Anchor cable made of continuous basalt fiber composite rib material

A technology of basalt fiber and composite bars, applied in sheet pile wall, excavation, construction, etc., can solve the problem of difficult removal of anchor cable and steel strand, and achieve the effect of light weight, good durability and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

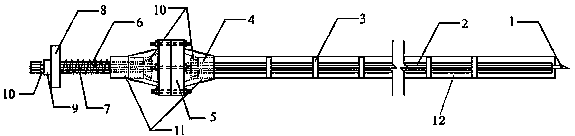

[0035] In this embodiment, a kind of anchor cable of continuous basalt fiber composite reinforcement is as follows: figure 1 As shown, the anchor cable of a continuous basalt fiber composite reinforcement provided in this embodiment is composed of a plurality of continuous basalt fiber composite tendons 2 and a plurality of positioning centering devices 3 . The positioning centering device 3 connects the continuous basalt fiber composite tendons 2 scattered around the grouting pipe 1 and the grouting pipe 1 into a whole.

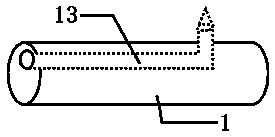

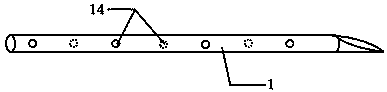

[0036] like figure 2 and image 3 As shown, the grouting pipe 1 of the anchor cable in this embodiment is evenly distributed on the pipe body of the anchor section with plum blossom-shaped grouting holes 1-1, and the head of the grouting pipe 1 to the flange 5 is embedded with a small-diameter anchoring grouting pipe 13 , the anchor slurry enters the inside of the flange 5 from the pipe to tightly connect the continuous basalt fiber composite tendon 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com