A high-performance battery

A battery, high-performance technology, applied in the direction of lead-acid battery, battery, lead-acid battery construction, etc., can solve the problems of low battery cycle charging times, shortened battery life, affecting battery charging acceptance ability, etc., to improve charging acceptance capacity and cycle life, the effect of extending service life, improving charge acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

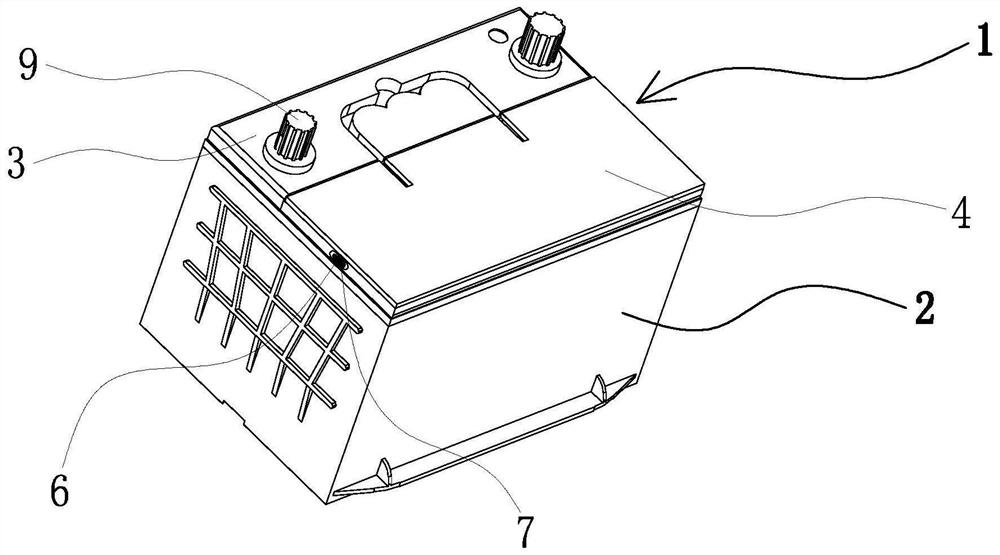

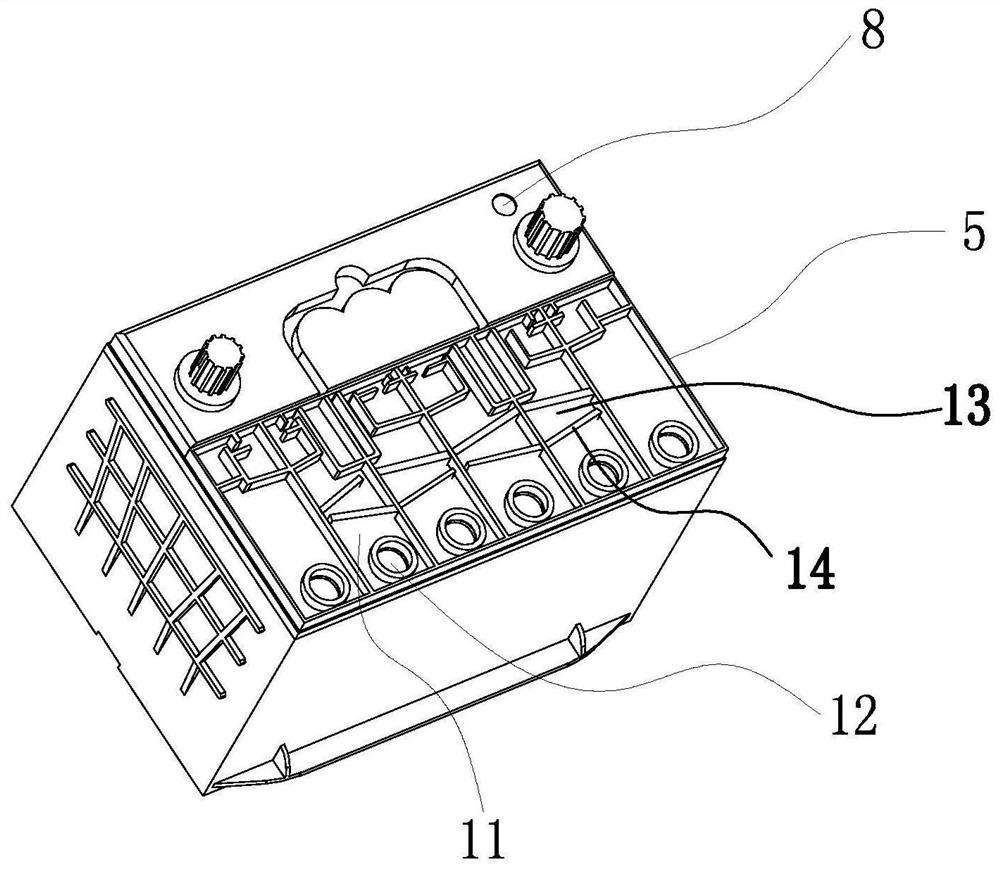

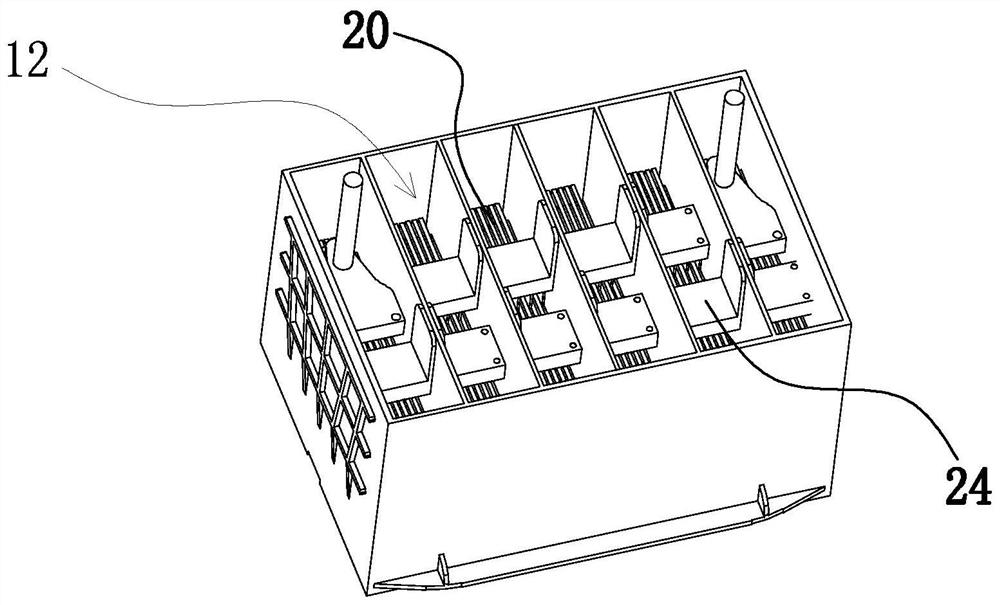

[0030] like Figure 1-5 As shown, a high-performance battery includes a battery cover 1 and a battery case 2; the battery cover 1 includes a large cover 3, a small cover 4 and a cover body 5, and the large cover 3 and the small cover 4 are mounted on the cover body 5; the cover The body 5 is connected to the battery case 2; the top surface of the large cover 3 is provided with two terminals 9, the battery case 2 is provided with a number of cavities 12, each cavity is provided with a pole group 20, and a plurality of pole groups 20 are arranged in the battery The cavity 12 of the shell 2 is connected in series with each other, and the head and tail are connected with the terminal 9; the electrode group 20 is filled with electrolyte; the middle of the large cover 3 is provided with a power indicator 8;

