Patents

Literature

43results about How to "Limit up and down movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

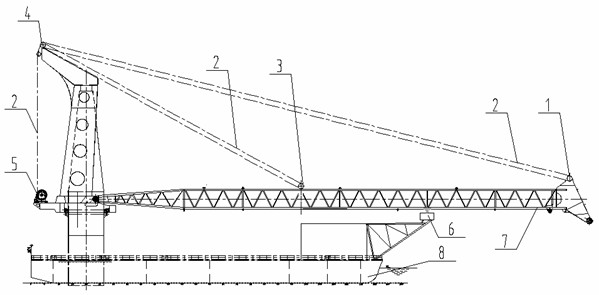

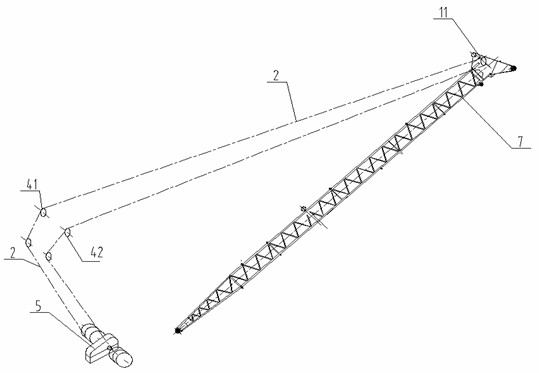

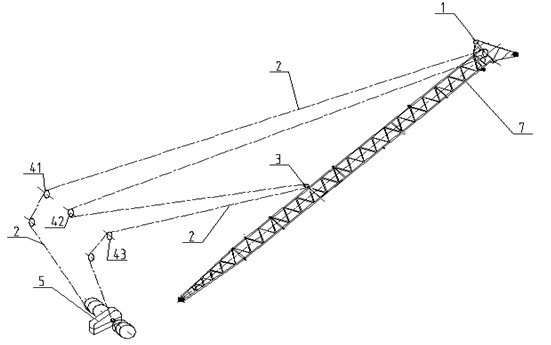

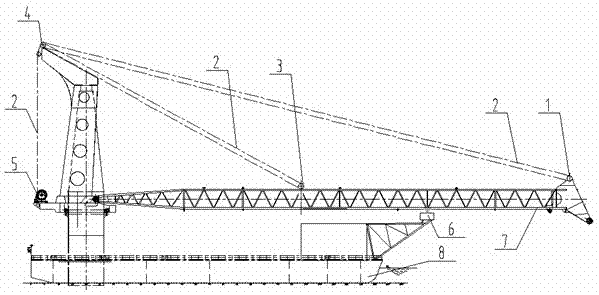

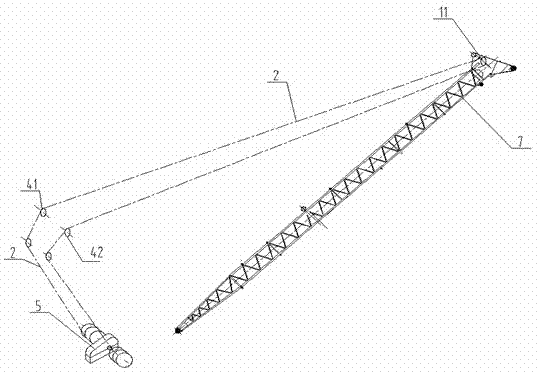

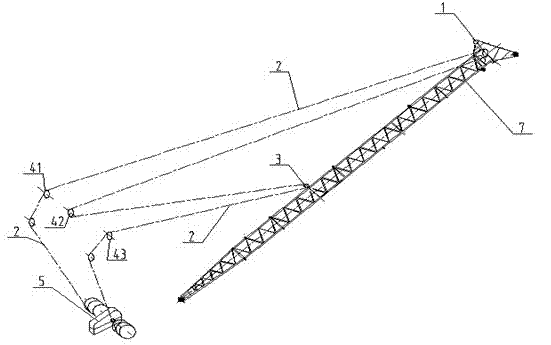

Pretension and lay-off method and device of crane jib for ship

InactiveCN101983894AReduce supportAvoid fatigue damageCargo handling apparatusPassenger handling apparatusEngineeringWinch

The invention relates to a pretension and lay-off method of a crane jib for a ship, belonging to the technical field of a crane. The crane comprises a luffing mechanism composed of a top pulley block, a jib, a winch, a luffing wire rope and a jib head pulley block and a bracket. The method comprises the following steps: A. operating the winch in the forward direction, loosening the jib and layingoff the jib onto the bracket; and B, operating the winch in the reverse direction, pulling the jib upwards to enable the pressure of the jib on the bracket to be less than the pressure on the bracketbefore being subjected to the upward pull, and stopping and shutting off the winch. The invention also relates to a pretension and lay-off device of a crane jib for a ship. The luffing mechanism alsocomprises a middle pulley arranged at the middle of the jib, and the luffing wire rope is connected with the jib head pulley block and the middle pulley through the top pulley block. The pretension and lay-off method and device of a crane jib for a ship can produce a pretension force on the jib by means of the luffing wire rope, thereby reducing the self-weight load of the jib as well as the influence and the destruction on the jib structure as a result of the shock load and the changing load of the bracket on the jib. Besides, the invention has the advantages of simple method and structure, convenient operation and low cost.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

