Bromine-free flame-retardant nylon

A technology of flame-retardant nylon and nylon, which is applied in the field of bromine-free flame-retardant nylon and its preparation, can solve the problems of high cost, pollute the environment, and high unit price, and achieve the effect of high flame retardancy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

[0026] After PA6 or PA66, two (hexachlorocyclopentadiene) cyclooctane, synergist and antioxidant are mixed according to the material proportion in table 1, add twin-screw extruder from main hopper, reinforcing agent from The feeding port in the middle of the twin-screw extruder is added, and the temperature of the twin-screw extruder is set as follows. Mixed by a twin-screw extruder, extruded by a die, and then water-cooled and pelletized to obtain bromine-free flame-retardant nylon, which can be packaged.

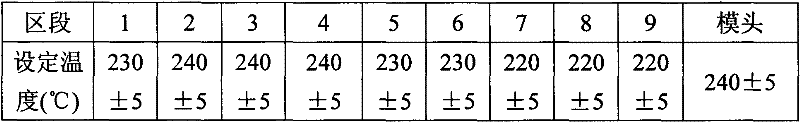

[0027] For flame retardant reinforced PA6, the set temperature of the twin-screw extruder is as follows:

[0028]

[0029] For flame retardant reinforced PA66, the set temperature of the twin-screw extruder is as follows:

[0030]

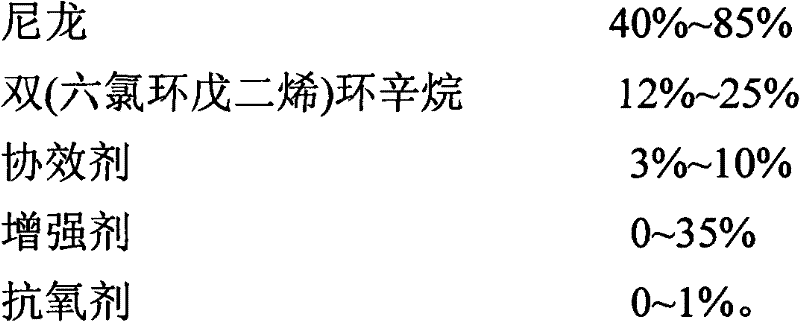

[0031] The material proportion of each embodiment of table 1 (material proportion is weight percent)

[0032]

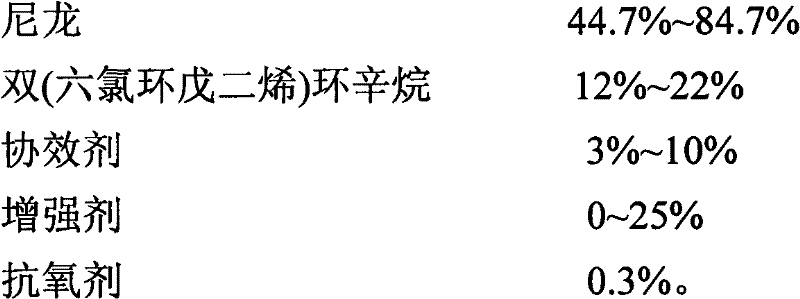

[0033] The material proportion of each embodiment of table 2 (material proportion is weight percent)

[0034]

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com