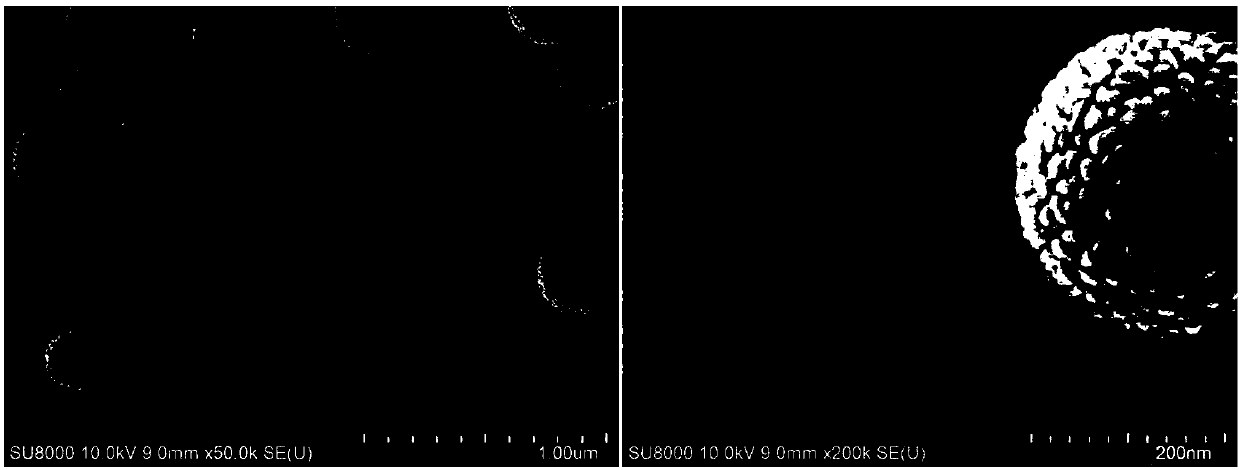

Hollow mesoporous carbon nanosphere immobilized enzyme and preparation method thereof

A technology of nano-carbon spheres and immobilized enzymes, which is applied in the direction of immobilization on or in the inorganic carrier, which can solve the problems that the enzyme is difficult to enter the hole, the enzyme is easy to leak, and the stability is not high enough to avoid friction and shearing force Effects of damage and leakage, improvement of immobilization capacity and stability, improvement of stability and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A hollow mesoporous nano-carbon sphere immobilized enzyme and a preparation method thereof, comprising the following steps:

[0036] 1) Silica / resorcinol-formaldehyde oligomer (SiO 2 Preparation of @RF): Disperse 96mmol (27.68mL) of tetrapropoxysilane into 640mL of ethanol / water reaction solvent with a volume ratio of 7:1, add 24mL, 25%-28% concentrated ammonia water as a catalyst, and stir for 20min , then add 3.2g resorcinol and 4.48mL formaldehyde, stir and react at 25°C for 24h, after the reaction, wash with distilled water and ethanol three times in turn, and dry at 50°C to obtain silica / resorcinol-formaldehyde oligomerization matter (SiO 2 @RF);

[0037] 2) Silicon dioxide / carbon (SiO 2 @C) Preparation of the composite: SiO obtained after drying 2 @RF was placed in a tube furnace, with high-purity nitrogen as a protective gas, raised from room temperature to 600 °C at a rate of 5 °C / min, and calcined at 600 °C for 5 h to obtain a silica / carbon composite ( SiO...

Embodiment 2

[0043] A hollow mesoporous nano-carbon sphere immobilized enzyme and a preparation method thereof, comprising the following steps:

[0044] 1) Silica / resorcinol-formaldehyde oligomer (SiO 2 Preparation of @RF): Disperse 96 mmol (21.00 mL) of tetraethoxysilane into 640 mL of ethanol / water reaction solvent with a volume ratio of 2:1, add 20 mL of 25% to 28% concentrated ammonia as a catalyst, and stir for 20 min , then add 3.2g resorcinol and 4.48mL formaldehyde, stir and react at 25°C for 24h, after the reaction, wash with distilled water and ethanol three times in turn, and dry at 50°C to obtain silica / resorcinol-formaldehyde oligomerization matter (SiO 2 @RF);

[0045] 2) Silicon dioxide / carbon (SiO 2 @C) Preparation: SiO obtained after drying 2 @RF was placed in a tube furnace, with high-purity nitrogen as a protective gas, raised from room temperature to 800 °C at a rate of 5 °C / min, and calcined at 800 °C for 5 h to obtain a silica / carbon composite ( SiO 2 @C);

[0...

Embodiment 3

[0050] A hollow mesoporous nano-carbon sphere immobilized enzyme and a preparation method thereof, comprising the following steps:

[0051] 1) Silica / resorcinol-formaldehyde oligomer (SiO 2 Preparation of @RF): Disperse 24mmol (5.25mL) of tetraethoxysilane and 72mmol (20.76mL) of tetrapropoxysilane into 640mL of ethanol / water reaction solvent with a volume ratio of 3:1, add 32mL, 25% to 28% concentrated ammonia water was used as a catalyst, stirred for 20 minutes, then added 3.2g resorcinol and 4.48mL formaldehyde, stirred and reacted at 25°C for 24h, after the reaction was completed, washed three times with distilled water and ethanol in sequence, and dried at 50°C to obtain Silica / resorcinol-formaldehyde oligomer (SiO 2 @RF);

[0052] 2) Silicon dioxide / carbon (SiO 2 @C) Preparation: SiO obtained after drying 2 @RF was placed in a tube furnace, with high-purity nitrogen as a protective gas, raised from room temperature to 700 °C at a rate of 5 °C / min, and calcined at 700...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com