Patents

Literature

32results about How to "Improve the oil blocking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special offshore deoiling oil absorbent felt and method for preparing oil absorbent felt

ActiveCN104874232AReduce manufacturing costExtended service lifeFiltration separationLiquid separationBlock effectPetroleum engineering

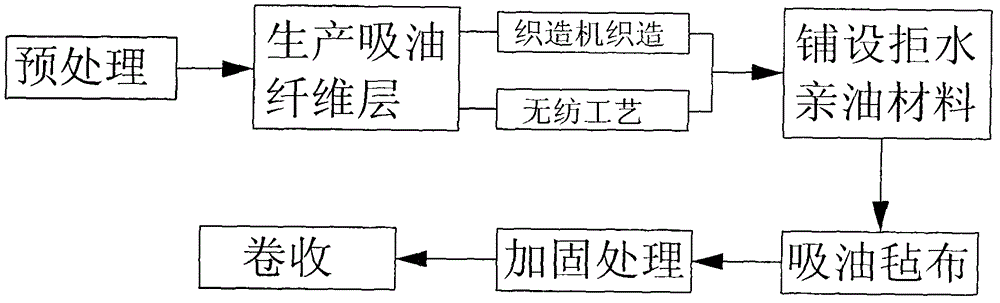

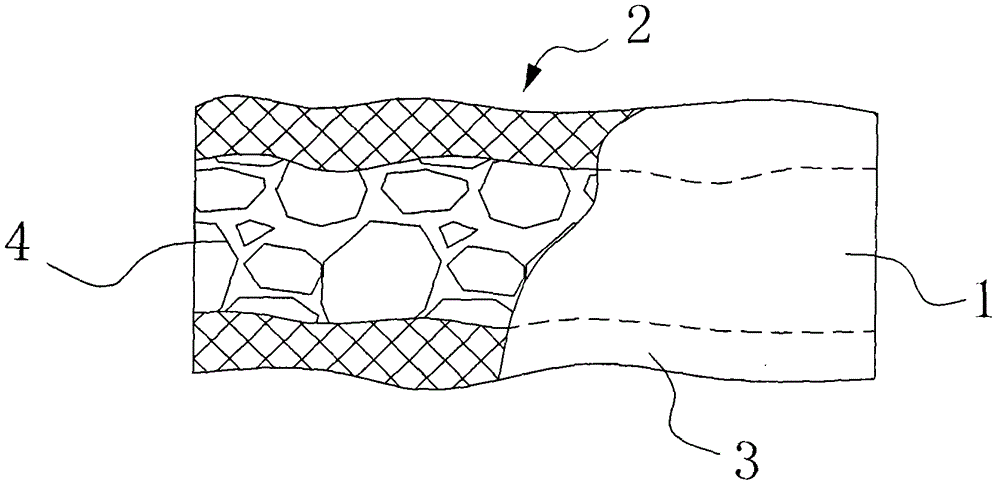

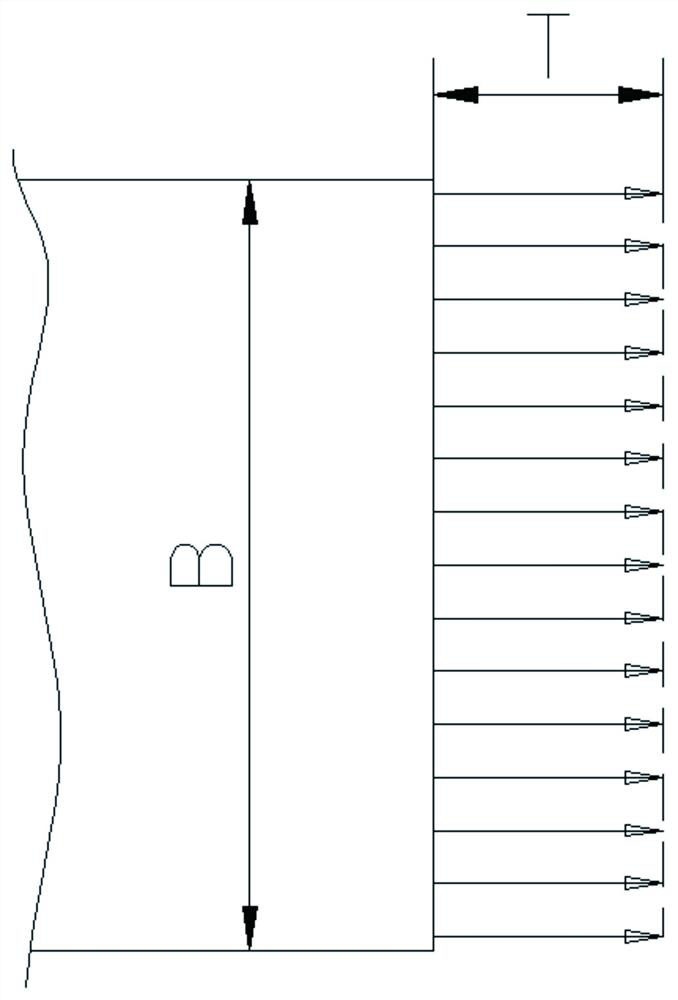

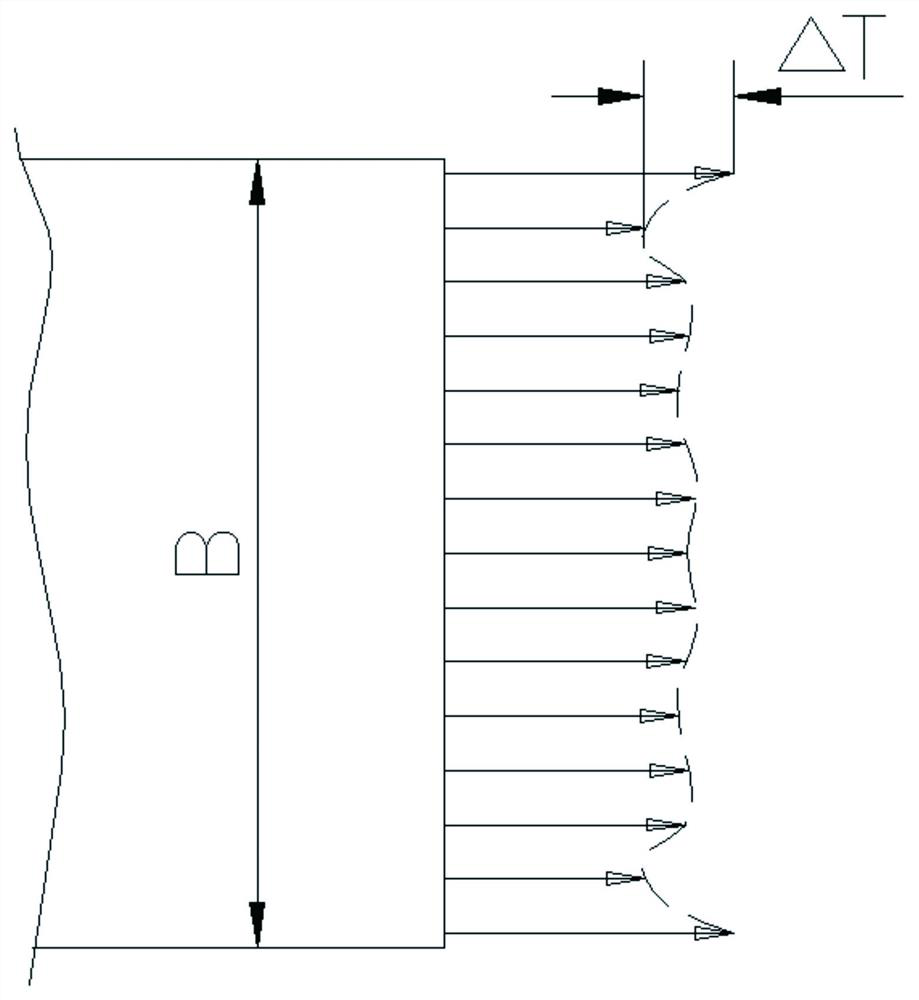

The invention discloses a special offshore deoiling oil absorbent felt. The special offshore deoiling oil absorbent felt comprises an oil absorbent felt body which is prepared from an oil absorbent fiber, is provided with an oil absorbent clearance part, and comprises two oil absorbent fiber layers; the oil absorbent clearance part formed between the two oil absorbent fiber layers is filled with a water-repellency oleophylic material, and the two oil absorbent fiber layers and the water-repellency oleophylic material are solidified integrally. The preparation method comprises the following steps: (1) pretreatment, namely preparing the water-repellency oleophylic material for filling for later use, and selecting an oil absorbent fiber for later use; (2) producing an oil absorbent fiber layer; (3) laying a water-repellency oleophylic material; (4) solidifying; and (5) coiling. An oil containment boom prepared from enteromorpha has good oil blocking and oil absorption performances, the use effect of the oil containment boom can be enhanced, the oil containment boom can float on the water surface for a long time after oil absorption, can not sink or deform, and has good oil absorbing and blocking effects.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

