Belt group abnormal state automatic touring detection system and detection method thereof

A detection system and abnormal state technology, applied in closed-circuit television systems, televisions, conveyor control devices, etc., can solve problems such as large equipment losses, hard to find in the early stages of wear, and belt wear, so as to reduce economic losses and avoid The effect of major production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

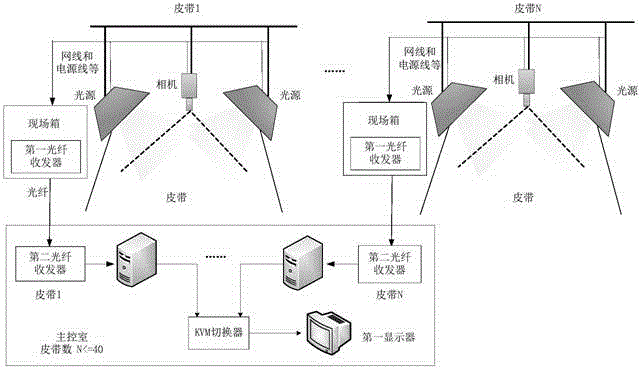

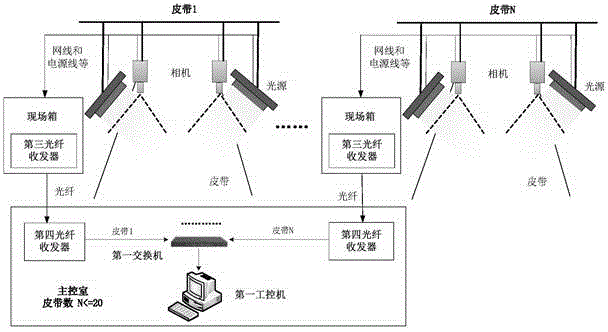

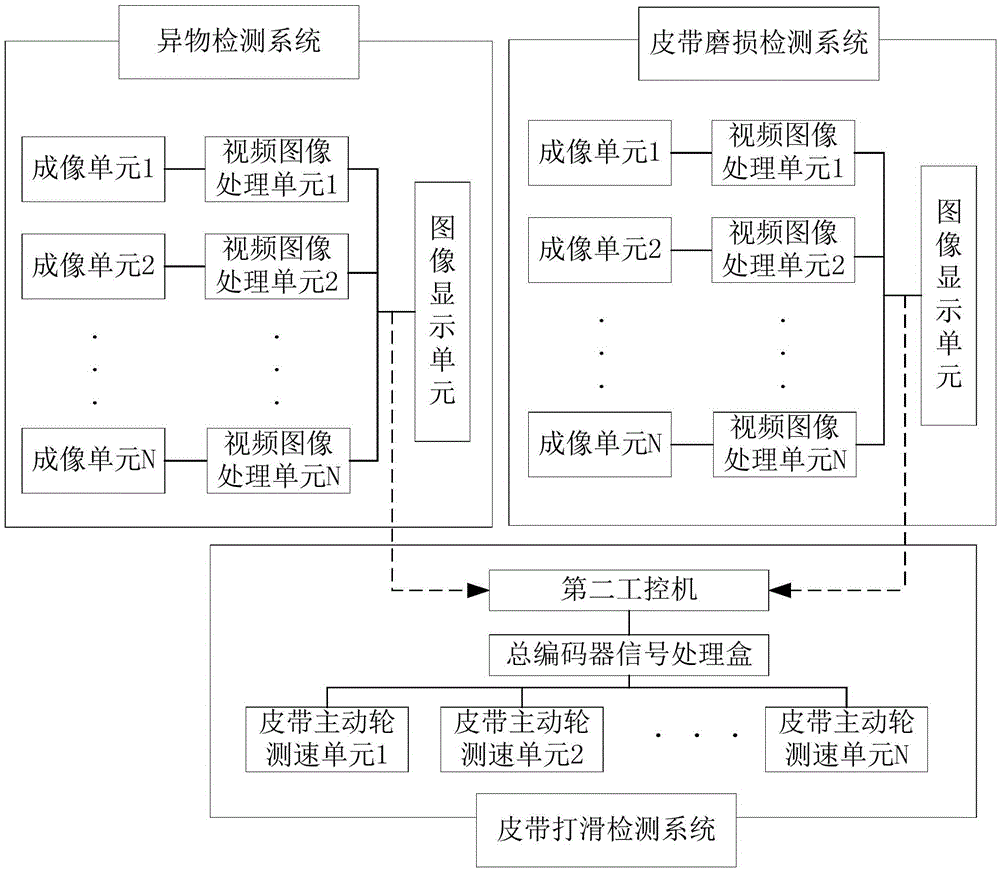

[0028] Such as figure 1 As shown, a belt group abnormal state automatic patrol detection system includes a foreign object detection system, a belt wear detection system and a belt slip detection system; wherein,

[0029] Both the foreign object detection system and the belt wear detection system include imaging equipment, and the imaging equipment includes an industrial camera and an industrial lens arranged in a protective sleeve; An opening is provided at the front end, so that the industrial lens can collect images through the opening; a gas purging device is also provided in the protective cover, and the gas is purged from the inside to the outside of the lens surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com