Refrigeration cycle apparatus

a technology of refrigeration cycle and apparatus, which is applied in the direction of mechanical apparatus, lighting and heating apparatus, refrigeration components, etc., can solve the problem that the refrigerant flowing through the circuit that bypasses the expander does not contribute to any improvement in system efficiency, so as to achieve the effect of improving the overall performance of the refrigeration cycle apparatus and avoiding the constant density ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

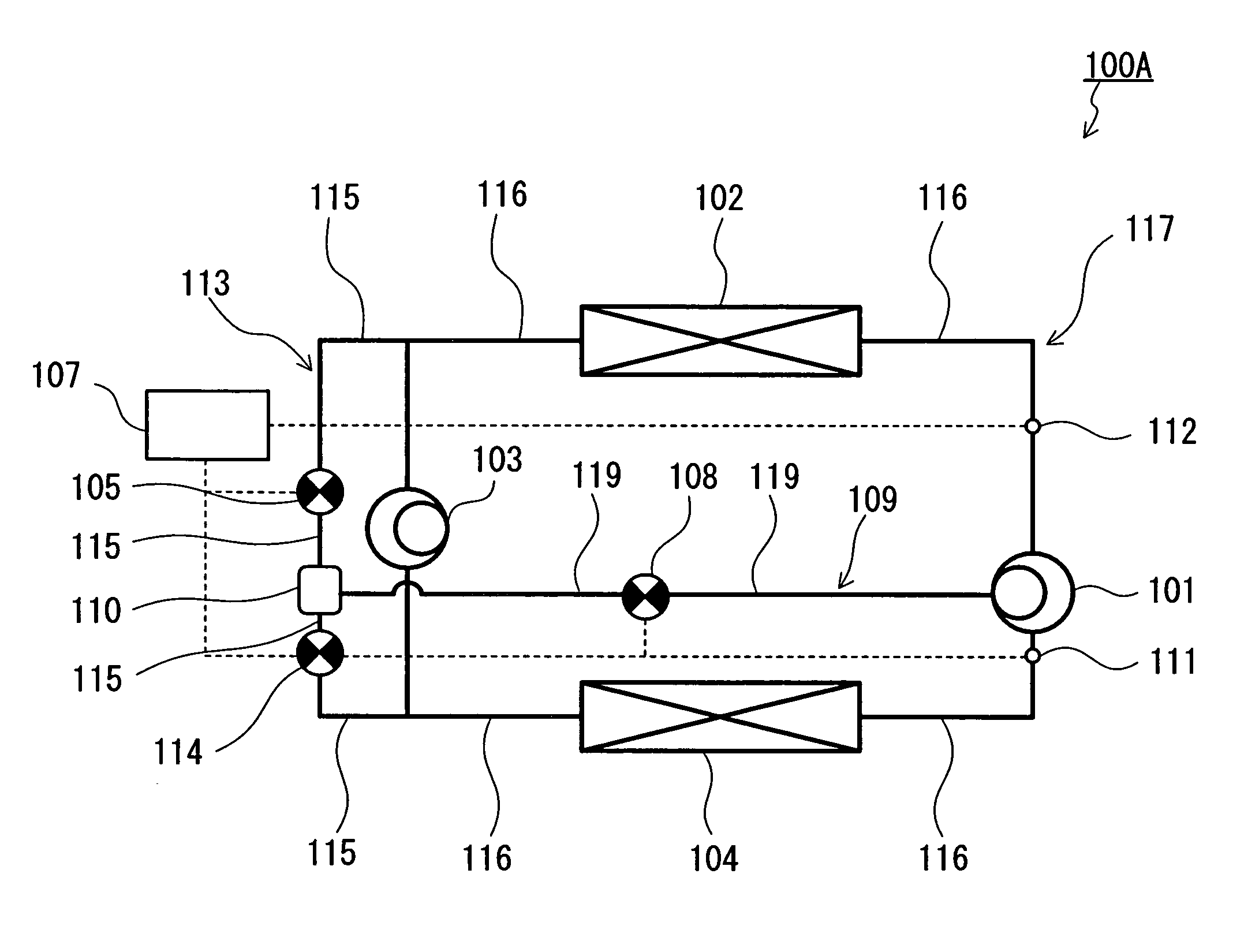

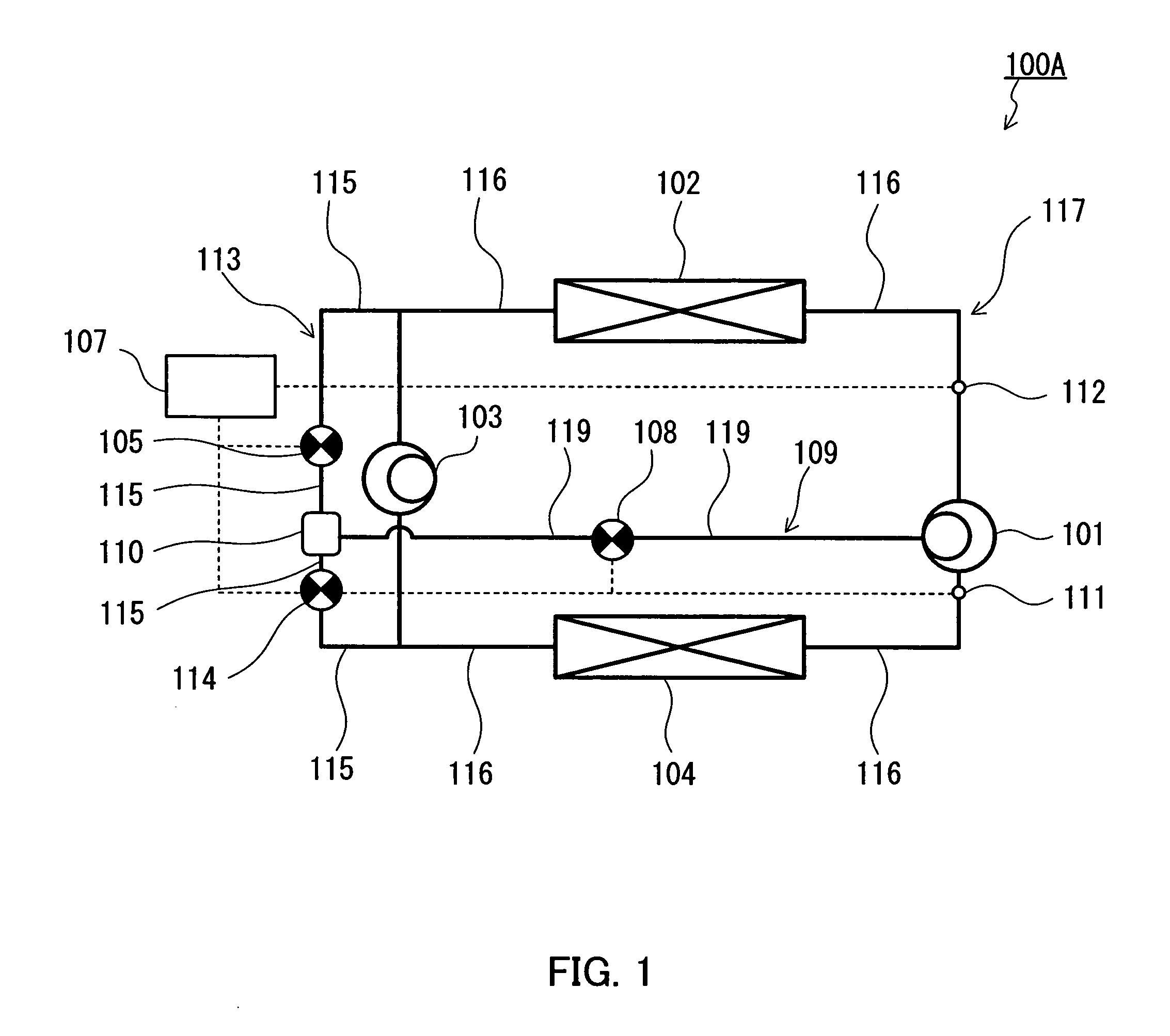

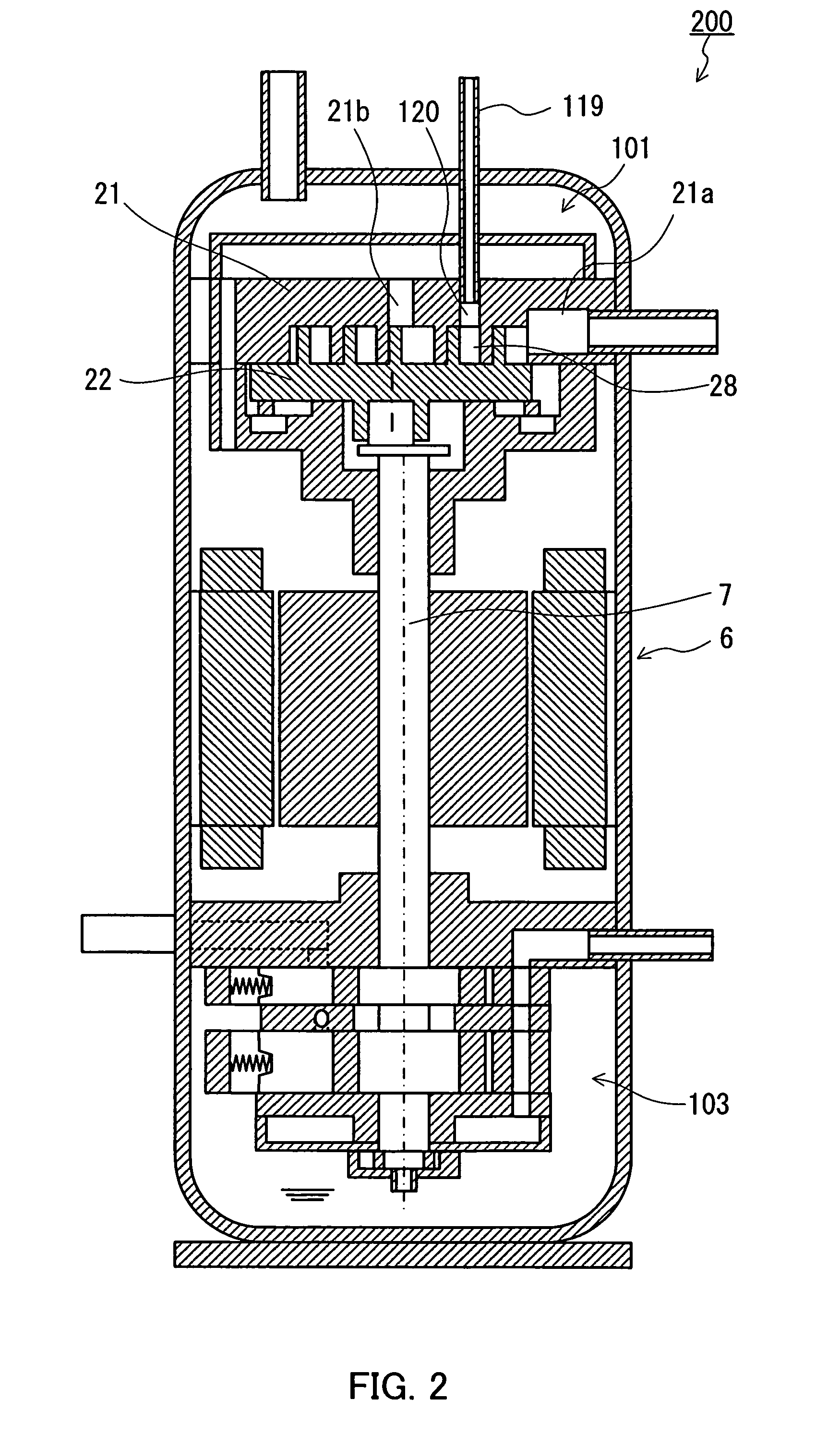

[0039]FIG. 1 is a configuration diagram illustrating a refrigeration cycle apparatus according to a first embodiment of the present invention. A refrigeration cycle apparatus 100A of the present embodiment is furnished with a compressor 101 for compressing a refrigerant such as hydrofluorocarbon or carbon dioxide, a radiator 102 for cooling the refrigerant compressed by the compressor 101, an expander 103 for decompressing and expanding the refrigerant cooled by the radiator 102 and recovering mechanical power from the refrigerant under expansion, an evaporator 104 for