Cold-resistant power line

A power cord, cold-resistant technology, used in circuits, insulated cables, electrical components, etc., can solve the problems of hard and brittle outer sheath, affecting the normal supply of power, and easy breaking of power cords, so as to achieve the effect of not easy to break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in further detail below in conjunction with specific embodiments.

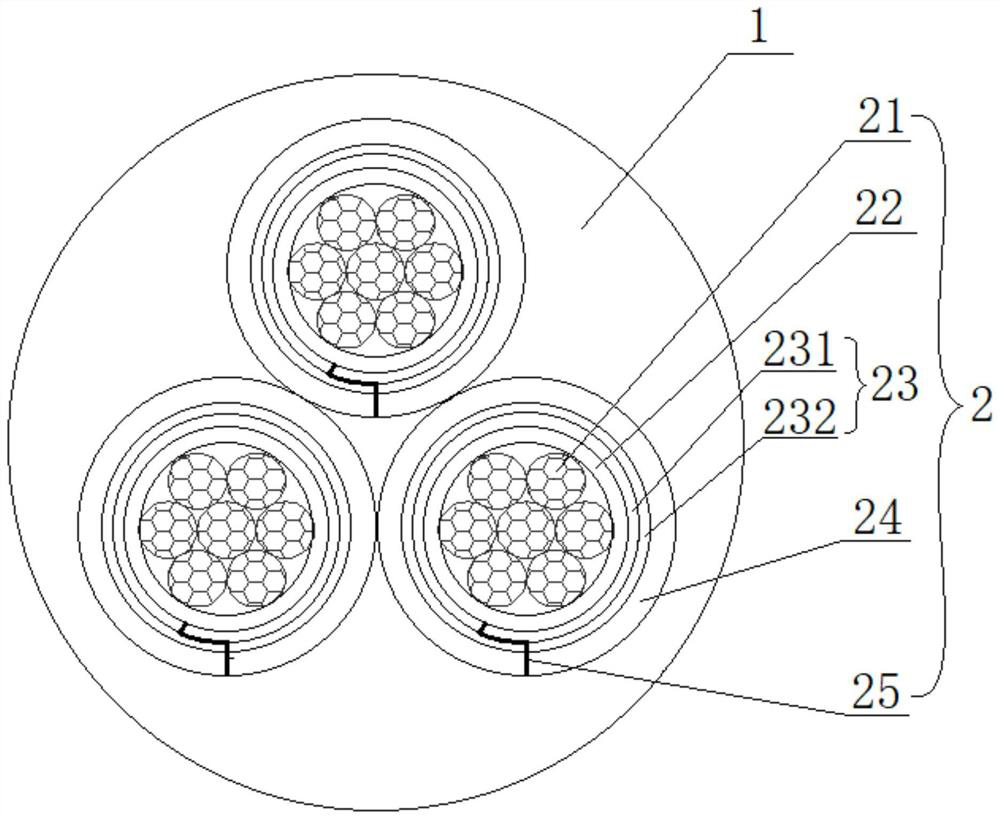

[0018] Such as figure 1 As shown, the cold-resistant power cord includes an outer sheath 1 and three insulated wires 2 , and the outer sheath 1 covers the three insulated wires 2 . Each insulated wire 2 includes a conductive wire core 21, a shielding layer 22, a refractory layer 23, an insulating layer 24, and a heat-conducting insulator 25. The conductive wire core 21 includes seven oxygen-free copper wires twisted with each other, the shielding layer 22, the refractory layer 23 and the insulating layer 24 are sequentially coated on the outside of the conductive wire core 21 from the inside to the outside.

[0019] The material of the outer sheath 1 and the insulating layer 24 is polytetrafluoroethylene (PTFE), which has the characteristics of heat resistance, cold resistance, acid resistance, alkali resistance, and resistance to various organic solvents, so as to play ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com