System and method for eradicating flow marks and water inclusion marks of spraying-free material during processing and forming

A material processing and spray-free technology, which is applied in the field of spray-free material processing and molding, can solve the problem that the spray-free material flow marks or water marks cannot be completely eradicated, and achieve the effects of increasing the curing time of the arrangement, delaying the curing speed, and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

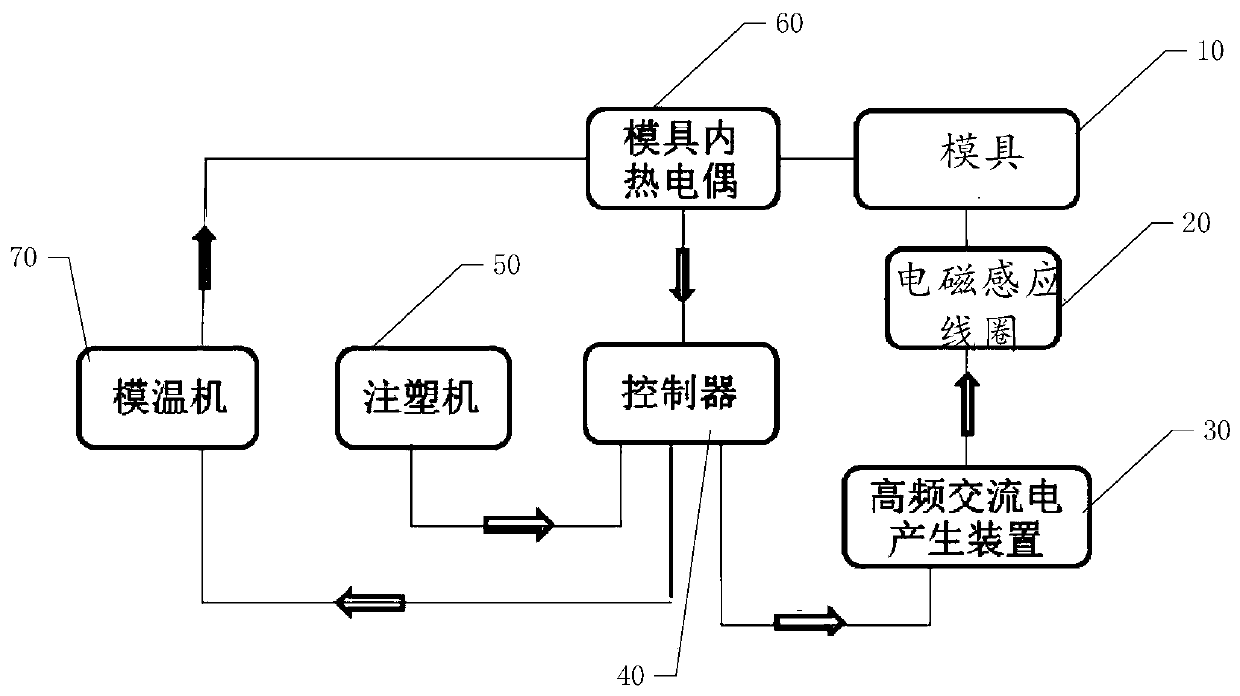

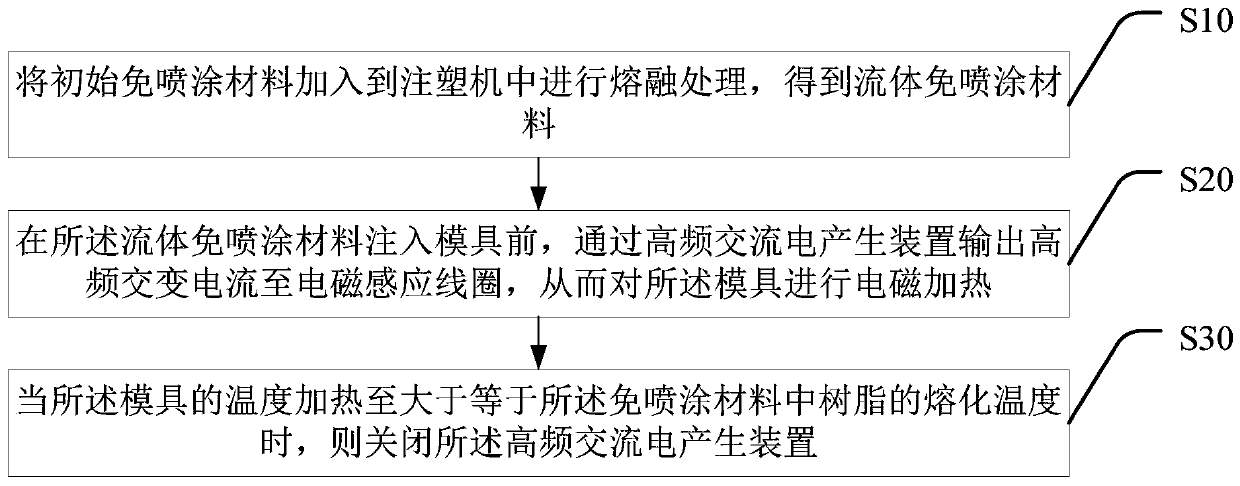

[0048] A method for eradicating flow marks and water inclusion marks in the processing and molding of spray-free materials based on the system, which includes the steps of:

[0049] Adding the initial spray-free material to the injection molding machine for melting treatment to obtain a fluid spray-free material;

[0050] Before the fluid spray-free material is injected into the mould, the high-frequency alternating current generating device outputs a 40kHZ high-frequency alternating current to the electromagnetic induction coil, thereby electromagnetically heating the mould, so that the mould is heated at 25°C / s Speed up the temperature, when the temperature of the mold is heated to be greater than or equal to the melting temperature of the resin in the spray-free material, then turn off the high-frequency alternating current generator, and then send a cooling command to the mold temperature machine, and the mold temperature machine according to The cooling instructions coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com