Construction method for assembling integral ring beam, lintel, waist beam and constructional column

A construction method and technology for constructing columns, which are applied in building structures, truss structures, columns, etc., can solve the problems of hazardous concrete waste, vibration leakage, honeycomb, pockmarked surfaces, voids, and prolonged construction period, and achieve the benefits of The effect of environmental protection and green construction, saving woodworking labor, and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

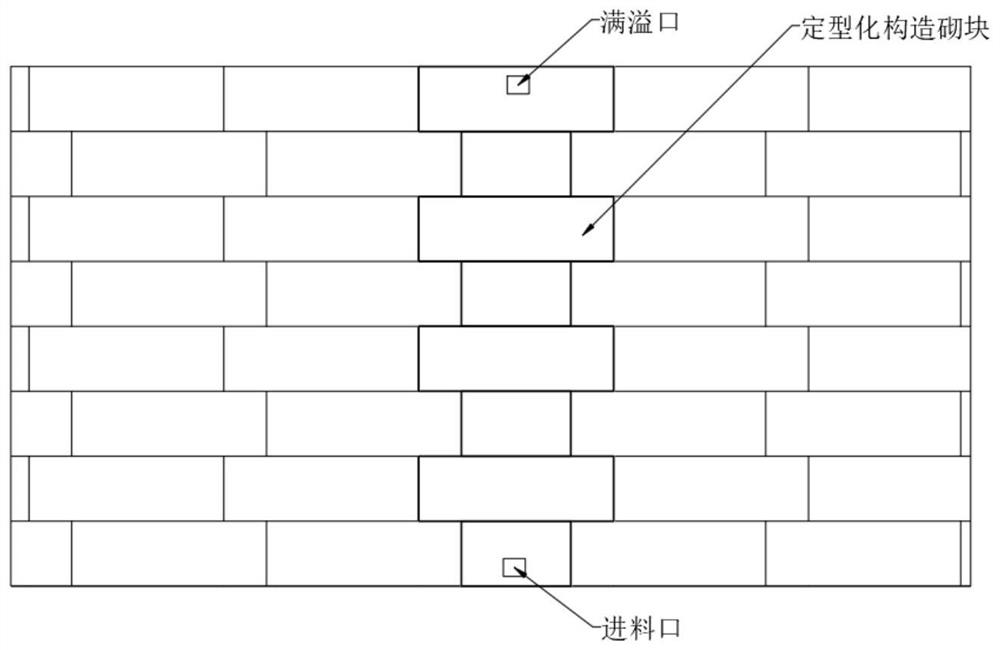

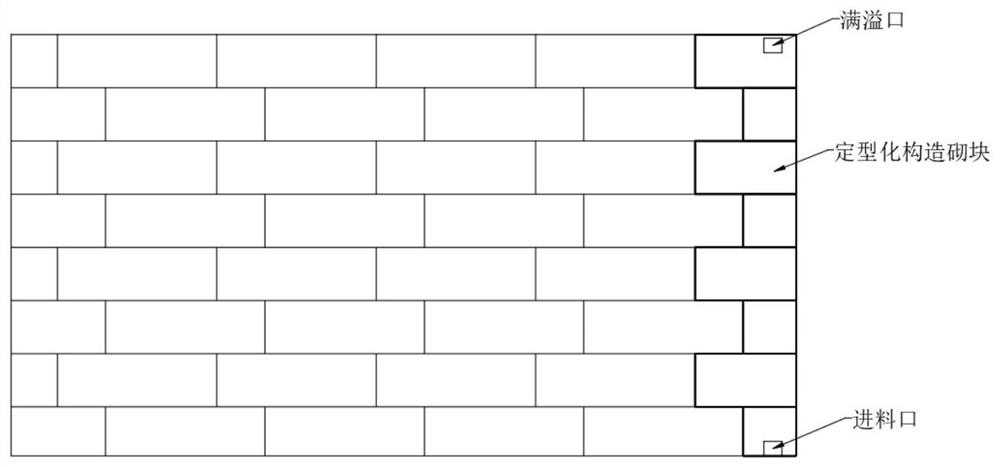

[0042] refer to Figure 1-2 , a construction method for assembling integral ring beams, lintels, waist beams, and structural columns, comprising the following steps:

[0043] S1, select the finalized structural blocks that match the blocks used in the wall engineering of ring beams, lintels, waist beams, and structural columns;

[0044] S2, the finalized structural blocks matched with the ring beam adopt a C-shaped cross-section, the finalized structural blocks are multiple spliced and the walls are matched, and the finalized structural blocks open upward;

[0045] The finalized structural blocks matched with the lintel adopt a C-shaped cross-section, the finalize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com