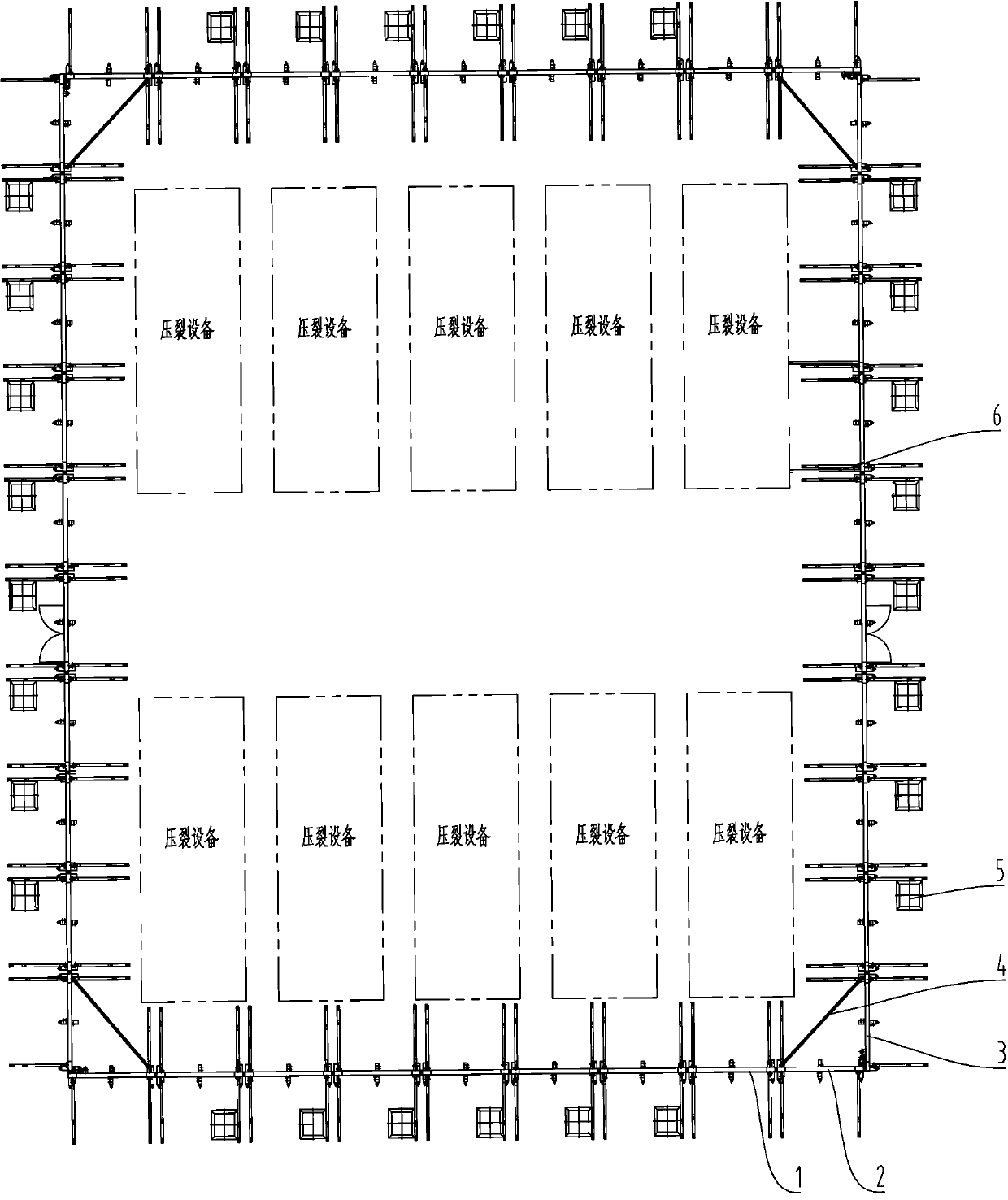

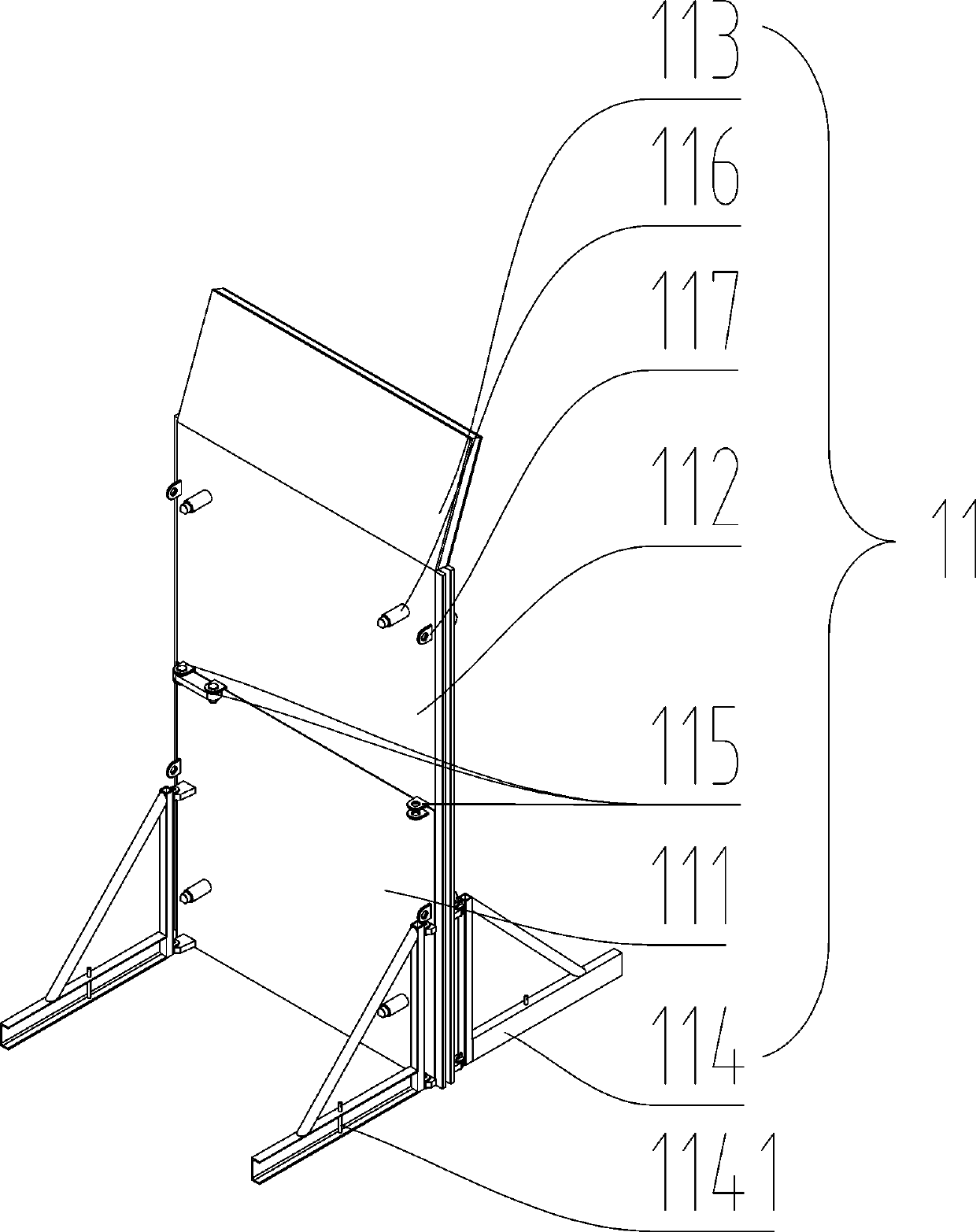

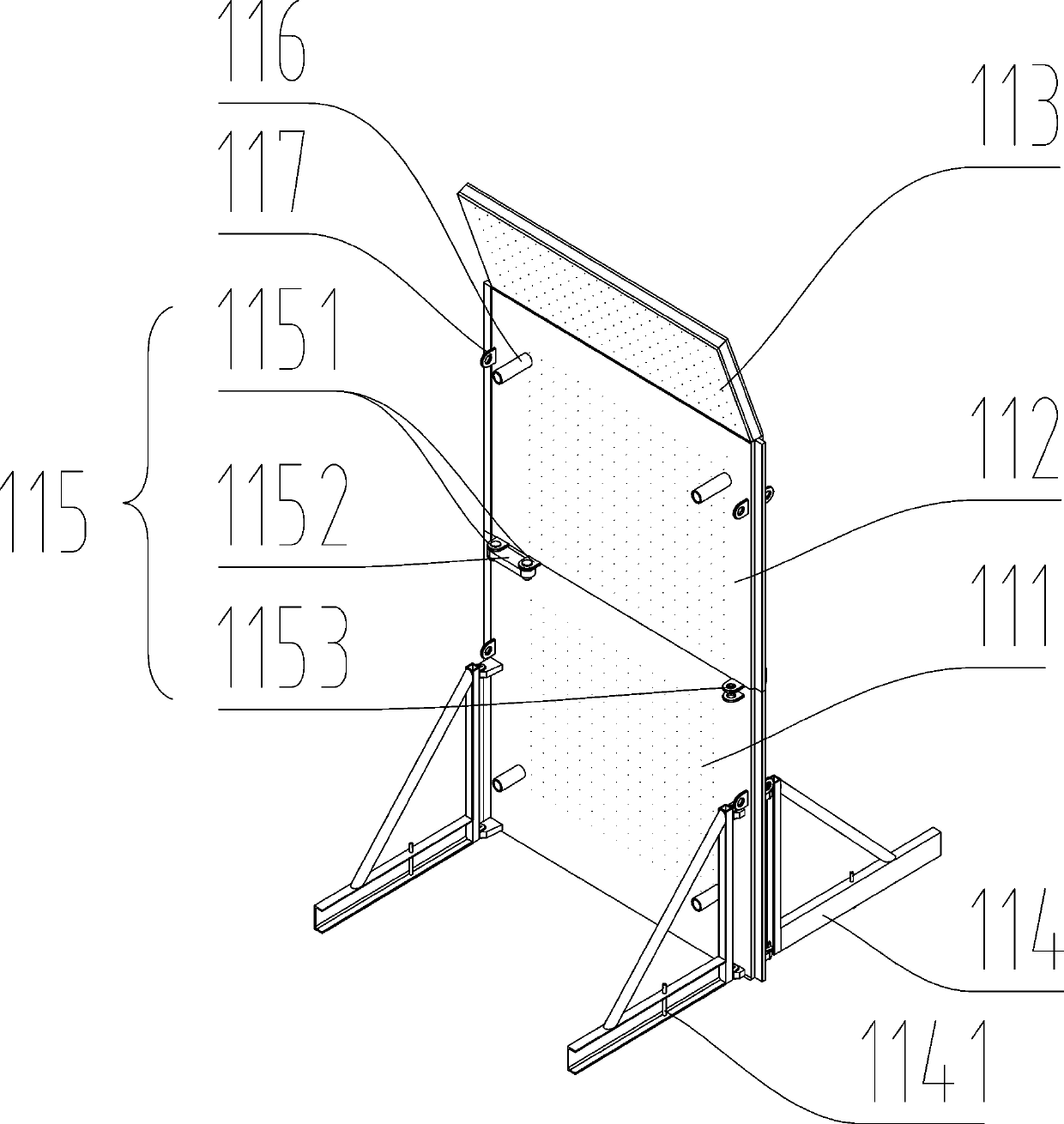

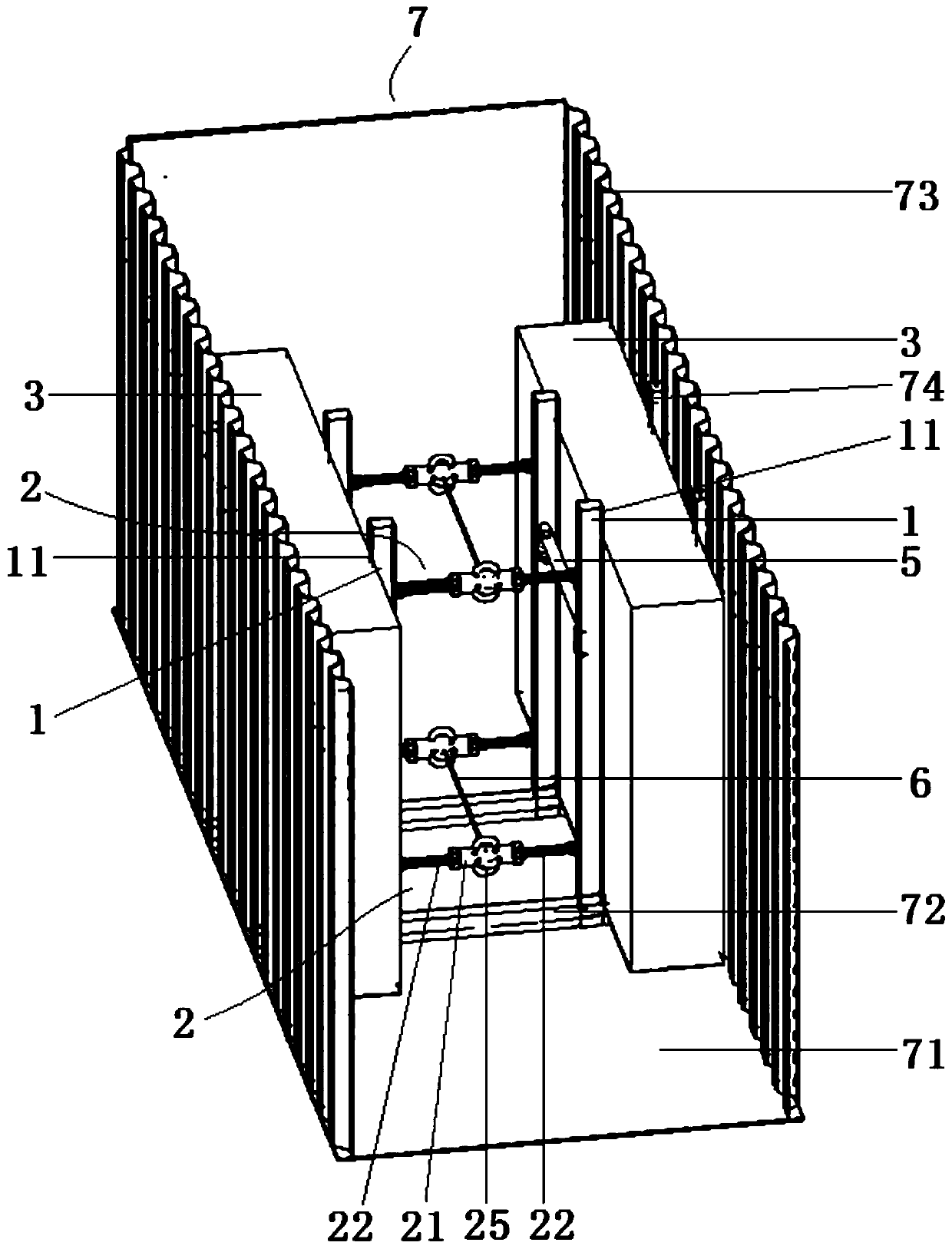

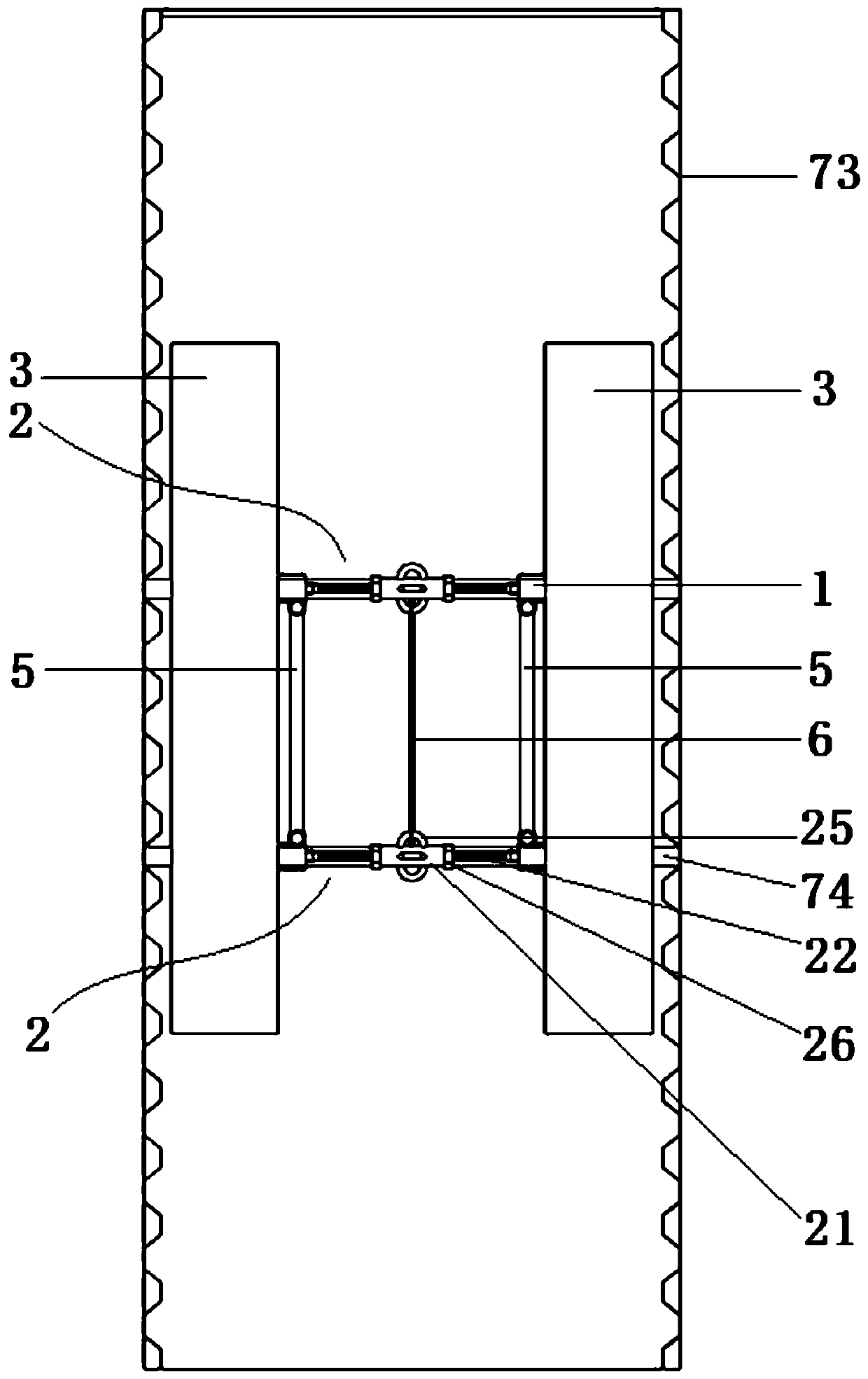

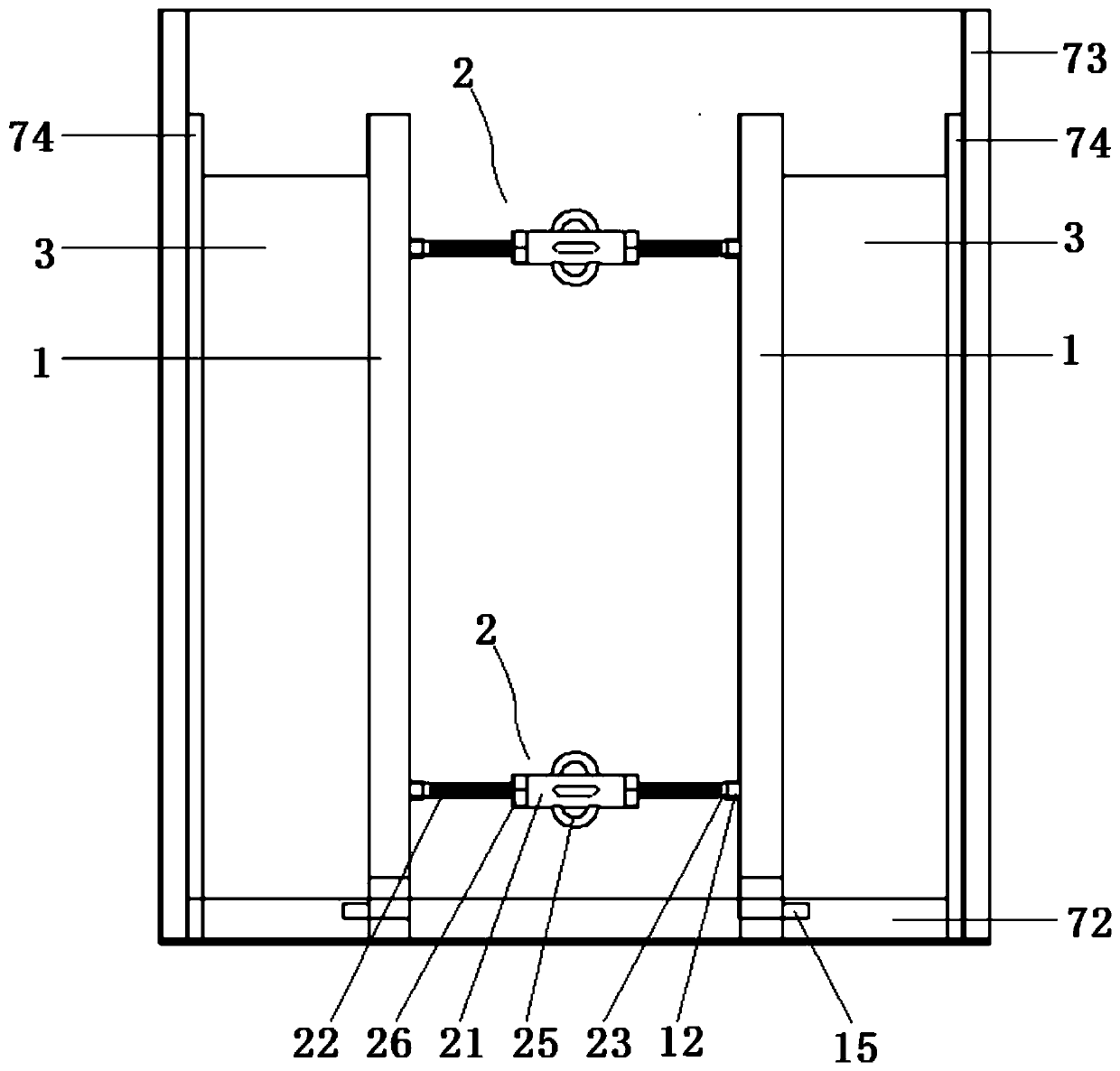

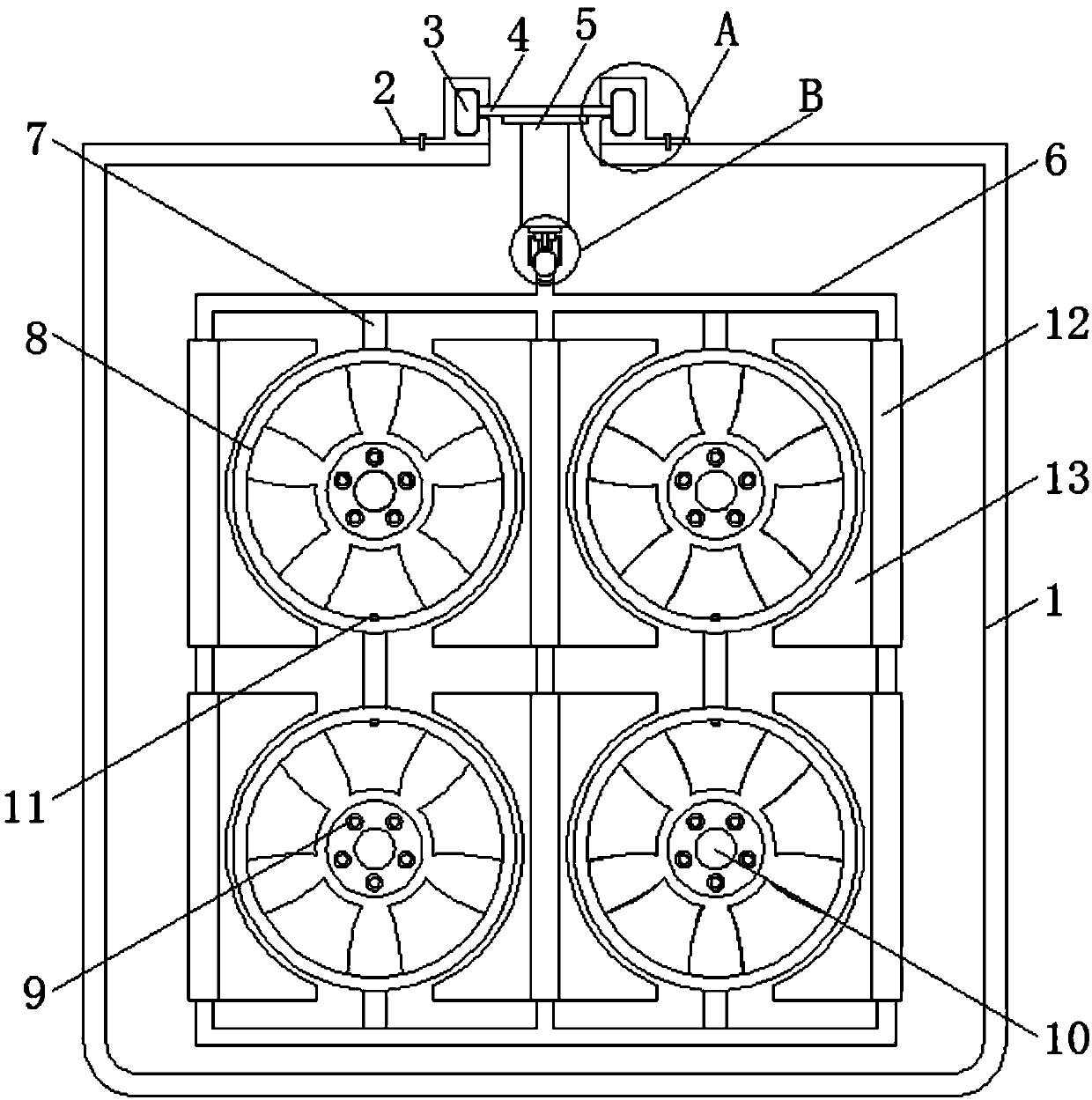

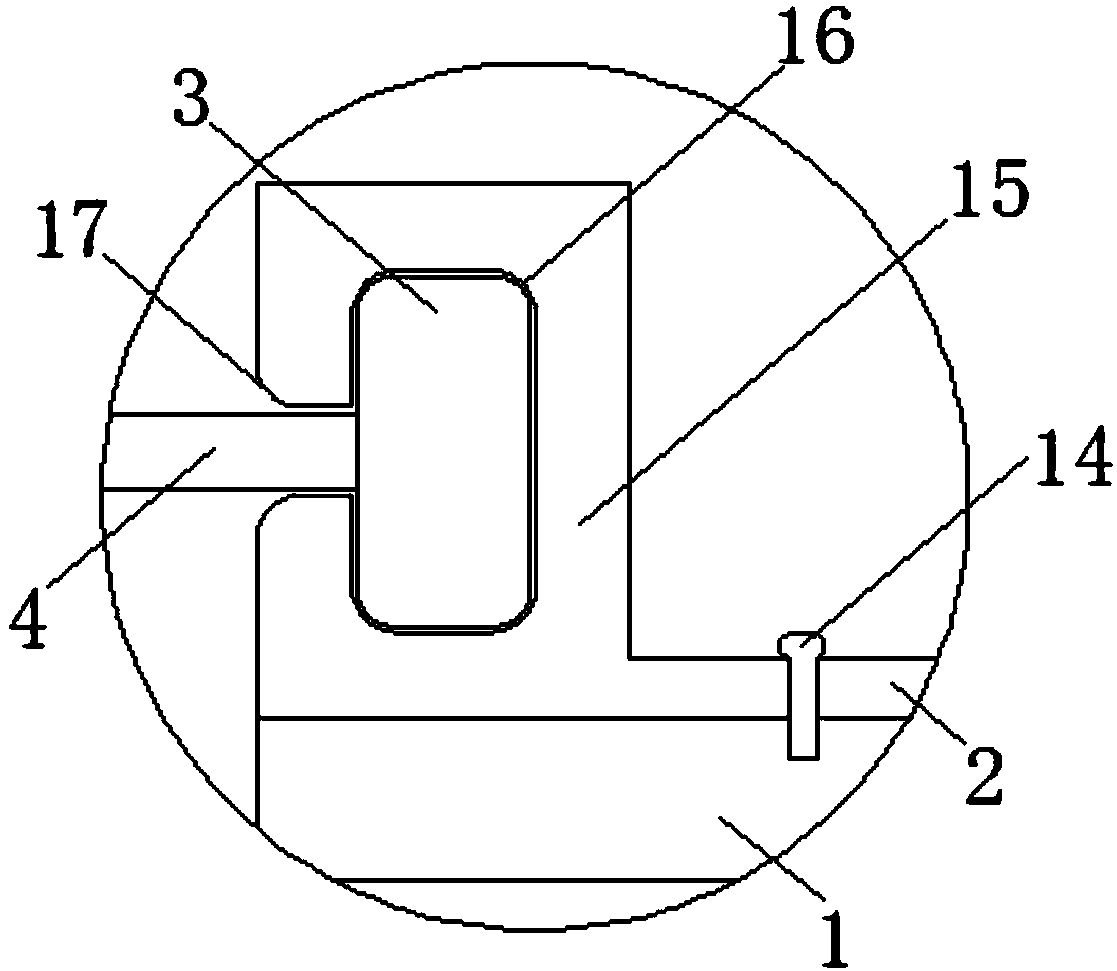

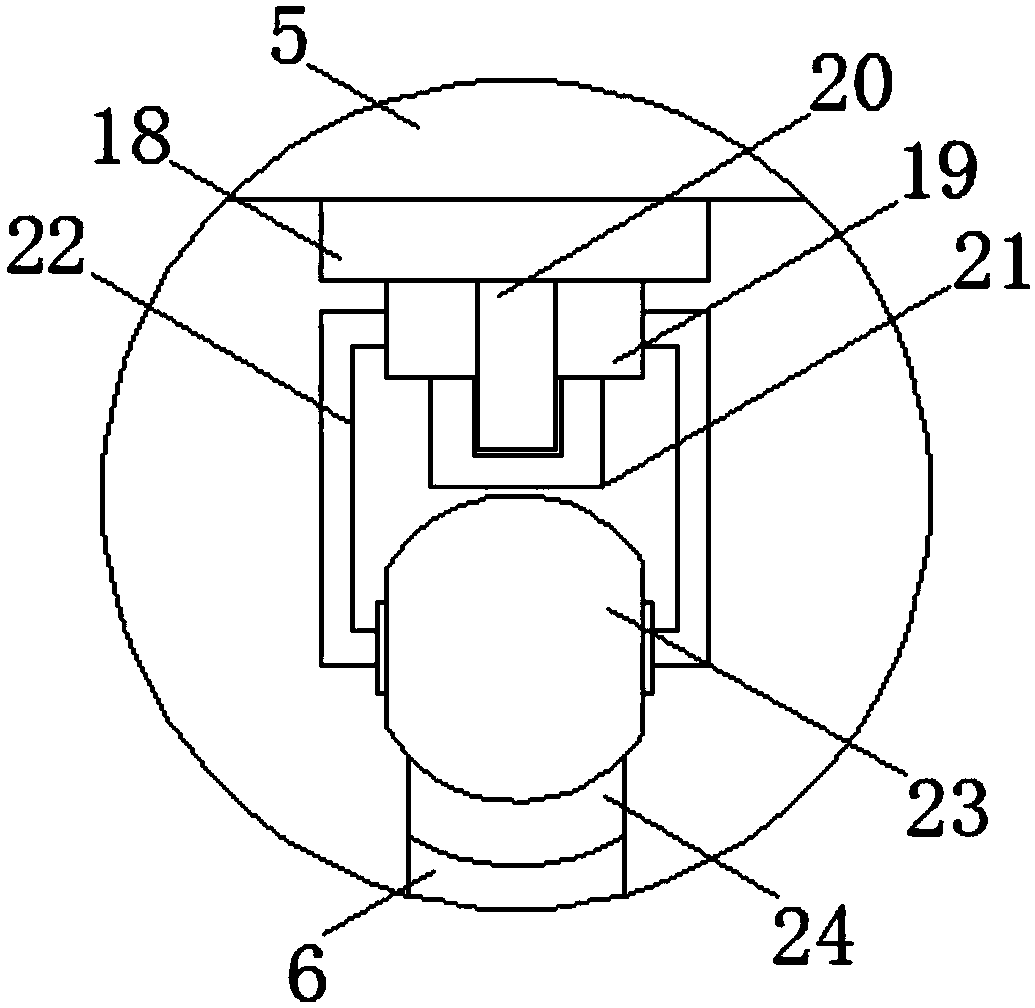

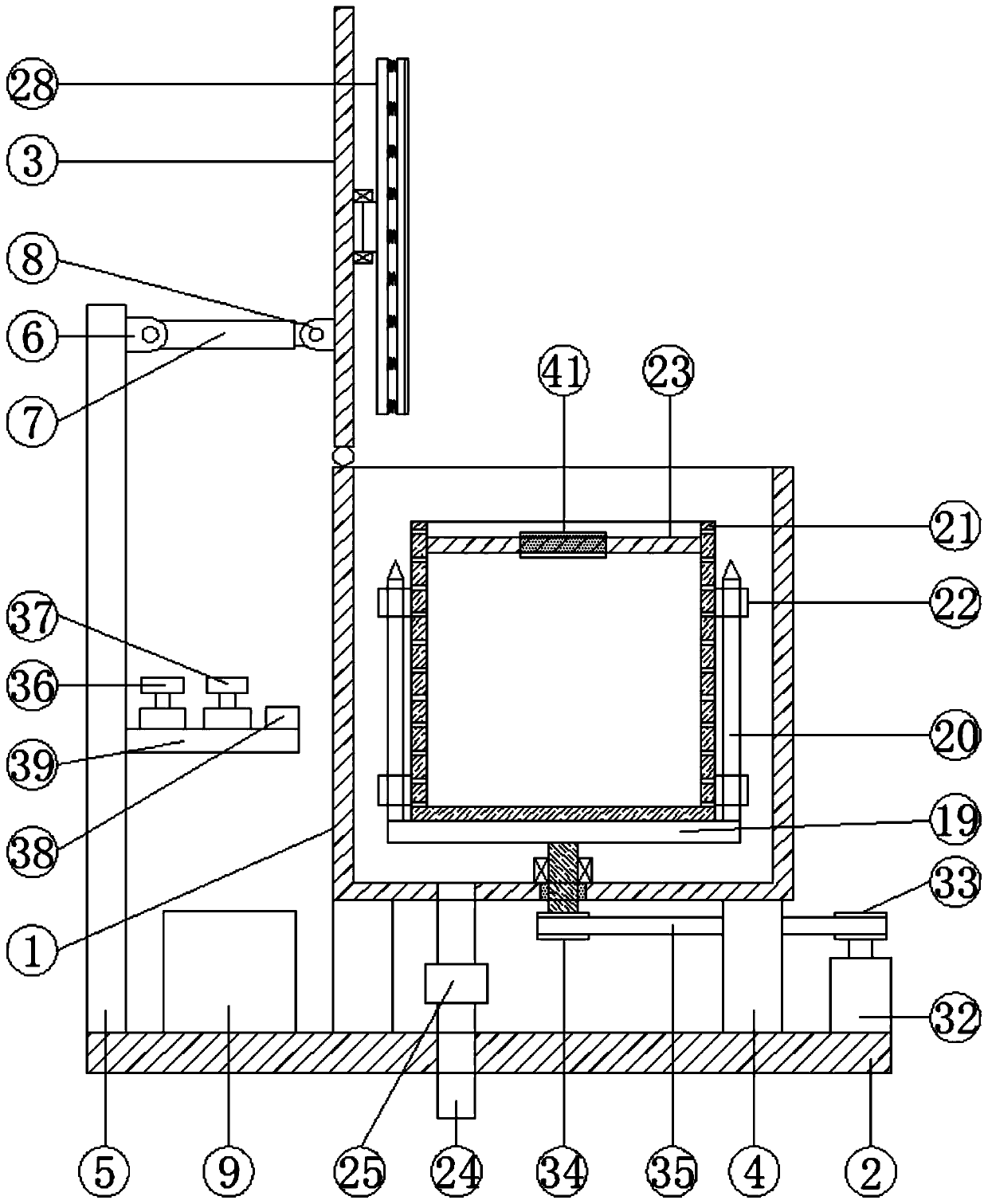

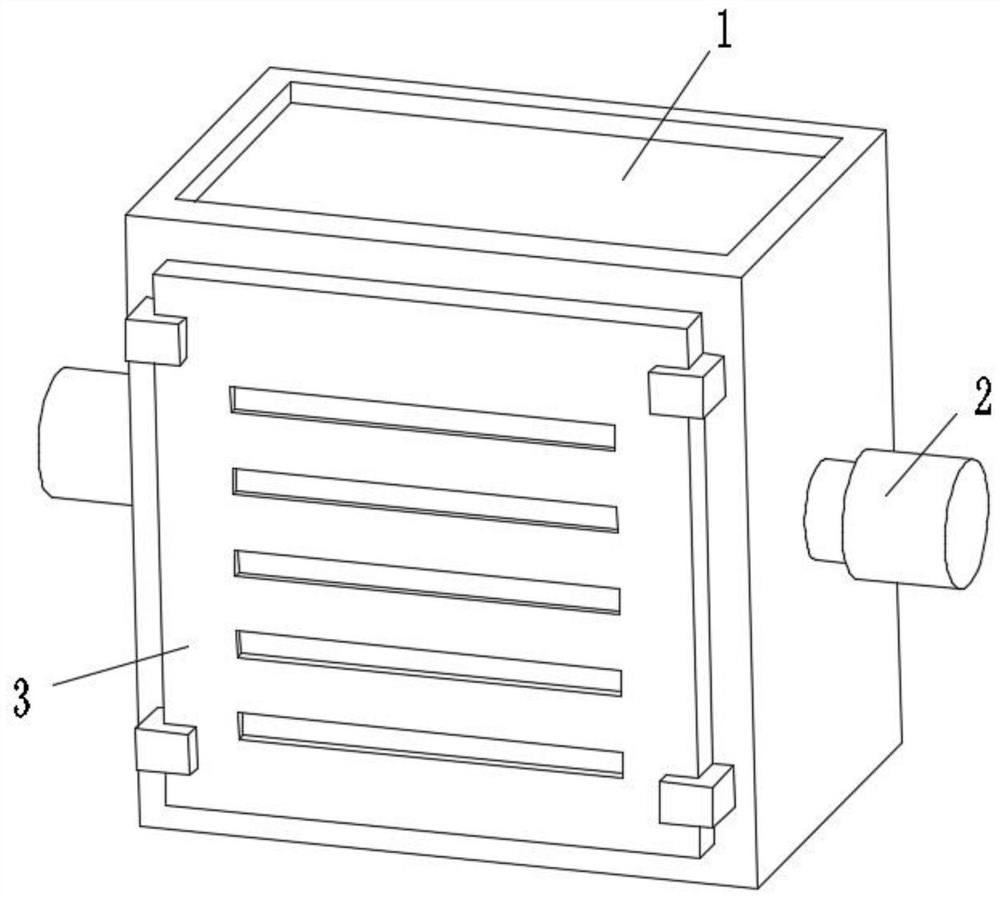

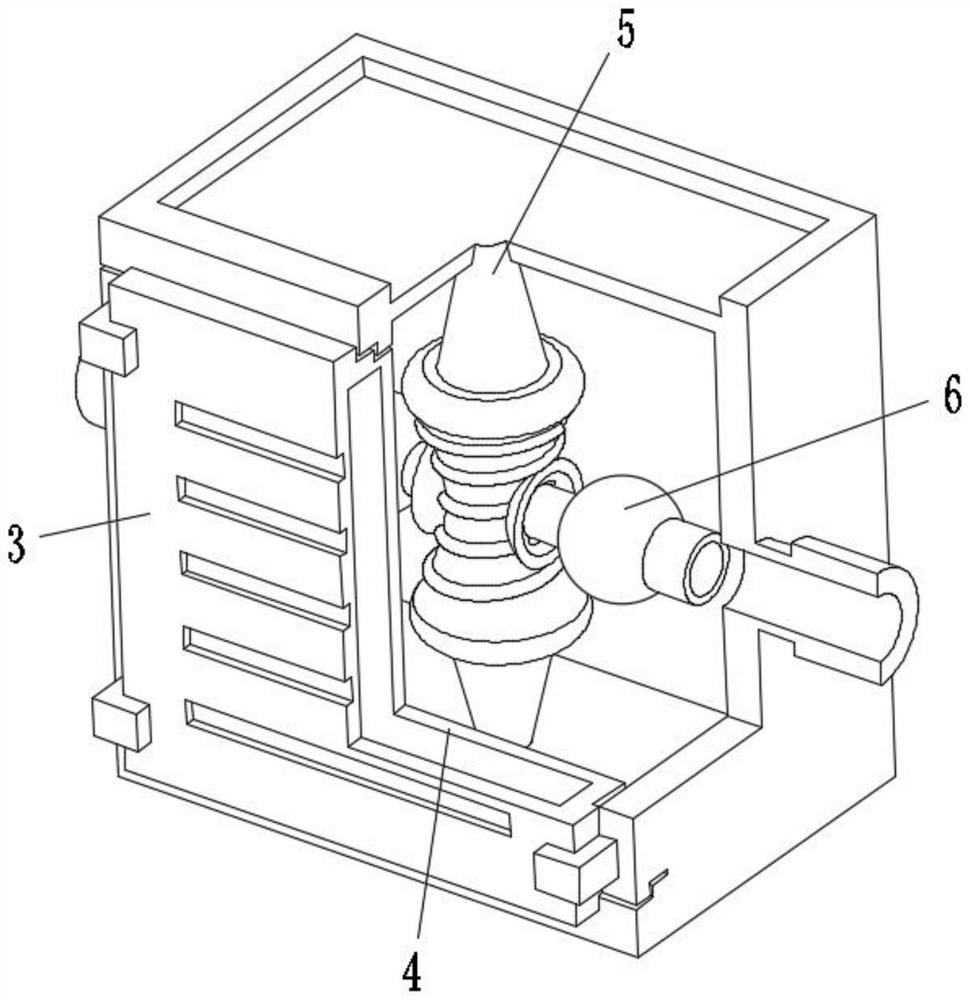

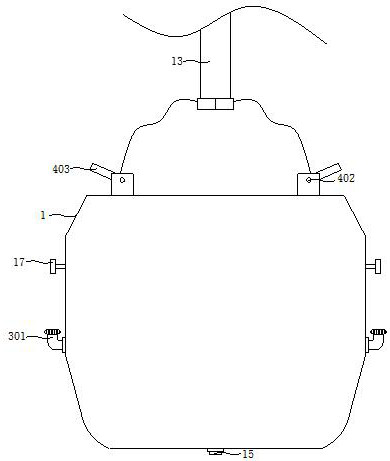

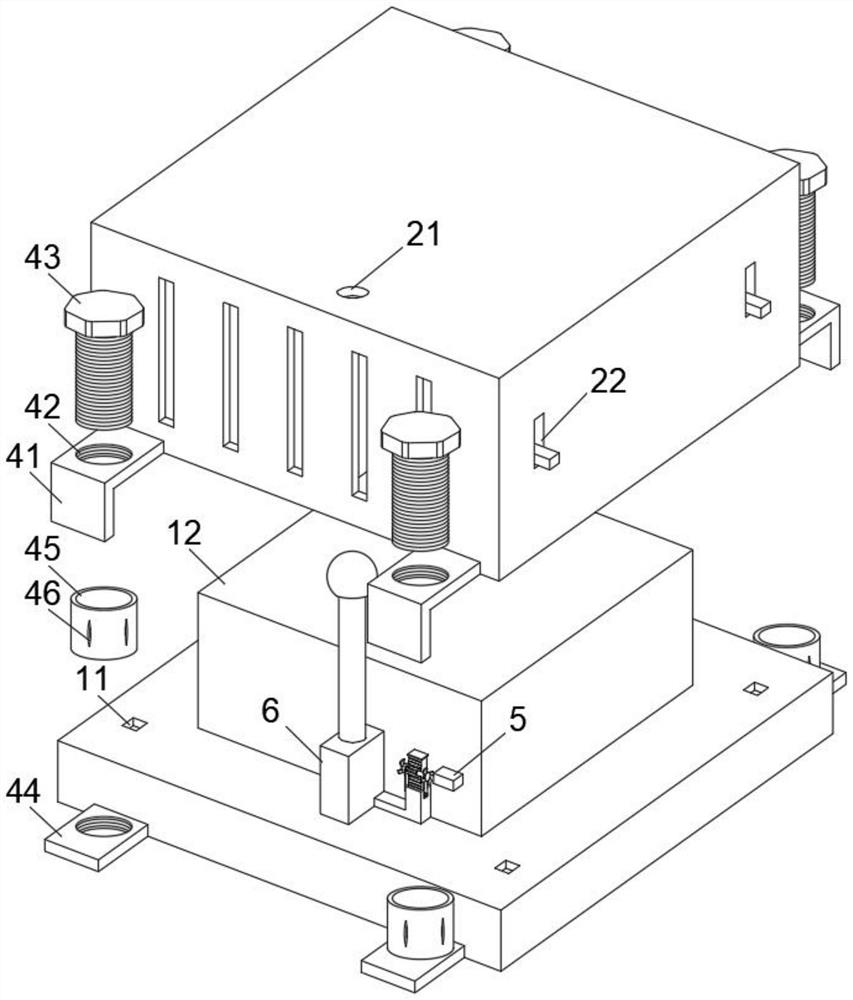

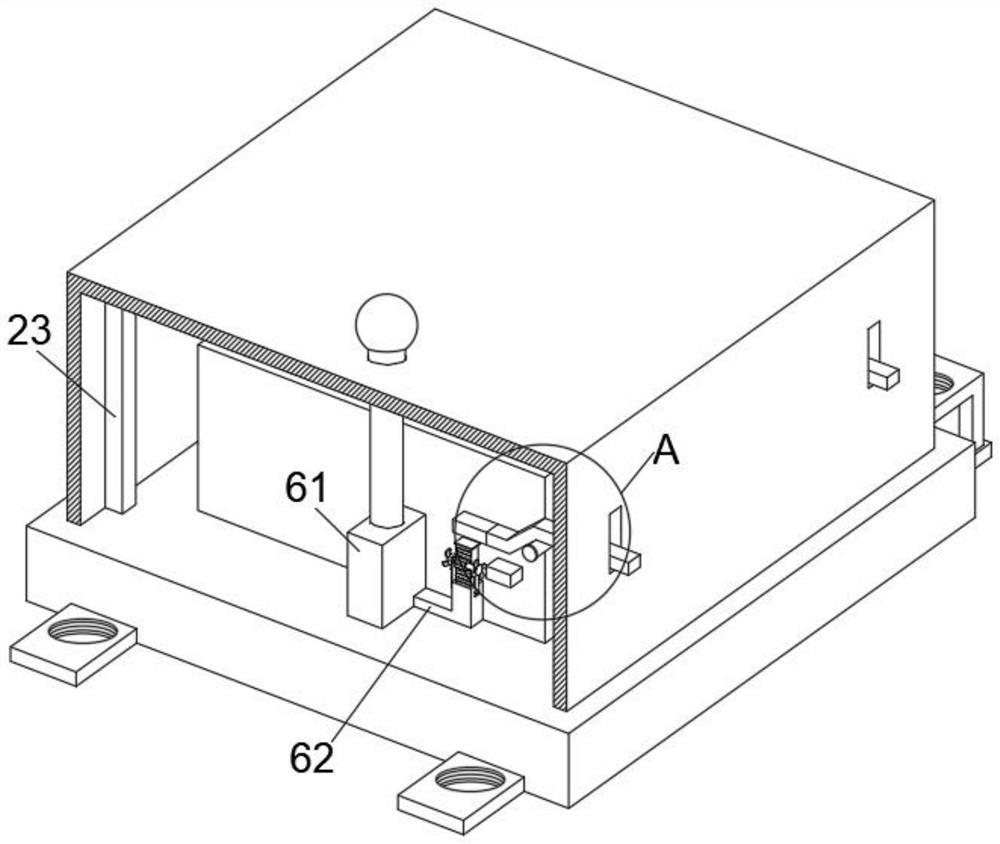

Protective noise reduction device for fracturing equipment operation

PendingCN110005085AAchieve modularityQuick dismantling and installationFencingSound proofingSlagComputer module

The invention relates to the field of oil drilling and exploitation equipment, in particular to a protective noise reduction device used in a fracturing equipment operation site. The protective noisereduction device comprises protective noise reduction walls movably connected with a foundation, first corner modules fixedly connected with one edges of the protective noise reduction walls, second corner modules fixedly connected with the first corner modules, and corner tie rods fixedly connected with the first corner modules and the second corner modules correspondingly. According to the protective noise reduction device, the structure is simple, by adopting the protective noise reduction device, the protective noise reduction walls can be prevented from being damaged by spattered high-pressure disintegrating slag, the noise sound level of night operation can be lowered to be 55dB or below, impact resistance of the protective noise reduction walls is strengthened, modular design is achieved, thus disassembly and loading and transportation are convenient, displacement at all directions among protective noise reduction modules, the first corner modules and the second corner modules is limited, and the positions of the modules in the transportation process are relatively fixed to each other.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

