Self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent

A sand control agent and temperature-resistant technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of affecting the sand control and sand-fixing effect, poor temperature resistance of the consolidated body, difficulty in field operation, etc., so as to prolong the field operation. The effect of improving time and curing strength and increasing the amount of carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

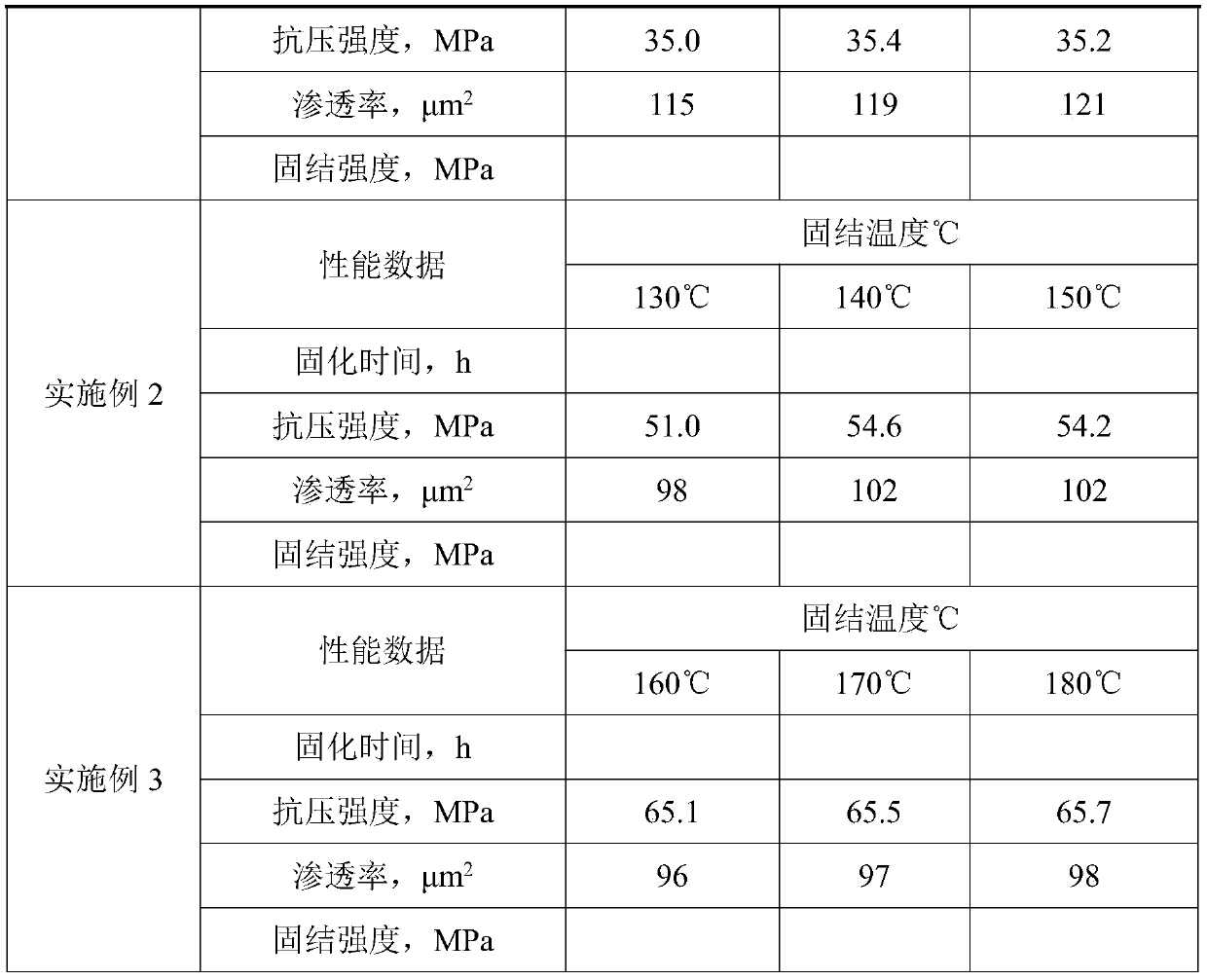

Embodiment 1

[0025] A kind of sand control agent is prepared as follows:

[0026] At room temperature, mix epoxy resin E-44, epoxy resin E-51, phenolic resin F-51, and polyvinylpyrrolidone K30 according to the mass ratio of epoxy resin E-44: epoxy resin E-51: phenolic resin F- 51: Polyvinylpyrrolidone K30=3:3:3:1 is mixed to prepare a resin compound system; p-nitrobenzoic anhydride and tetrachlorophthalic anhydride are mixed according to a mass ratio of 1:1 to prepare a curing agent; then The resin compounding system, cyclohexanone, coupling agent N-aminoethyl-3-aminopropylmethyldimethoxysilane, emulsifier, filler, and curing agent are in a mass ratio of 30:47:5:8: 5:5 mixed to make liquid sand control agent. Among them, the emulsifier is a compound of styrene-sodium maleate and polyoxyethylene sorbitan monooleate in a mass ratio of 1:1; the filler is high-temperature-resistant multi-mineral fine powder and phenolic fiber, according to the Compounding agent with a mass ratio of 4:1, the ...

Embodiment 2

[0037] A kind of sand control agent is prepared as follows:

[0038]At room temperature, mix epoxy resin E-44, epoxy resin E-51, phenolic resin F-51, and polyvinylpyrrolidone K30 according to the mass ratio of epoxy resin E-44: epoxy resin E-51: phenolic resin F- 51: Polyvinylpyrrolidone K30=2:3:4:1 is mixed to prepare a resin compound system; p-nitrobenzoic anhydride and tetrachlorophthalic anhydride are mixed according to a mass ratio of 1:1 to prepare a curing agent; then The resin compounding system, cyclohexanone, coupling agent N-aminoethyl-3-aminopropylmethyldimethoxysilane, emulsifier, filler, and curing agent are in a mass ratio of 40:40:6:5: Mix 5:4 to make liquid sand control agent. Among them, the emulsifier is a compound of styrene-sodium maleate and polyoxyethylene sorbitan monooleate in a mass ratio of 1:1; the filler is high-temperature-resistant multi-mineral fine powder and phenolic fiber, according to the The compounding agent with a mass ratio of 3:1, the...

Embodiment 3

[0049] A kind of sand control agent is prepared as follows:

[0050] At room temperature, mix epoxy resin E-44, epoxy resin E-51, phenolic resin F-51, and polyvinylpyrrolidone K30 according to the mass ratio of epoxy resin E-44: epoxy resin E-51: phenolic resin F- 51: Polyvinylpyrrolidone K30=30:25:40:5 is mixed to form a resin compound system; p-nitrobenzoic anhydride and tetrachlorophthalic anhydride are mixed according to a mass ratio of 1:1 to form a curing agent; then The resin compounding system, cyclohexanone, coupling agent N-aminoethyl-3-aminopropylmethyldimethoxysilane, emulsifier, filler, and curing agent are in a mass ratio of 30:49:7:5: Mix 5:4 to make liquid sand control agent. Among them, the emulsifier is a compound of styrene-sodium maleate and polyoxyethylene sorbitan monooleate in a mass ratio of 1:1; the filler is high-temperature-resistant multi-mineral fine powder and phenolic fiber, according to the The compounding agent with a mass ratio of 3:1, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com