High-strength and two-way-stretching PEN film and preparation method thereof

A biaxially stretched, high-strength technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as large gaps and poor thickness uniformity, and achieve improved stiffness and high tensile strength , The effect of corrosion resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

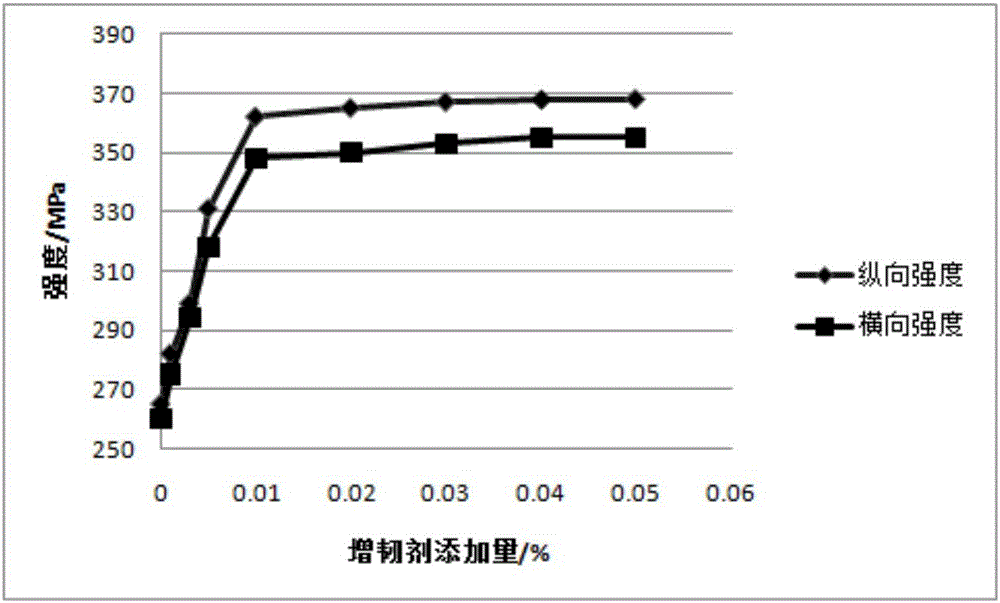

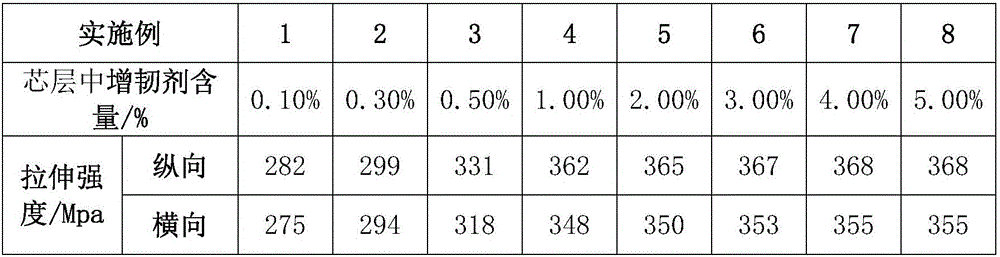

Examples

Embodiment 1

[0036] The upper and lower surface layers are composed of polyethylene naphthalate slices and anti-adhesive agent, the proportion of anti-adhesive agent is 0.5% by weight, and the balance is polyethylene naphthalate slices; the core layer is polyethylene naphthalate slices. The polyethylene naphthalate chip and the toughening agent consist of 0.1% of the toughening agent, and the balance is the polyethylene naphthalate chip.

[0037] The film is carried out as follows:

[0038] (1) Mix the polyethylene naphthalate chips and the toughening agent according to the ratio, and dry them in a fluidized bed at 130-180°C for at least 40 minutes, then dry them in a drying tower at 130-180°C for 2- 8 hours;

[0039] (2) Add the dried polyethylene naphthalate chip and toughening agent mixture into the main extruder and heat it into a molten state as the main extruded melt of the core layer. The temperature of the main extruder is 265 ~ 305°C;

[0040] (3) Add the polyethylene naphthala...

Embodiment 2

[0048] The upper and lower surface layers are composed of polyethylene naphthalate slices and anti-adhesive agent, the proportion of anti-adhesive agent is 0.5% by weight, and the balance is polyethylene naphthalate slices; the core layer is polyethylene naphthalate slices. The ethylene naphthalate chips and the toughening agent consist of 0.3% of the toughening agent, and the balance is polyethylene naphthalate chips.

[0049] Its production method is the same with embodiment 1.

Embodiment 3

[0051] The upper and lower surface layers are composed of polyethylene naphthalate slices and anti-adhesive agent, the proportion of anti-adhesive agent is 0.5% by weight, and the balance is polyethylene naphthalate slices; the core layer is polyethylene naphthalate slices. The ethylene naphthalate chips and the toughening agent consist of 0.5% of the toughening agent, and the balance is polyethylene naphthalate chips.

[0052] Its production method is the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com