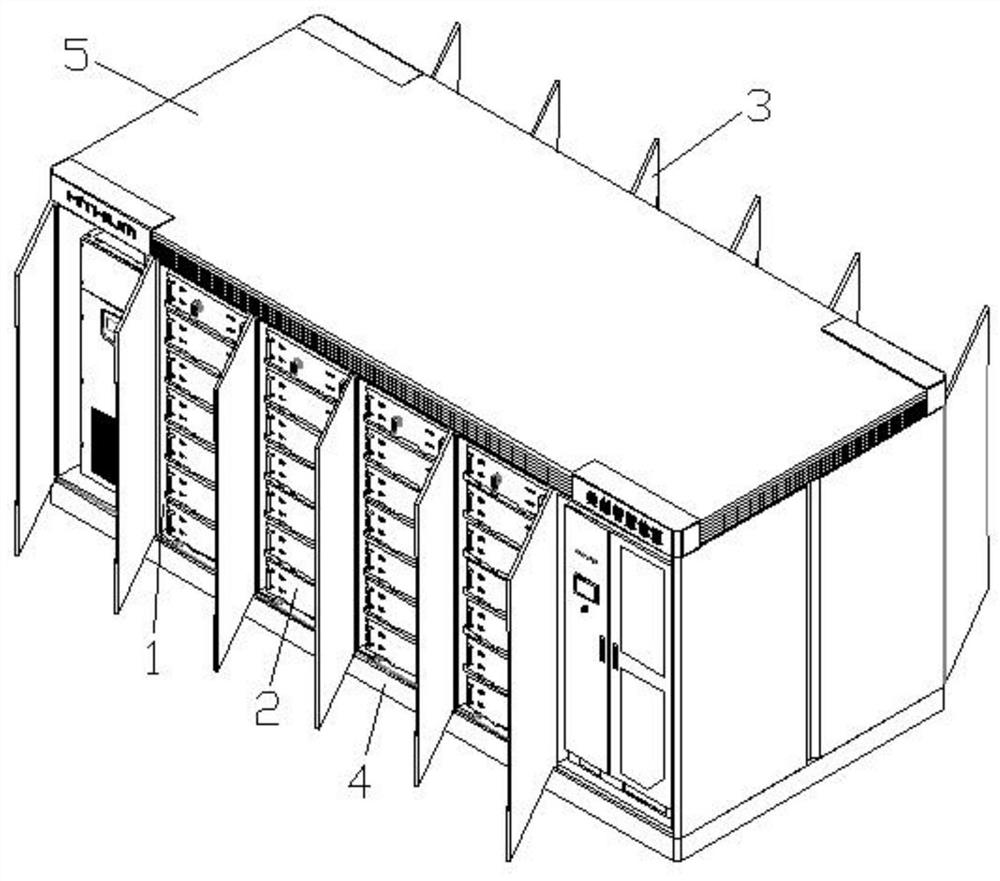

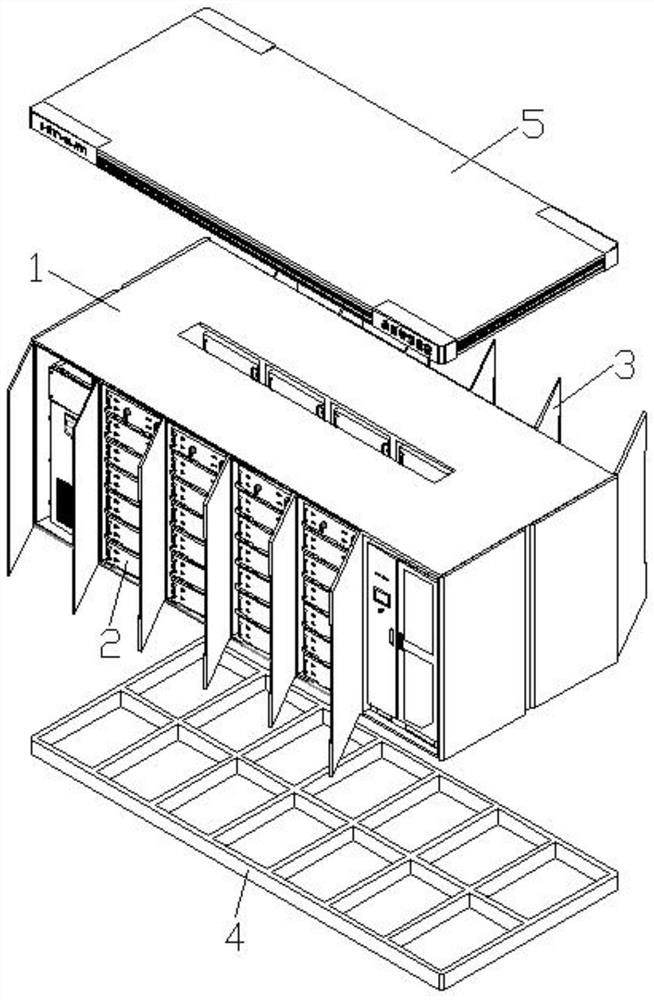

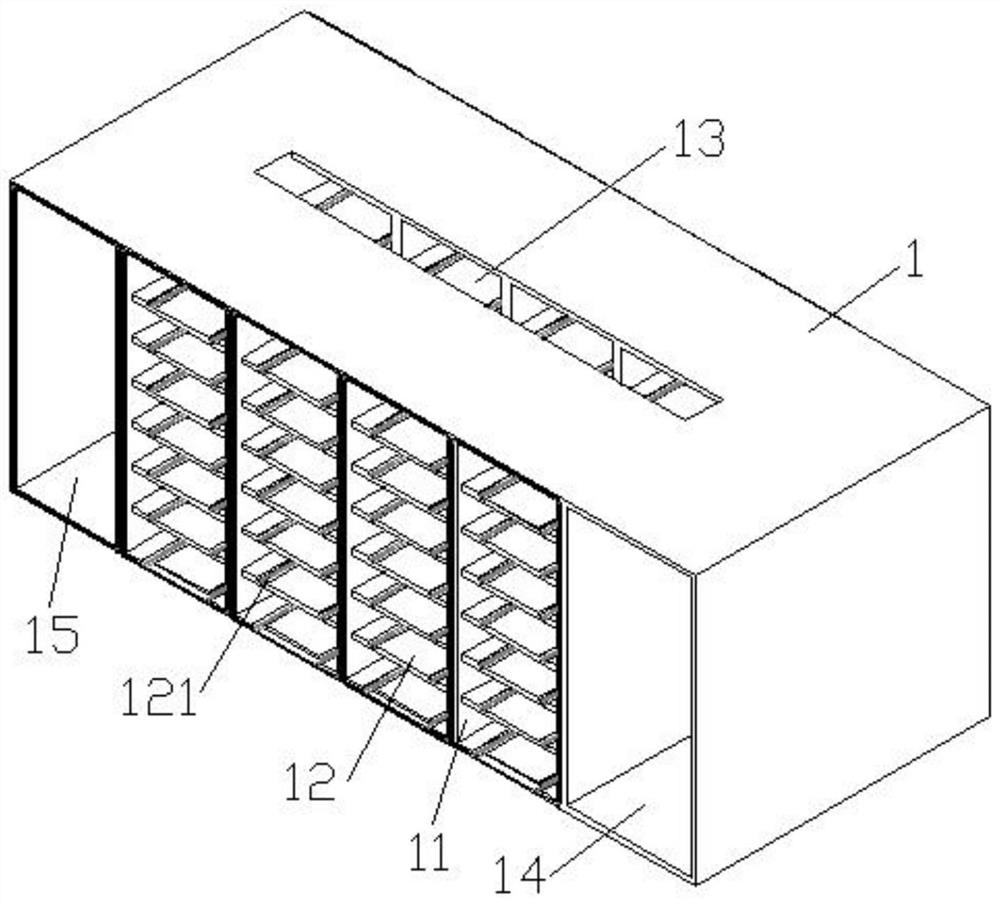

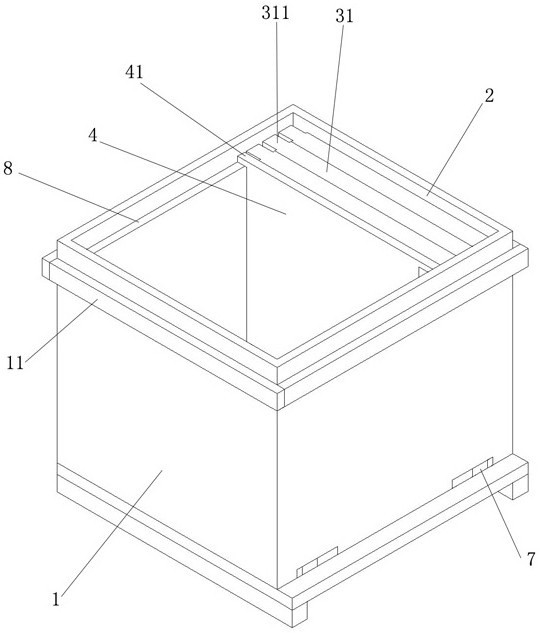

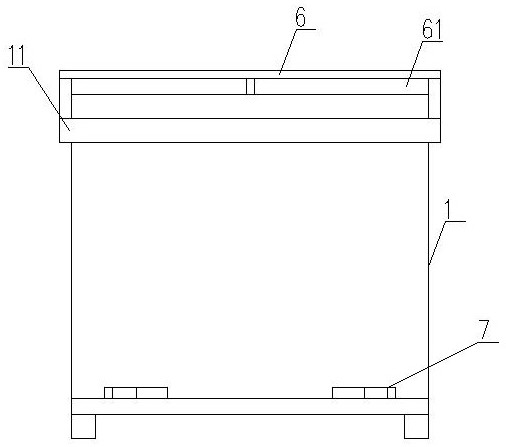

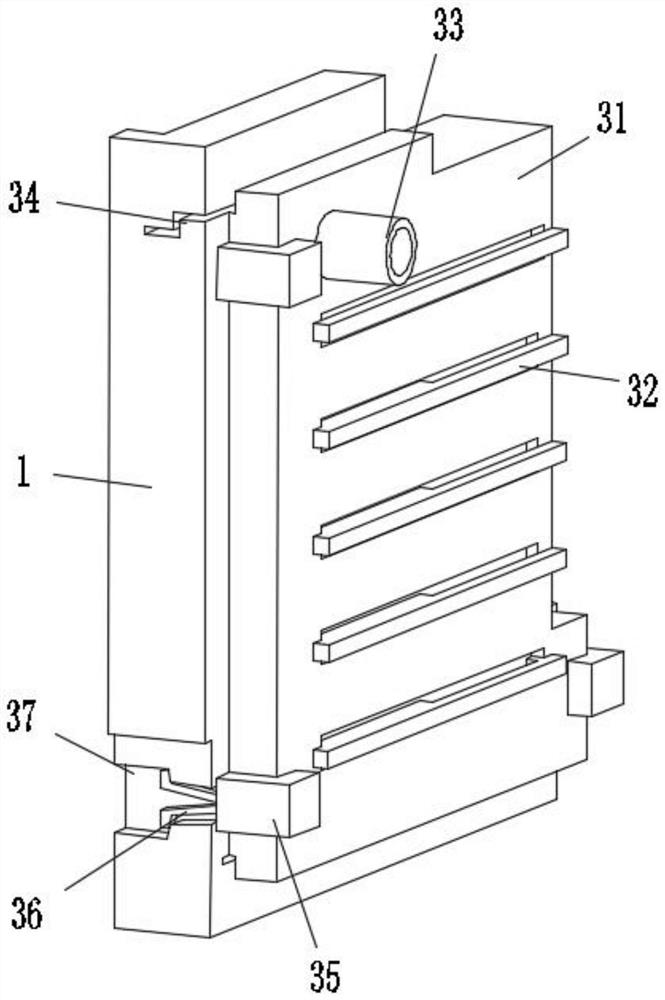

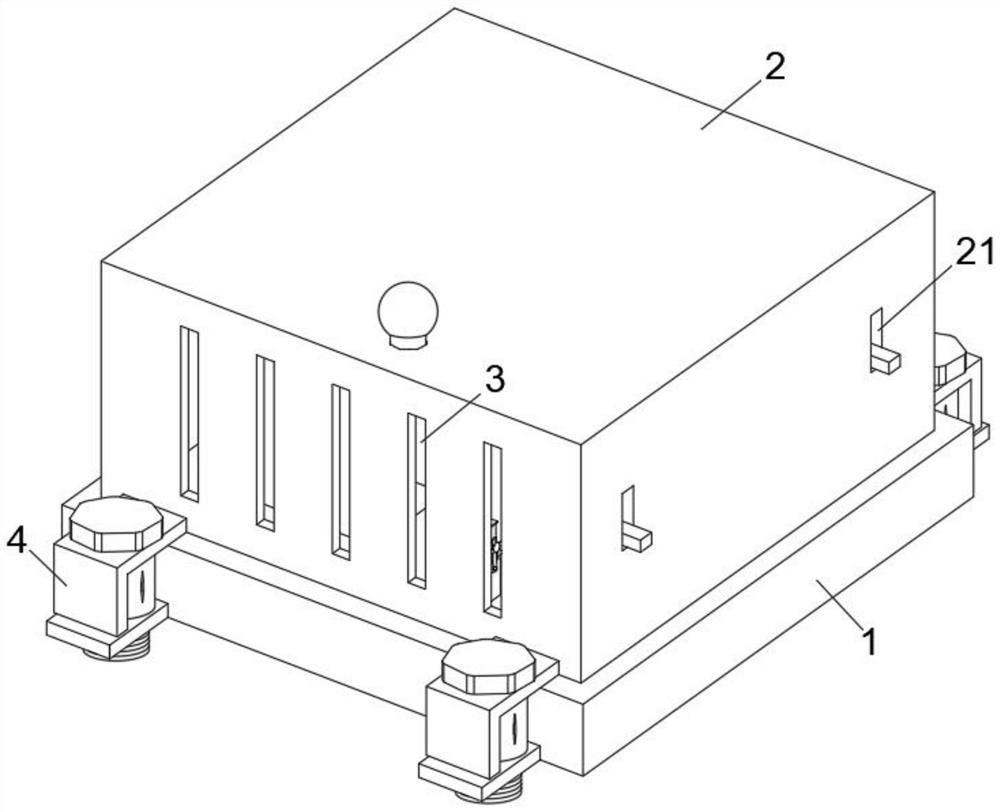

Cabinet type container for energy storage and energy storage system

PendingCN112803099AIncrease profitImprove space utilizationSecondary cellsCell component detailsStructural engineeringMechanical engineering

The invention discloses a cabinet type container for energy storage and an energy storage system. The cabinet type container comprises a cabinet body in the shape of a rectangular box body, the two side faces of the cabinet body in the width direction are of an open structure, a plurality of vertical plates are arranged in the cabinet body in parallel, and all the vertical plates are evenly arranged at intervals in the width direction of the cabinet body. A plurality of transverse plates are uniformly arranged between adjacent vertical plates in parallel at intervals, battery modules are oppositely arranged on each transverse plate at intervals, a rectangular air duct notch is formed in the center of the top surface of the cabinet body, and the air duct notch downwards cuts all the vertical plates and the transverse plates between the two vertical plates located on the outermost side from the top surface of the cabinet body. A plurality of openable cabinet doors are arranged on the two side faces of the cabinet body in the width direction. According to the energy storage system, a traditional maintenance passage is omitted, doors are opened on the two sides, the integral battery rack is adopted, installation and maintenance are convenient and fast, meanwhile, the energy density can be improved, installation of the battery modules on the battery rack is improved, and the structural stability of the energy storage system is improved.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

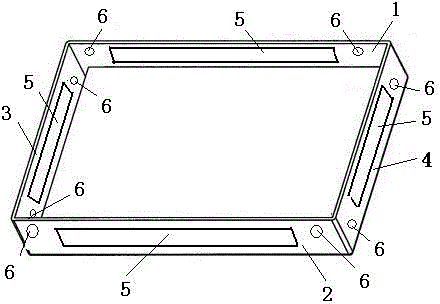

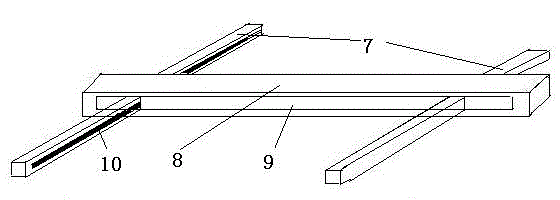

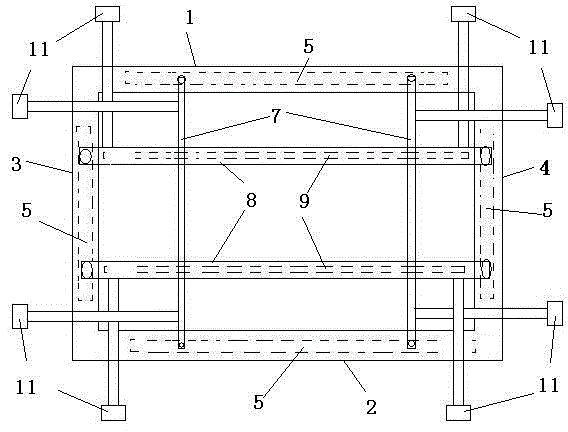

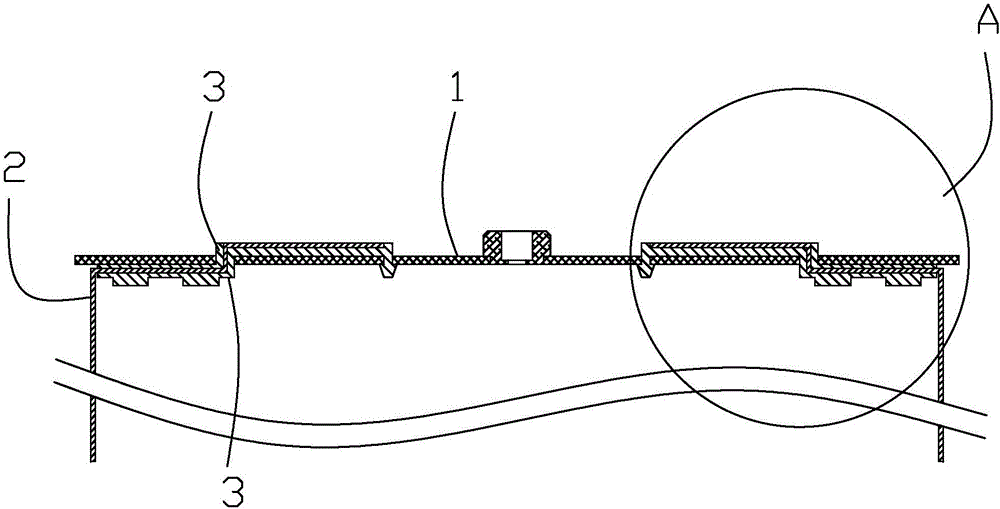

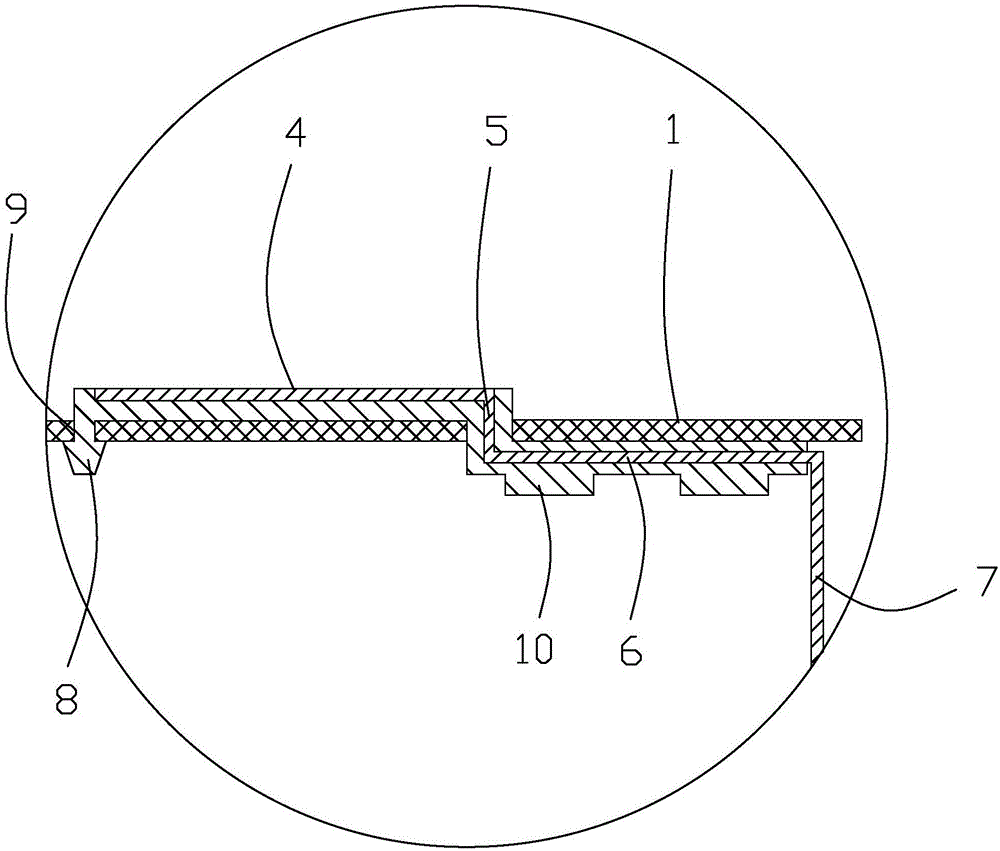

Fixing device for a special-shaped PCB

InactiveCN104159403ALow costLimit up and down movementPrinted circuit manufactureEngineeringComputer engineering

Owner:SUZHOU HUANING MACHINERY MFG

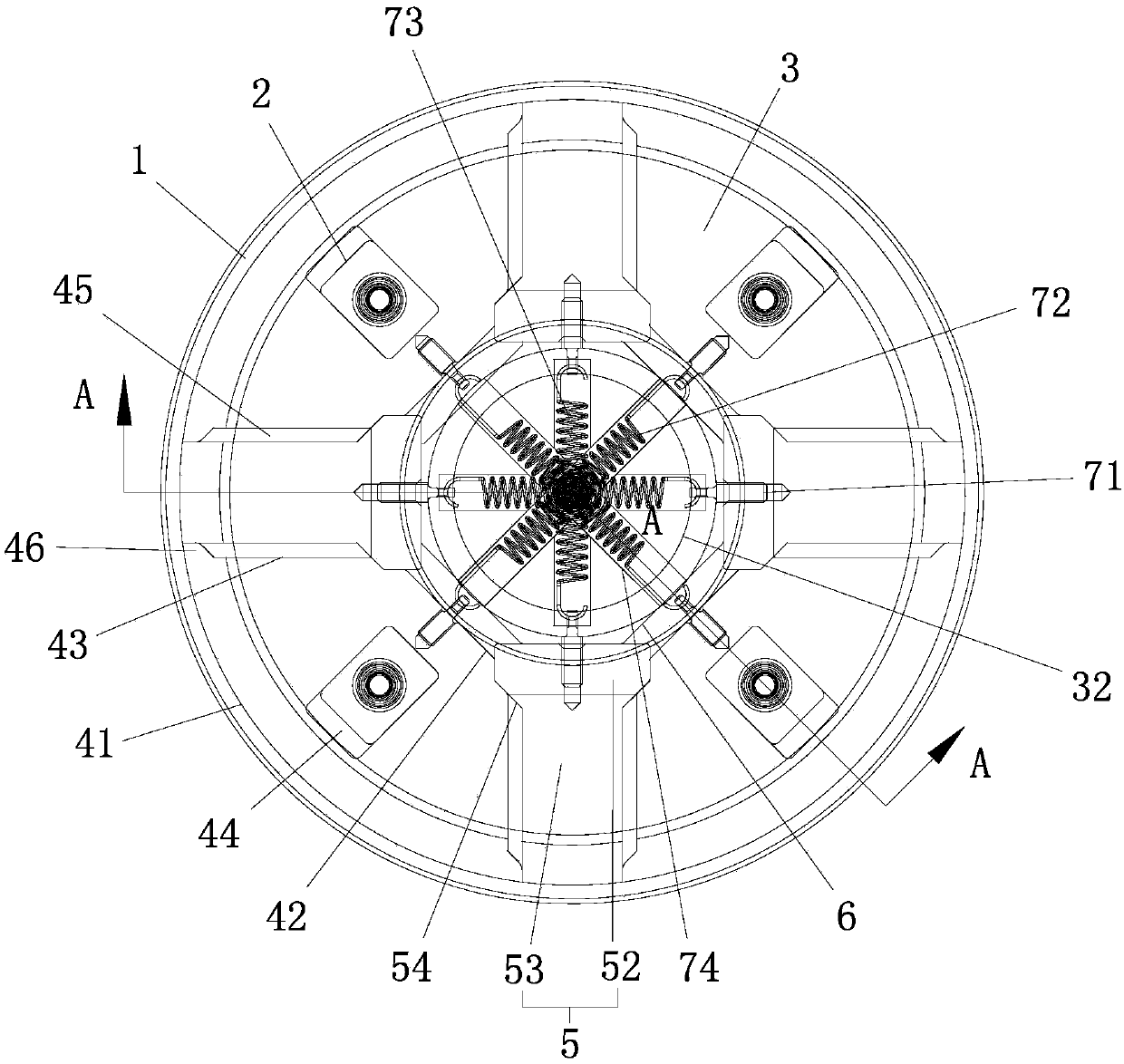

Material clamping device of track trolley

PendingCN112027542AReliable clampingClamping is reliableConveyor partsMechanical conveyorsPhysicsTrackway

The invention discloses a material clamping device of a track trolley. The material clamping device of the track trolley comprises a shell, a first sensor, a second sensor, a third sensor, a fourth sensor, a cylinder, a top plate, a first blocking sheet, a left clamping plate, a right clamping plate, a second blocking sheet, a travel switch and a cone. According to the material clamping device ofthe track trolley, effective safety protection measures are provided, and the movement of the FOUP can be limited from all directions after clamping; The mode that the left clamping plate and the right clamping plate move in the opposite directions is adopted, the top plate is located below the mushroom head and above the mushroom head; and moreover, the top plate makes close contact with the mushroom head all the time under the action of spring force, so that the problem of not tight clamping is solved; and the spring force is accurately calculated and tested, so that the FOUP cannot be damaged while it is guaranteed that the FOUP is reliably clamped. Therefore, the problem of over-tight clamping is avoided. The problems that clamping is too tight, clamping deviation is likely to happen,falling is likely to happen, and the position is wrong and cannot be recognized in the FOUP clamping and transferring process of an FOUP clamping device in the prior art are solved.

Owner:上海新创达半导体设备技术有限公司

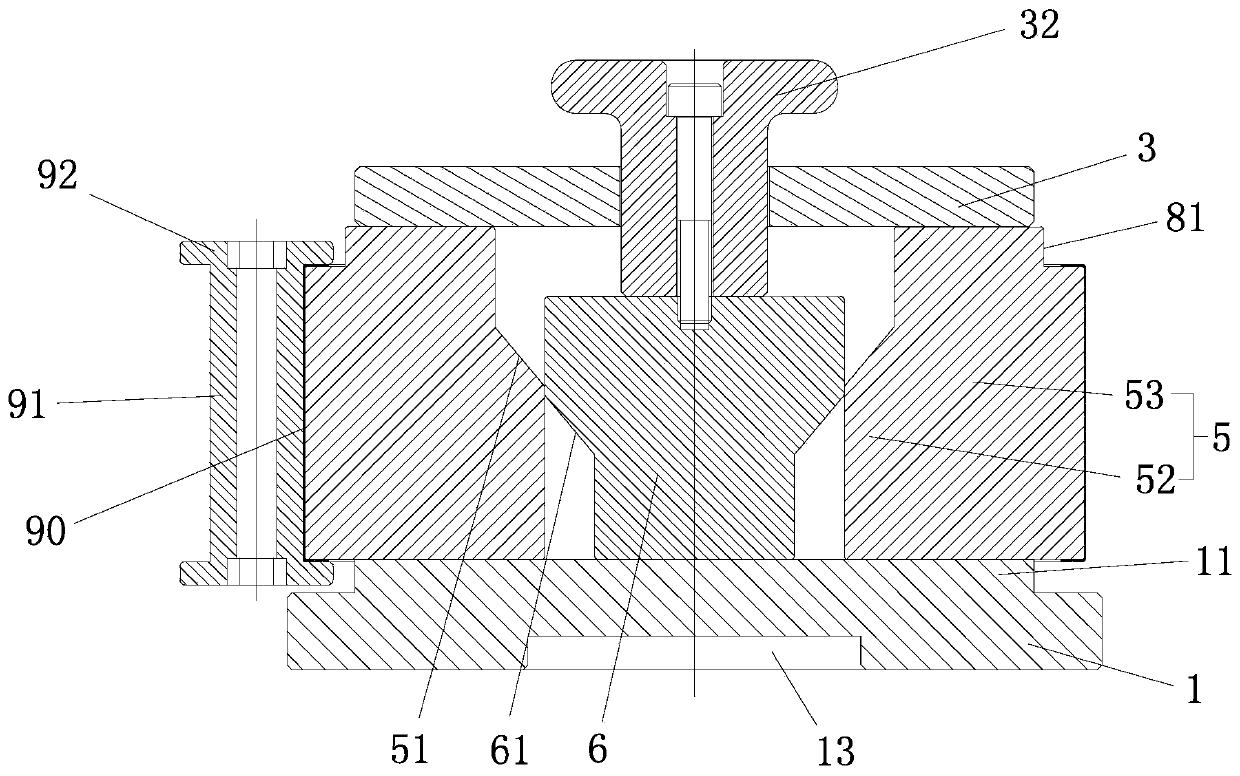

Inner sliding block contraction mould

ActiveCN108031749AAchieve shrinkageTake it out smoothlyShaping toolsHollow articlesDistractionContraction function

Disclosed is an inner sliding block contraction mould. The inner sliding block contraction mould comprises a bottom plate, a plurality of guiding blocks evenly distributed on the bottom plate in the circumferential direction of the center of the bottom plate and an upper cover plate fixed to the guiding blocks. A plurality of first sliding blocks, second sliding blocks used for driving the first sliding blocks to slide towards the outer side and tapered wedges used for driving the second sliding blocks to slide towards the outer side are arranged between the bottom plate and the upper cover plate. The first sliding blocks and the second sliding blocks are located at the peripheries of the tapered wedges. Each first sliding block is mounted on the corresponding guiding block in a sleeving mode. Each second sliding block is located between the two adjacent first sliding blocks. The inner side faces of the first sliding blocks and the second sliding blocks are connected with reset mechanisms used for driving the first sliding blocks and the second sliding blocks to slide towards the center. The inner sliding block contraction mould has the distraction and contraction functions, in theworkpiece forming process, a workpiece is supported and abutted against through the distracted first sliding blocks and the distracted second sliding blocks; and after workpiece forming, the first sliding blocks and the second sliding blocks are contracted, the workpiece is taken out, and machining of inward folding or the pressure level of a round barrel body part is facilitated.

Owner:佛山市顺德区和协模具制造有限公司

High-efficiency and high-rate lithium battery structure

ActiveCN106601973ASolve the problem of welding process bottleneckImprove discharge rateFinal product manufactureCell component detailsElectricityHigh rate

The invention relates to a high-efficiency and high-rate lithium battery structure, and is used for solving the problems that since a general lithium battery pole ear is used for conducting electric energy by welded pole columns, a welding process is difficult, the electrical conduction efficiency of a lithium battery is affected by welding spots and the discharging rate of the lithium battery is limited. The battery structure comprises a seal cover; electricity-taking pole ears are arranged below the seal cover, and the front end part of each electricity-taking pole ear passes through the seal cover and is located on the surface of the seal cover; each electricity-taking pole ear is wrapped with an insulating layer, and the front end part of each electricity-taking pole ear is exposed on the upper surface of the insulating layer located on the seal cover to form an external terminal. The battery structure has the advantages that the electricity-taking pole ears adopt integral design, the problem that a conventional lithium battery has process bottlenecks for welding the pole ears and the pole columns, the discharge rate of the lithium battery is increased, and the resistance and heat radiation conditions caused by the welding points during large current discharge are reduced. The electricity-taking pole ears are directly wrapped by the insulating layers of the pole ears, and the insulating layers of the pole ears have good sealing and insulation performance with the battery seal cover. The lithium battery structure has simple whole structure, reduces lithium battery manufacturing process, shortens the production time and reduces material costs.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD

Lateral shoring device for goods in container and method for reinforcing goods in container

PendingCN110092107ALimit up and down movementReinforcement and stabilityPackage recyclingLarge containersSupport surface

Owner:BEIJING HONGTONG SUPPLY CHAIN MANAGEMENT CO LTD

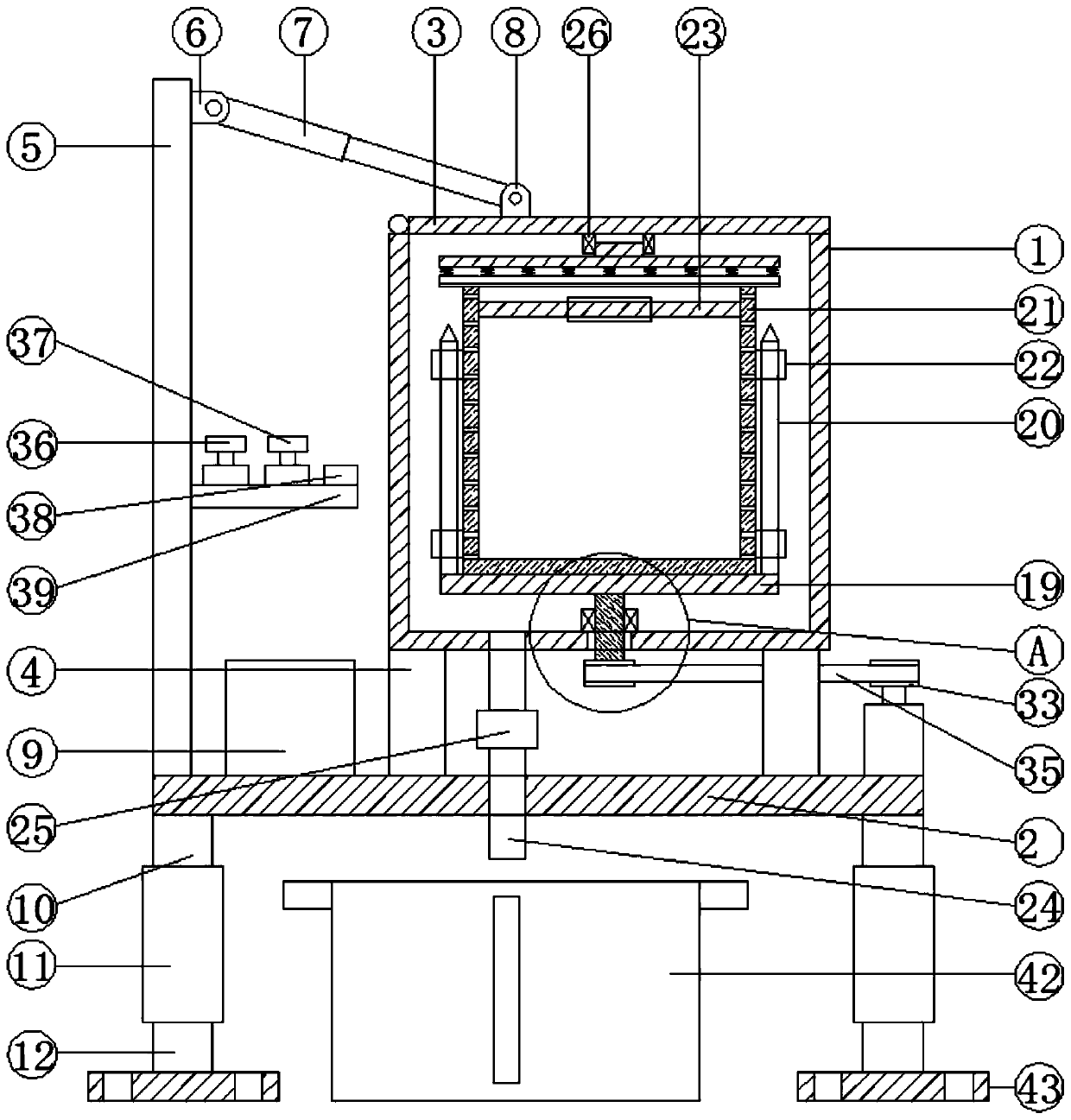

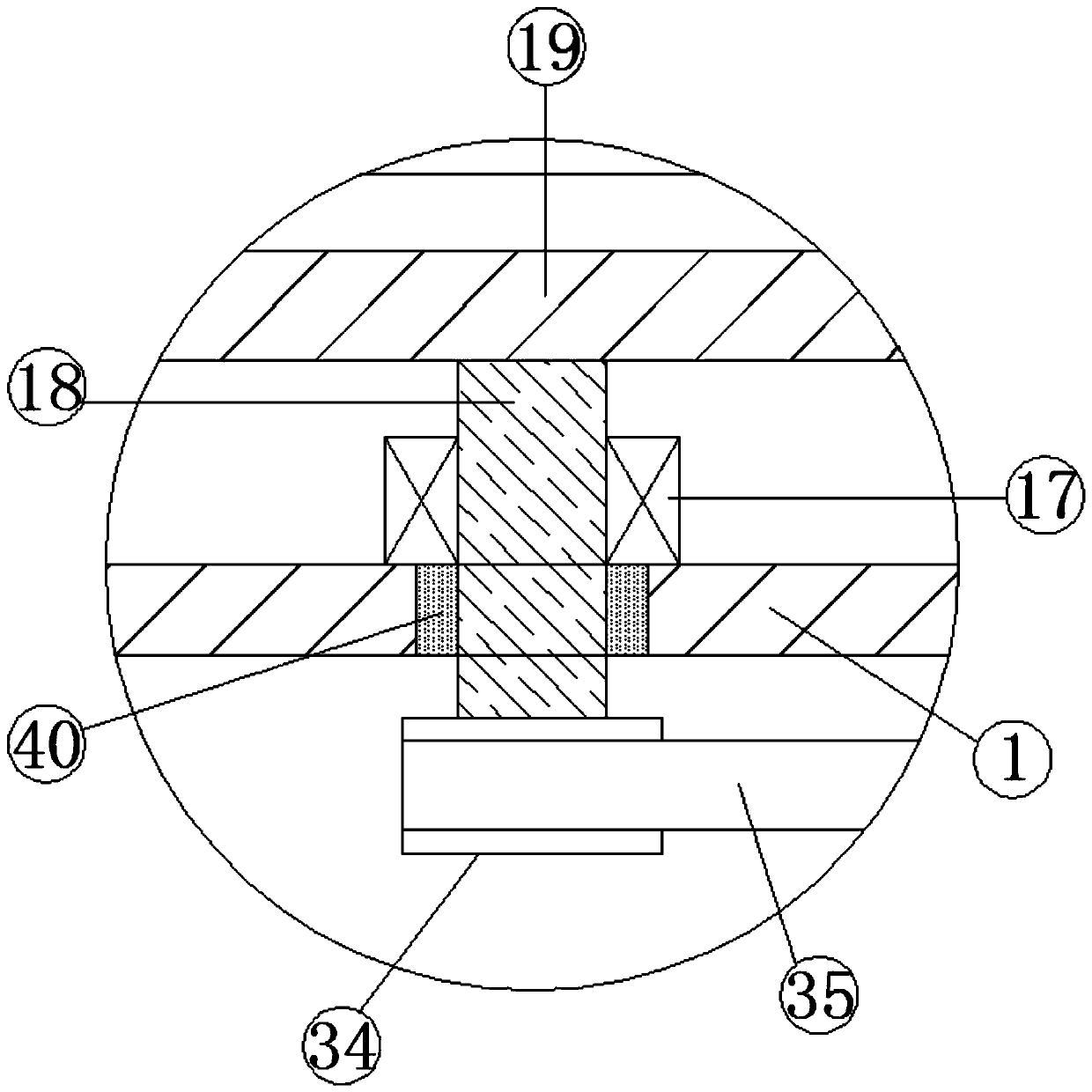

Aluminum alloy hub heat treatment device capable of effectively improving yield of hubs

PendingCN107794361AImprove yieldSmooth slidingFurnace typesHeat treatment furnacesEngineeringAlloy wheel

The invention relates to the technical field of wheel hub processing, and discloses an aluminum alloy wheel hub heat treatment device that can effectively improve the yield, including a heat treatment furnace body, and two mounting blocks are fixedly installed on the top of the heat treatment furnace body. The blocks are fixedly equipped with pulleys, and the opposite side of the pulleys is fixedly installed with a fixed cross bar above the heat treatment furnace body. The bottom of the hanging block is fixedly installed with an installation frame, the inner cavity of the installation frame is fixedly installed with a hanging rod, and the front surface of the hanging rod is fixedly installed with a wheel hub ring located in the inner cavity of the heat treatment furnace. The heat treatment device for aluminum alloy wheels that can effectively improve the yield can effectively ensure that the overall installation frame is more stable when sliding on the slider, and will not derail and other situations, causing the wheels to fall off and fall, affecting the overall yield of the aluminum alloy wheels. question.

