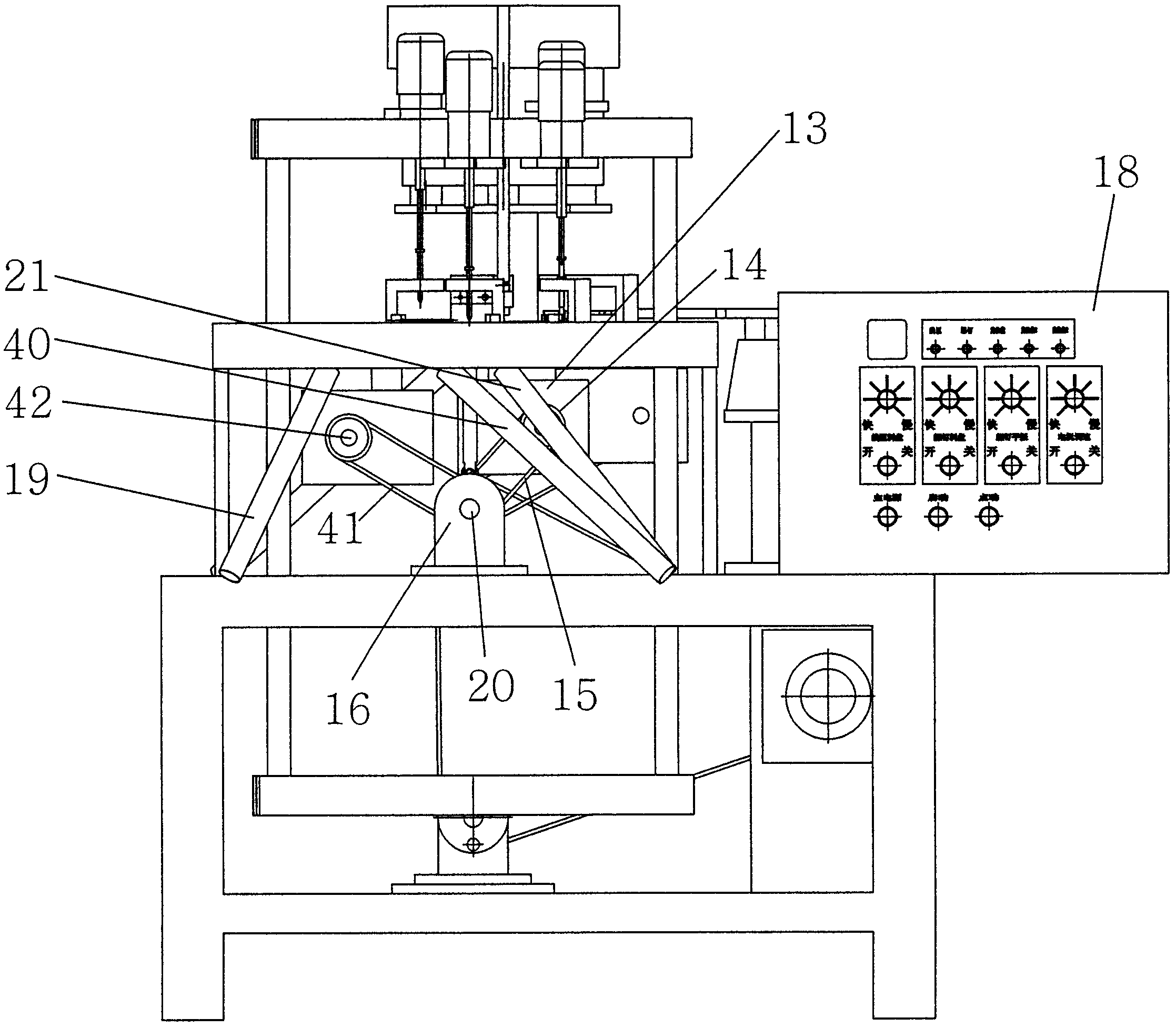

[0037] Please refer to Figure 5 , the first electric screwdriver 51, the second electric screwdriver 52, the third electric screwdriver 48, and the fourth electric screwdriver 49 are respectively fixed on the crossbeam 17 of the horizontally arranged gantry by a screwdriver positioning clip 10, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com