Rapid precipitation construction method for anti-floating anchor rod

A technology of anti-floating anchor rods and construction methods, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of waste of artificial materials, reduction of bearing capacity, and delay in construction period, so as to save the cost of forming holes, reduce disturbance, The effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

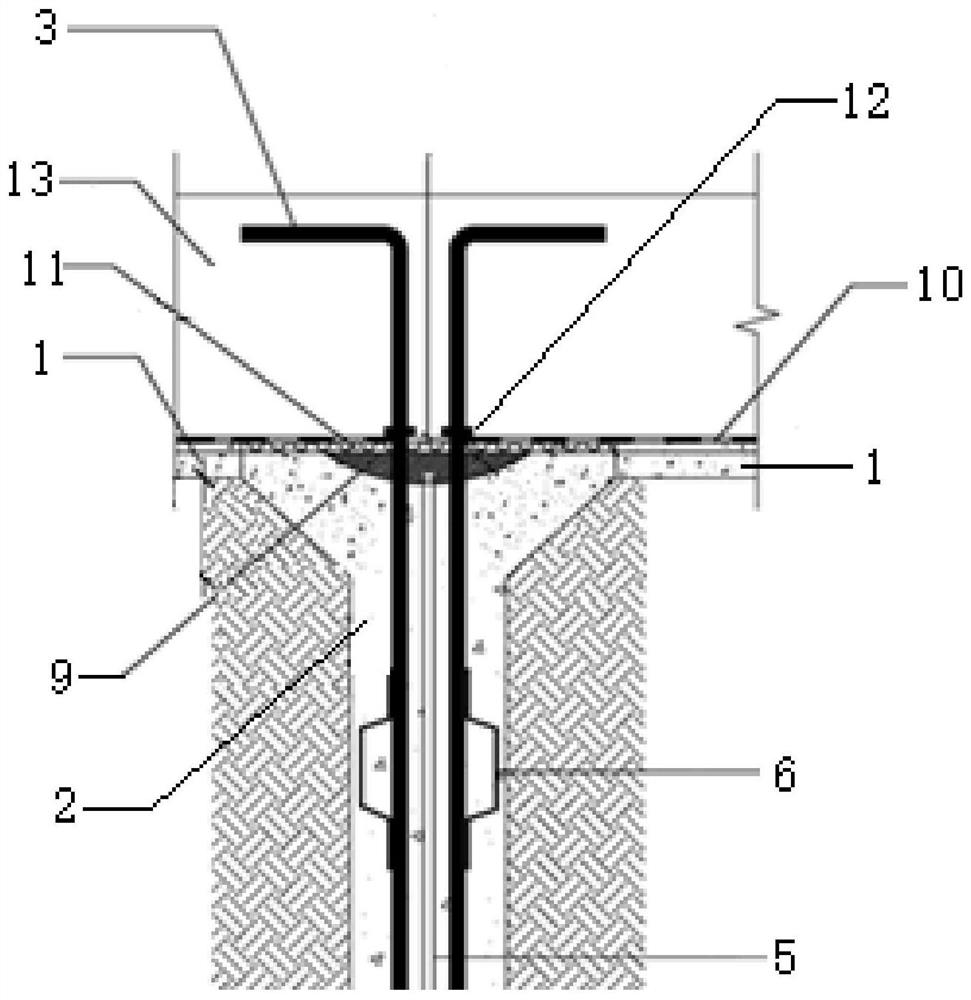

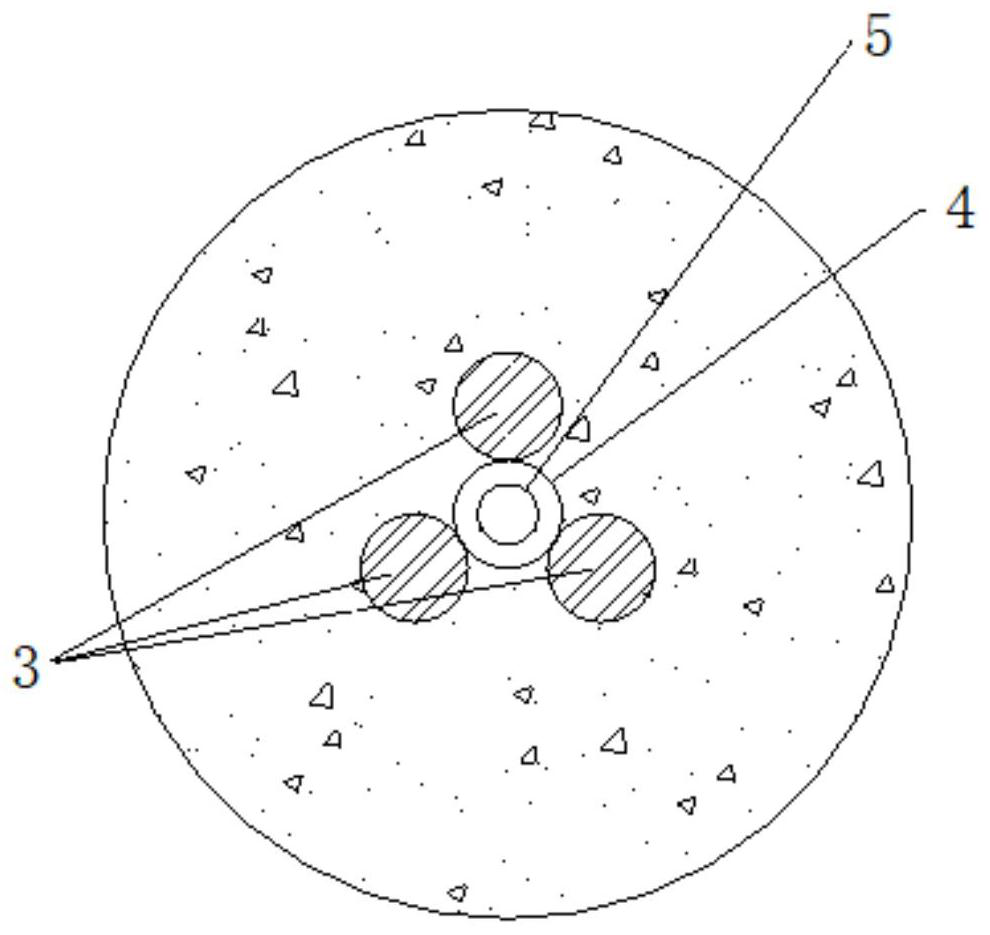

[0030] Such as Figure 1-6 As shown, a rapid dewatering construction method for anti-floating bolts, this construction method is applied to sandy mudstone rich in underground fissure water, and the underground fissure water and replenishment water in sandy mudstone are ground seepage water