Owner:何琼

Food dicing machine

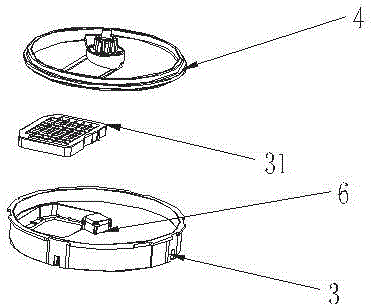

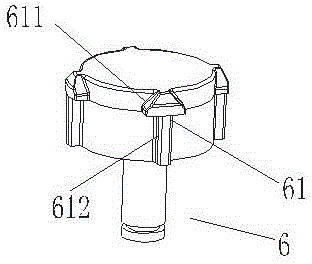

InactiveCN105437298ASimple structureEasy to install and operateMetal working apparatusMesh gridEngineering

The invention discloses a food dicing machine. The food dicing machine comprises a container, a gridding knife assembly and an upper cover, wherein the gridding knife assembly is installed at an opening of the container, and the upper cover is arranged above the opening of the container. The gridding knife assembly comprises a gridding knife plate and a rotating cutter placed on the gridding knife plate. The middle of the container is provided with a transmission shaft. The transmission shaft upwards and freely penetrates through a center hole of the gridding knife plate to be detachably connected with the rotating cutter. The upper end of the transmission shaft is provided with a transmission head connected with the rotating cutter. The connecting position of the transmission head and the rotating cutter is provided with a buckling structure easy to disassemble and assemble. The buckling structure is further provided with a limiting device in the vertical direction. When the rotating cutter is placed on the transmission head and rotates, a driving buckling part arranged on the rotating cutter and a driven buckling part arranged on the transmission head are buckled with each other, so that the transmission shaft is driven to rotate, and the rotating cutter does not shift up and down during rotating through the limiting device of the buckling structure. According to the food dicing machine, the structure is simple, in addition, the rotating cutter can be restricted from being shifted up and down, installing and operating are convenient and easy, and cleaning is convenient.

Owner:HOME CULTURE APPLIANCES SHENZHEN

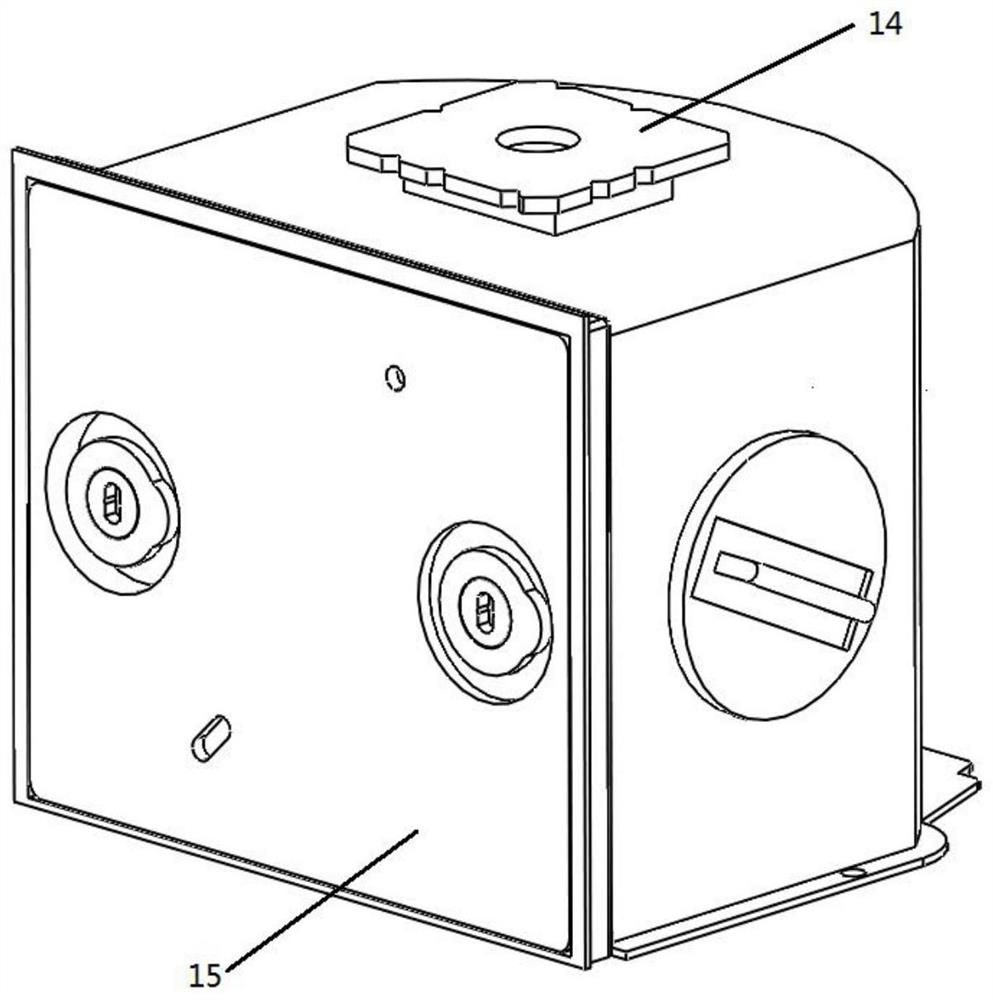

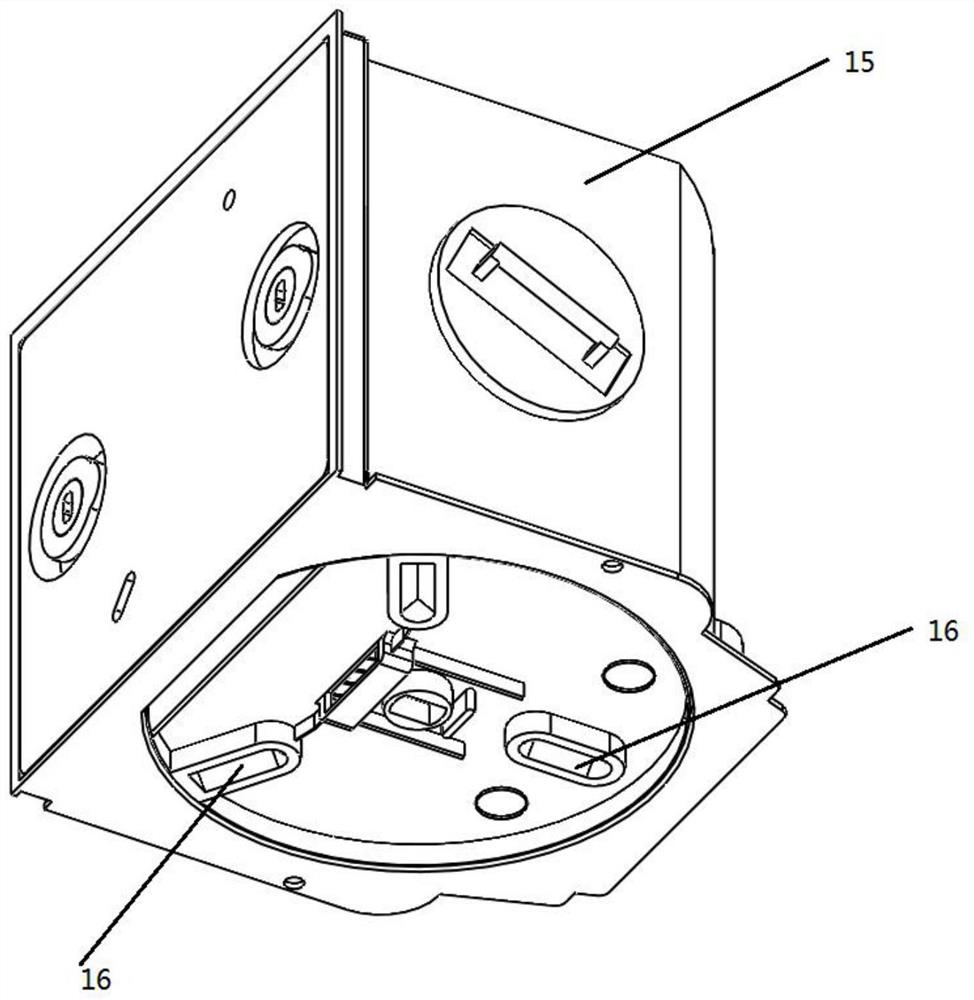

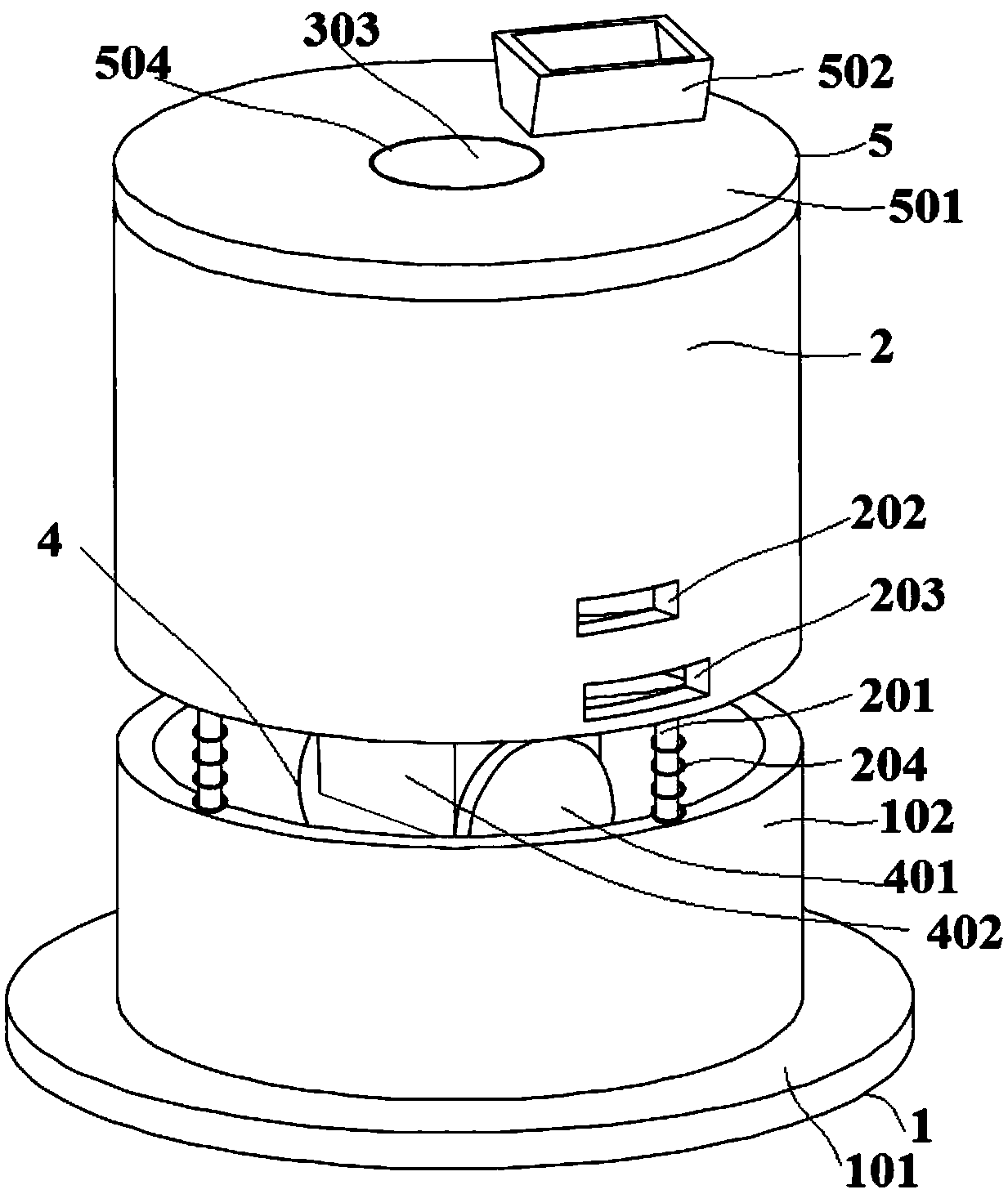

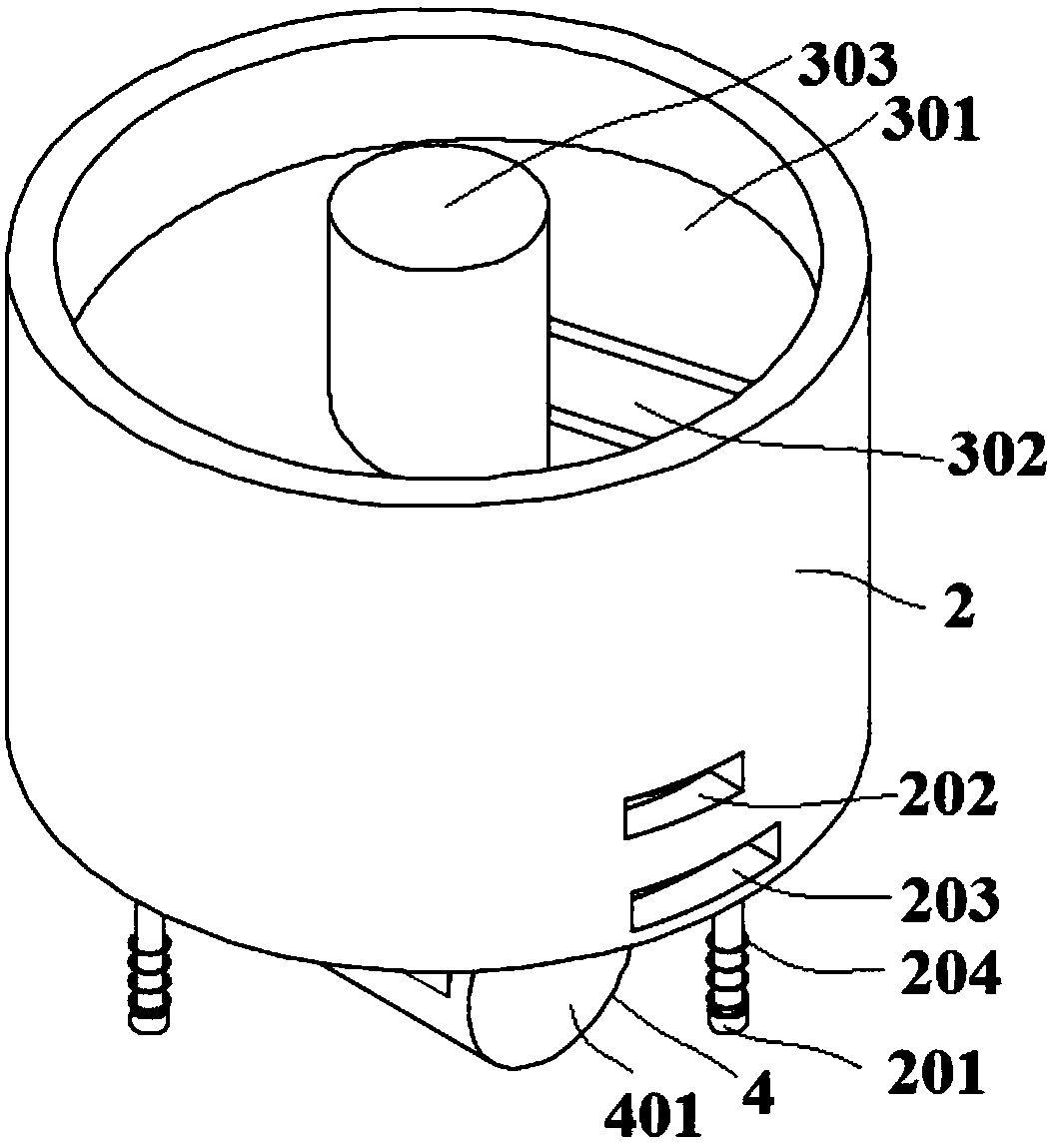

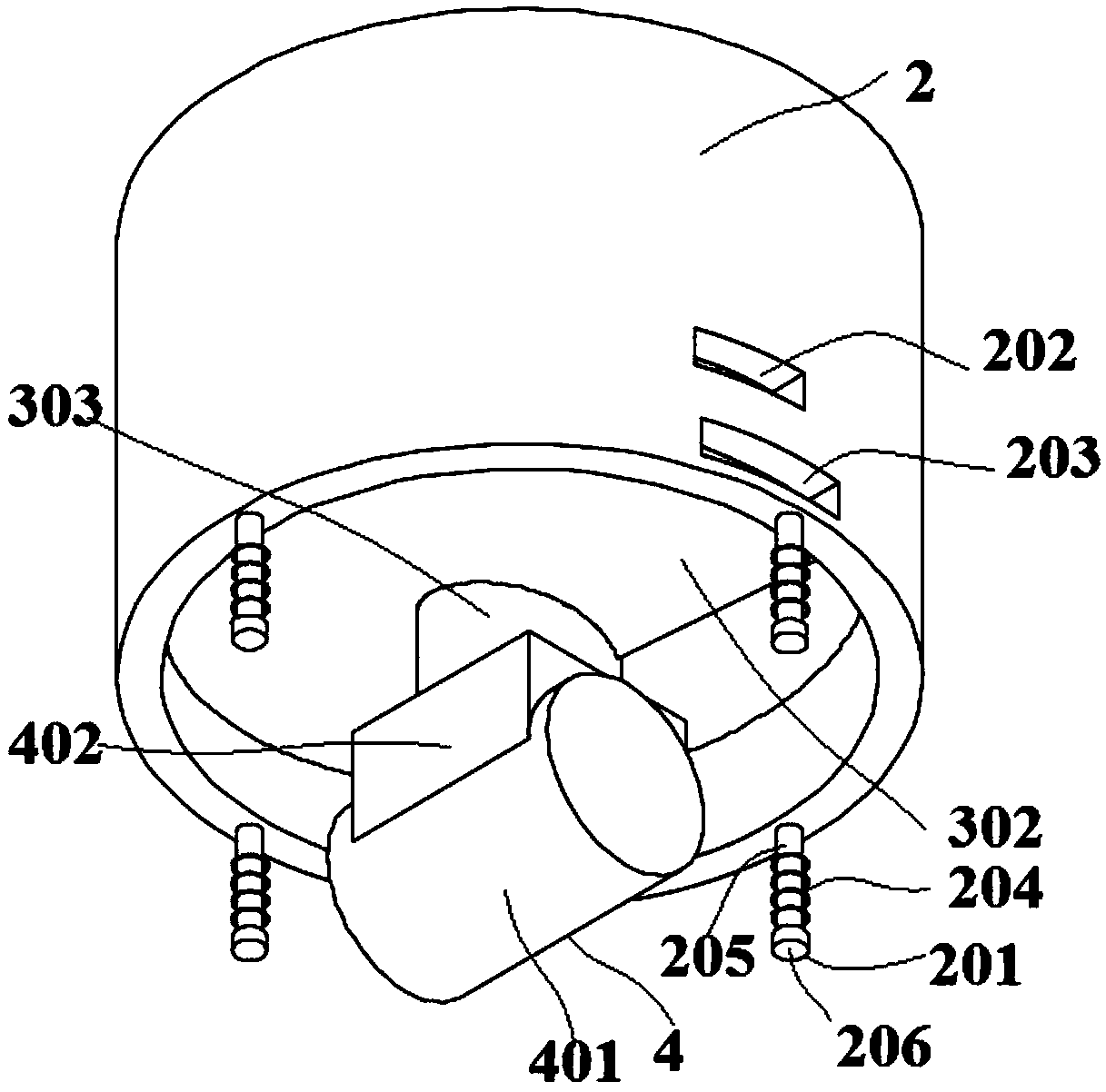

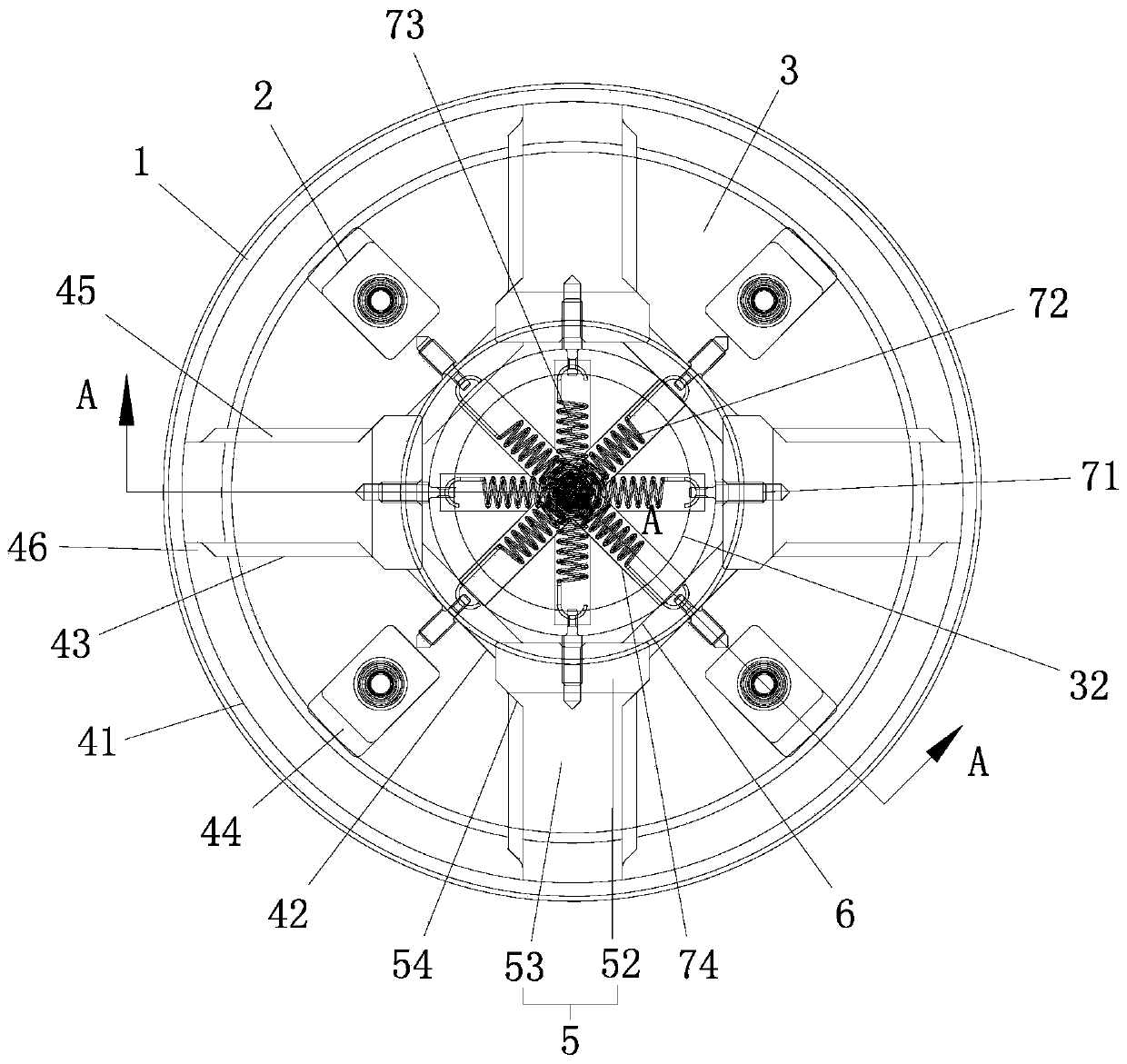

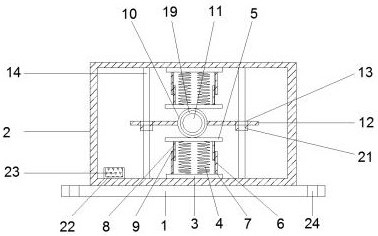

Automatic deoiling device for bolt deoiling

InactiveCN111013832APlay the role of shock absorption protectionEasy to unloadCentrifugesEnergy absorptionWorkbench

The invention discloses an automatic deoiling device for bolt deoiling. The automatic deoiling device comprises a shell and a workbench; the shell is of a cylindrical structure; a cover plate is movably arranged on the shell through a rotating shaft; four fixed columns are fixedly arranged below the shell; all the fixed columns are fixed to the workbench, a side column is fixedly arranged at one end of the workbench; a first hinged support is fixedly arranged at the upper end of the side column, an electric telescopic rod is hinged to the interior of the first hinged support, a second hinged support is fixedly arranged on the cover plate, and one end, away from the first hinged support, of the electric telescopic rod is hinged to the second hinged support. The automatic deoiling device hasthe beneficial effects that a centrifugal barrel can be taken out of the shell, so that deoiled bolts can be directly poured out, blanking can be facilitated, the damping effect can be achieved through cooperation of a second spring and an energy absorption material, the damping protection effect on the deoiling assembly can be achieved, and noise generated by vibration can be reduced.

