Yellow pigment for color liquid crystal filter and preparation method thereof

A technology of yellow pigment and color filter, which is applied in the field of yellow pigment and its preparation, can solve the problems of not being able to reach liquid crystal color filters, and achieve the effects of high grayscale, high contrast, good fluidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of the yellow pigment used for the color liquid crystal color filter that the present invention relates to mainly comprises the following operations:

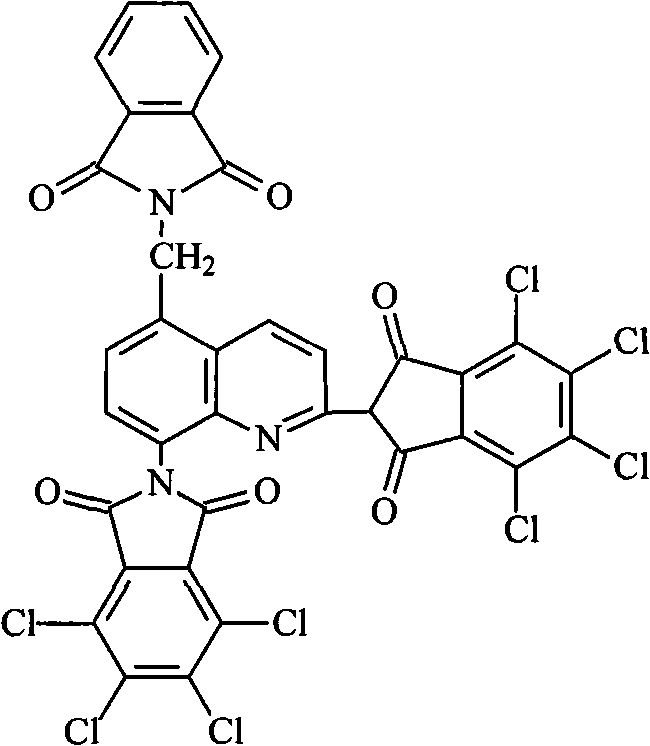

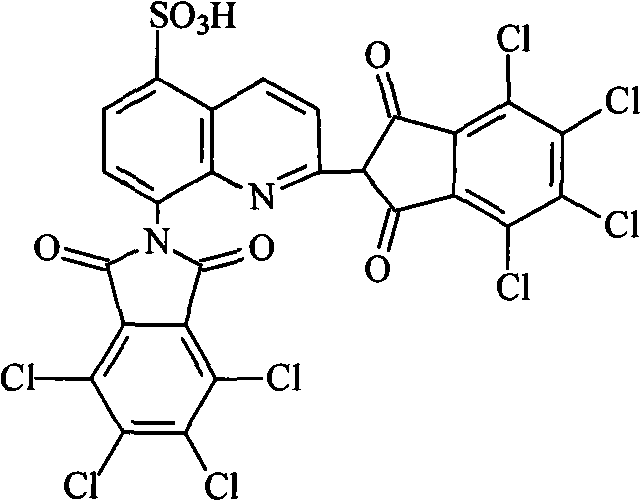

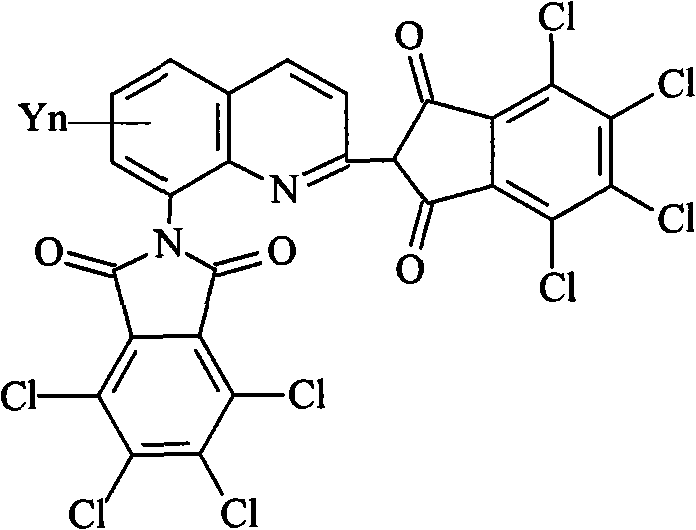

[0065] A, taking 2-methyl-8-aminoquinoline and tetrachlorophthalic anhydride as the basic raw material synthetic structural formula is the yellow pigment crude product of compound I;

[0066] B. Pigmentation processing of crude yellow pigment.

[0067] The synthetic method of yellow pigment crude product is roughly as follows:

[0068] a. In trichlorobenzene or other inert high-boiling solvents, add 2-methyl-8-aminoquinoline and tetrachlorophthalic anhydride, anhydrous zinc chloride;

[0069] b. Heating to a boiling state and keeping boiling for several hours;

[0070] c. Add dimethylformamide, stir and reflux for about 1 hour;

[0071]d. Then filter while hot, and wash with dimethylformamide;

[0072] e. Finally, wash with ethanol, and dry the filter cake to obtain the crude yellow pigment who...

Embodiment 1

[0090] Synthesis of Compound I

[0091] In a reaction kettle, add 3000 parts of trichlorobenzene, slowly add 158 parts of 2-methyl-8-aminoquinoline, 600 parts of tetrachlorophthalic anhydride, and 50 parts of zinc chloride while stirring. The temperature is raised to boiling temperature, the water produced by the reaction is discharged from the reactor through the condenser, and the trichlorobenzene is condensed and then returned to the reactor. Keep boiling for 4 hours, add 600 parts of dimethylformamide DMF to lower the reflux temperature to 175°C, then filter at 150-175°C, continue to wash with 1500 parts of dimethylformamide DMF, and finally wash with 500 parts of ethanol, filter The cake was dried to obtain the crude product of yellow pigment, that is, compound I.

[0092] Pigmentation treatment of crude pigment

[0093] a) Pigment pre-grinding

[0094] In a 10-square ball mill, add steel balls accounting for 75% of the volume, the yellow pigment crude product of 1000 ...

Embodiment 2

[0100] Synthesis of Compound I

[0101] In a reaction kettle, add 3000 parts of trichlorobenzene, slowly add 158 parts of 2-methyl-8-aminoquinoline, 800 parts of tetrachlorophthalic anhydride, and 60 parts of zinc chloride while stirring. The temperature is raised to boiling temperature, the water produced by the reaction is discharged from the reactor through the condenser, and the trichlorobenzene is condensed and then returned to the reactor. Keep boiling for 5 hours. Filter, wash with 2,000 parts of 160°C dimethylformamide DMF, and finally wash with 500 parts of ethanol, and dry the filter cake to obtain a crude yellow pigment that is Compound I.

[0102] Pigmentation treatment of crude pigment

[0103] a) Pigment pre-grinding

[0104] In a 10 cubic meter ball mill, add steel balls accounting for 75% of the volume, the yellow pigment crude product of 1500 kilograms of example 1, and 500 kilograms of sodium sulfate. Start the grinder to grind for 40 hours, and control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com