Composition for flame-retardant floating cover, flame-retardant floating cover material and preparation method of flame-retardant floating cover material

A composition and floating cover technology, applied in the field of fire protection, can solve the problems of unrecyclable, reduced volatilization rate, polluting materials, etc., and achieve the effect of reducing VOCs emission rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

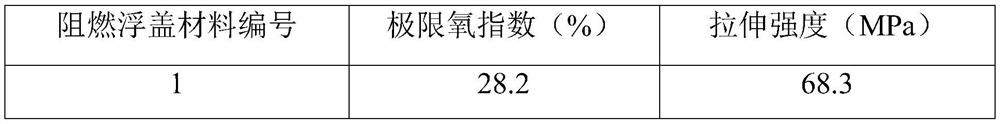

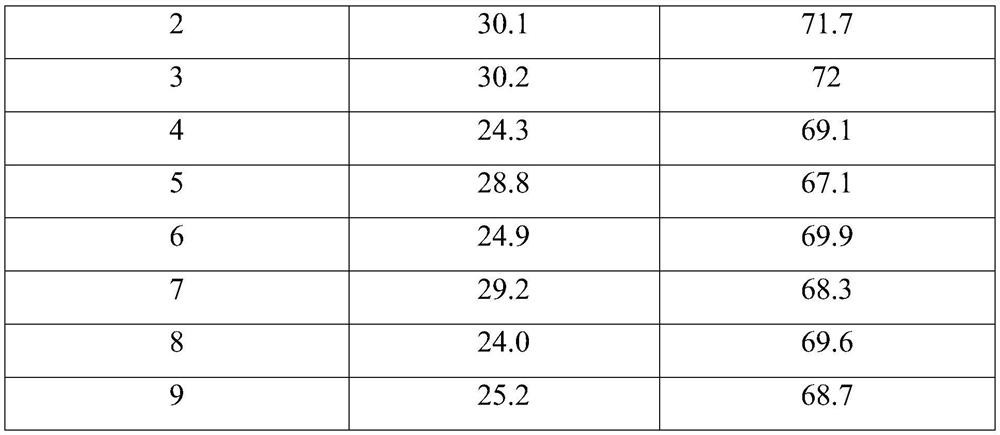

Examples

Embodiment 1

[0056] Raw material formula (weight%): polyamide 66: 75%, decabromodiphenylethane 5%, expanded graphite 15%, cuprous iodide: 1%, N,N'-bis-(3-(3,5 -Di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine 0.5%, silicone powder: 0.5%, nano silicon dioxide 3%.

[0057] Preparation method: Dry the granular polyamide raw material at 90°C for 2 hours, then mix it with decabromodiphenylethane in a mixer for 20 minutes (conditions: normal temperature, stirring speed 60rpm), and then add Expanded graphite, nano-silica, silicone powder, N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, cuprous iodide. Mix in a mixer for 30 minutes (conditions: normal temperature, speed 60 rpm). Then the mixed material is mixed and extruded by a twin-screw extruder. After the extruded material is water-cooled and drawn, it is pelletized by a pelletizer and then sieved, dehydrated, and dried. The drying temperature is 100 ° C. The drying time was 1 hour. Obtain the flam...

Embodiment 2

[0061] Raw material formula (weight%): polyamide 6: 80%, brominated polystyrene 12%, antimony trioxide 3%, expanded graphite 5%, 4,4'-bis(phenylisopropyl) diphenylamine 1 %, tris(2,4-di-tert-butylphenyl)phosphite 0.5%, vinyl bisstearamide 0.5%, potassium titanate whiskers 3%.

[0062] Preparation method: Dry the granular nylon raw material at 100°C for 3 hours, then mix it with brominated polystyrene in a mixer for 20 minutes (conditions: normal temperature, speed 60rpm), then add expanded graphite, Potassium titanate whiskers, vinylbisstearamide, tris(2,4-di-tert-butylphenyl)phosphite, 4,4'-bis(phenylisopropyl)diphenylamine. Mix in a mixer for 20 minutes (conditions: normal temperature, speed 60 rpm). Then the mixed material is mixed and extruded by a twin-screw extruder. After the extruded material is water-cooled and drawn, it is pelletized by a pelletizer and then sieved, dehydrated, and dried. The drying temperature is 100 ° C. The drying time is 2 hours. Obtain the fl...

Embodiment 3

[0066] Raw material formula (weight%): polyamide 610: 75%, brominated polystyrene 12%, magnesium hydroxide 3%, expanded graphite 5%, 4,4'-bis(phenylisopropyl) diphenylamine 1% , Tris (2,4-di-tert-butylphenyl) phosphite 0.5%, vinyl bis stearamide 0.5%, potassium titanate whiskers 3%.

[0067] The granular nylon raw material was dried at 100° C. for 2 hours, and then mixed with brominated polystyrene and magnesium hydroxide in a mixer for 10 minutes (conditions: normal temperature, speed 60 rpm). Then add expanded graphite, potassium titanate whiskers, vinyl bisstearamide, tris(2,4-di-tert-butylphenyl) phosphite, 4,4'-bis(phenylisopropyl)di Aniline, mixed in a mixer for 30 minutes (conditions: normal temperature, speed 60rpm). Then the mixed material is mixed and extruded by a twin-screw extruder. After the extruded material is water-cooled and drawn, it is pelletized by a pelletizer and then sieved, dehydrated, and dried. The drying temperature is 100 ° C. The drying time was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com