Owner:ZHEJIANG COWIN FASTECH

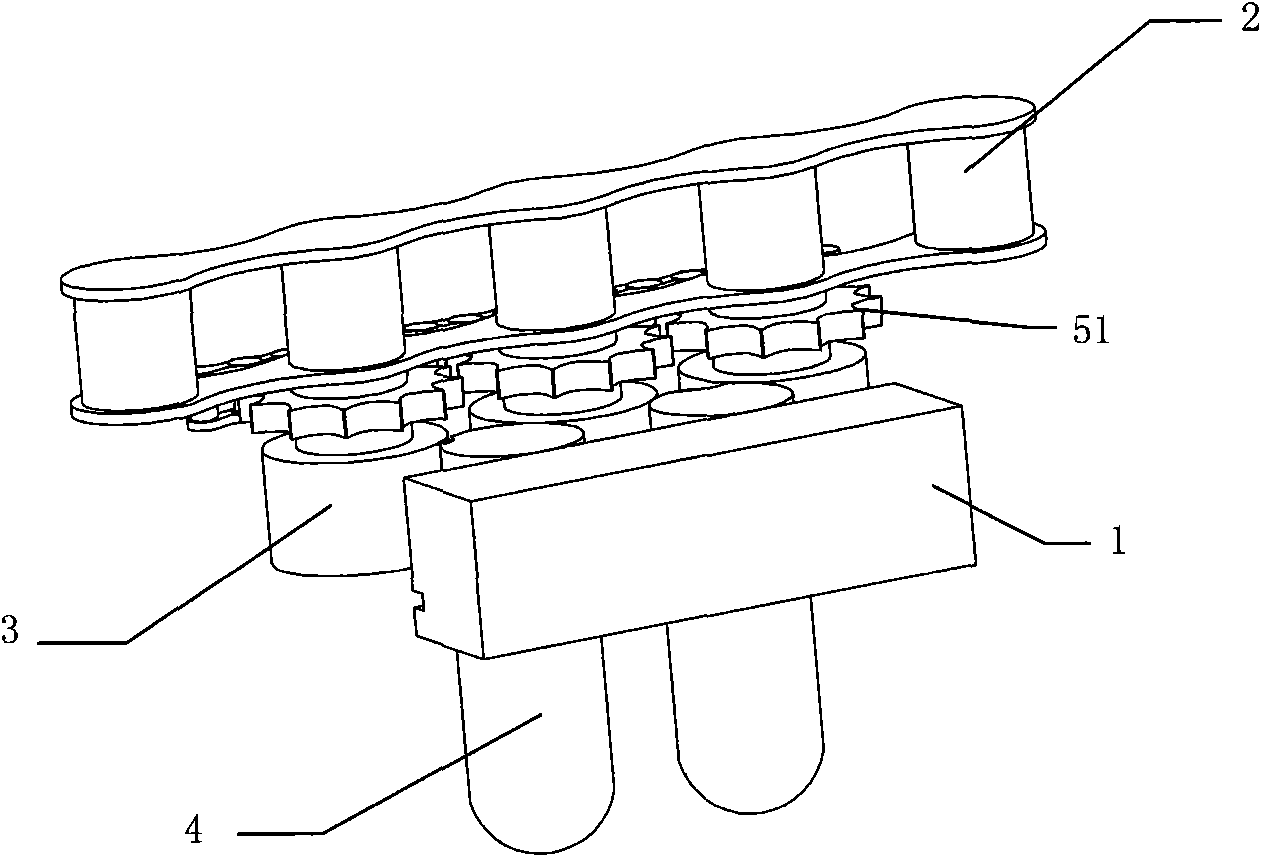

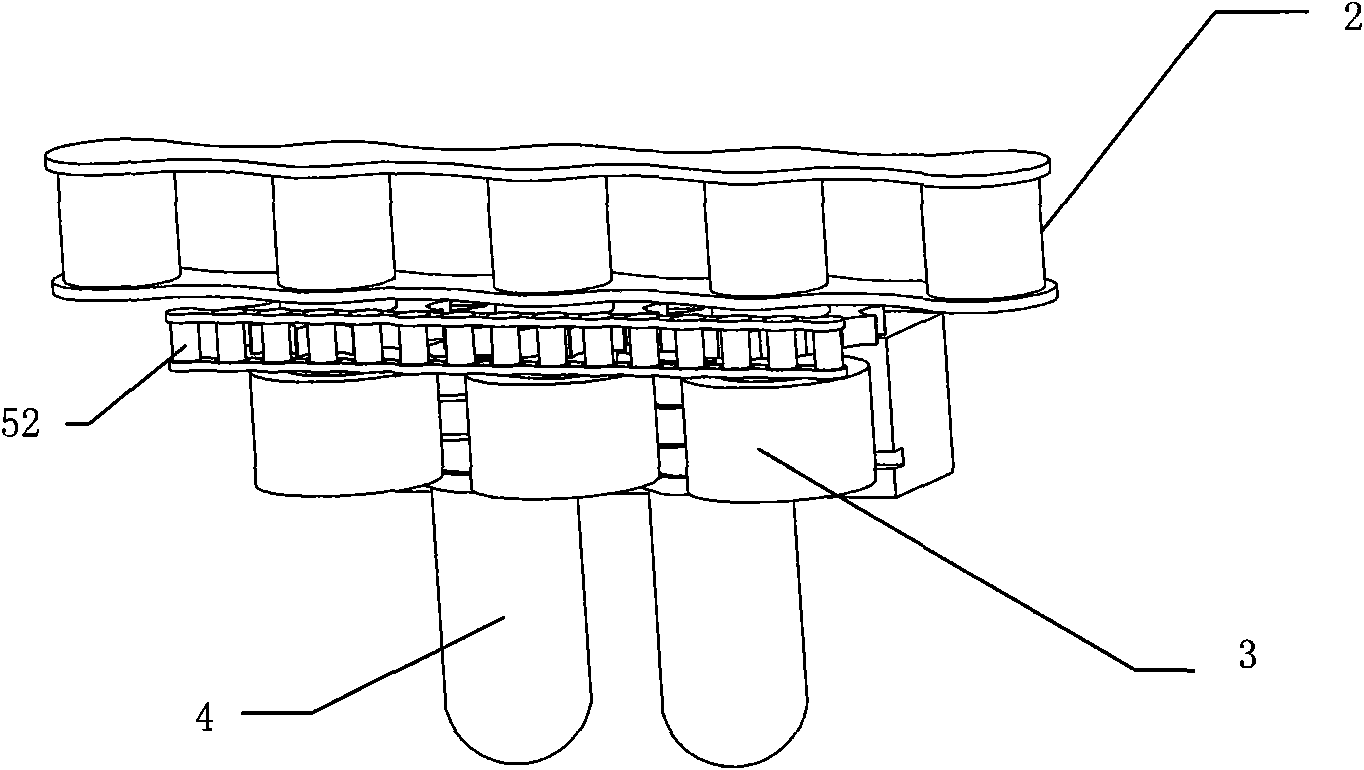

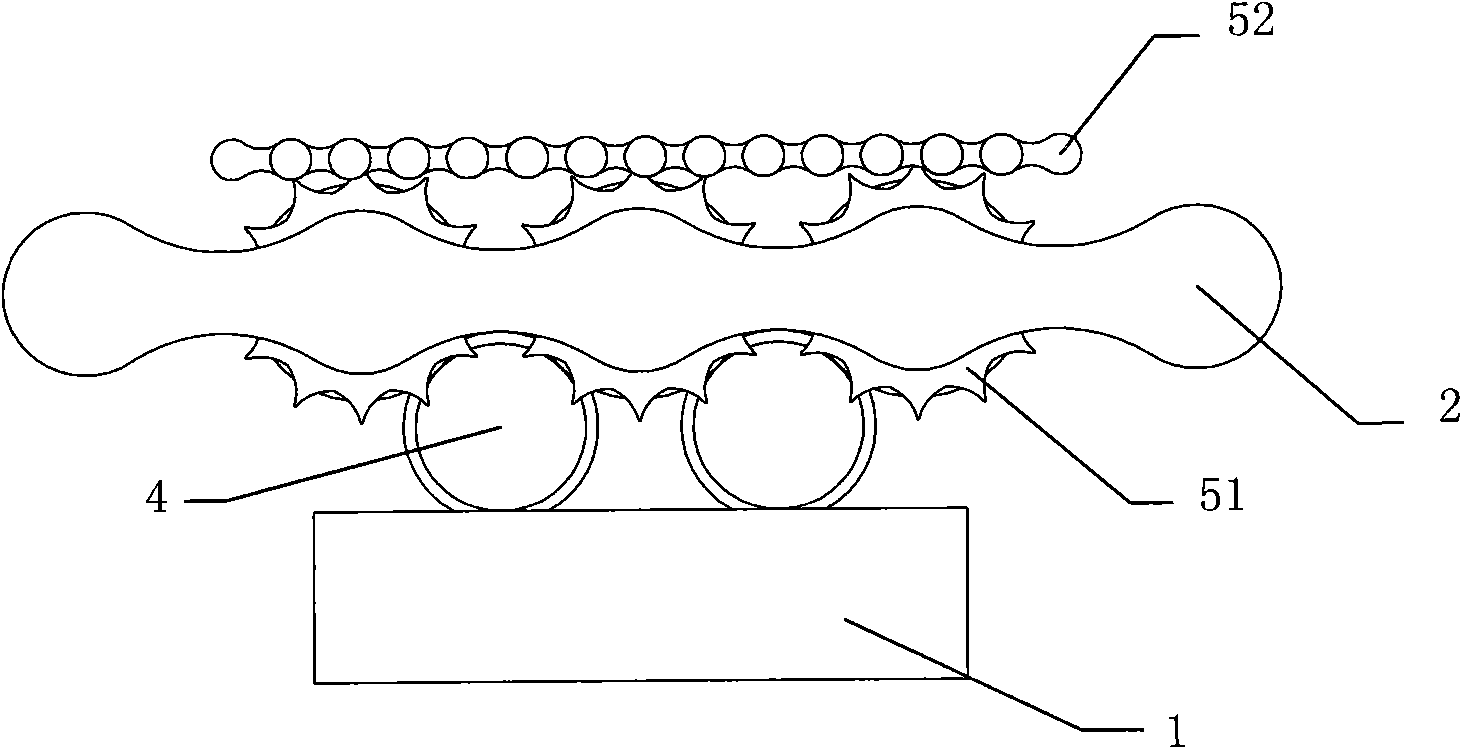

Bottle base conveying device

InactiveCN101579918ADecreased climbing forceLimit up and down movementHollow articlesWater channelEngineering

The invention provides a bottle base conveying device. The device comprises a cooling water channel and a chain bracket which are arranged on a heater, wherein the chain bracket is provided with a transmission chain; the transmission chain is provided with a friction wheel; the friction wheel is inserted between plastic bottle bases in operation, and tightly pulls a screw socket of the plastic bottle base on the wall surface of the cooling water channel; the cooling water channel is provided with a groove to be inserted by a convex ring of the screw socket of the plastic bottle base; the height of the groove is matched with that of the convex ring; the friction wheel is connected with a self-transmission drive mechanism. The bottle base conveying device has the advantages of good conveying stability, good durability and good heat dissipation effect.

Owner:林子祥

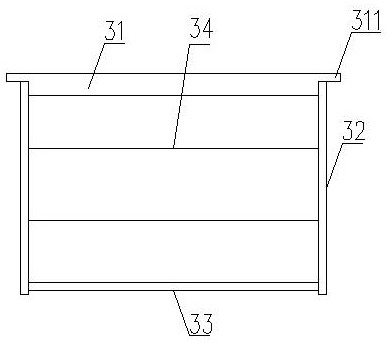

Chinese bee hive

The invention discloses a Chinese bee hive. The Chinese bee hive comprises a hive body, hive walls, hive frames, upper beams, frame lugs, side strips, lower beams, frame lines, partition plates, partition plate lugs, auxiliary covers, hive covers, hive doors and frame supports. The adjacent upper beams of the hive frames in the hive body tightly lean against each other so as to avoid forming inter-frame bee ways, a honeycomb structure similar to a natural honeycomb with closed hive tops is achieved, and gaps are formed between the frame lugs. According to the Chinese bee hive, the hive framesis convenient to arrange and extract when a honeycomb is checked, ventilation in the honeycomb is facilitated, unsmooth ventilation caused by closing of the tops in the bee hive due to the fact that the upper beams are tightly close to each other is avoided, bees staying on the upper beams of the hive frames can return to the honeycomb through the gaps formed between the frame lugs during box opening checking, and losses of the bees are avoided.

Owner:广西壮族自治区养蜂指导站

Double-layer spiral vibrating screen

InactiveCN107649371AAvoid excessive accumulationGrowth screening pathSievingScreeningCircular discHelix

The invention discloses a double-layer spiral vibrating screen and relates to the technical field of vibrating screens. The double-layer spiral vibrating screen comprises a base, a vibrating cabin anda spiral vibrating device, wherein the base comprises a circular disc and a circular ring; the circular ring is fixed on one surface of the circular disc; a plurality of stepped holes are formed in one surface of the circular ring and are matched with stepped columns of the vibrating cabin; a plurality of stepped columns are arranged on one surface of the vibrating cabin; the circumferential sidefaces of the stepped columns are matched with springs; the internal surface of the vibrating cabin is matched with the spiral vibrating device; the spiral vibrating device comprises a spiral vibrating screen, a spiral vibrating plate and a central shaft; the spiral vibrating screen and the spiral vibrating plate are arranged on the circumferential side face of the central shaft; the spiral vibrating plate is positioned below the spiral vibrating screen; a vibration motor device is fixed at one end of the central shaft of the spiral vibrating device; and the other end of the central shaft is matched with a dustproof cover. According to the invention, through action of the double-layer spiral vibrating screen, the vibration motor and the vibrating cabin, the problems that material in screenmeshes of the vibrating screen is jammed and excessive materials of the vibrating screen are piled up are solved.

Owner:安徽省正宇粮机科技股份有限公司

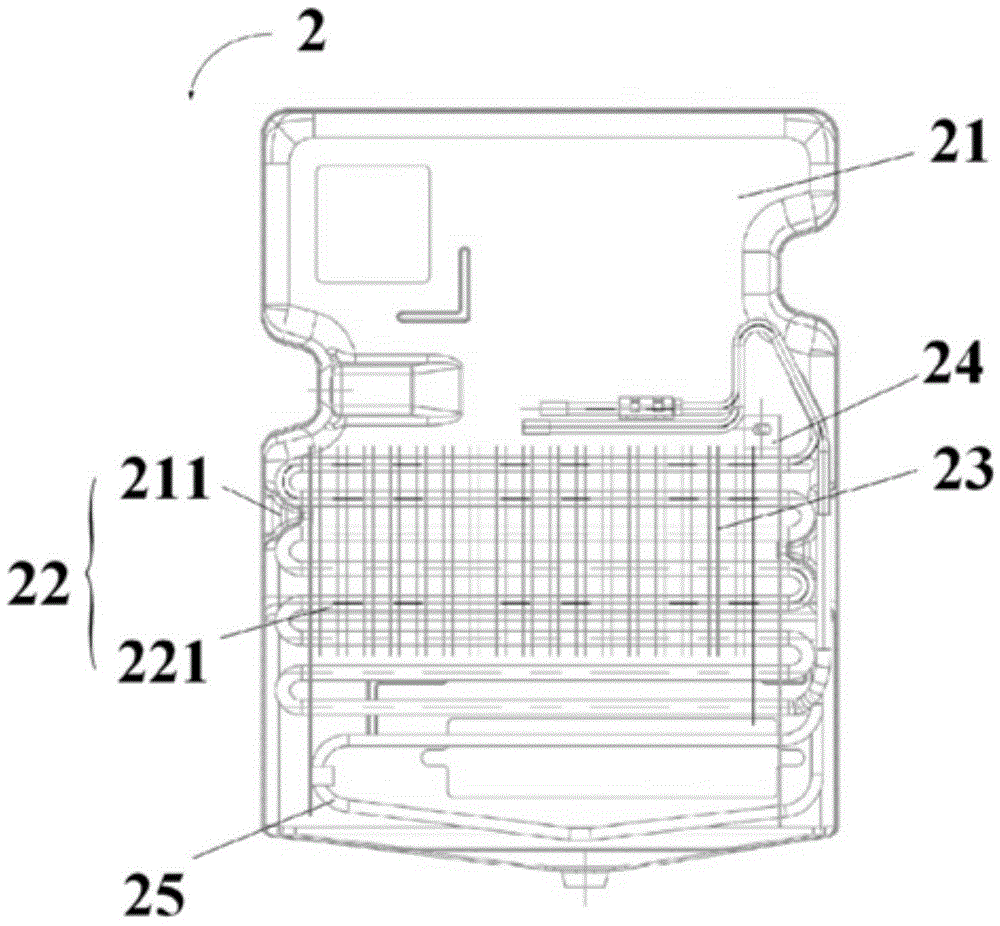

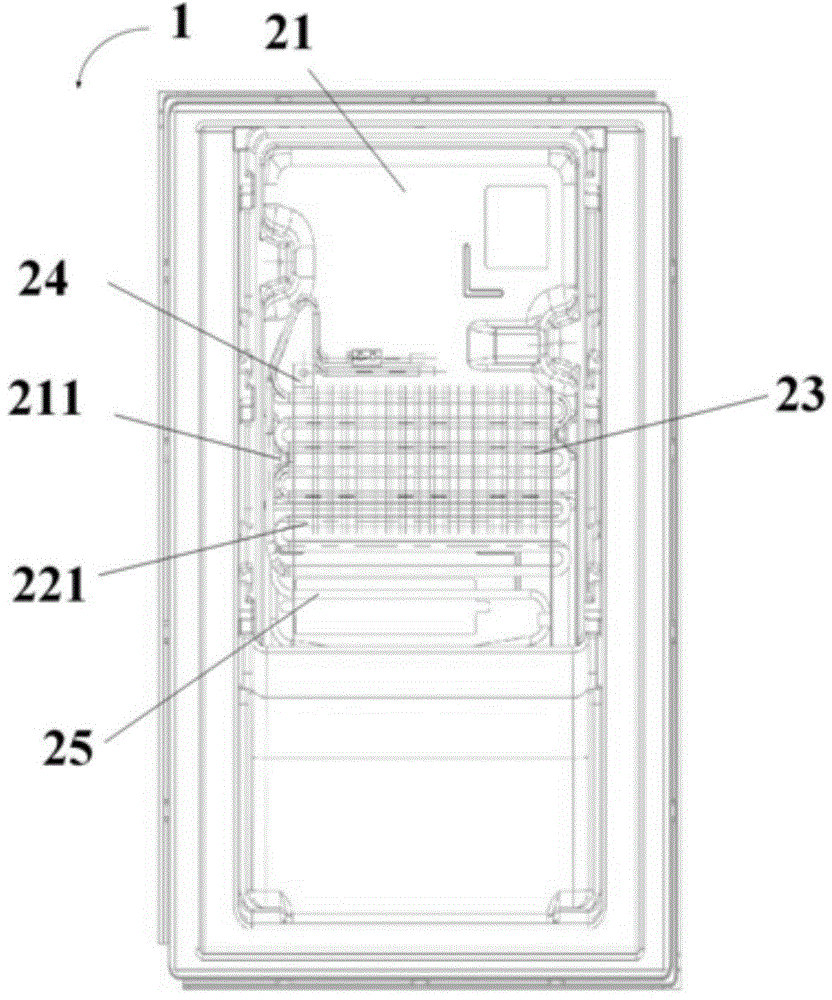

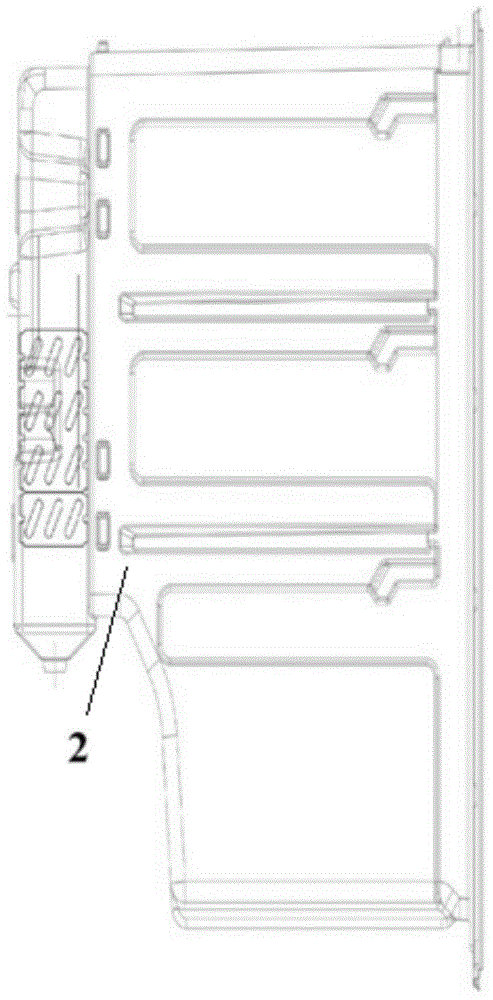

Refrigerator inner container and refrigerator

InactiveCN104864663AAvoid deformationLimit up and down movementLighting and heating apparatusRefrigeration devicesRefrigerator carRefrigerated temperature

The invention provides a refrigerator inner container and a refrigerator. The refrigerator inner container comprises an evaporator and a refrigerator inner container body; the evaporator comprises evaporating pipes; the inner wall of the refrigerator inner container body is provided with bosses which are located below the evaporating pipes and make contact with the outer walls of the evaporating pipes, wherein the bosses are used for supporting the evaporating pipes to enable the evaporator to be assembled on the refrigerator inner container body. According to the technical scheme, the bosses are arranged on the inner wall of the refrigerator inner container body, when the evaporator is installed on the refrigerator inner container body, the bosses can be clamped in the middles of the evaporating pipes of the evaporator to limit the evaporating pipes to move up and down, a role of supporting the evaporating pipes is played, therefore, the stability of the evaporator in the transportation process can be improved, the problems that the evaporating pipes at the bottom of the evaporator is too close to or makes contact with the bottom of the refrigerator inner container body due to the fact that the evaporator falls caused by road bumping can be avoided, then the problem that the refrigerator inner container body is deformed due to the too high temperature can be avoided, and the using safety of the refrigerator can be effectively improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

