Body flame-retardant polystyrene foaming wood-imitation material and preparation method thereof

A technology of polystyrene foaming and polystyrene, which is applied in the field of imitation wood materials, can solve the problems of uneven surface of polystyrene imitation wood materials, degradation of flame retardant performance, decomposition of flame retardants, etc., and achieve durable flame retardancy High performance, extended service life, excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

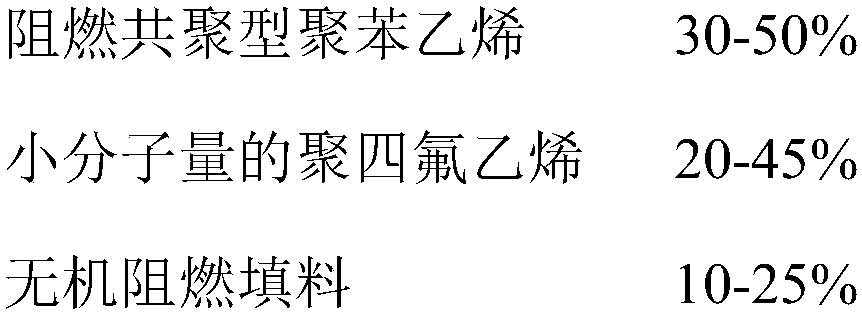

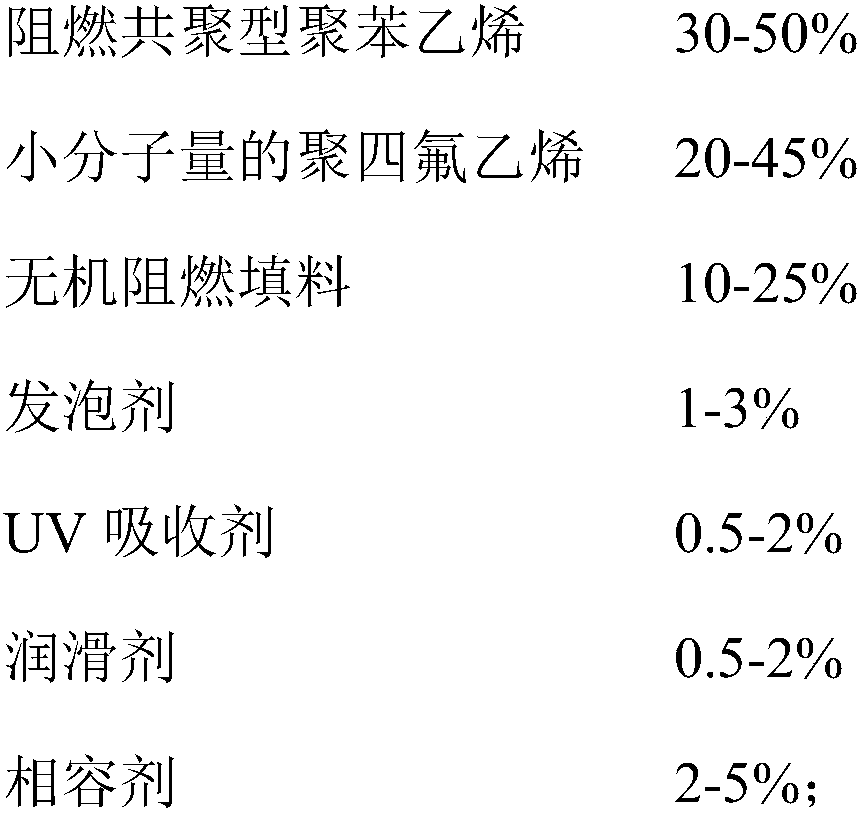

[0049] A body flame-retardant polystyrene foam imitation wood material, the mass percentage of its raw materials is composed of:

[0050]

[0051]

[0052] Among them, the molecular weight of small molecular weight polytetrafluoroethylene is 300,000;

[0053] The inorganic flame retardant filler is aluminum hydroxide;

[0054] The blowing agent is p-toluenesulfonyl hydrazide.

[0055] The UV absorber is phenyl salicylate;

[0056] The lubricant is trimethylolpropane triheptanoate;

[0057] The compatibilizer is trioctyl trimellitic anhydride.

[0058] Concrete preparation is carried out according to the following steps:

[0059] A. Mix resin, inorganic filler and various additives according to the proportion of components to obtain a special compound;

[0060] B. The above-mentioned special compound is added to a twin-screw extruder to extrude and granulate; the process conditions are: the barrel temperature is 160°C, and the screw speed is 200rpm;

[0061] C. Put ...

Embodiment 2

[0064] A body flame-retardant polystyrene foam imitation wood material, the mass percentage of its raw materials is composed of:

[0065]

[0066]

[0067] Among them, the molecular weight of small molecular weight polytetrafluoroethylene is 280,000;

[0068] The inorganic flame retardant filler is magnesium hydroxide;

[0069] The blowing agent is p-isopropylidene acetone sulfonyl hydrazide.

[0070] The UV absorber is 2,2'-methylenebis(4-tert-octyl-6-benzotriazolephenol);

[0071] The lubricant is mineral oil;

[0072] The compatibilizer is dioctyl phthalate.

[0073] The preparation method is the same as in Example 1.

Embodiment 3

[0075] A body flame-retardant polystyrene foam imitation wood material, the mass percentage of its raw materials is composed of:

[0076]

[0077] Among them, the molecular weight of small molecular weight polytetrafluoroethylene is 260,000;

[0078] The inorganic flame retardant filler is aluminum hydroxide;

[0079] The blowing agent is mesityl oxide sulfonyl hydrazide.

[0080] The UV absorber is 2,2'-methylenebis(4-tert-octyl-6-benzotriazolephenol);

[0081] The lubricant is mineral oil;

[0082] The compatibilizer is trioctyl trimellitic anhydride.

[0083] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com