[0031] The bottom surface of the cover body 5 is provided with a plurality of strip-shaped overflow grooves 11 corresponding to the cavity 12 . The overflow groove 11 is provid...

Embodiment 2

[0043] The positive lead paste is made from the following weights: fiber 0.09%, water 10%, sulfuric acid 5%, sodium persulfate 0.5%; the balance is ground lead powder; the negative lead paste is made from the following weights : Fiber 0.08%, water 9%, expansion agent 0.3%, sulfuric acid 5%, graphite 0.85%; the balance is ground lead powder.

[0044] The positive grid is made from the following weights: tin 1.7%; calcium 0.08%; aluminum 0.03%, with the balance lead; the negative grid is made from the following weights: tin 1.0%; calcium 0.11%; aluminum 0.021%, the balance is lead.

[0045] For other contents of this embodiment, reference may be made to Embodiment 1.

Embodiment 3

[0047] The positive lead paste is made from the following weights: fiber 0.02%, water 7%, sulfuric acid 3%, sodium persulfate 0.2%; the balance is ground lead powder; the negative lead paste is made from the following weights : Fiber 0.06%, water 5%, expansion agent 0.1%, sulfuric acid 3%, graphite 0.90%; the balance is ground lead powder.

[0048] The positive grid is made of the following weights: tin 1.6%; calcium 0.07%; aluminum 2%, the balance is lead; the negative grid is made of the following weights: tin 0.9%; calcium 0.10%; aluminum 0.020%, the balance is lead.

[0049] For other contents of this embodiment, reference may be made to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com