PVC (polyvinyl chloride) stretch film and method for preparing same

A technology of wrapping film and PVC resin, applied in the field of PVC wrapping film and its preparation, can solve the problems of easy cracking, insufficient resilience and adhesion force of PVC wrapping film, and achieve the effect of improving resilience and adhesion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

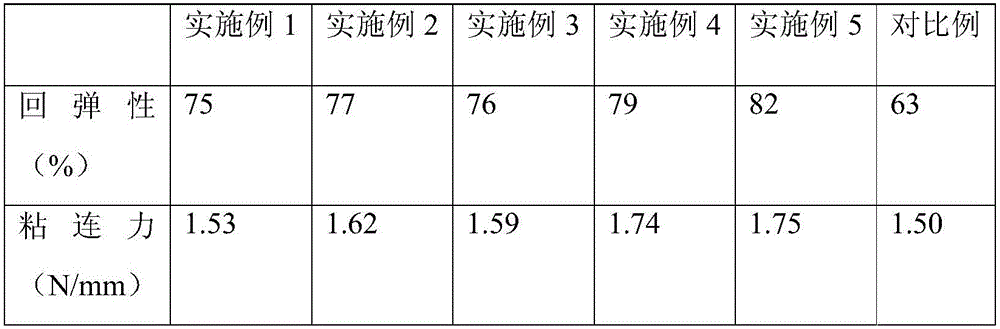

Examples

Embodiment 1

[0016] A PVC stretch film, consisting of the following components by mass: 41 parts of PVC resin, 3 parts of polypropylene carbonate, 3 parts of epoxy soybean oil, 2 parts of sodium laureth sulfate, phthalic acid 1 part of dioctyl ester, 4 parts of polyisobutylene, 7 parts of tributyl phosphate, 4 parts of triethyl citrate, 2 parts of hexachlorocyclopentadiene, and 5 parts of hydroxypropyl methylcellulose.

[0017] Preparation:

[0018] (1) According to the above mass parts, PVC resin, polypropylene carbonate, epoxidized soybean oil, sodium laureth sulfate, dioctyl phthalate, polyisobutylene, tributyl phosphate, tricitric acid Ethyl ester, hexachlorocyclopentadiene, and hydroxypropyl methylcellulose are mixed, placed in a mixer, and stirred evenly at 200°C to obtain a mixture;

[0019] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature in the first zone is 175°C, the temperature in the second zone is 180°C, the temperature in t...

Embodiment 2

[0022] A PVC stretch film, consisting of the following components by mass: 55 parts of PVC resin, 20 parts of polypropylene carbonate, 16 parts of epoxy soybean oil, 15 parts of sodium laureth sulfate, phthalic acid 19 parts of dioctyl ester, 12 parts of polyisobutylene, 17 parts of tributyl phosphate, 14 parts of triethyl citrate, 13 parts of hexachlorocyclopentadiene, and 16 parts of hydroxypropyl methylcellulose.

[0023] Preparation:

[0024] (1) According to the above mass parts, PVC resin, polypropylene carbonate, epoxidized soybean oil, sodium laureth sulfate, dioctyl phthalate, polyisobutylene, tributyl phosphate, tricitric acid Ethyl ester, hexachlorocyclopentadiene, and hydroxypropyl methylcellulose are mixed, placed in a mixer, and stirred evenly at 230°C to obtain a mixture;

[0025] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature of the first zone is 190°C, the temperature of the second zone is 195°C, the temper...

Embodiment 3

[0028] A PVC stretch film, consisting of the following components by mass: 45 parts of PVC resin, 6 parts of polypropylene carbonate, 7 parts of epoxy soybean oil, 7 parts of sodium laureth sulfate, phthalic acid 6 parts of dioctyl ester, 7 parts of polyisobutylene, 10 parts of tributyl phosphate, 6 parts of triethyl citrate, 6 parts of hexachlorocyclopentadiene, and 6 parts of hydroxypropyl methylcellulose.

[0029] Preparation:

[0030] (1) According to the above mass parts, PVC resin, polypropylene carbonate, epoxidized soybean oil, sodium laureth sulfate, dioctyl phthalate, polyisobutylene, tributyl phosphate, tricitric acid Ethyl ester, hexachlorocyclopentadiene, and hydroxypropyl methylcellulose are mixed, placed in a mixer, and stirred evenly at 210°C to obtain a mixture;

[0031] (2) Extrude the mixture obtained in step (1) through a twin-screw extruder, wherein the temperature in the first zone is 180°C, the temperature in the second zone is 185°C, the temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com