Welding clamp

A technology of welding jigs and clamping rods, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unfavorable economic benefits for manufacturers, waste of resources and money, and occupying extra space, etc., and achieve good application prospects, The effect of reducing manpower and material resources and increasing welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

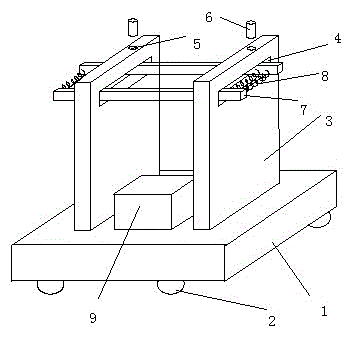

[0016] Such as figure 1 As shown, a welding fixture includes a base 1, preferably the base 1 is square, its structure is simple and easy to manufacture, and the surface is smooth and stable, and the lower part of the base 1 is provided with several universal wheels 2 with brakes , the universal wheel 2 is set to facilitate the movement of the welding fixture as a whole, and is equipped with a brake at the same time, which can be positioned and fixed in time without affecting the welding effect. Around the side, the movement is stable, ensuring the safety of the welding fixture. In detail, the base 1 is provided with a pair of symmetrically arranged support plates 3, and the support plate 3 is provided with a perforation 4 arranged along the width direction of the support plate 3 and a clamping assembly passing through the two perforations 4 , the two ends of the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com