Heat dissipation fan with multiple oil return functions

A heat dissipation fan and multiple technologies, which are applied to parts of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve the problems of low lubricating oil storage, increased friction, and oil stains, etc. Achieve the effect of avoiding aggregation, increasing oil blocking effect and reducing being thrown out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

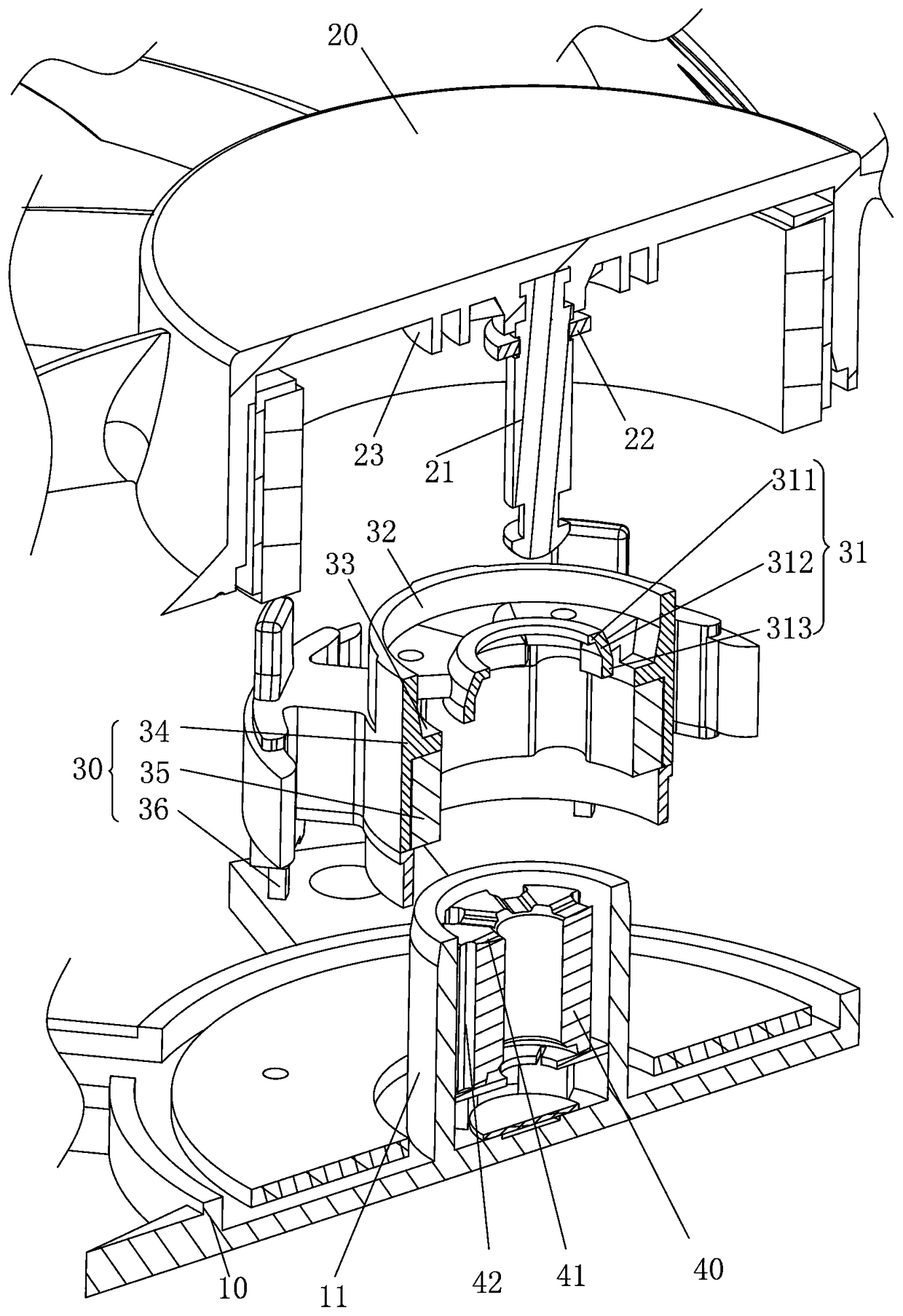

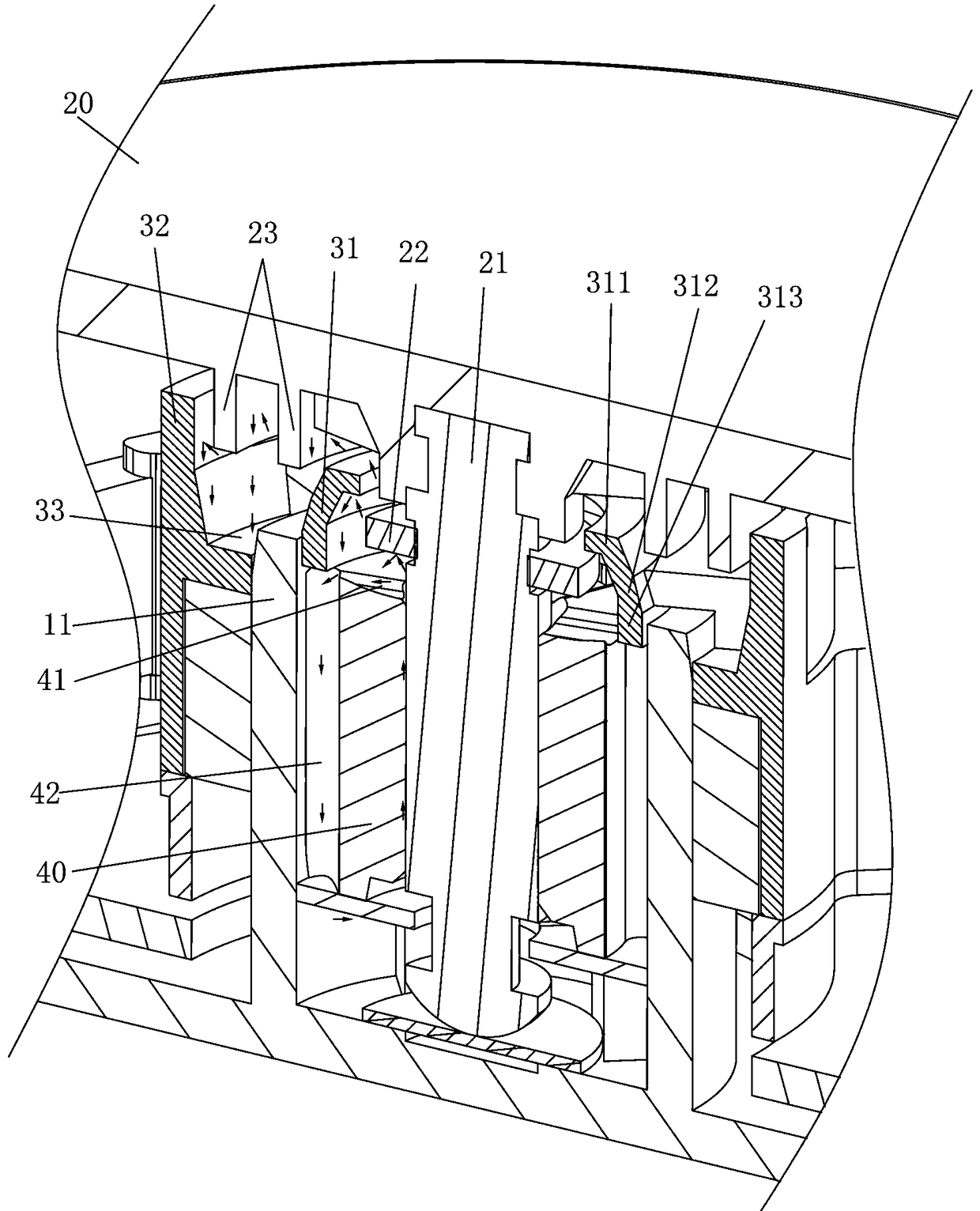

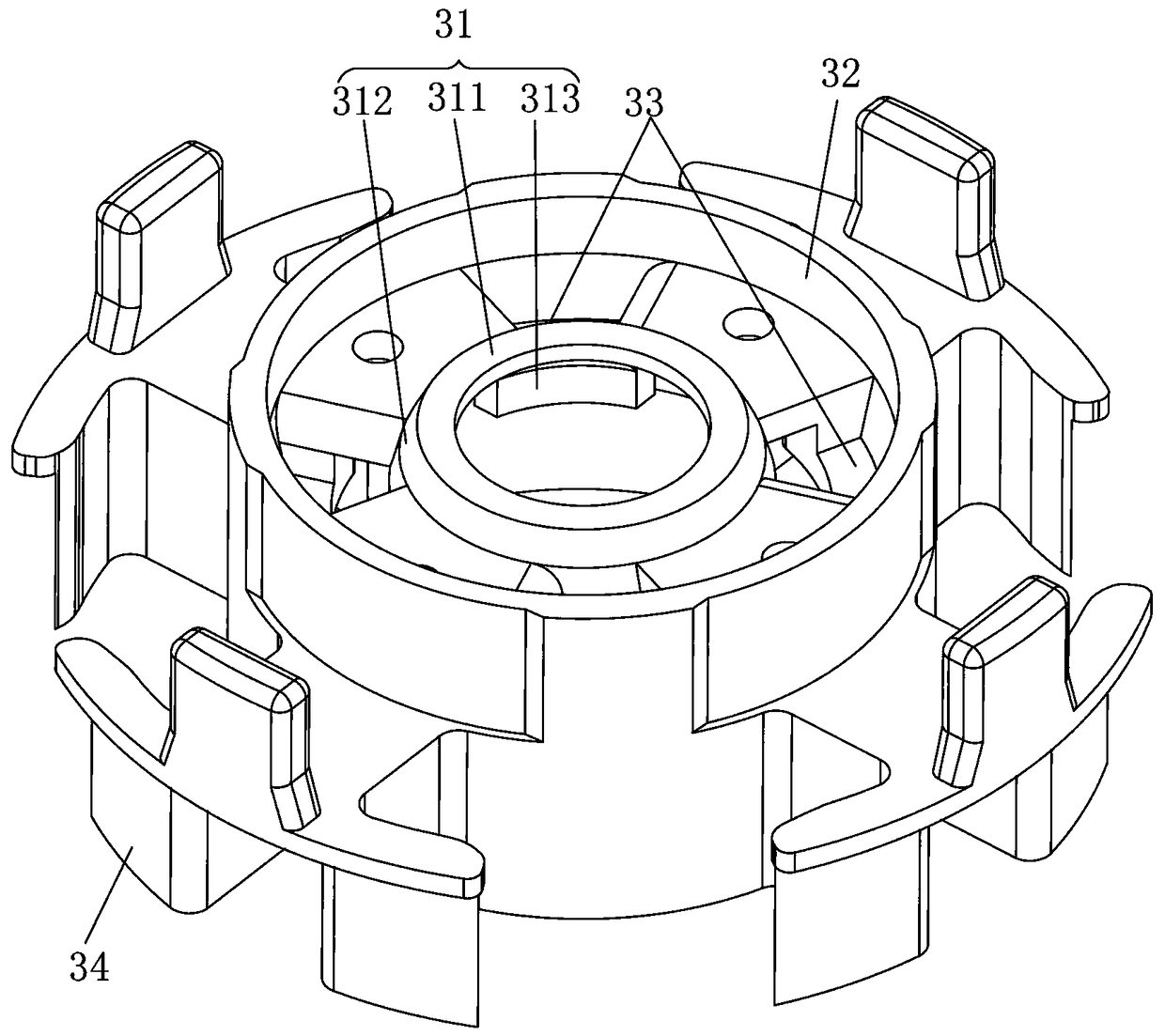

[0026] like Figure 1-4 As shown, the embodiment provided by the present invention is a heat dissipation fan with multiple oil returns, including a fixed seat 10, fan blades 20 and a stator 30, the center of the fixed seat 10 is provided with a shaft sleeve 11, and the center of the stator 30 is provided with an insertion hole. The shaft sleeve 11 is inserted into the socket so that the stator 30 is sheathed outside the shaft sleeve 11 , and the rotating shaft 21 of the fan blade 20 is installed in the shaft sleeve 11 through the bearing 40 .

[0027] The inner wall of the socket is connected with an oil deflector ring 31, and the oil deflector ring 31 is located above the shaft sleeve 11 and the distance is set outside the rotating shaft 21; the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com