Solvent-free environment-friendly coating and preparation method thereof

An environmentally friendly coating and solvent-free technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as blistering and coating pinholes, and achieve the effects of reducing costs, improving wear resistance, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

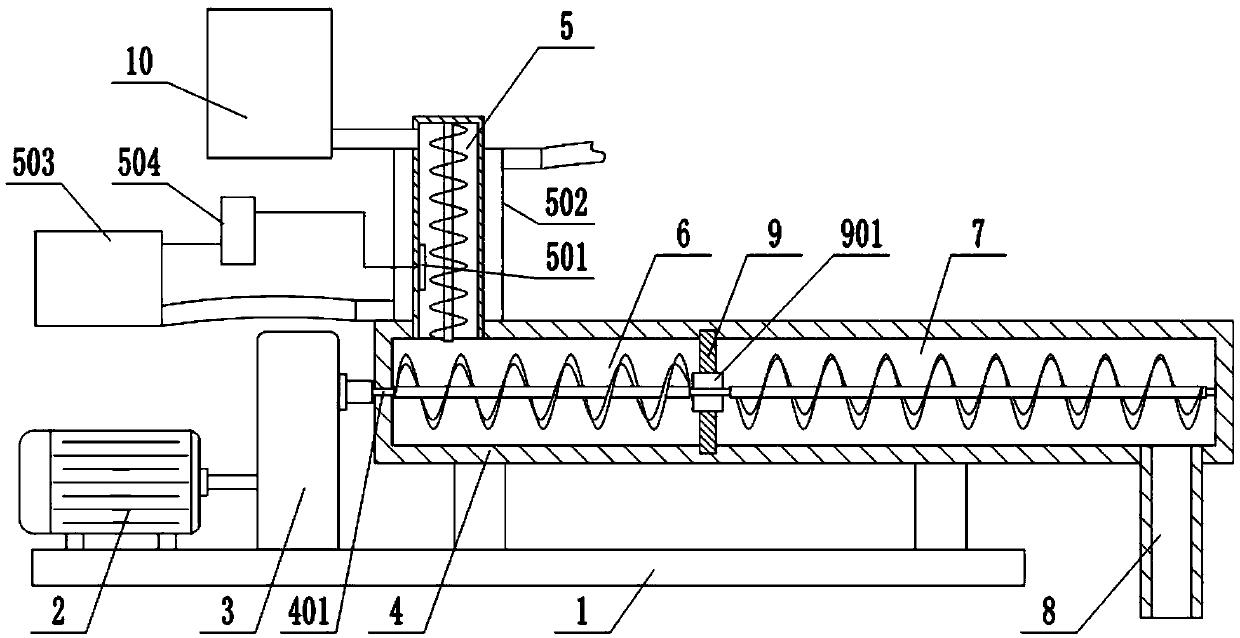

Image

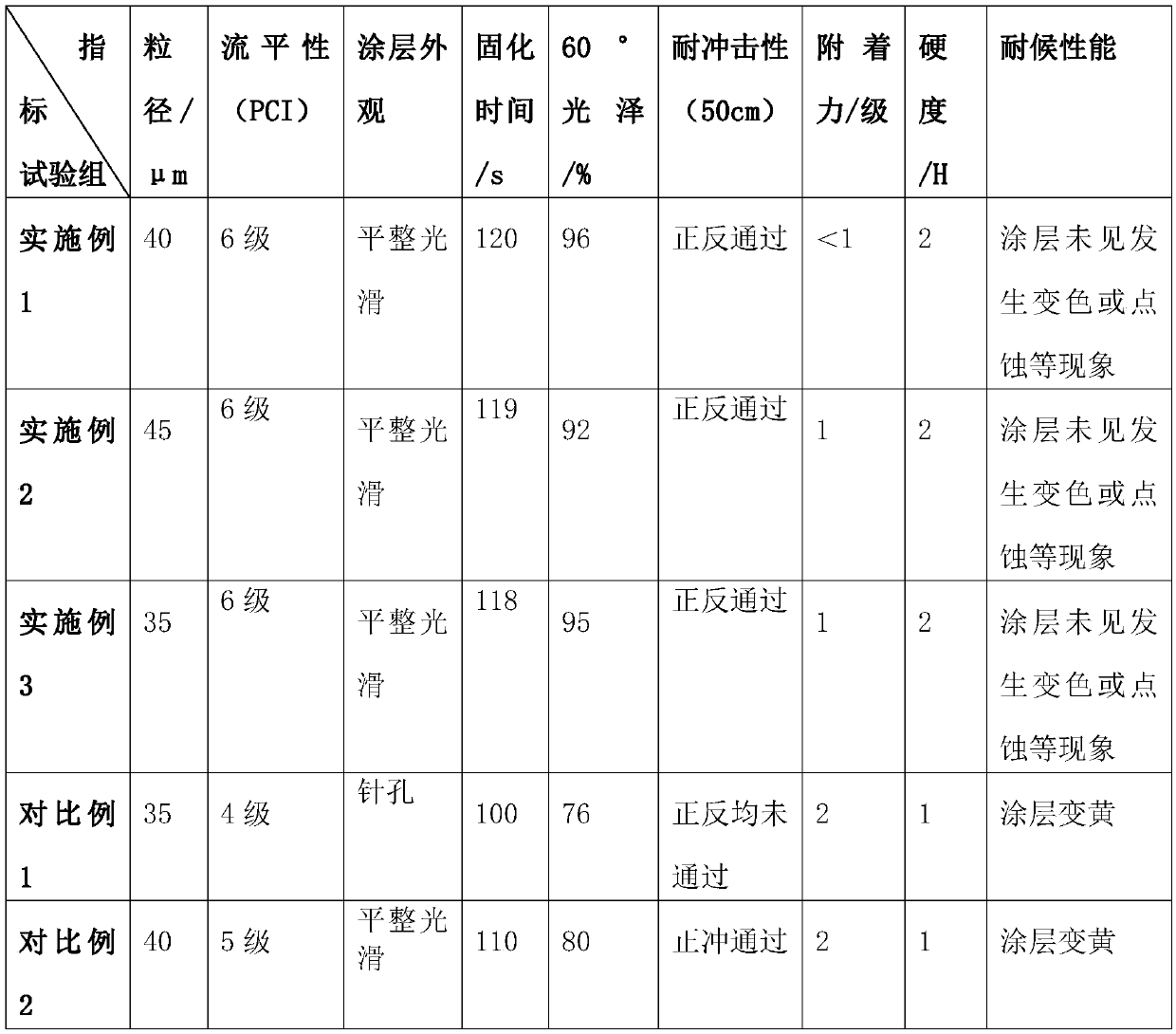

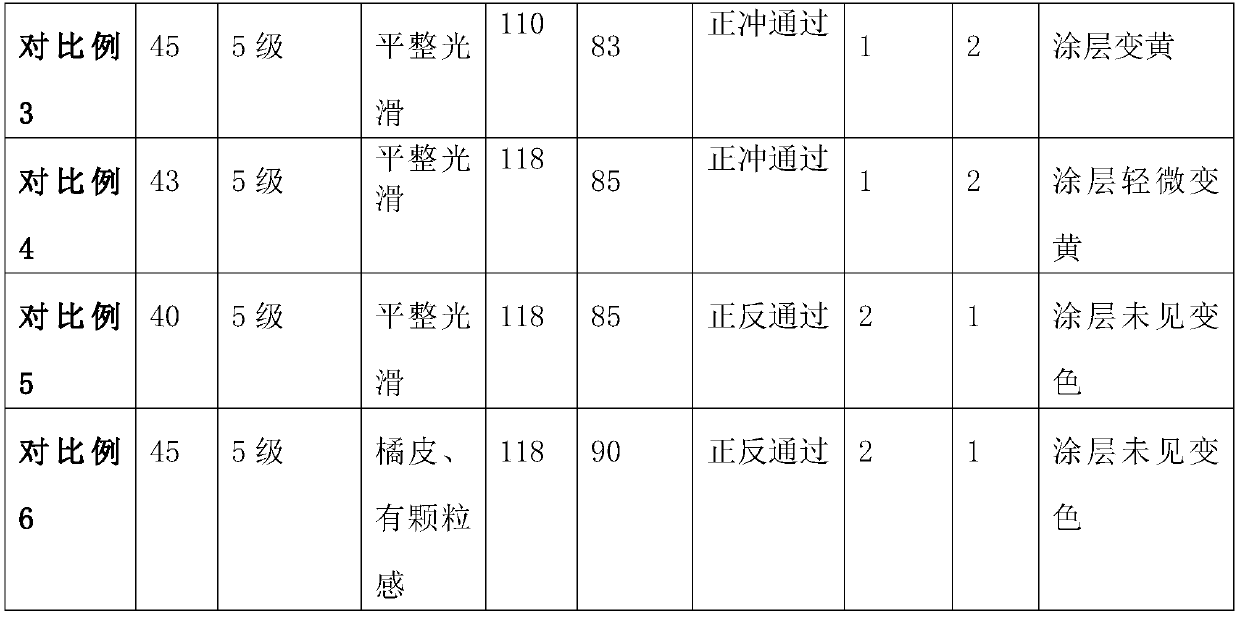

Examples

Embodiment 1

[0033] A kind of solvent-free environmental protection paint, comprises following raw material, and raw material is counted by mass percent: 56% of polyester resin, 4% of hydroxyalkylamide, 10% of high gloss barium sulfate, 4% of precipitated barium sulfate, 3% of calcium carbonate, rutile type titanium White powder 10%, mica powder 3%, nano calcium carbonate 4%, hollow glass microspheres 4%, curing inhibitor 0.05%, lubricant 0.3%, leveling agent 0.65%, benzoin 0.5%, anti-ultraviolet absorber 0.5%. Among them, the curing inhibitor is a quaternary ammonium salt or a quaternary phosphonium salt series compound, specifically triphenylethylphosphine bromide, and the leveling agent is ethylene bisstearamide.

