Flame retardant resin and preparation method thereof

A flame-retardant resin and raw material technology, applied in the field of flame-retardant resin and its preparation, can solve the problems of resin physical property decline, static bending strength, internal bonding strength and elastic modulus performance parameters are difficult to achieve ideal results, and achieve performance Excellent and good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

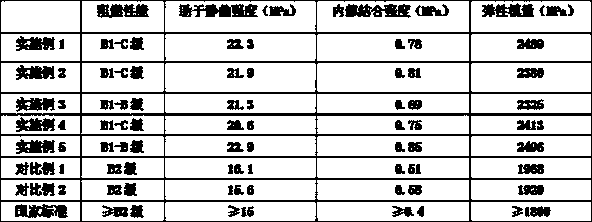

Examples

Embodiment 1

[0026] The flame retardant resin includes the following raw materials in parts by weight: 26 parts of styrene dichloride, 5 parts of maleic anhydride, 28 parts of tetrachlorophthalic anhydride, 32 parts of neopentyl glycol, 6 parts of methyl methacrylate, poly 3 parts of ester fiber, 9 parts of copper naphthenate, 4 parts of cobalt isooctanoate, 20 parts of calcium carbonate, 2 parts of silicon dioxide, 1 part of urotropine, 6 parts of perlite powder, 3 parts of aluminosilicate, graphite 4 parts, 6 parts of diammonium hydrogen phosphate, 2 parts of magnesium hydroxide, 1 part of aluminum hydroxide.

[0027] The graphite is expanded graphite.

[0028] The aluminosilicate is montmorillonite.

[0029] A kind of preparation method of above-mentioned fire retardant resin, comprises the following steps:

[0030] Step 1: at normal temperature, weigh the above-mentioned raw materials in parts by weight, and set aside;

[0031] Step 2: Put maleic anhydride, tetrachlorophthalic anhyd...

Embodiment 2

[0040] The flame retardant resin includes the following raw materials in parts by weight: 32 parts of styrene dichloride, 9 parts of maleic anhydride, 36 parts of tetrachlorophthalic anhydride, 38 parts of neopentyl glycol, 12 parts of methyl methacrylate, poly 7 parts of ester fiber, 15 parts of copper naphthenate, 8 parts of cobalt isooctanoate, 30 parts of calcium carbonate, 6 parts of silicon dioxide, 5 parts of urotropine, 12 parts of perlite powder, 7 parts of aluminosilicate, graphite 9 parts, 10 parts of diammonium hydrogen phosphate, 5 parts of magnesium hydroxide, 5 parts of aluminum hydroxide.

[0041] The graphite is expanded graphite.

[0042] The aluminosilicate is montmorillonite.

[0043] A kind of preparation method of above-mentioned fire retardant resin, comprises the following steps:

[0044] Step 1: at normal temperature, weigh the above-mentioned raw materials in parts by weight, and set aside;

[0045] Step 2: Put maleic anhydride, tetrachlorophthalic...

Embodiment 3

[0054] The flame retardant resin includes the following raw materials in parts by weight: 28 parts of styrene dichloride, 6 parts of maleic anhydride, 30 parts of tetrachlorophthalic anhydride, 34 parts of neopentyl glycol, 8 parts of methyl methacrylate, poly 4 parts of ester fiber, 11 parts of copper naphthenate, 5 parts of cobalt isooctanoate, 24 parts of calcium carbonate, 3 parts of silicon dioxide, 2 parts of urotropine, 8 parts of perlite powder, 4 parts of aluminosilicate, graphite 5 parts, 7 parts of diammonium hydrogen phosphate, 3 parts of magnesium hydroxide, 2 parts of aluminum hydroxide.

[0055] The graphite is expanded graphite.

[0056] The aluminosilicate is montmorillonite.

[0057] A kind of preparation method of above-mentioned fire retardant resin, comprises the following steps:

[0058] Step 1: at normal temperature, weigh the above-mentioned raw materials in parts by weight, and set aside;

[0059] Step 2: Put maleic anhydride, tetrachlorophthalic an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com