Aerial operation clamp library access device for white vehicle body welding

A body-in-white and fixture technology, which is applied in the field of entry and exit devices for the fixture warehouse in the air, can solve the problems of difficulty in increasing the operating precision of the mechanism, safety hazards, ineffective stability of the guide column mechanism, and high requirements for the height of the workshop, so as to improve the overall stability. and control accuracy, reasonable layout of welding equipment, and the effect of improving welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

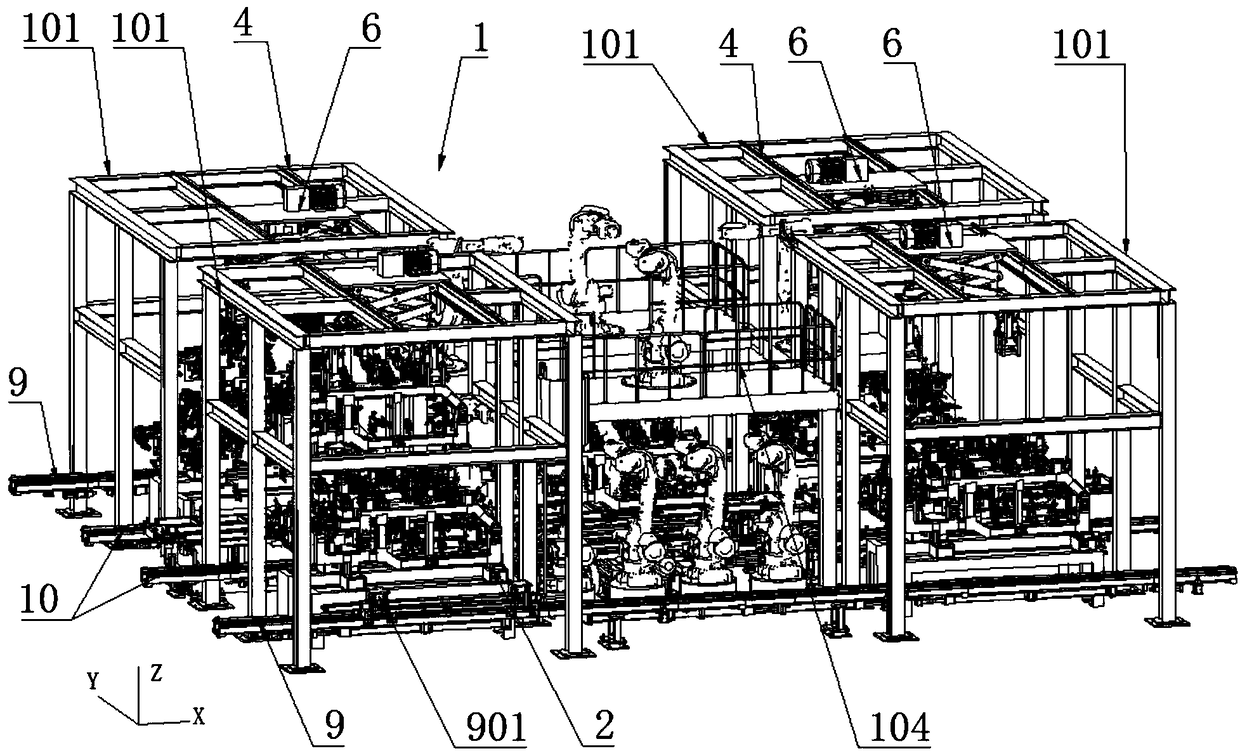

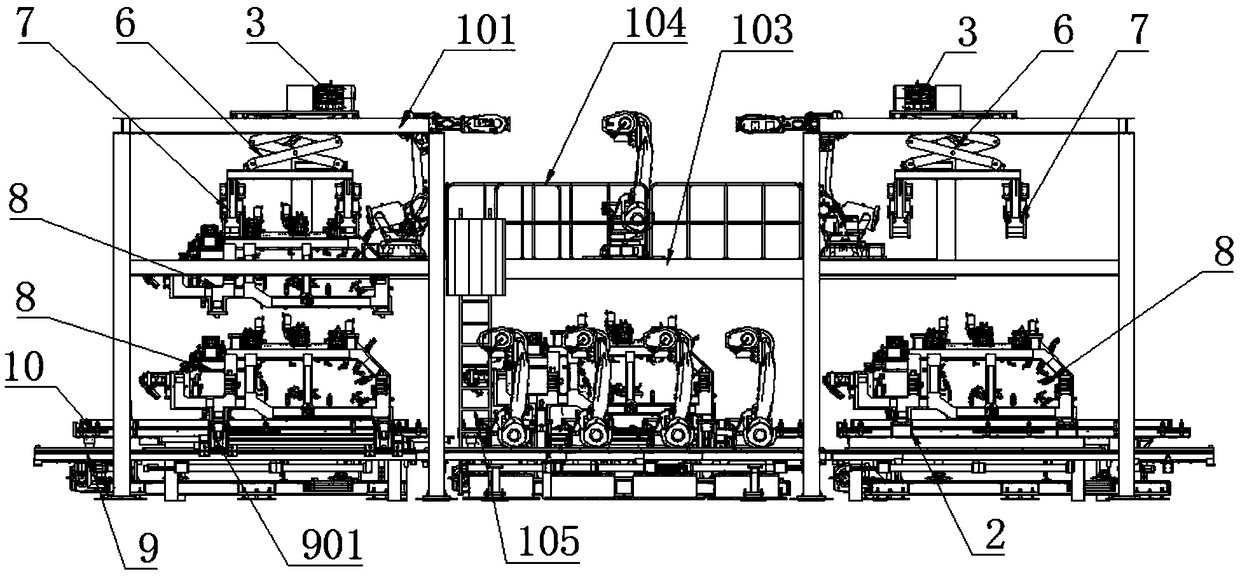

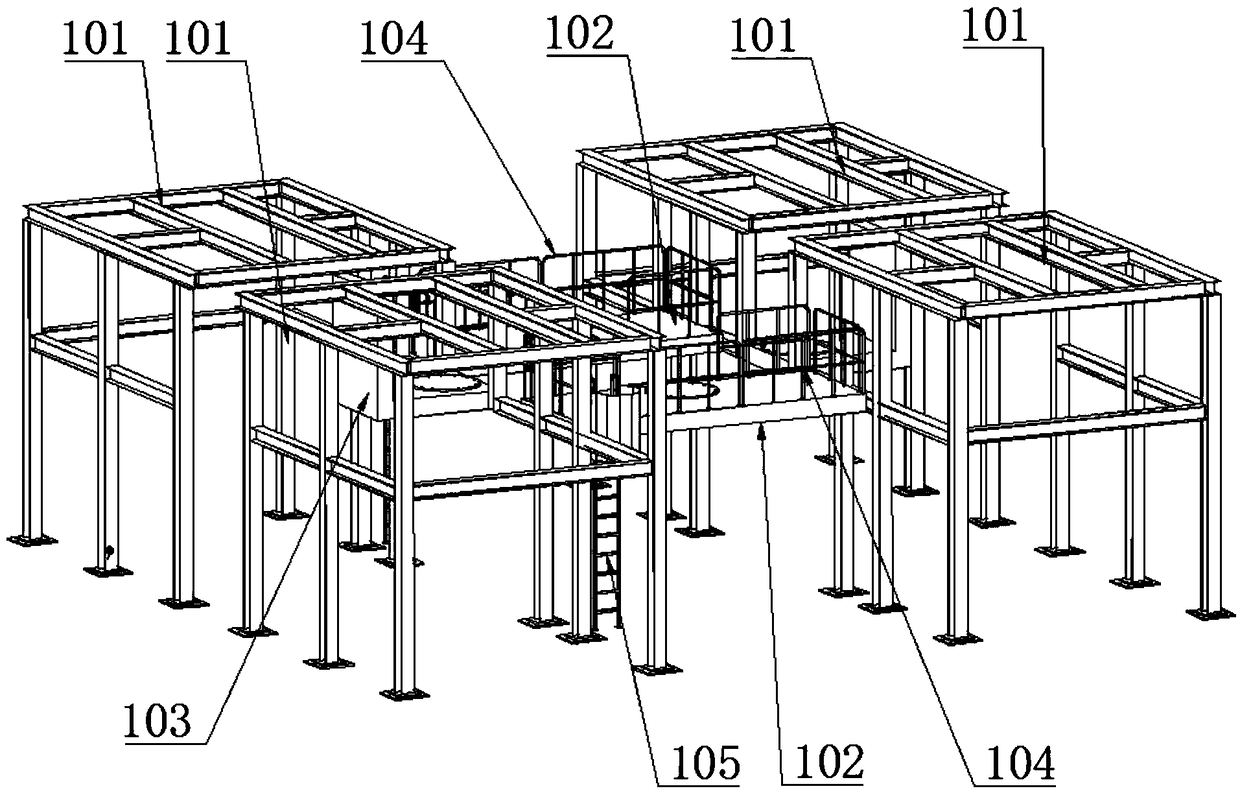

[0026] The specific embodiment of the present invention is like this: as Figure 1-6 As shown, the horizontal direction in the figure is the X direction, and the longitudinal direction is the Y direction (as attached figure 1 shown in the three-dimensional coordinates at the lower left corner of ), an air-operated fixture library access device for body-in-white welding, including a welding platform 1 composed of a plurality of uniformly arranged support frames 101 and a The lower X-direction vehicle body conveying track 10, fixture positioning seat 2 and X-direction fixture conveying track 9, the X-direction vehicle body conveying track 10 is located in the middle, used for transporting the vehicle body, and the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com