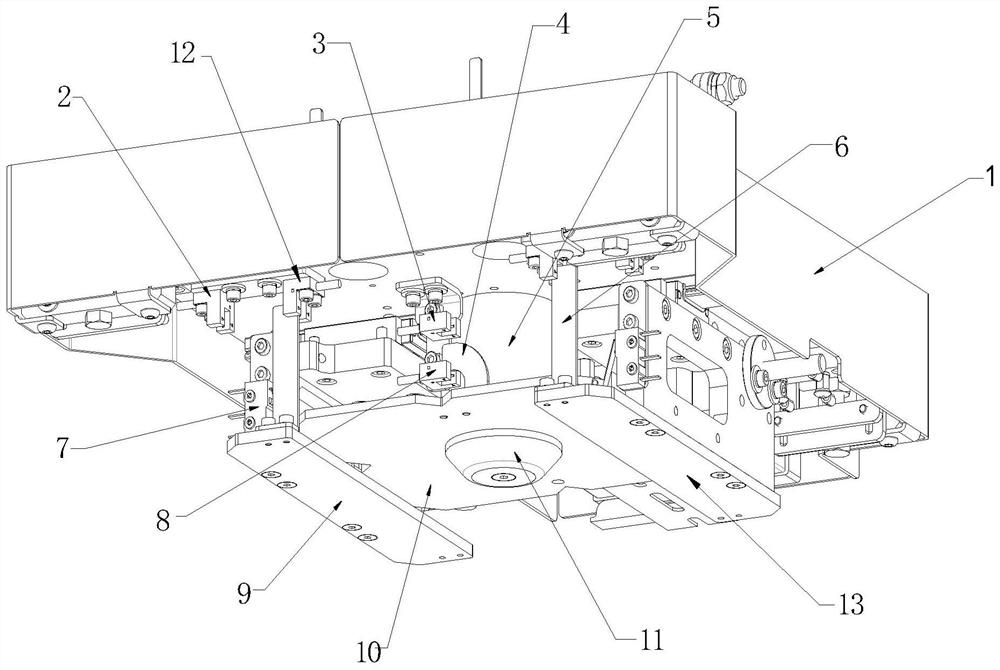

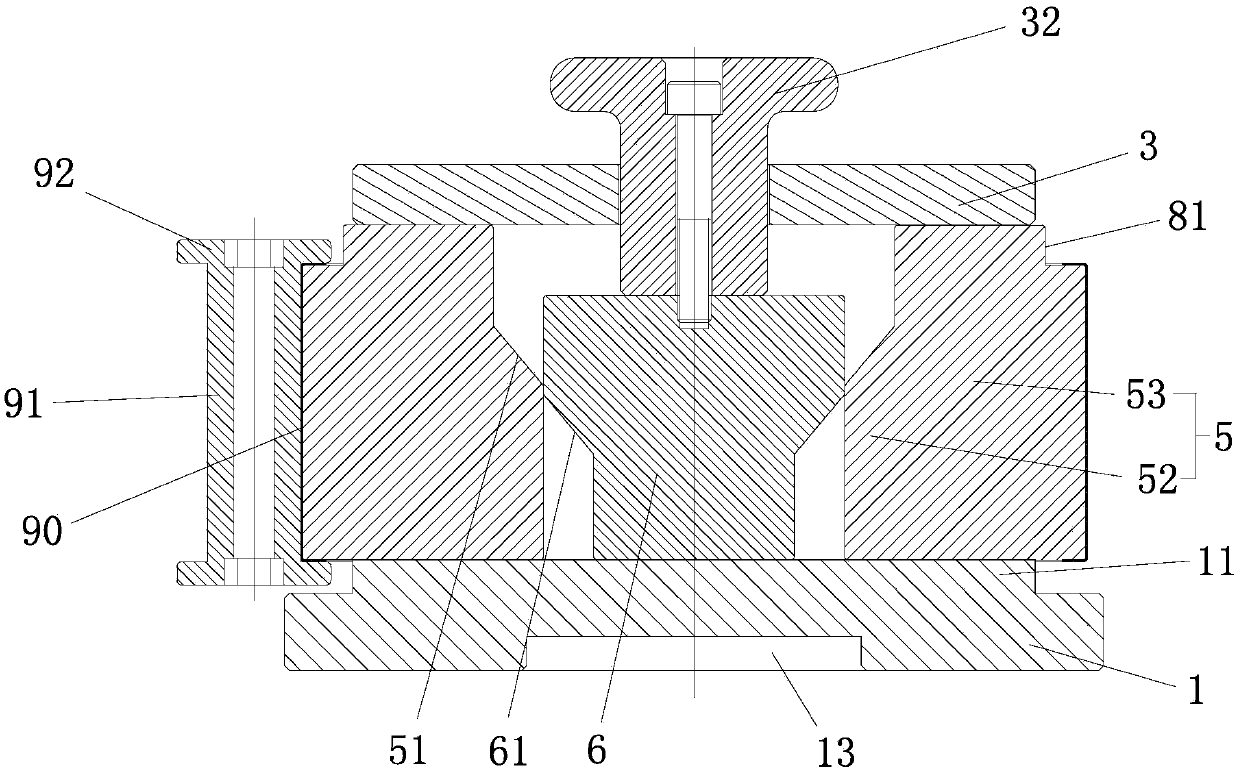

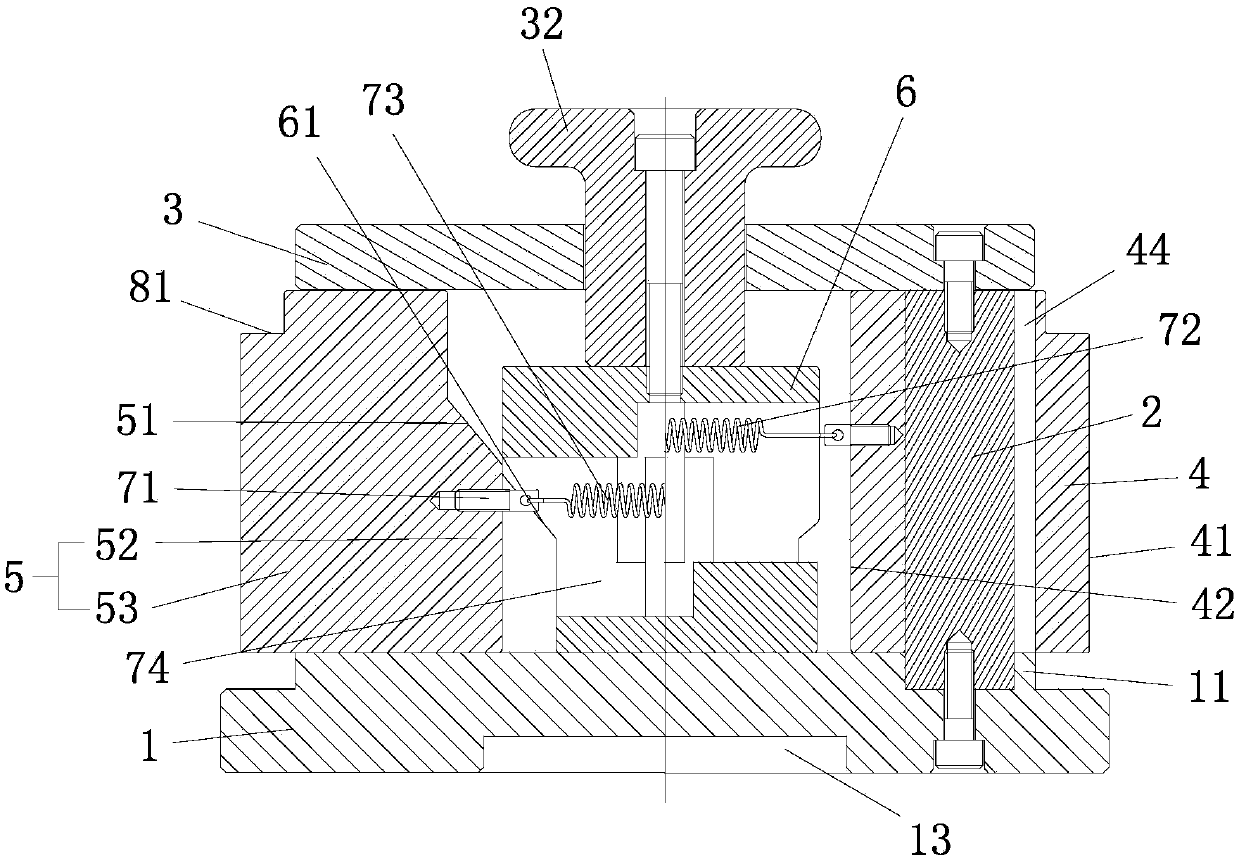

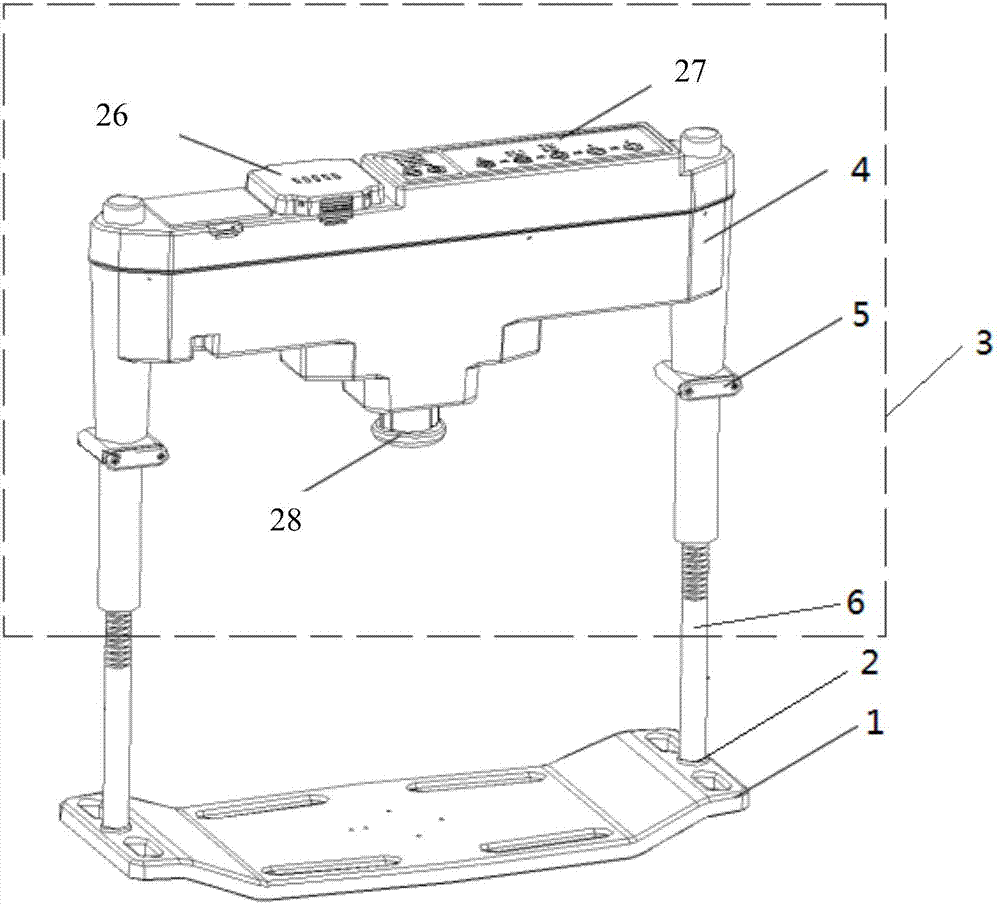

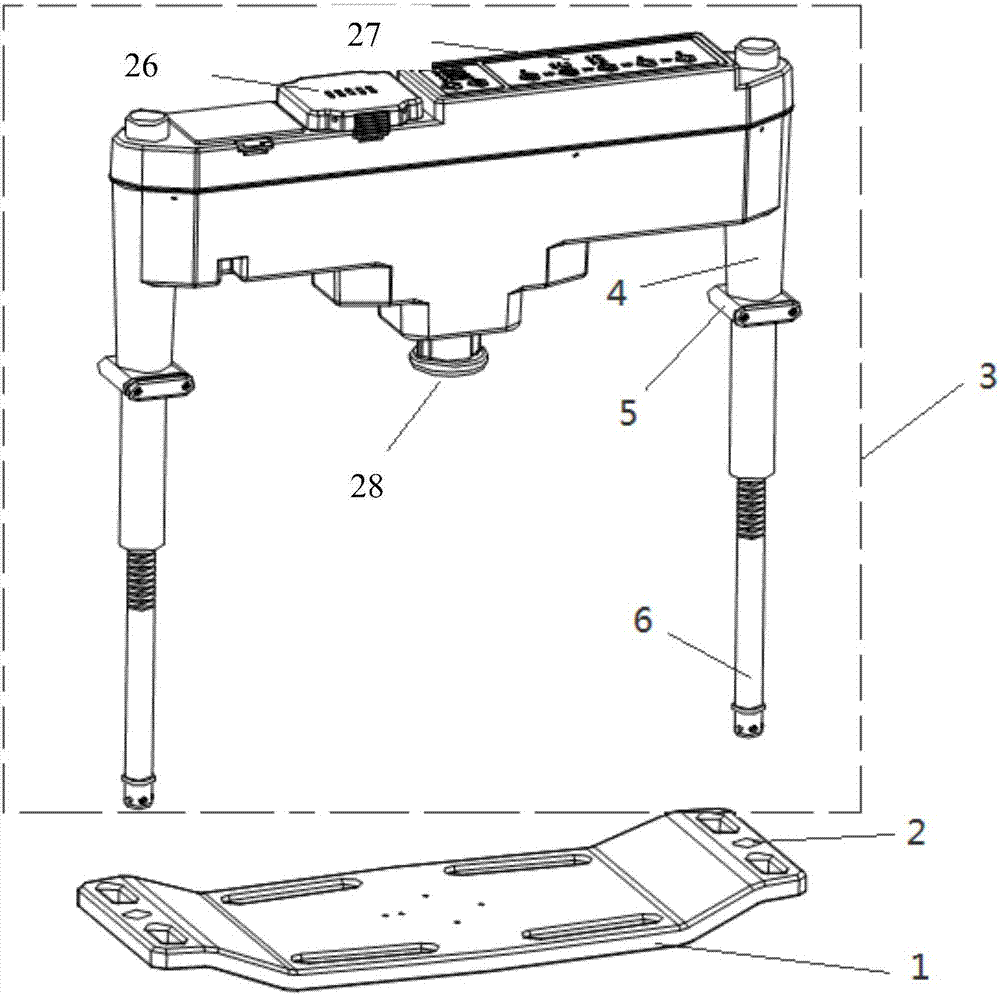

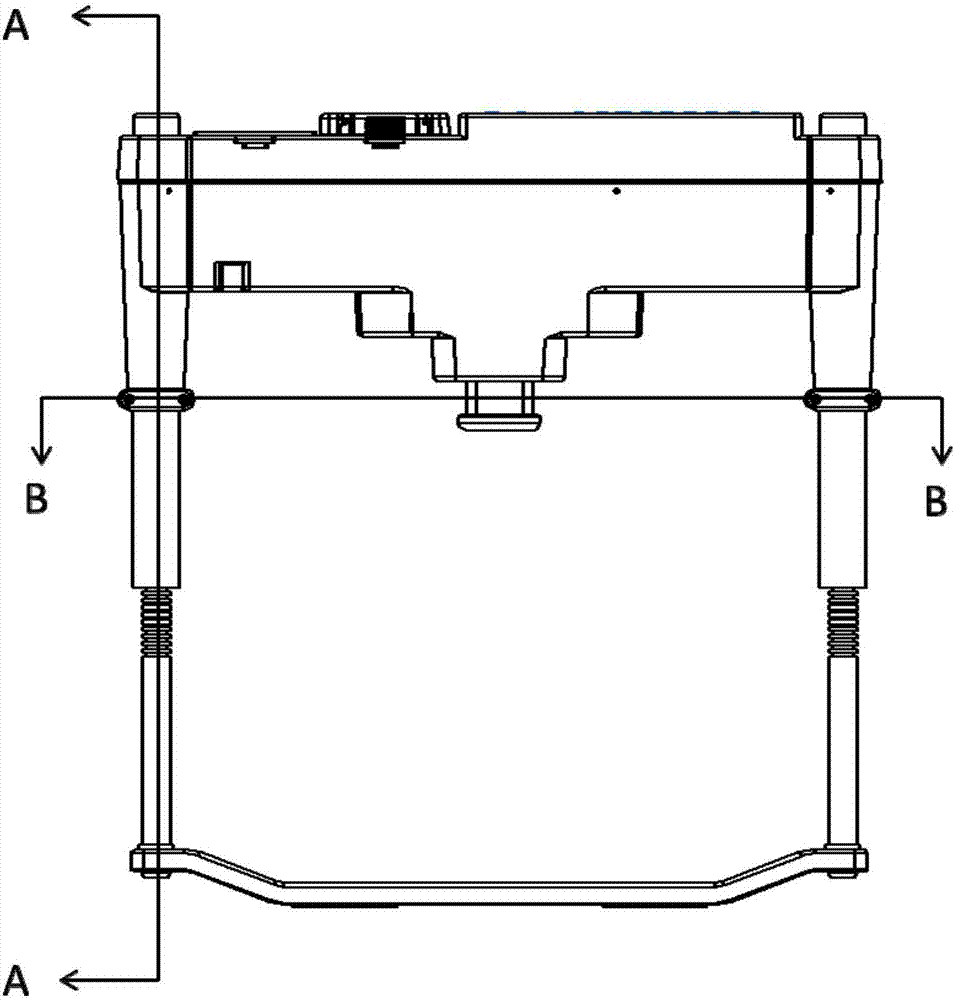

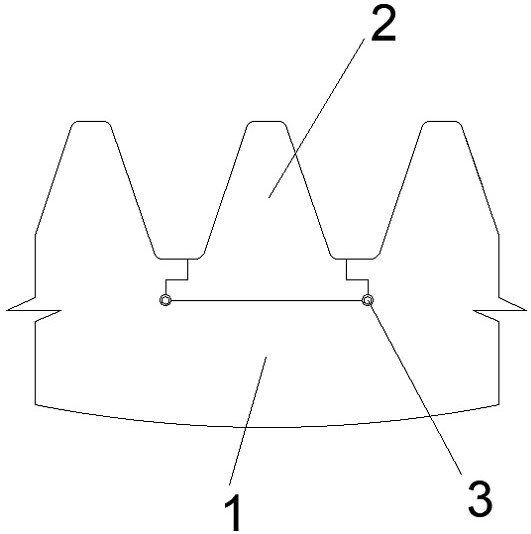

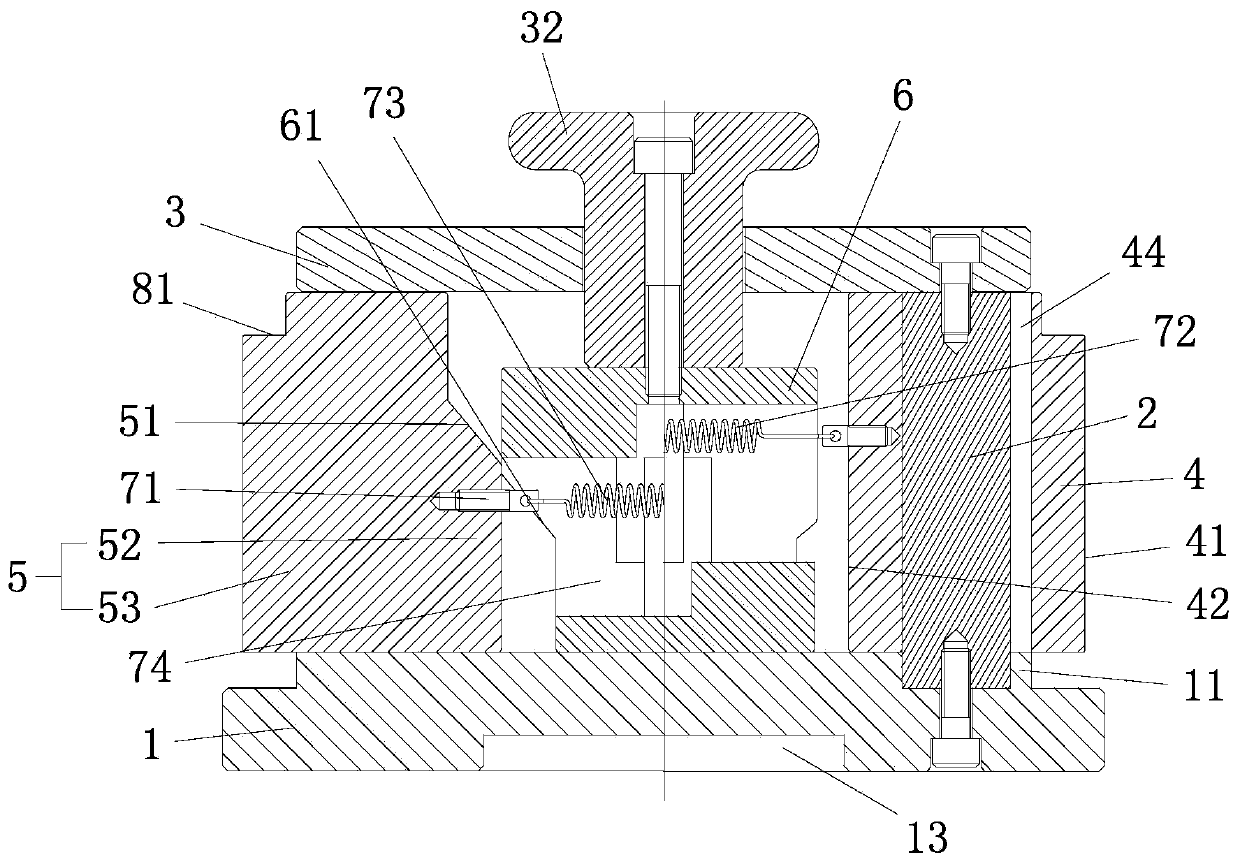

Installing and adjusting device for cardio-pulmonary resuscitation device

ActiveCN107260522AReduce installation adjustment timeSpeed up start timeElectrotherapyRod connectionsEngineeringCardiopulmonary resuscitation

The invention belongs to the field of medical apparatus and instruments, and particularly relates to an installing and adjusting device for a cardio-pulmonary resuscitation device. The installing and adjusting device comprises a back plate and an installing and adjusting assembly, wherein a fixing hole is formed in the back plate; the installing and adjusting assembly comprises an upper framework, an adjusting component and a sliding rod, the upper framework is connected with the adjusting component, and the adjusting component is connected with the sliding rod; the sliding rod is inserted into or pulled out of the fixing hole, and the adjusting component controls the upper framework to move on the sliding rod. In order to solve the problems, the invention provides the installing and adjusting device for the cardio-pulmonary resuscitation device, installation and height adjustment can be synchronously carried out, so that the installation and adjustment time of a cardio-pulmonary resuscitation machine is reduced, and the success rate of cardio-pulmonary resuscitation is improved.

Owner:GUANGZHOU LANDSWICK MEDICAL TECH LTD

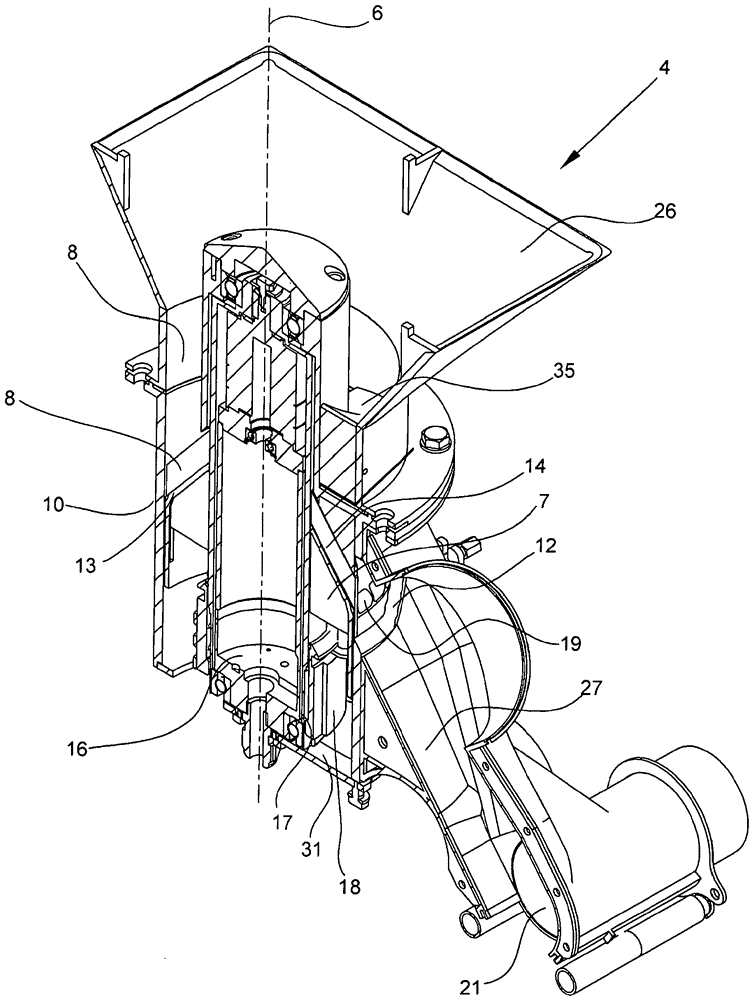

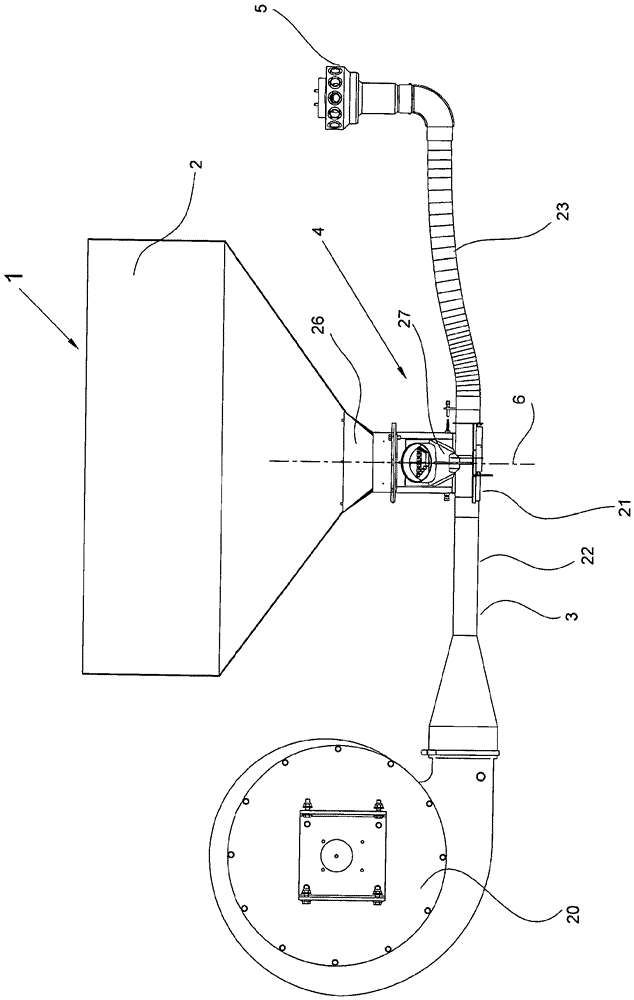

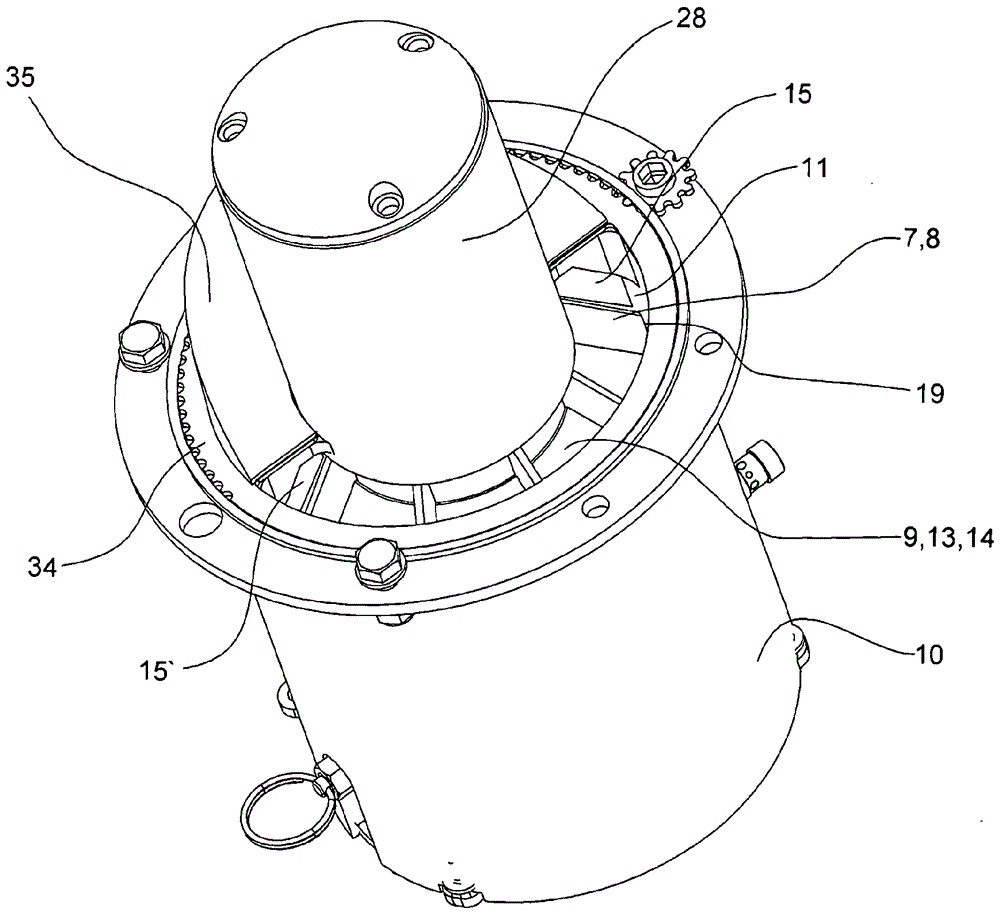

Dispensing system for an agricultural spreader machine

InactiveCN105764322AReliable fillingFill reliably and completelyAgricultural machinesMovable measuring chambersEngineeringRotary feeder

Proposed is a dispensing system (4) for an agricultural spreader machine (1) for discharging granular or granulated material, wherein an upright rotary feeder arrangement (7) is provided, which in combination with an adjustable rotary feeder base (13, 14) allows the dispensing quantity to be varied within a broad range with a reduced drive energy requirement.

Owner:LEMKEN

Pretension and lay-off method and device of crane jib for ship

InactiveCN101983894BReduce supportAvoid fatigue damageCargo handling apparatusPassenger handling apparatusPull forceEngineering

The invention relates to a pretension and lay-off method of a crane jib for a ship, belonging to the technical field of a crane. The crane comprises a luffing mechanism composed of a top pulley block, a jib, a winch, a luffing wire rope and a jib head pulley block and a bracket. The method comprises the following steps: A. operating the winch in the forward direction, loosening the jib and layingoff the jib onto the bracket; and B, operating the winch in the reverse direction, pulling the jib upwards to enable the pressure of the jib on the bracket to be less than the pressure on the bracketbefore being subjected to the upward pull, and stopping and shutting off the winch. The invention also relates to a pretension and lay-off device of a crane jib for a ship. The luffing mechanism alsocomprises a middle pulley arranged at the middle of the jib, and the luffing wire rope is connected with the jib head pulley block and the middle pulley through the top pulley block. The pretension and lay-off method and device of a crane jib for a ship can produce a pretension force on the jib by means of the luffing wire rope, thereby reducing the self-weight load of the jib as well as the influence and the destruction on the jib structure as a result of the shock load and the changing load of the bracket on the jib. Besides, the invention has the advantages of simple method and structure, convenient operation and low cost.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

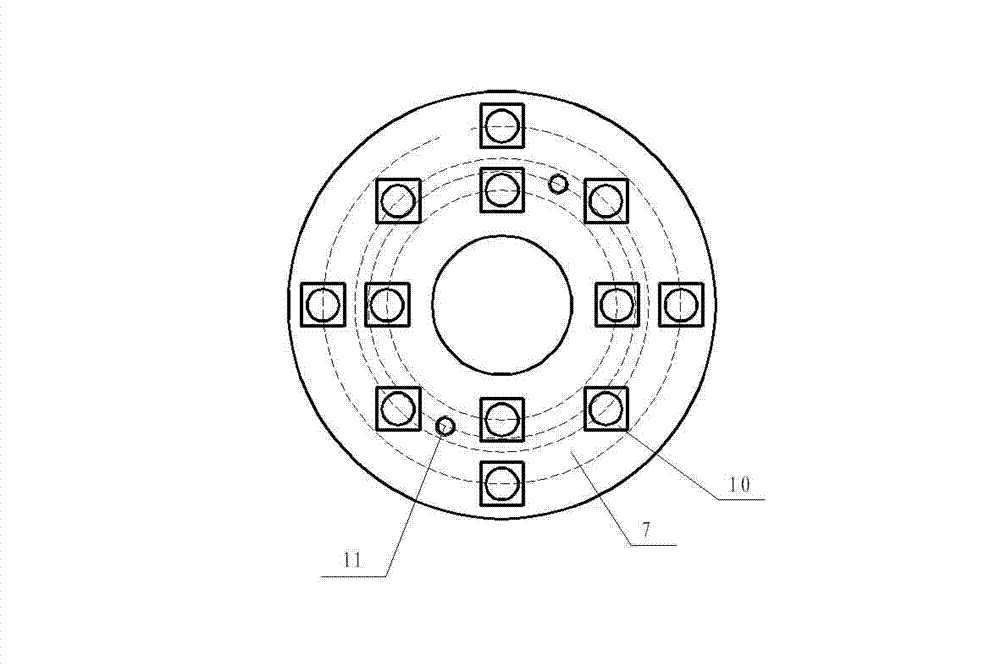

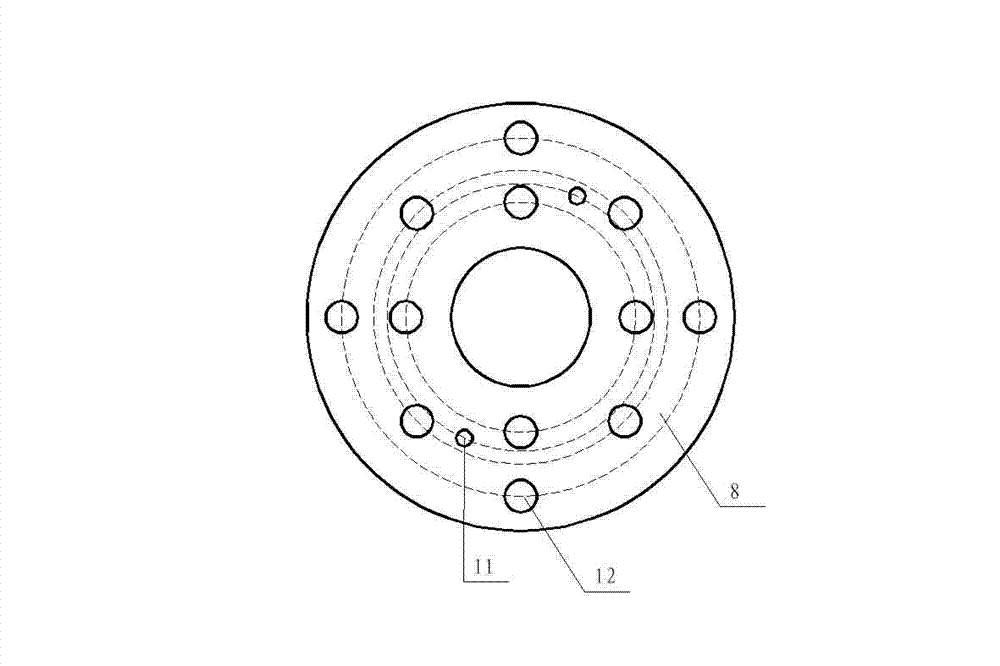

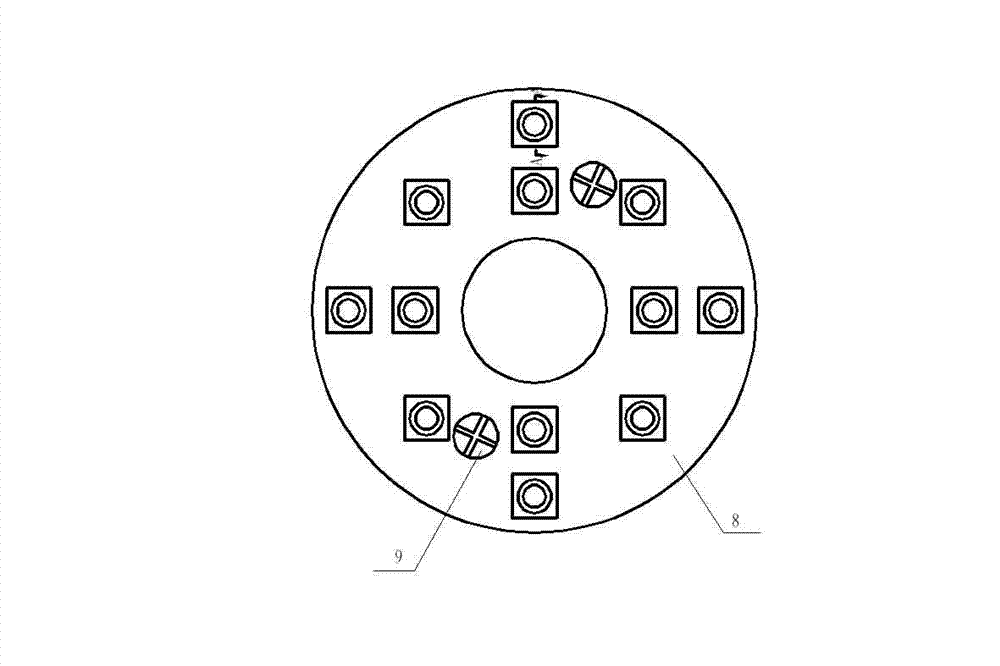

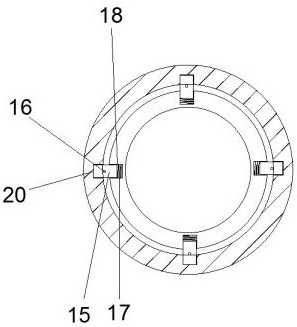

Disc type movable polishing grinding tool

InactiveCN102267106BLimit up and down movementRealize batch processingBonded abrasive wheelsEngineeringMachine tool

A disc type movable polishing grinding tool relates to a polishing grinding tool for a stone machine tool, which aims at carrying out polishing treatment on planes of irregular stones. The disc type movable polishing grinding tool is structurally characterized in that a plurality of grooves are arranged on a grinding disc pedestal and are internally provided with a grinding unit body respectively; each grinding unit body is structurally characterized in that a sheath is connected with a base, a spring is sheathed outside a single grinding head which is fixed in the sheath through a limiting pin, and a limit gasket is arranged between the sheath and the base; and through holes of which the number and positions correspond to those of the grooves are arranged on a grinding disc cover plate, and the single grinding head of each grinding unit body penetrates through the through holes of the grinding disc cover plate after the grinding disc cover plate is connected with the grinding disc pedestal. The disc type movable polishing grinding tool is applicable to the stone machine tool for carrying out polishing treatment on planes of irregular stones, can also carry out polishing treatmenton the surfaces of non-planar stones while realizing the polishing treatment on the planes, thus being capable of greatly improving the current polishing treatment efficiency on the surfaces of non-planar stones.

