Neutralization apparatus for nitric phosphate fertilizer production mother liquid ammonia neutralization process

A technology of nitrophosphate fertilizer and mother liquor, which is applied in the field of neutralization devices used in the production of nitrophosphate fertilizer mother liquor ammonia neutralization process, can solve the problems of large loss of ammonia escape, harsh operating environment, and material caking in neutralization tanks, and achieve high turbulence The degree of mobility, the reduction of emissions, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

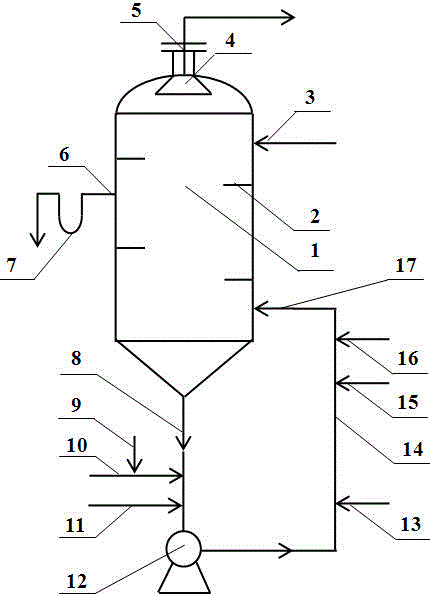

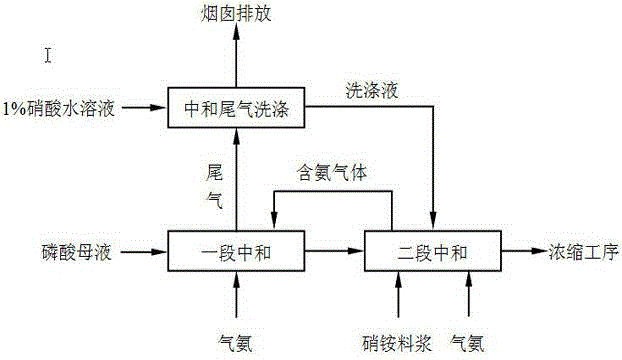

[0030] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, but the content of the present invention is not limited to the scope of the listed embodiments.

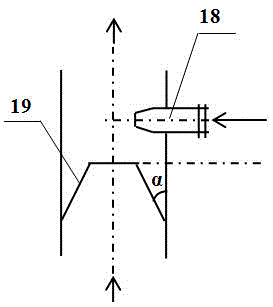

[0031] The present invention, on the basis of the existing neutralization device used for the neutralization process of mother liquid ammonia of nitrophosphate fertilizer, combines the characteristics of phosphate rock in my country, and proceeds from the essential properties of the material, further improves the neutralization device of the ammonia neutralization process of mother liquid ammonia of nitrophosphate fertilizer Improve, and aim at the deficiencies of the neutralization device of the neutralization process, select a suitable multi-point feeding point, so that the neutralization process can smoothly avoid the slurry viscous area under the operating condition of a relatively stable pH value , the pH value of the process is easy to control, it is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com