Split mounting type prefabricated reinforced concrete construction temporary road

A reinforced concrete and temporary road technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of heavy traffic vehicles, unfavorable green construction, concrete crushing, etc., to reduce construction waste, improve the level of civilized construction, and avoid easy damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

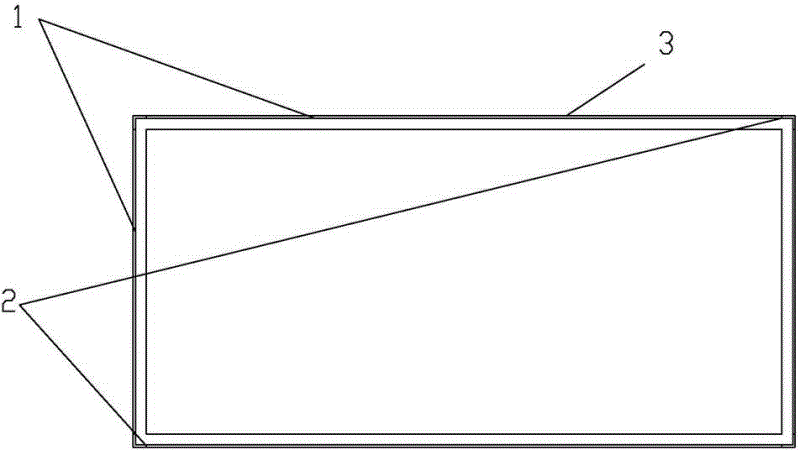

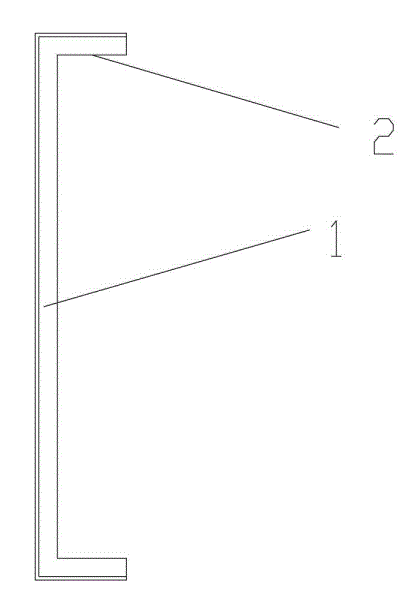

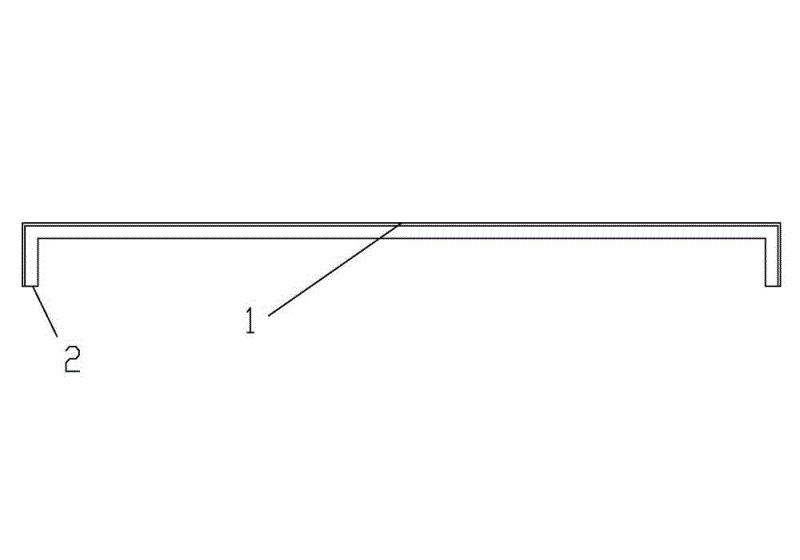

[0025] Such as Figure 1 to Figure 3 As shown, according to the size of the temporary road at the construction site, the rectangular member 1 is welded with angle steel, and the same angle steel as the rectangular member 1 is used to weld the legs 2 of the rectangular member at the four corners of the lower end of the rectangular member 1 to form an assembled prefabricated reinforced concrete construction temporary road Box member 3.

[0026] Such as Figure 4 to Figure 6 As shown, the box-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com