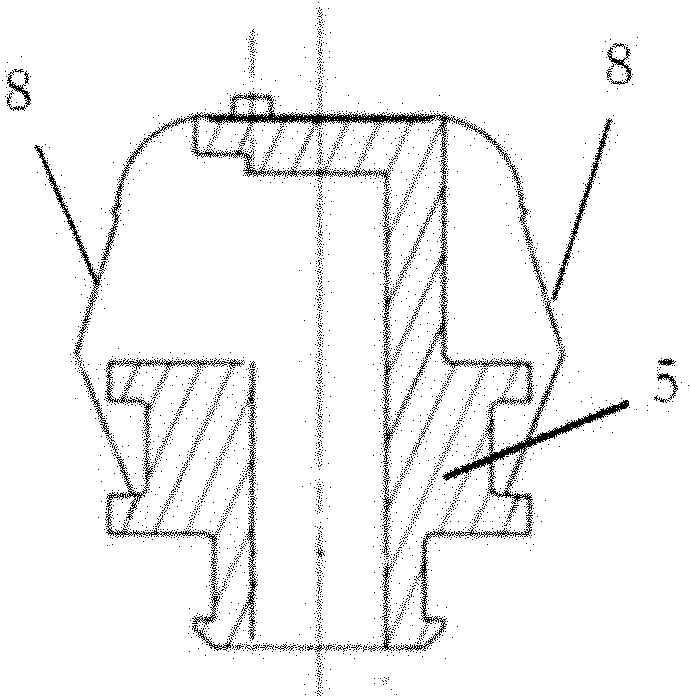

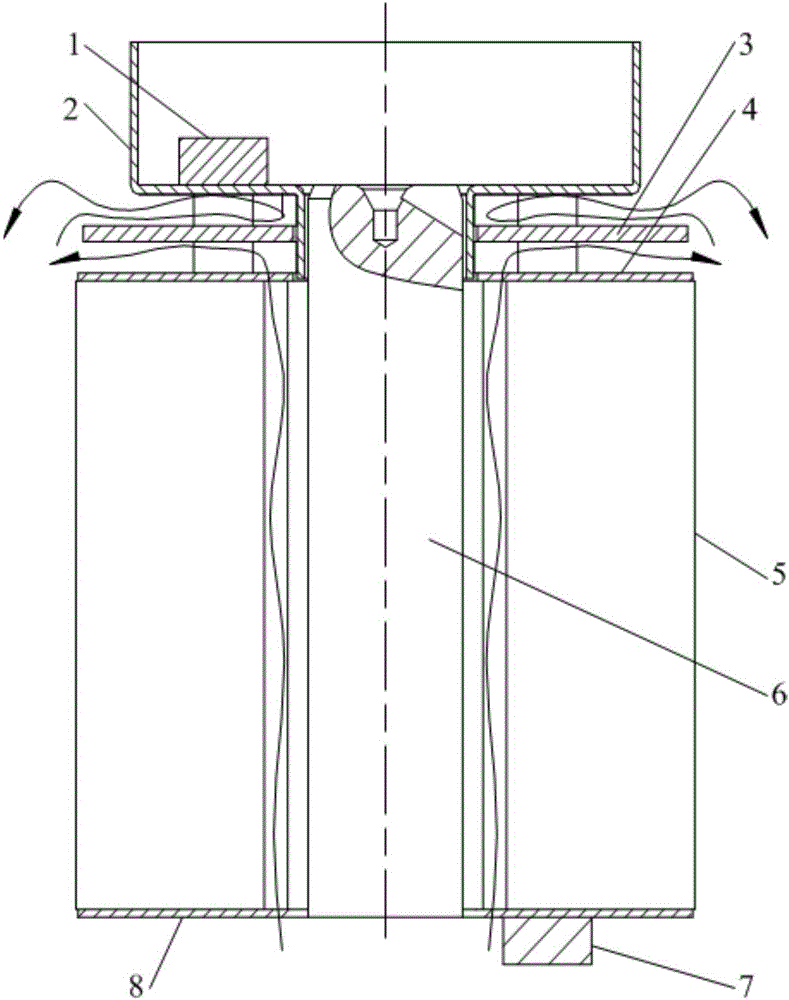

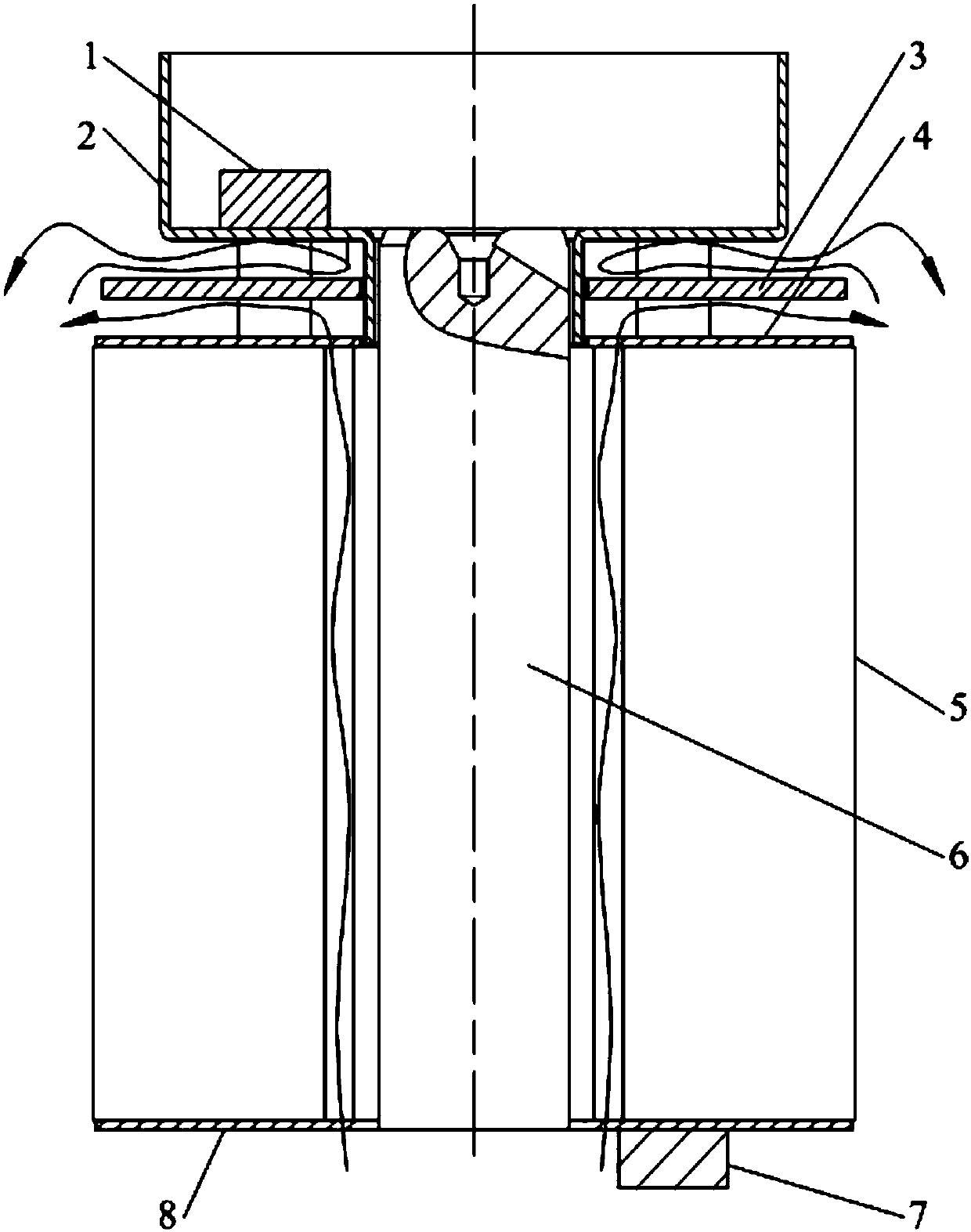

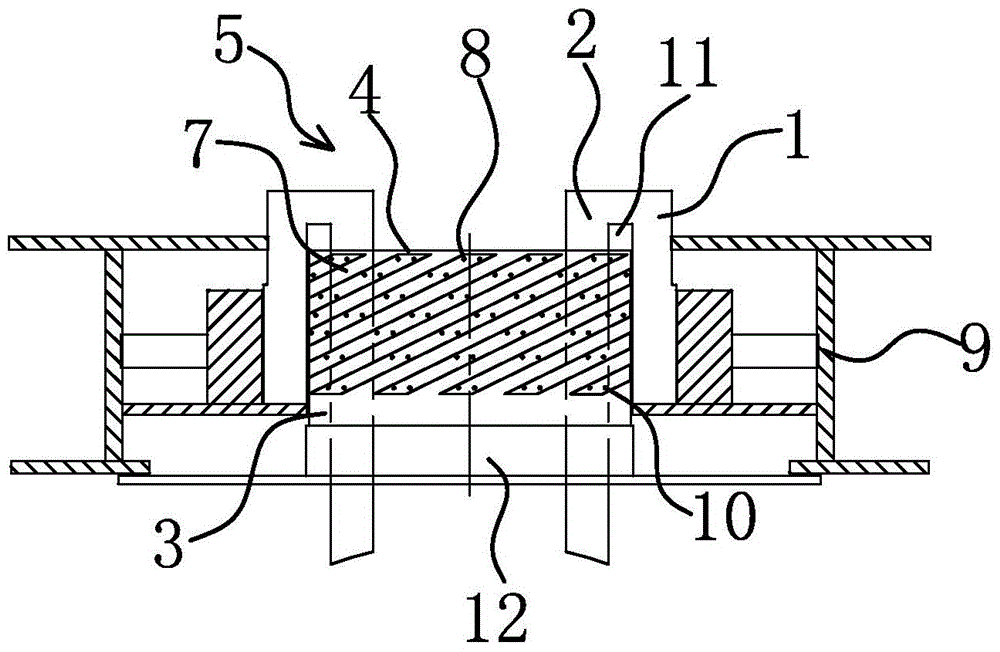

Oil baffle type ventilation mechanism

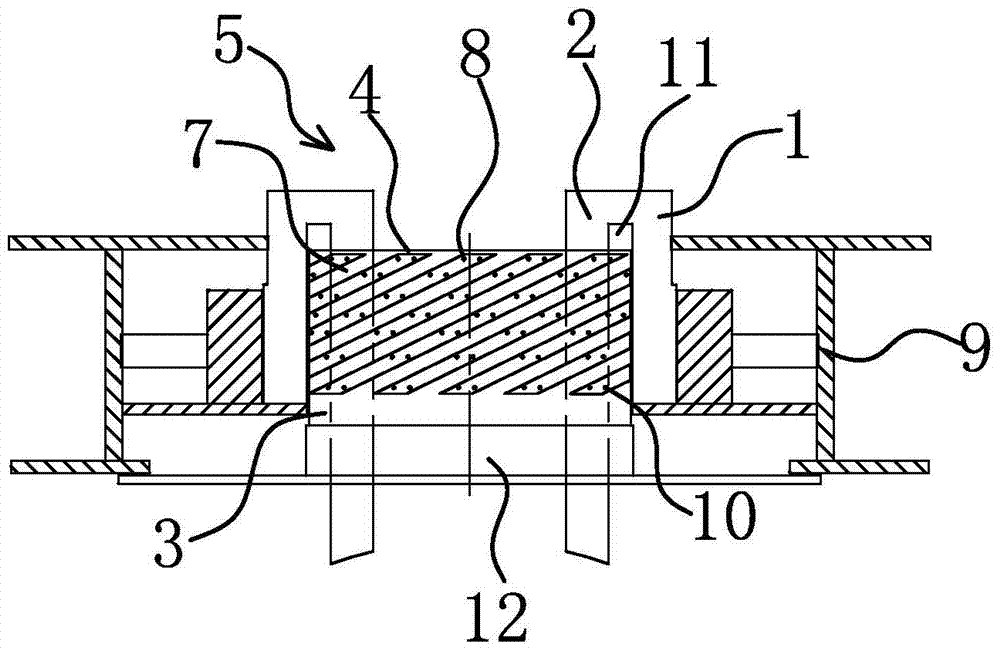

InactiveCN101949444AImprove ventilation and leak preventionImprove the oil blocking effectGearing detailsSemi openClosed cavity

The invention discloses an oil baffle type ventilation mechanism in the technical field of manual transmissions, comprising a ventilation assembly, an oil baffle, an oil retaining clapboard and a bolt, wherein the oil baffle is fixedly arranged on the shell of a transmission and forms a semi-closed cavity with the shell, the oil retaining clapboard is fixedly arranged below the oil baffle, the ventilation assembly is located on the side face of the shell of the transmission and is communicated with the semi-closed cavity, and the oil baffle is in a semi-open structure and comprises a bottom plate and a baffle arranged vertically above the bottom plate. The invention has the advantages of simple structure, obvious oil retaining effect, good oil-leakage prevention effect, reliable ventilation and the like, and solves the problem that the ventilation plug of the transmission is easy to leak oil due to the traditional ventilation plug is arranged in an oil splashing direction.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