heating the refrigerant decompressed by the expander 103, and a plurality of main pipes 116 (main conduits) for connecting the compressor 101, the radiator 102, the expander 103, and the evaporator 104 in that order. The compressor 101, the radiator 102, the expander 103, the evaporator 104, and the main pipes 116 constitute a main circuit 117 through which the refrigerant circulates.

[0040] In the first embodiment, t...

second embodiment

[0064] The first embodiment has described the case in which the injection circuit 109 is connected directly to the compressor 101. By contrast, the refrigeration cycle apparatus according to the second embodiment differs from the first embodiment in that it has a plurality of compressors. It should be noted, however, that the advantageous effects achieved by the bypass circuit and the injection circuit are common between the second embodiment and the first embodiment.

[0065] As illustrated in FIG. 6, a refrigeration cycle apparatus 100B of the second embodiment is furnished with a low-pressure-side compressor 101A, and a high-pressure-side compressor 101B connected in series with the low-pressure-side compressor 101A via one of the main pipes 116. Specifically, a multi-stage compressor including the low-pressure-side compressor 101A and the high-pressure-side compressor 101B is employed as the compressor for compressing a refrigerant. In this case, the intermediate pressure portion ...

third embodiment

[0067]FIG. 7 illustrates a configuration diagram of a refrigeration cycle apparatus according to a third embodiment. A refrigeration cycle apparatus 100C shown in FIG. 7 differs from that of the first embodiment in that an injection circuit 109′ further includes an injector 123 provided downstream from the second flow rate control valve 108. In other respects, the present embodiment is similar to the first embodiment, and in the drawings, the same reference numerals designate the same components.

[0068] The injector 123 in the injection circuit 109′ is capable of switching between an open state that permits passage of the refrigerant (gas refrigerant) and a closed state that inhibits passage of the refrigerant, and it may be, for example, a solenoid valve controlled by the controller 107. Thus, the present embodiment makes it possible to control even the timing of injecting the gas refrigerant into the intermediate pressure portion of the compressor 101. For example, by controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com