Viscous, elastic and anti-buckling brace combined damper

An anti-buckling support and composite damping technology, which is applied in the direction of earthquake resistance, building components, building types, etc., can solve the problems of unsatisfactory low-cycle fatigue performance, large strain of steel core elements, and reduced cycle times, so as to prevent shear damage, Good energy consumption capacity, the effect of improving the dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

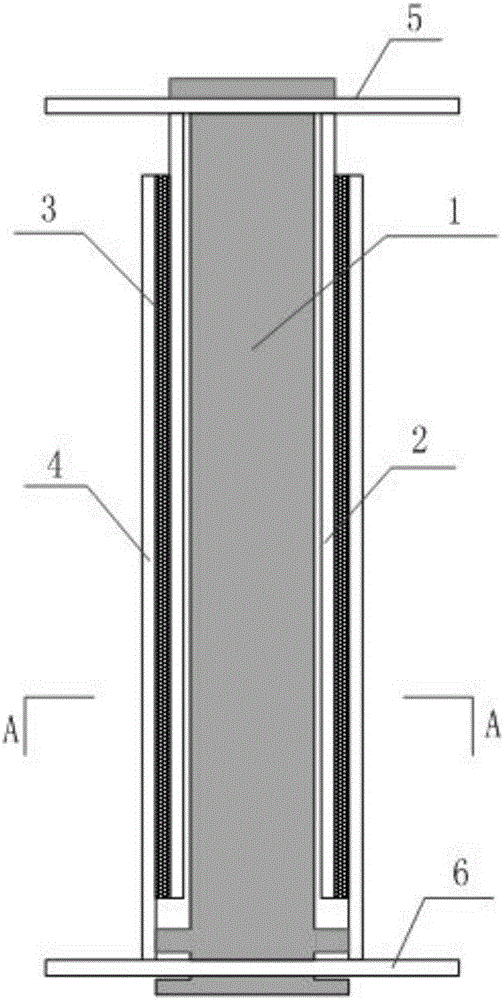

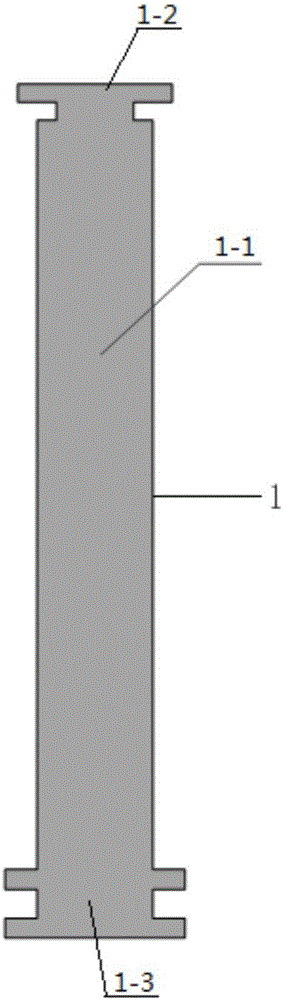

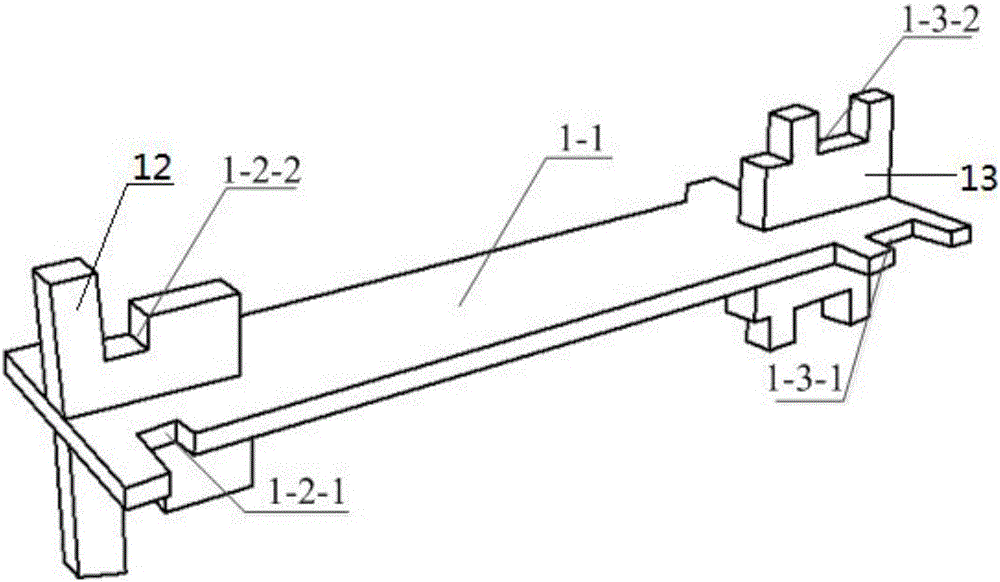

[0021] The viscoelasticity-buckling-resistant support composite damper of the present invention comprises a steel plate 1 arranged at the center, an annular inner steel cylinder 2 sleeved outside the steel plate 1, and an annular outer sleeve sleeved outside the annular inner steel cylinder 2 from inside to outside. The steel cylinder 4, the annular inner steel cylinder 2 and the annular outer steel cylinder 4 are filled with a viscoelastic material layer 3, and the annular inner steel cylinder 2, the viscoelastic material layer 3 and the annular outer steel cylinder 4 are connected by high temperature and high pressure vulcanization; The inventive viscoelasticity-bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com