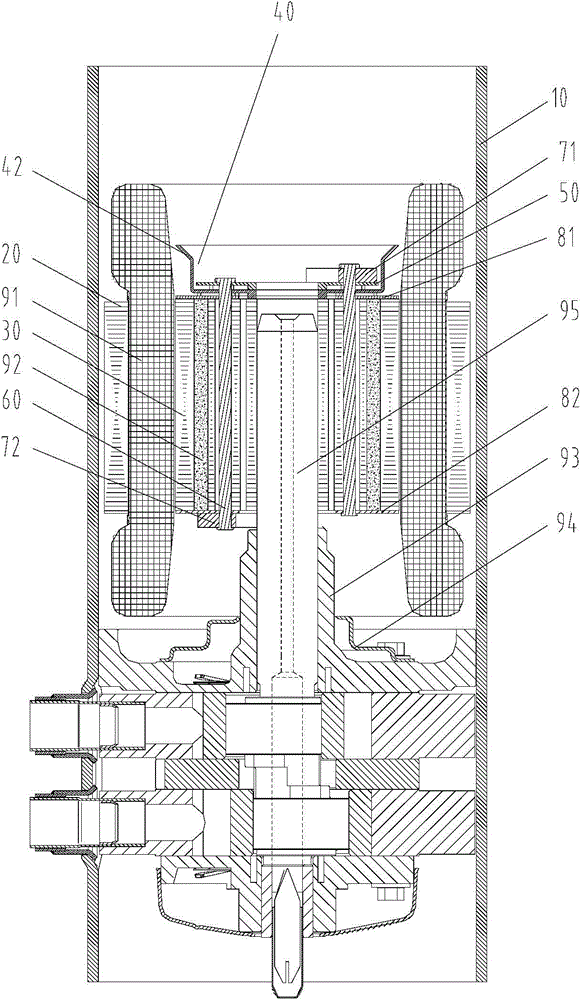

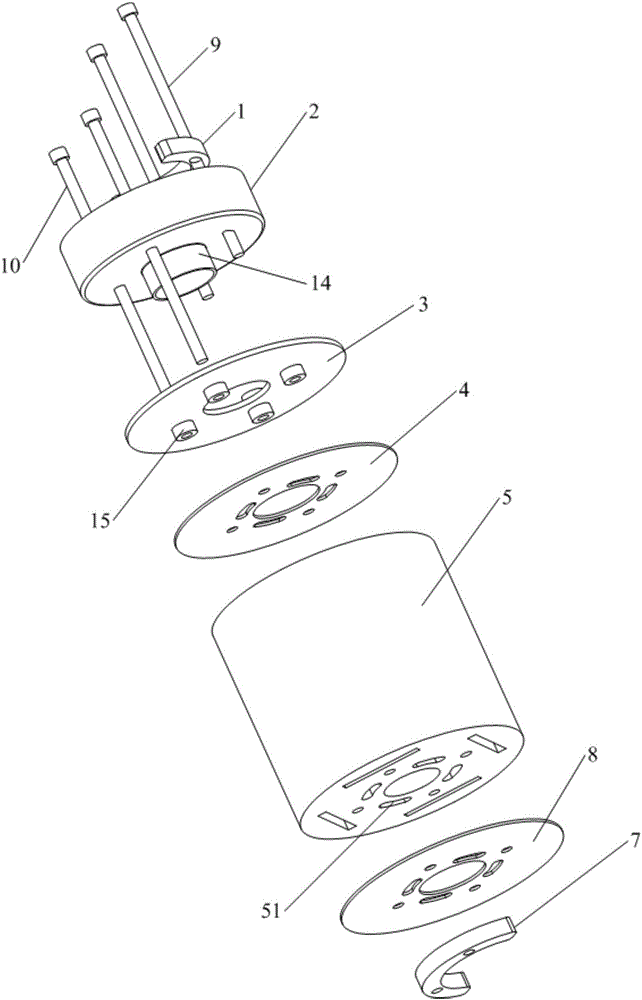

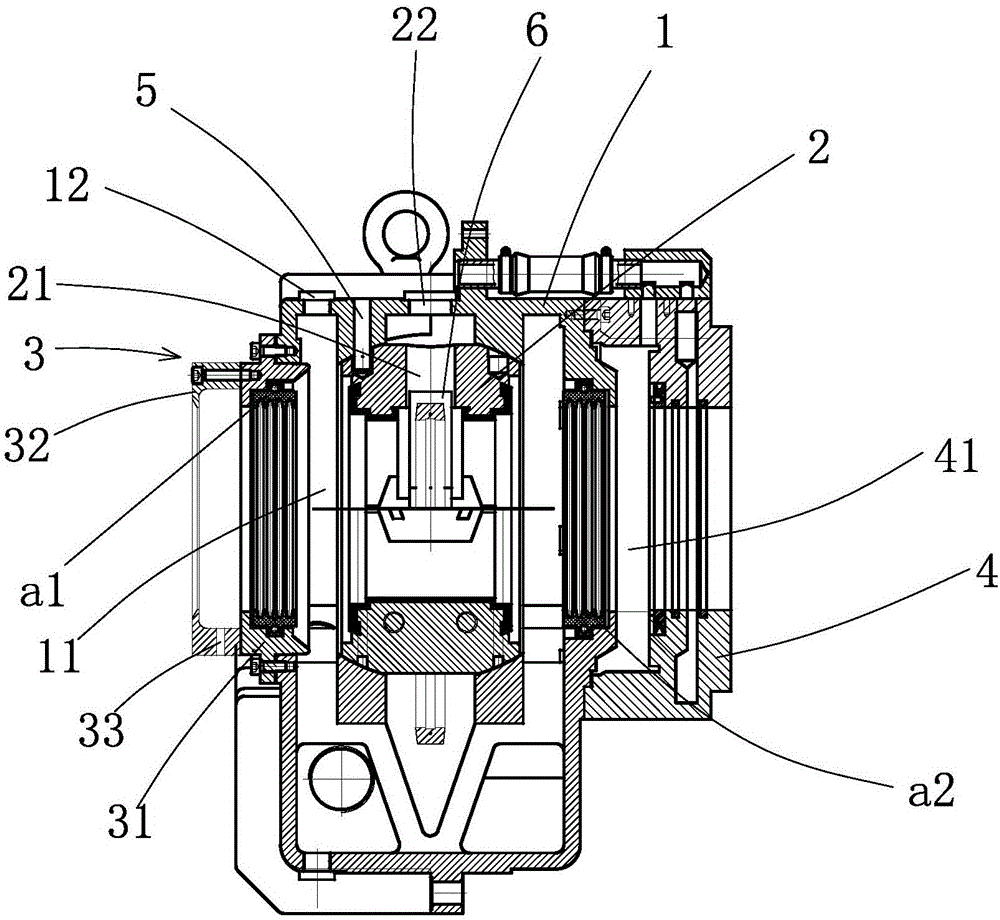

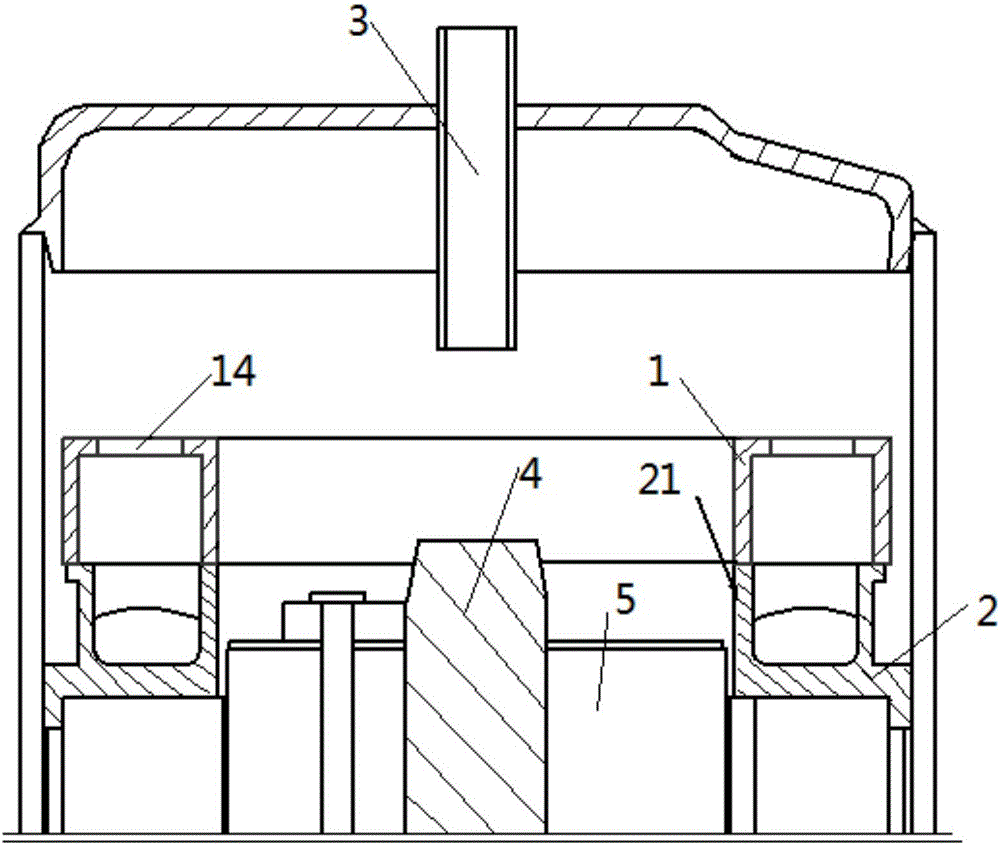

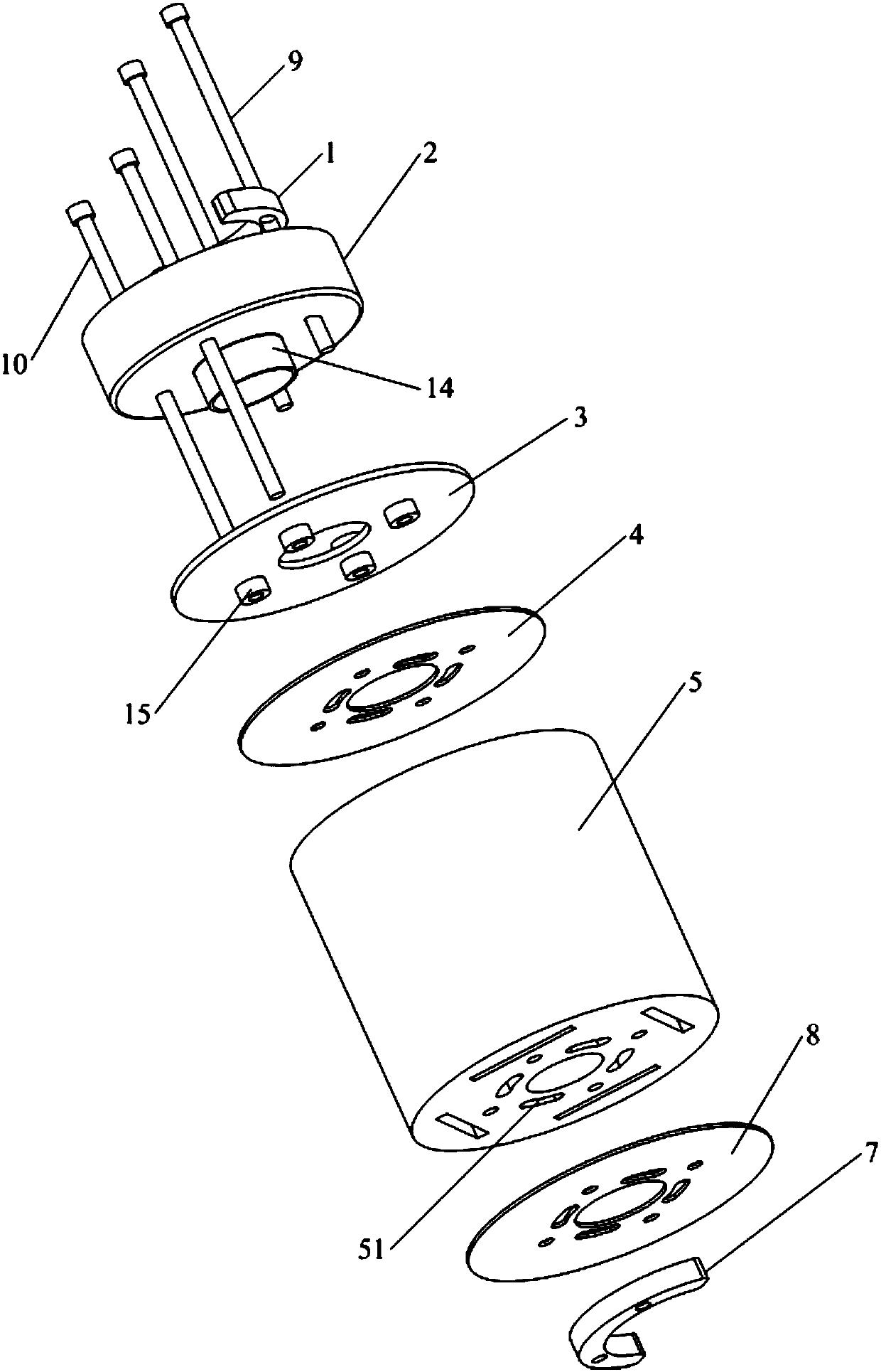

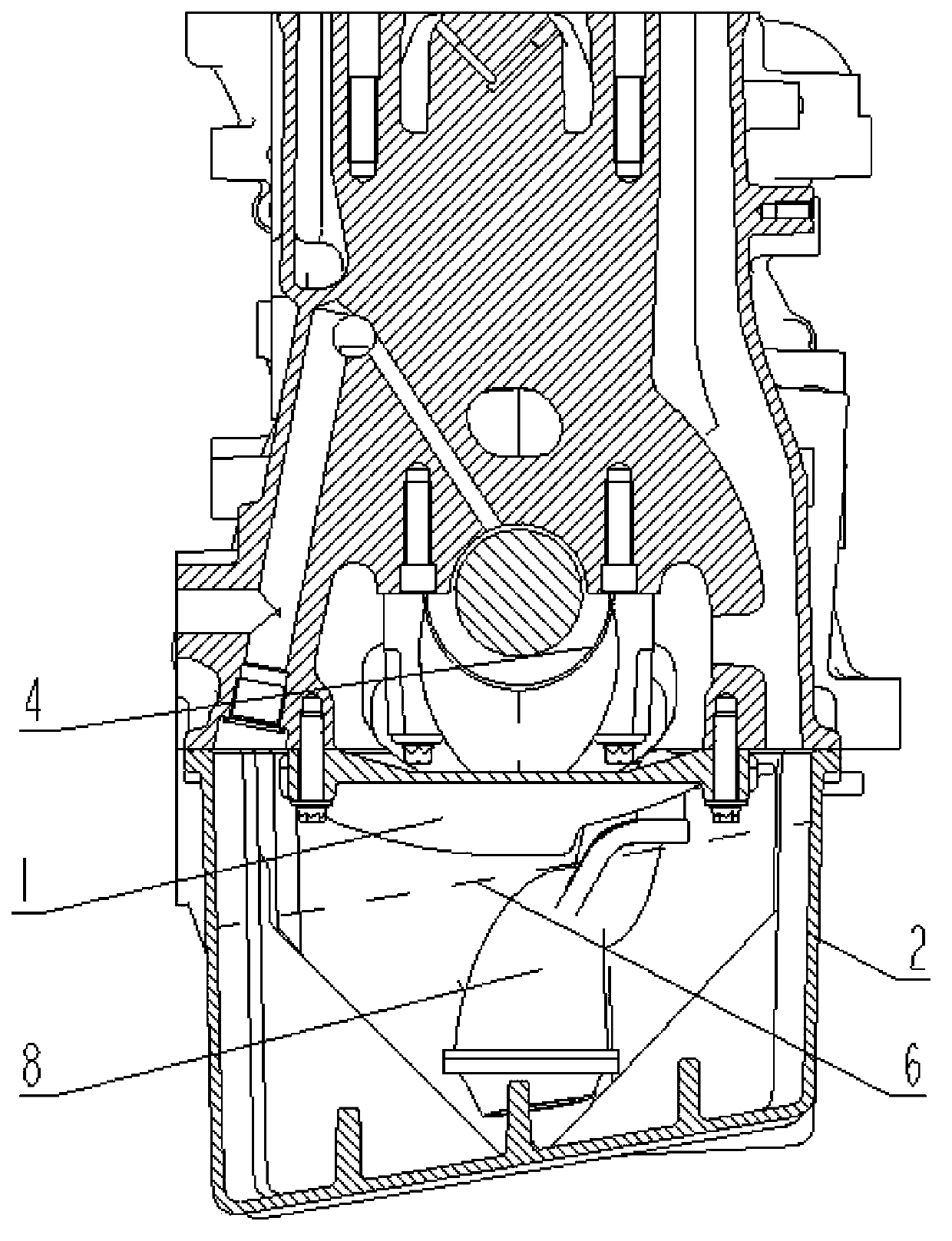

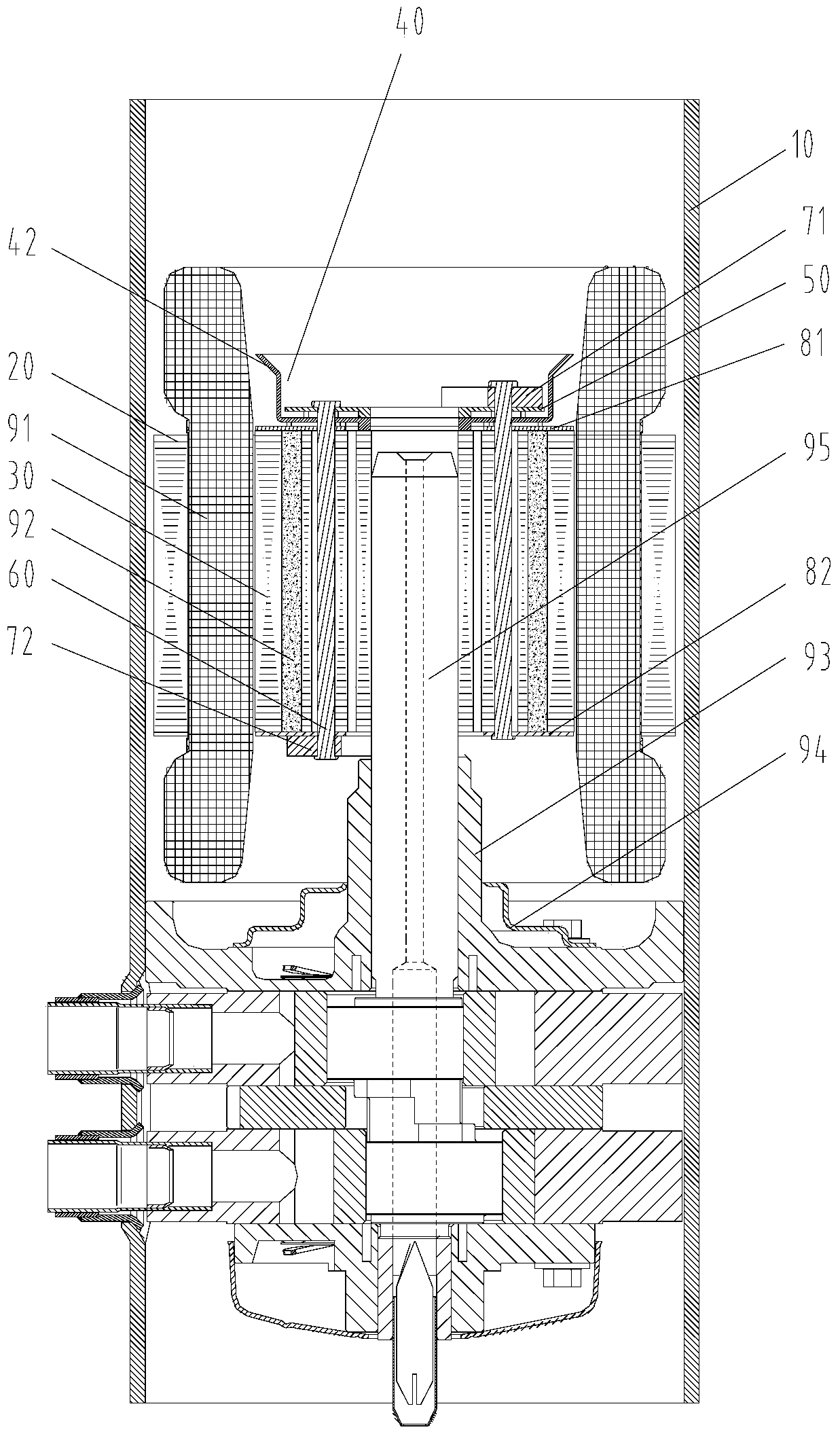

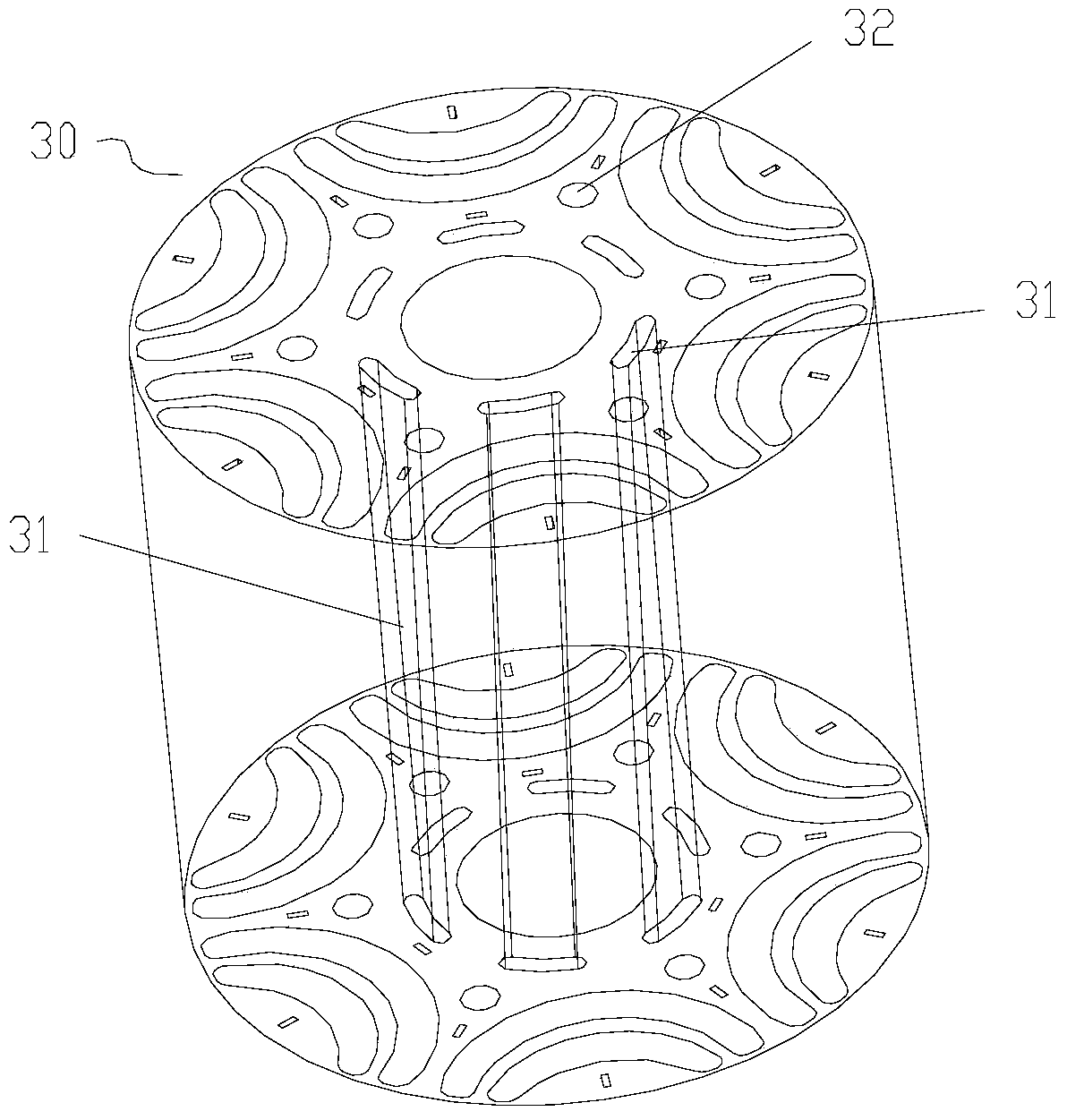

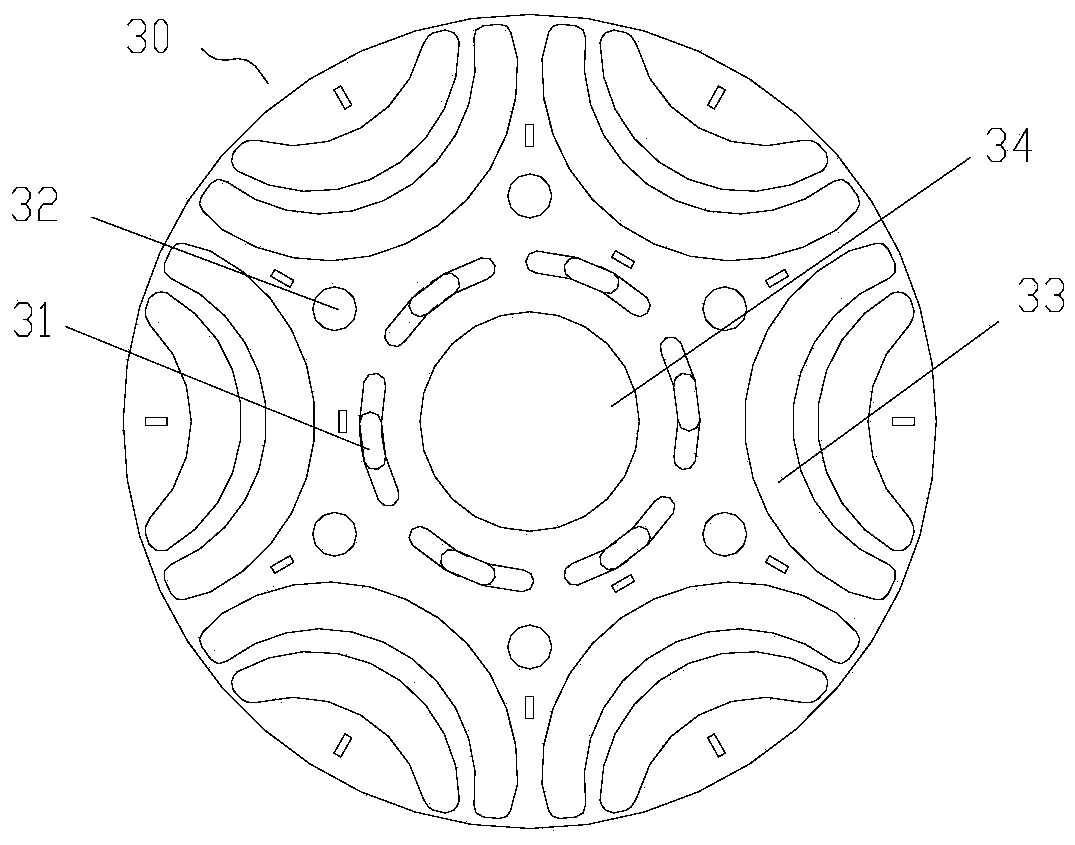

Compressor

ActiveCN105782053AIncrease the itineraryOil blocking effect is goodRotary/oscillating piston pump componentsLiquid fuel engine componentsStatorMechanical engineering

The invention provides a compressor comprising a shell, a stator core, a rotor core and a first baffle, wherein the stator core and the rotor core are arranged in the shell; the stator core is arranged around the rotor core; circulating holes formed along the axial direction of the rotor core are formed in the rotor core; and the first baffle comprises a bottom plate part and an oil retaining side edge arranged at the upper side of the bottom plate part, and the first baffle is opposite to the upper end surface of the rotor core, so that lubricating oil carried by a refrigerant comes into collision with the oil retaining side edge to form oil drops falling back below the rotor core after the refrigerant flowing out of the circulating holes passes through the bottom plate part. By using the compressor, the refrigerant can return from the upside to the downside of a motor of the compressor, so that the stroke of the refrigerant is increased; in addition, due to the adoption of the design of the non-swirl baffle located above the rotor core, an extremely good oil retaining effect is taken while no wind resistance is generated, and the condition that the lubricating oil is discharged from the compressor is avoided, so that the oil throughput rate of the compressor is effectively reduced, the performance of a unit is improved, and the power consumption of the compressor is reduced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI +1