Owner:SHENYANG INST OF ENG

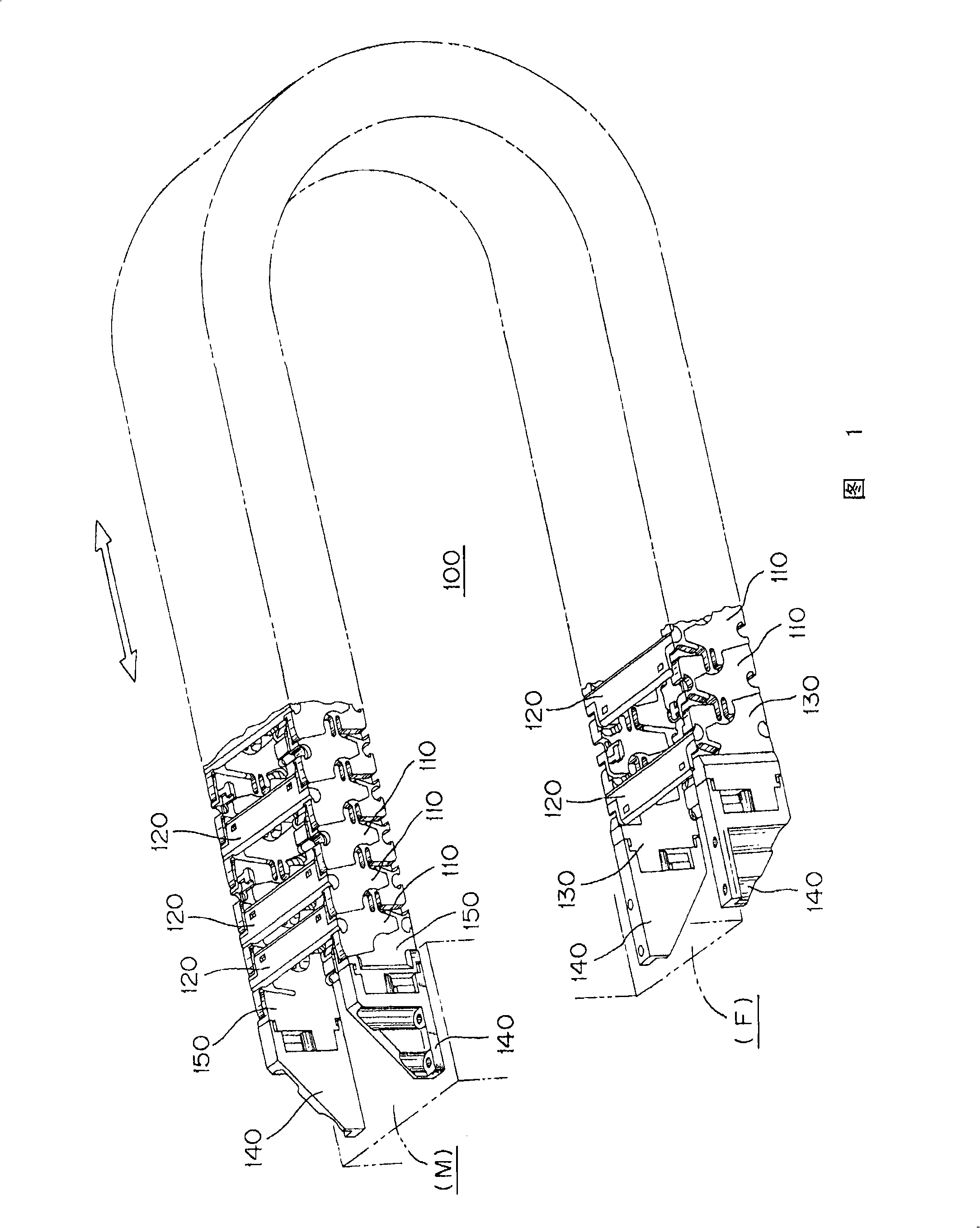

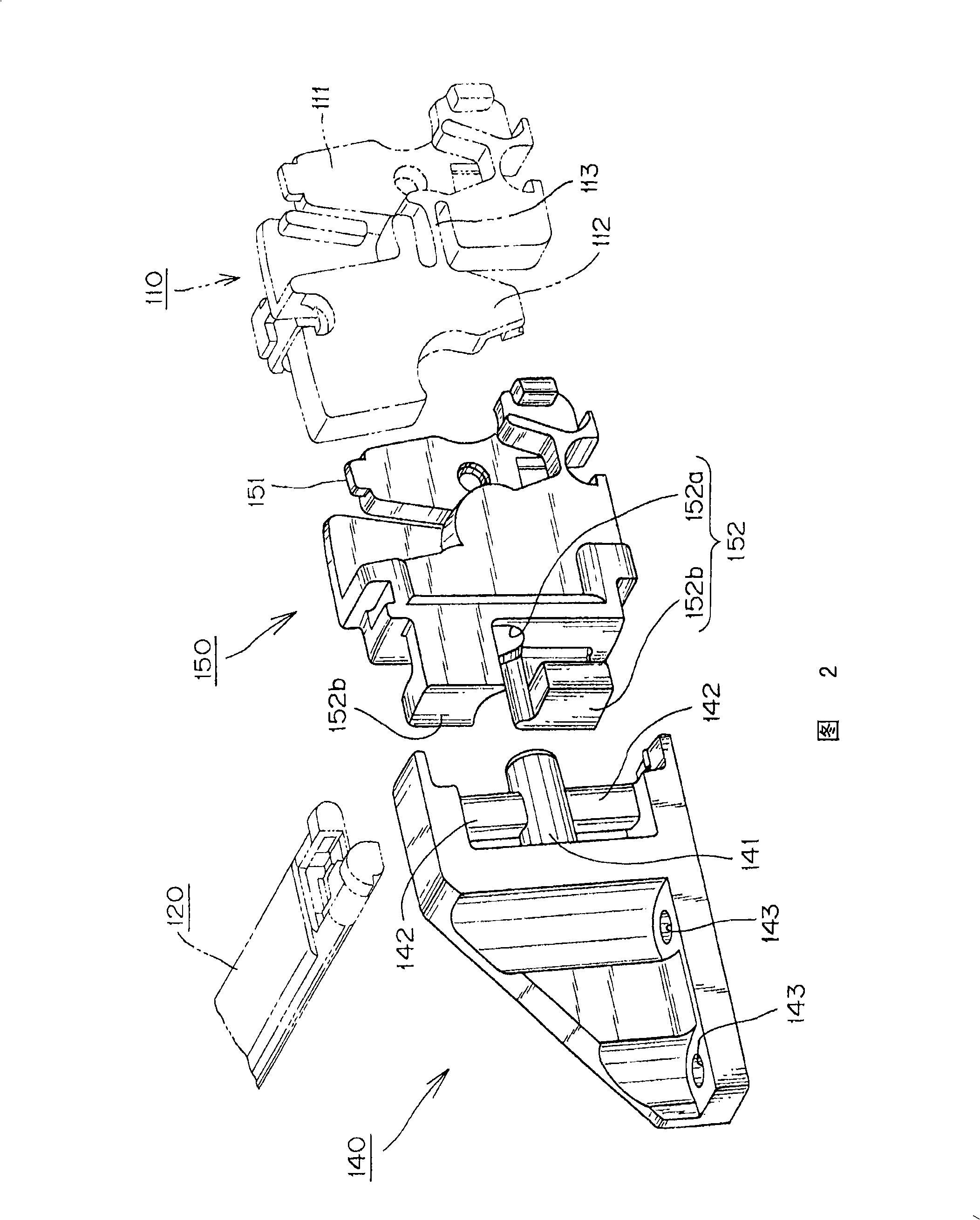

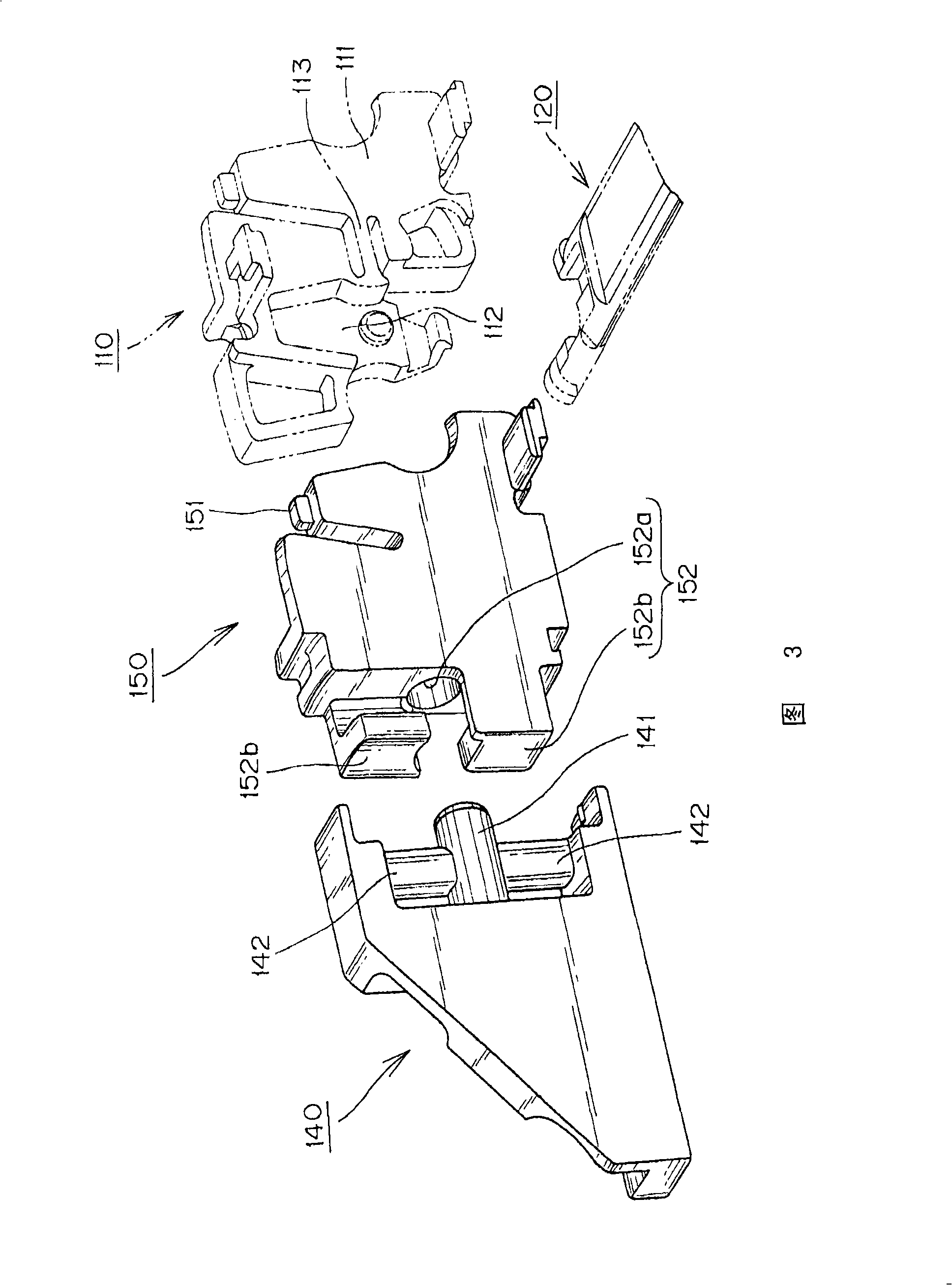

Cable protection and guide device

ActiveCN101294613AStable fastening forceLimit up and down movementHauling chainsHoisting chainsScrew thread

Owner:TSUBAKIMOTO CHAIN CO

Power connection device of power supply system power connection terminal

PendingCN113972610AThe relative position relationship is stableAvoid short circuitCable junctionsSurface corrosionElectrical and Electronics engineering

Owner:唐锟

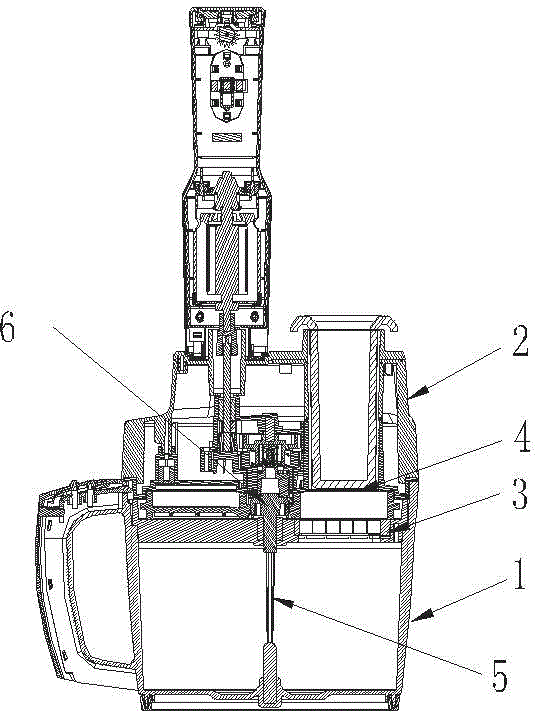

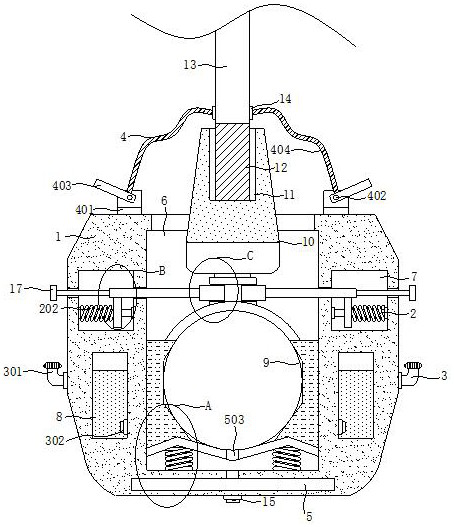

Vertical assembling tool for automobile engine ball head assembly

ActiveCN112922955AImprove plasticityEasy to limit handlingEngine sealsPivotal connectionsFriction forceAutomotive engine

The invention discloses a vertical assembling tool for an automobile engine ball head assembly, and relates to the technical field of automobile parts. The vertical assembling tool for the automobile engine ball head assembly comprises a ball seat, a limiting mechanism, a lubricating mechanism and a damping mechanism are arranged in the ball seat, a dustproof mechanism is arranged above the ball seat, and a first cavity, a second cavity and a lubricating oil cavity are formed in the ball seat. According to the vertical assembling tool for the automobile engine ball head assembly, through cooperative use of an oil inlet nozzle, an oil inlet pipe and an oil uniformizing sponge, a ball pin can be conveniently lubricated, and the problems that the ball pin is used for a long time, due to the fact that the friction force is too large, the wear condition of the ball pin is serious, a ball head is loosened, and consequently an automobile shakes in running and is difficult to return are solved; and friction between the ball pin and other parts in the using process can be effectively reduced, the service life of the ball head assembly is prolonged, and therefore popularization and use are convenient.

Owner:重庆峰聂机械有限公司

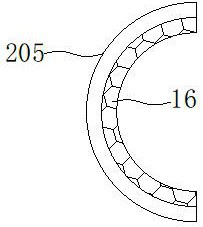

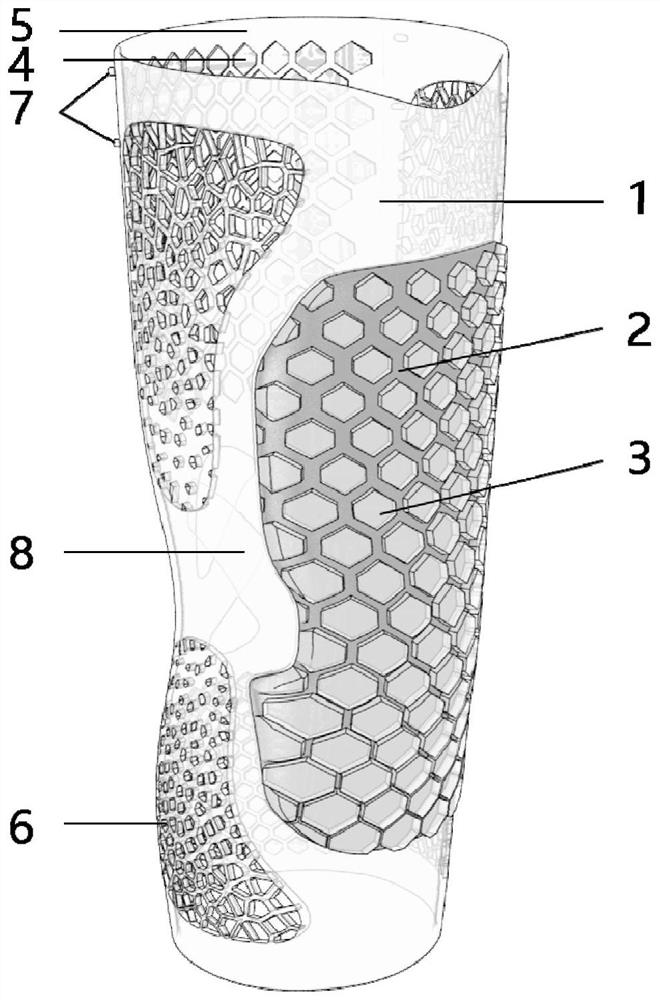

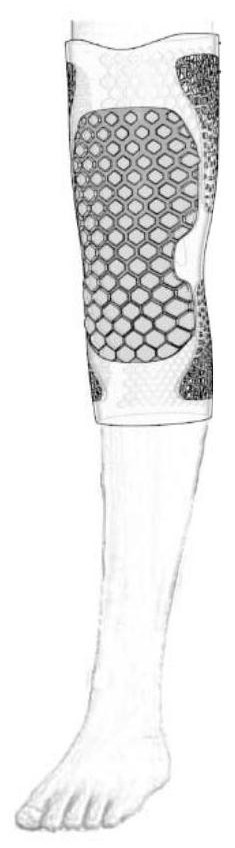

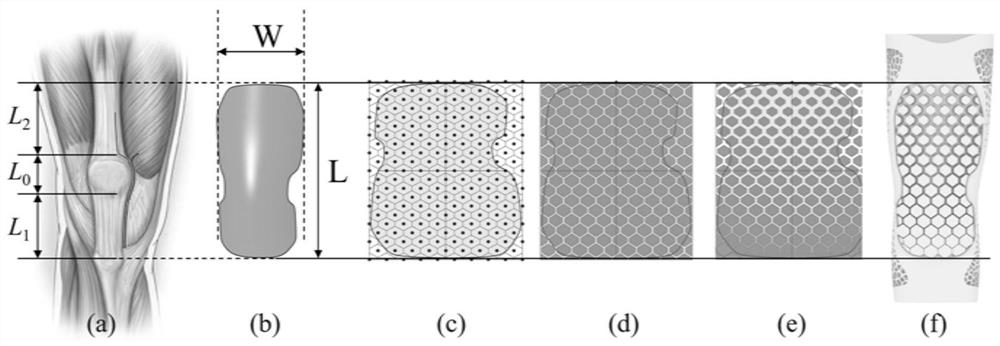

In-vitro orthopedic device and manufacturing method thereof

ActiveCN112137785ATo achieve a gradual change in stiffness to largeStimulate contractionMedical scienceOrthopedic devicesKnee Joint

The invention discloses an in-vitro orthopedic device and a preparation method thereof. The in-vitro orthopedic device comprises an orthopedic main body, a front orthopedic surface and a rear orthopedic surface, wherein the orthopedic main body is in a hollow cylinder shape, openings are formed in the front surface, the rear surface, the left surface and the right surface of the orthopedic main body, and the front orthopedic surface and the rear orthopedic surface are arranged in the front opening and the rear opening of the orthopedic main body respectively. A front blocky structure bottom surface and front outer side unit blocks form a front blocky structure area. The front outer side unit blocks are hexagonal unit blocks which are distributed from top to bottom, from small to large in size and from large to small in gaps, and when the knee joint of a user stretches backwards and is in a bent state, the gaps between part of the front outer side unit blocks can be shrunk to start to generate contact extrusion, and tiny deformation resistance can be generated. According to the blocky structure, gradual change of rigidity is achieved by adjusting the gaps between the front outer side unit blocks.

Owner:XI AN JIAOTONG UNIV

Method for repairing large gear ring of embedded shield main bearing

The invention discloses a method for repairing a large gear ring of an embedded shield main bearing, and belongs to the technical field of shield tunneling machines. The problems that in the prior art, the repairing process is complex, the repairing cost is high, stress concentration is prone to being generated, and the safety performance of the large gear ring is affected are solved. The method comprises the following steps: 1, analyzing a large gear ring material; 2, analyzing and designing a tooth shape; 3, mounting grooves for mounting the embedded teeth are formed in the large gear ring; 4, carrying out embedded tooth machining and heat treatment according to the tooth shape, size and chemical components; 5, mounting the embedded teeth and the mounting grooves in an interference fit manner; and 6, forming threaded holes in the connecting positions of the embedded teeth and the large gear ring, locating one part of the hole wall of each threaded hole on the corresponding embedded tooth, locating the other part of the hole wall of each threaded hole on the corresponding mounting groove, mounting screws through the threaded holes, and finally carrying out cold welding treatment on gaps between the embedded teeth and the large gear ring. The repairing method is simple, the phenomenon of stress concentration is avoided, and the repairing effect and safety performance of the large gear ring are improved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

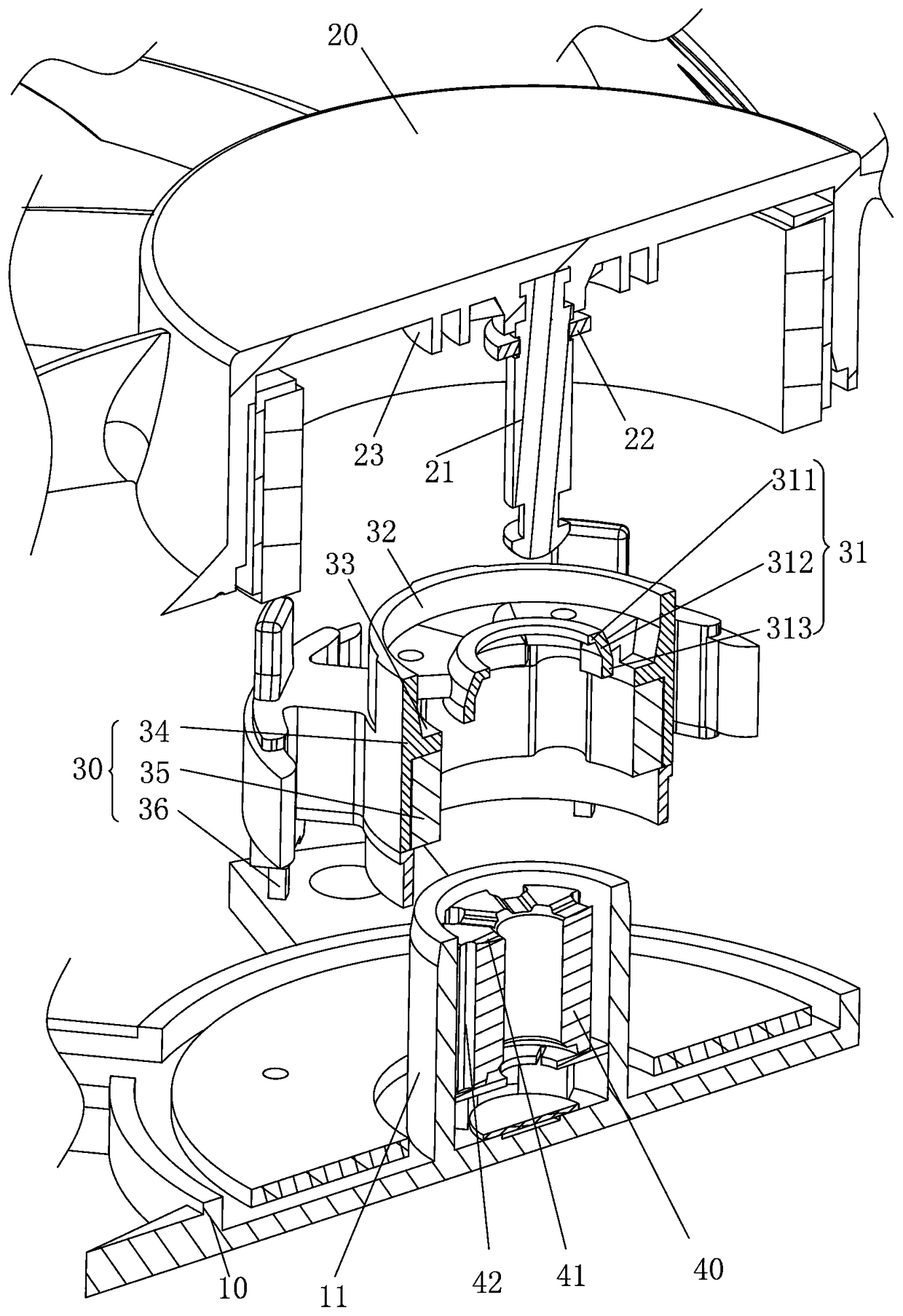

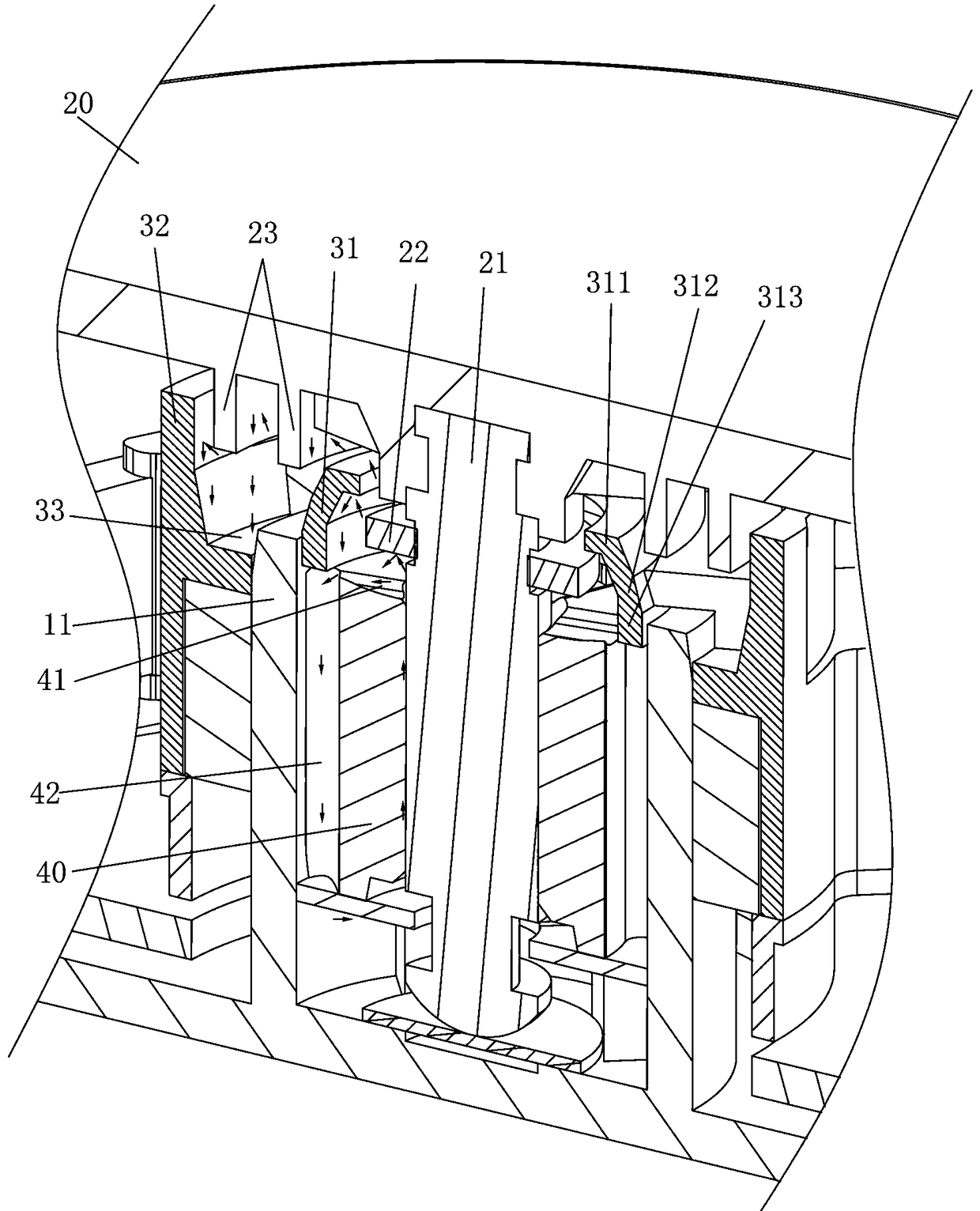

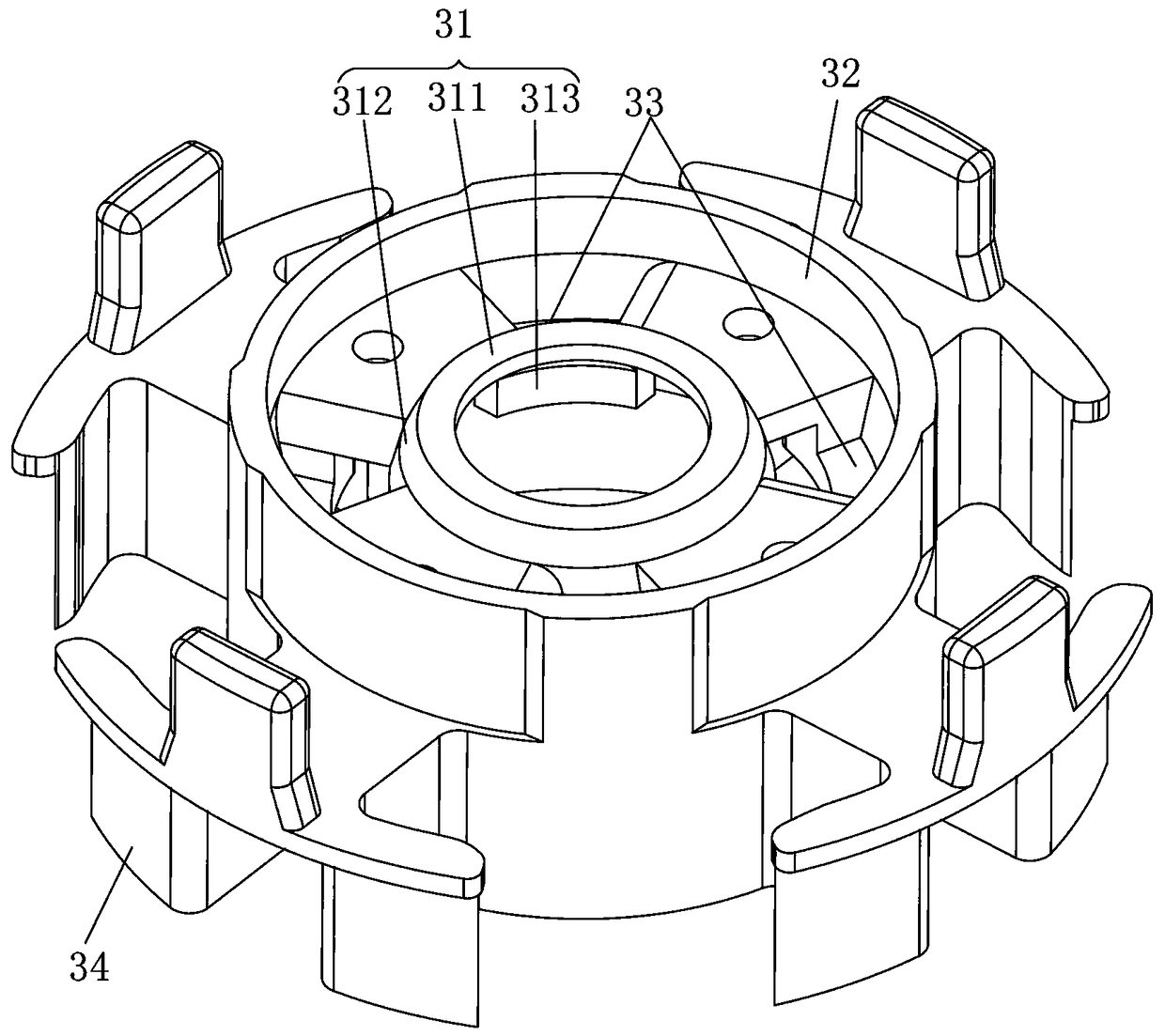

A shrinking mold for an inner slider

ActiveCN108031749BAchieve shrinkageTake it out smoothlyShaping toolsHollow articlesDistractionContraction function

Disclosed is an inner sliding block contraction mould. The inner sliding block contraction mould comprises a bottom plate, a plurality of guiding blocks evenly distributed on the bottom plate in the circumferential direction of the center of the bottom plate and an upper cover plate fixed to the guiding blocks. A plurality of first sliding blocks, second sliding blocks used for driving the first sliding blocks to slide towards the outer side and tapered wedges used for driving the second sliding blocks to slide towards the outer side are arranged between the bottom plate and the upper cover plate. The first sliding blocks and the second sliding blocks are located at the peripheries of the tapered wedges. Each first sliding block is mounted on the corresponding guiding block in a sleeving mode. Each second sliding block is located between the two adjacent first sliding blocks. The inner side faces of the first sliding blocks and the second sliding blocks are connected with reset mechanisms used for driving the first sliding blocks and the second sliding blocks to slide towards the center. The inner sliding block contraction mould has the distraction and contraction functions, in theworkpiece forming process, a workpiece is supported and abutted against through the distracted first sliding blocks and the distracted second sliding blocks; and after workpiece forming, the first sliding blocks and the second sliding blocks are contracted, the workpiece is taken out, and machining of inward folding or the pressure level of a round barrel body part is facilitated.