and underground stock water with fracture development , which has the characteristics of small water supply and scattered water sources. The main steps are as follows:

[0031] Step 1. When the earthwork is excavated to a design elevation of 300mm or more, manually pick up the bottom to 100mm below the design elevation.

[0032] Step 2: Concrete is used to pour the cushion layer 1; excavation and hardening of the sump are carried out.

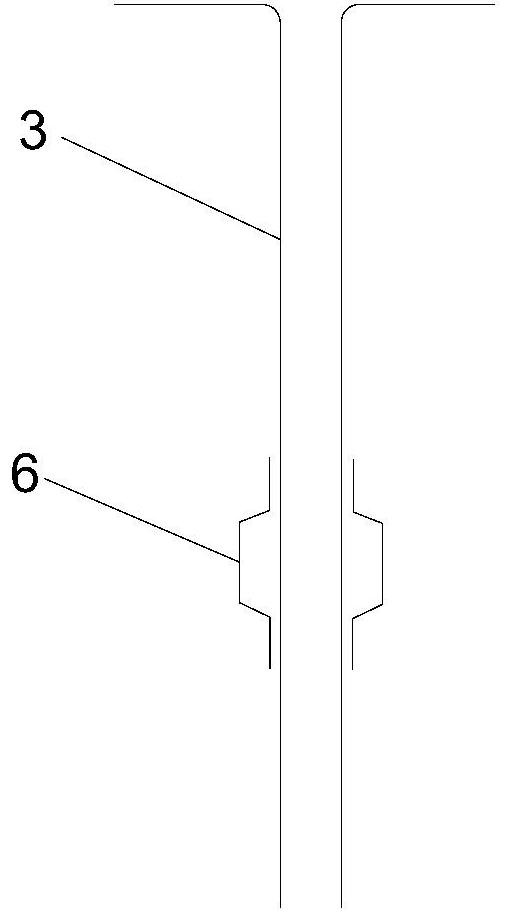

[0033] Step 3: Carry out the construction of the anchor hole 2 of the anti-floating anchor rod. When there is serious water gushing at the construction site of the anchor hole 2, first construct the anchor hole 2 around the place, and make a record of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com