[0034] The preparation method of above-mentioned a kind of solvent-free environmental protection paint, comprises the following steps:

[0035] (1) Drying: Dry all the raw materials before mixing, and the drying temperature is controlled at 65°C;

[0036] (2) Mixing: Put the...

Embodiment 2

[0047] A kind of solvent-free environmental protection paint, comprises following raw material, and raw material is counted by mass percentage: polyester resin 52%, hydroxyalkyl amide 2%, high-gloss barium sulfate 12%, precipitated barium sulfate 5%, calcium carbonate 3%, anatase type Titanium dioxide 12%, mica powder 3%, nano calcium carbonate 5%, hollow glass microspheres 4%, curing inhibitor 0.03%, lubricant 0.1%, leveling agent 0.6%, benzoin 0.67%, anti-ultraviolet absorbing agent 0.6% . Wherein, the curing inhibitor is a quaternary ammonium salt or a quaternary phosphonium salt series compound, specifically cetyltrimethylammonium bromide, and the lubricant is stearic acid.

[0048] The preparation method of above-mentioned a kind of solvent-free environmental protection paint, comprises the following steps:

[0049] (1) Drying: all raw materials are dried before mixing, and the drying temperature is controlled at 60°C;

[0050] (2) Mixing: Put the weighed raw materials ...

Embodiment 3

[0057] A kind of solvent-free environmental protection paint, comprises following raw material, and raw material is counted by mass percent: 58% of polyester resin, 8% of hydroxyalkylamide, 8% of high gloss barium sulfate, 4% of precipitated barium sulfate, 3% of calcium carbonate, rutile type titanium White powder 7%, mica powder 3%, nano calcium carbonate 3%, hollow glass microspheres 3%, curing inhibitor 0.1%, lubricant 0.4%, leveling agent 1.5%, benzoin 0.5%, anti-ultraviolet absorber 0.5%. Wherein, the curing inhibitor is a series compound of quaternary ammonium salt or quaternary phosphonium salt, specifically, benzyl trimethyl phosphorus chloride is used, and the lubricant is stearamide.

[0058] The preparation method of above-mentioned a kind of solvent-free environmental protection paint, comprises the following steps:

[0059] (1) Drying: Dry all raw materials before mixing, and the drying temperature is controlled at 70°C;

[0060] (2) Mixing: Put the weighed raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com