Owner:佛山市顺德区和协模具制造有限公司

Heat dissipation fan with multiple oil return functions

PendingCN109488624AReduce throwRealize oil return functionPump componentsPump installationsReturn functionFan blade

The invention provides a heat dissipation fan with multiple oil return functions. The heat dissipation fan comprises a fixed seat, a fan blade and a stator, wherein a shaft sleeve is arranged in the center of the fixed seat, an inserting hole is formed in the center of the stator, the shaft sleeve is inserted into the inserting hole to enable the stator to sleeve outside the shaft sleeve, and therotating shaft of the fan blade is installed in the shaft sleeve through a bearing; the inner wall of the inserting hole is connected with an oil baffle ring, and the oil baffle ring is positioned above the shaft sleeve and sleeves outside the rotating shaft; and a plurality of oil return top grooves are formed in the top surface of the bearing, a plurality of oil return side grooves are formed inthe side face, the inner ends of the oil return top grooves communicate with bearing holes of the bearings, and the outer ends of the oil return top grooves communicate with the upper ends of the oilreturn side grooves. According to the heat dissipation fan, the oil baffle ring can block most lubricating oil thrown out from the opening of the shaft sleeve, the blocked lubricating oil falls backto the surface of the bearing and reenters the gap between the bearing and the rotating shaft sequentially along the bottom gaps among the oil return top grooves, the oil return side grooves, the bearing and the shaft sleeve, so that the oil return function is realized, and the lubricating oil is reduced from being thrown out.

Owner:SHENZHEN GAO YU ELECTRONIC TECHNOLOGY CO LTD

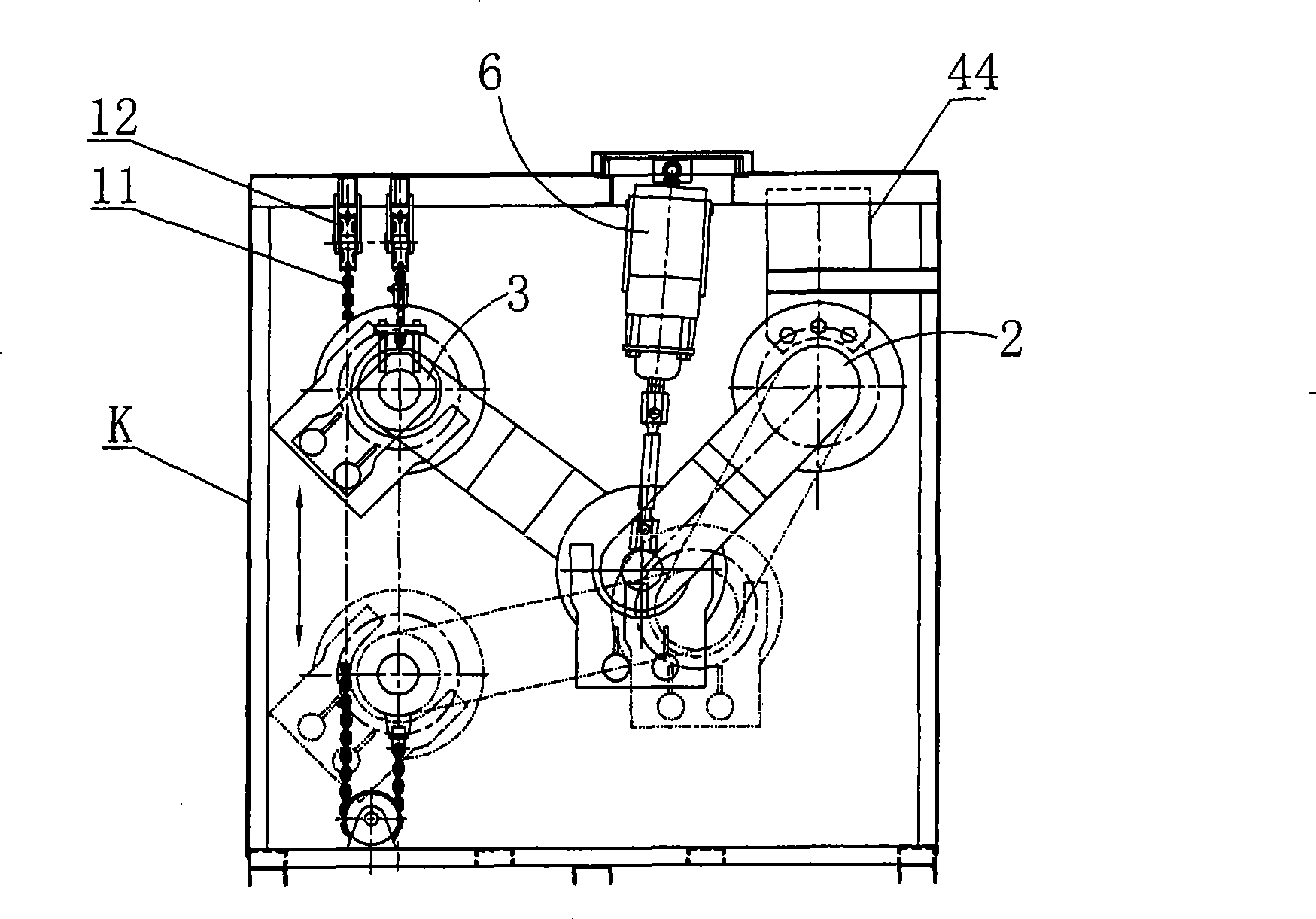

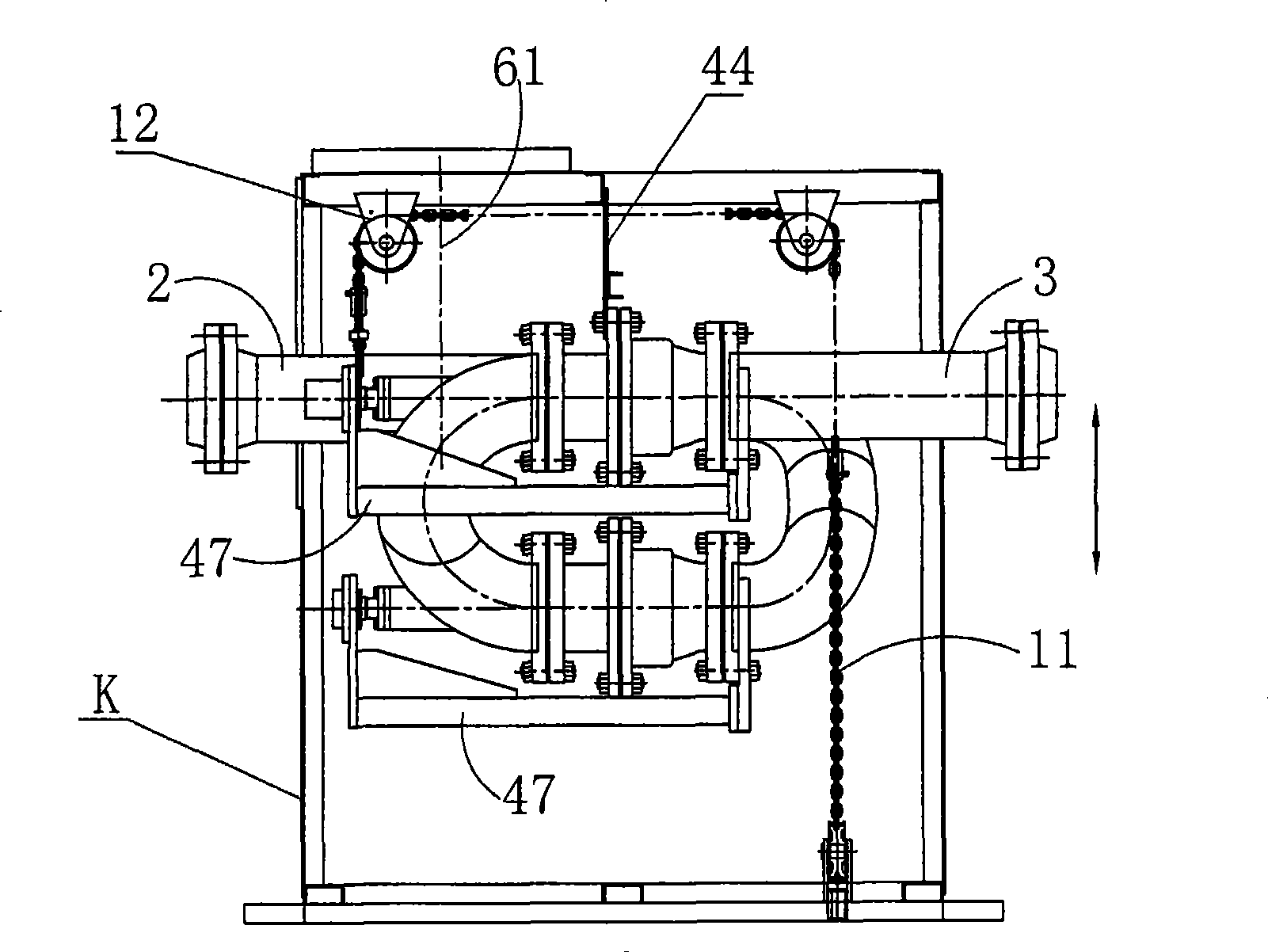

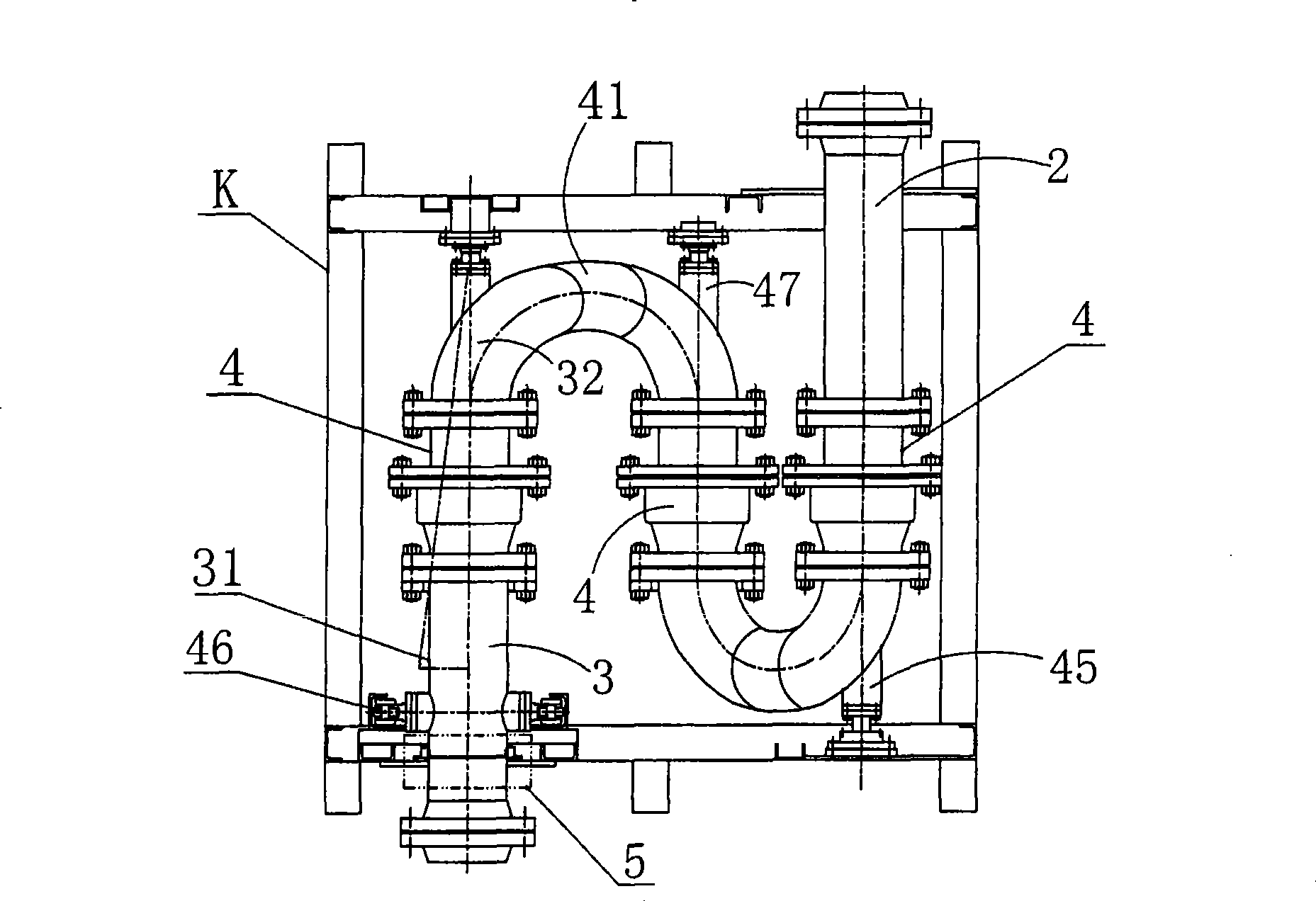

Flexible apparatus of balanced type movable hood

ActiveCN101418364BFlexible movementReduce resistanceManufacturing convertersChimneysBalancing machineSpherical joint

The invention discloses a flexible device for a balanced movable smoke cover, which comprises an S-shaped rotary loop mechanism, wherein one end of the S-shaped rotary loop mechanism is provided with a fixed part and the other end of the S-shaped rotary loop mechanism is provided with a movable part. The flexible device for the balanced movable smoke cover is characterized in that the device alsocomprises a balance mechanism which can make the front end and the rear end of the movable part maintained on the horizontal position, wherein one end of the balance mechanism is connected with the front end of the movable part and the other end of the balance mechanism is connected with the rear end of the movable part. Moreover, balanced chainwheel and chain structures are arranged on front pipeline sections and rear pipeline sections of spherical joints of the movable end, so that front pipeline sections and rear pipeline sections of a first group of spherical joints of the movable part are guaranteed to maintain on the horizontal position during the process of vertical motion, thereby the flexible device is flexible to move and has the smallest resistance.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

High-voltage control box for power electronic converter of new energy automobile

PendingCN114516271ALimit up and down movementPrevent disengagementElectric powerVehicular energy storageNew energyScrew thread

The invention relates to the technical field of new energy automobile accessories, and discloses a new energy automobile power electronic converter high-voltage control box which comprises a base and an outer shell arranged at the upper end of the base, a built-in element is fixedly installed on the base, and a fixing mechanism is fixedly installed on one side of the outer shell. The fixing mechanism comprises an L-shaped clamping plate fixedly installed at one end of the outer shell and a connecting plate fixedly installed at one end of the base, threaded holes are formed in the L-shaped clamping plate and the connecting plate, bolts are connected into the threaded holes in a threaded mode, a rubber sleeve is further fixedly installed on the connecting plate, the rubber sleeve and the threaded holes are communicated with each other, and the connecting plate is fixedly connected with the base. An expansion opening is formed in the surface of the rubber sleeve in the circumferential direction. The inner wall of the rubber sleeve is attached to the bolt, friction force is increased, up-and-down movement of the bolt is limited, the bolt is prevented from being separated from the threaded hole due to up-and-down vibration, and the anti-thread-slipping effect and the fastening effect are good.

Owner:HEILONGJIANG INST OF TECH

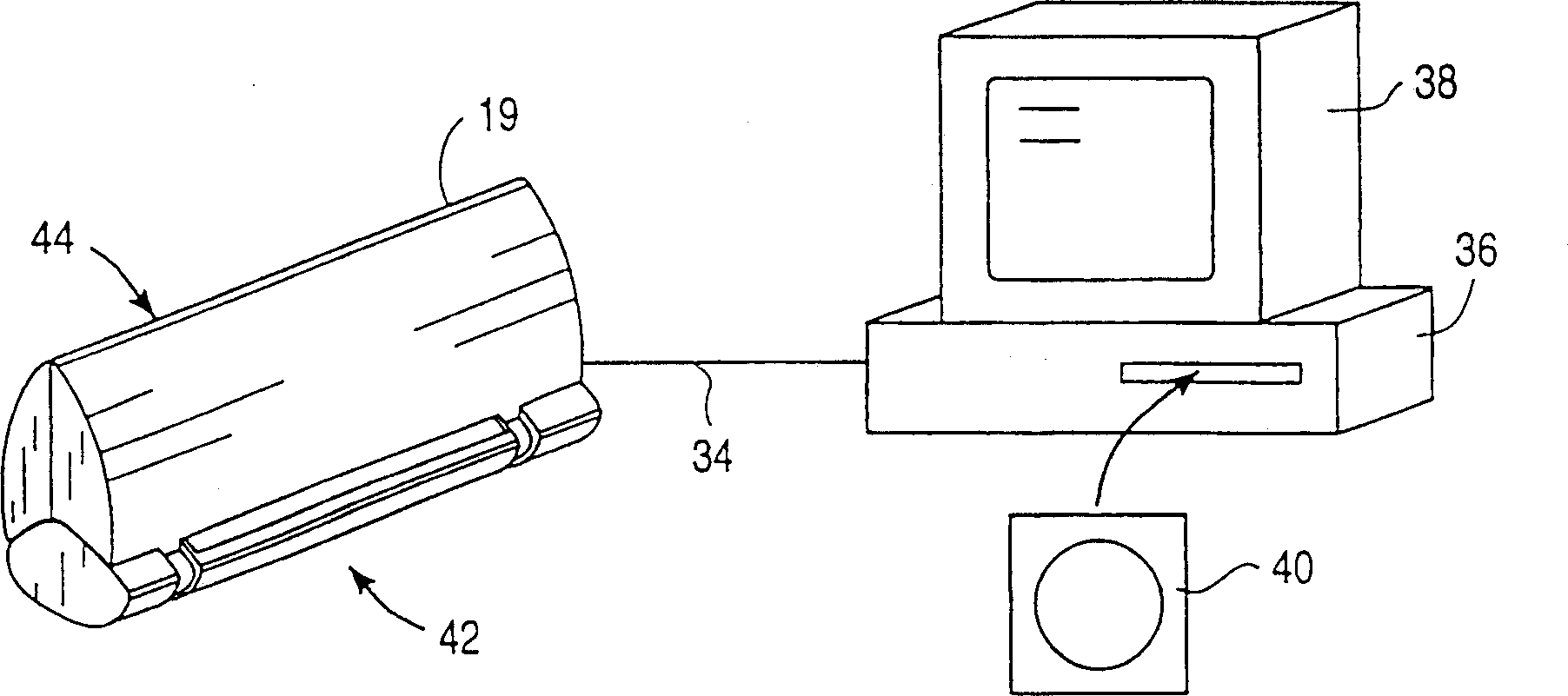

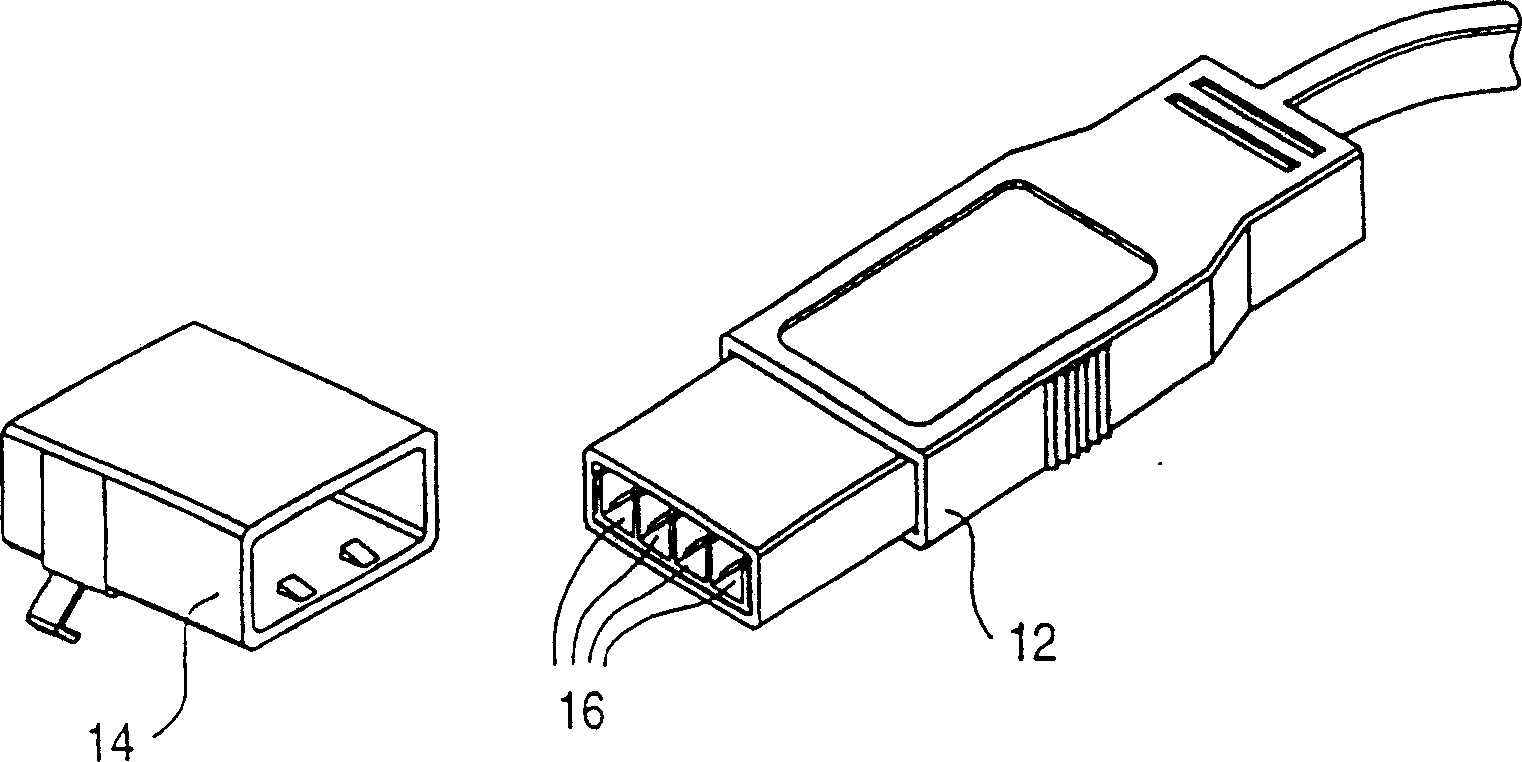

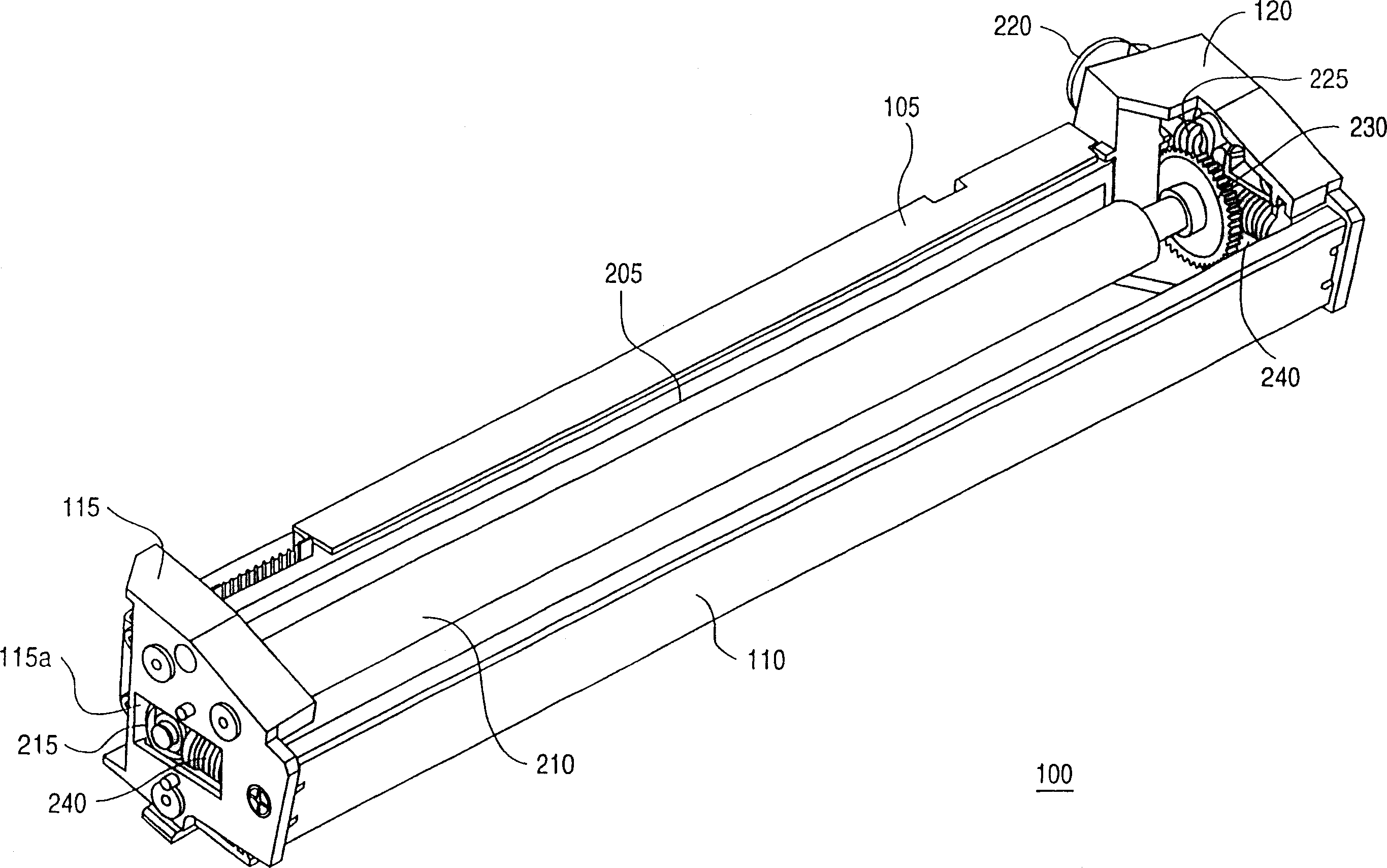

Scanner powered by peripheral bus

InactiveCN1159903CLimit up and down movementEliminate torqueImage data processing detailsPictoral communicationContact image sensorEngineering

A scanner powered by the limited power available on a peripheral bus. In particular, the scanner can operate within the 2.2 watts provided over a USB connector. The scanner of the present invention uses a contact image sensor (CIS) which uses optics to distribute light from each light emitter to multiple pixel positions, preferably using a single LED for each color. An electric motor for driving the platen uses rare earth magnets to limit the power required. Instead of the traditional method of biasing the CIS scanner against the platen with a spring, the platen itself is spring-biased. The moveable spring biasing of a platen is possible because a worm drive motor is used allowing a helical thread on the worm drive to contact the platen gears as they move up and down as biased. Preferably, the helical thread of the worm gear has a single point of contact with a gear on the platen, further limiting the friction and allowing the platen to move up and down with respect to the stationary motor.

Owner:LITE ON TECH CORP

Electrical automation instrument protection device

InactiveCN112378472AImprove accuracyExtended service lifeVolume meteringVibration amplitudeStructural engineering

The invention discloses an electrical automation instrument protection device which comprises a supporting plate, a box body is fixedly arranged on the supporting plate, damping devices are symmetrically and fixedly arranged on the upper inner wall and the lower inner wall of the box body, each damping device comprises a first fixing plate, a first spring and a second fixing plate, and the first fixing plates are installed on the upper inner wall and the lower inner wall of the box body. The two first springs are fixedly arranged on the side, away from the inner wall of the box body, of the first fixing plate, the second fixing plates are fixedly arranged at the ends of the sides, away from the first fixing plate, of the first springs, and first semi-annular plates are fixedly arranged atthe two ends of the first fixing plate. The device has the advantages that the vibration amplitude of the annular protective frame is reduced, the vibration amplitude of a flow meter is reduced, the reading accuracy of the meter is improved, the service life of the meter is prolonged, and the effects of damping and protecting the flow meter are achieved.

Owner:XIAN LANXIN IND AUTOMATION ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com