Method for preparing high-quality DRCP

A cloned, high-quality technology, applied in the field of chemical engineering, can solve the problems of short reaction time, high reaction temperature, limited product application, etc., and achieve the effect of simple and easy method, easy industrialization, and load reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

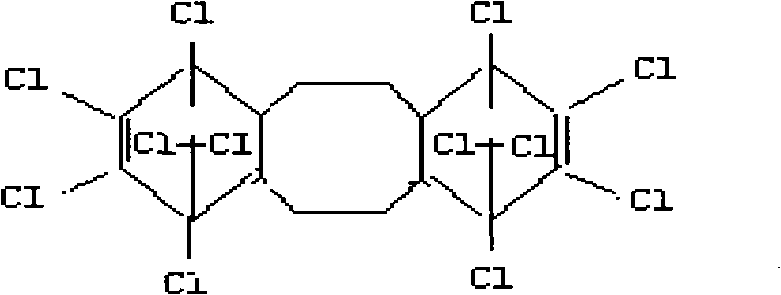

Image

Examples

Embodiment 1

[0017] Add 118.6 grams (0.43 moles) of hexachlorocyclopentadiene and 70 grams of tetrachloroethane into a 250 mL four-neck flask equipped with a stirrer and a thermometer, raise the temperature to 140°C and add 21.6 grams (0.2 moles) of cyclooctadiene dropwise After dropping, the temperature is controlled at 150-160°C, and the temperature is kept at 150-160°C, and the temperature is kept for 5 hours. The cyclooctadiene peak disappears according to the gas spectrometry, the temperature is lowered, filtered, the solid is rinsed with xylene, and dried to obtain 122.8 grams of clones with a whiteness of 98 and a yield of 94. %.

Embodiment 2

[0019] Add 112.5 grams (0.41 moles) of hexachlorocyclopentadiene and 70 grams of cyclohexane into the autoclave, raise the temperature to 140°C, add 21.6 grams (0.2 moles) of cyclooctadiene dropwise, and control the temperature at 160-170°C after dropping. Keep warm for 5 hours, cool down, filter, rinse the solid with toluene, and dry to obtain 128.4 g of clones with a whiteness of 98.5 and a yield of 98.5%.

Embodiment 3

[0021] Add 112.5 grams (0.41 moles) of hexachlorocyclopentadiene and 70 grams of dichloroethane into the autoclave, raise the temperature to 140°C, add 21.6 grams (0.2 moles) of cyclooctadiene dropwise, and control the temperature at 160-170°C after dropping , keep warm for 4 hours, cool down, filter, rinse the solid with dichloroethane, and dry to obtain 127.1 grams of clones, with a whiteness of 98.1 and a yield of 97.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com