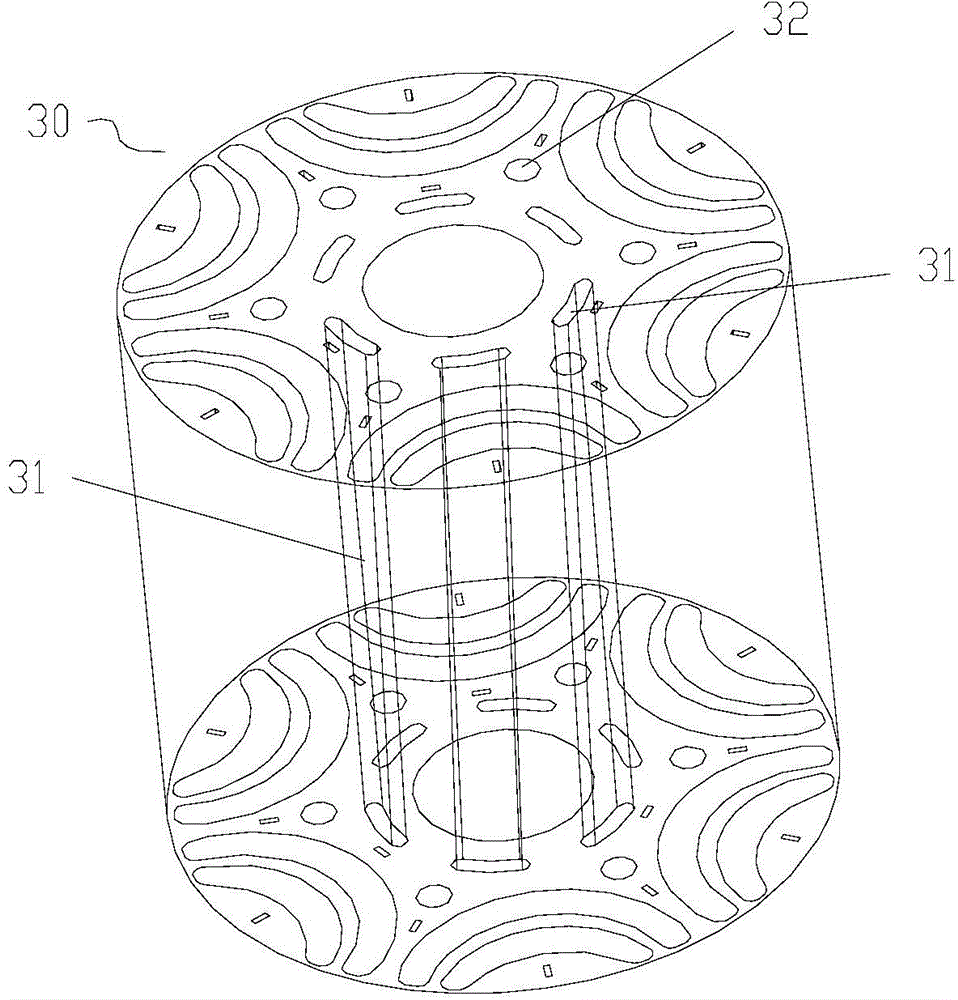

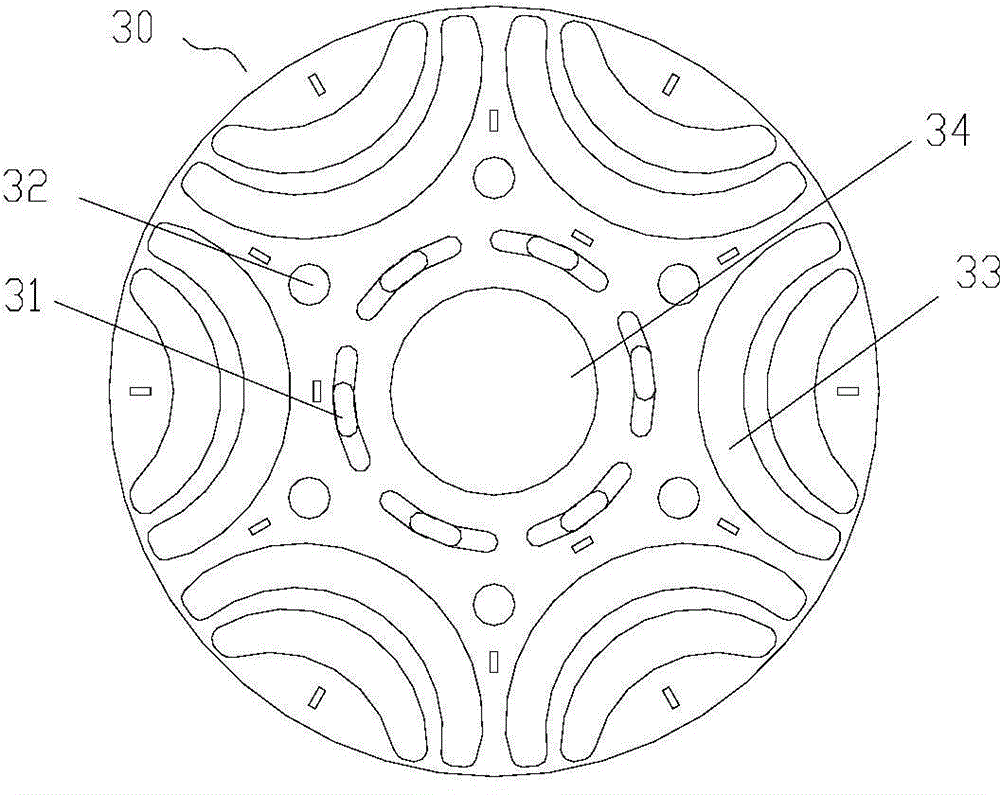

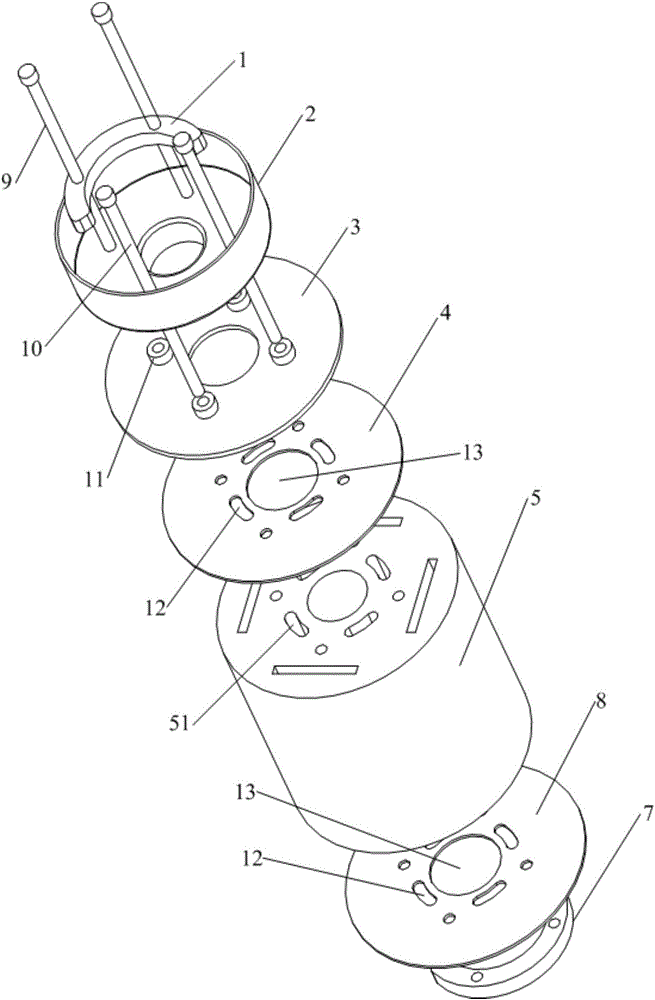

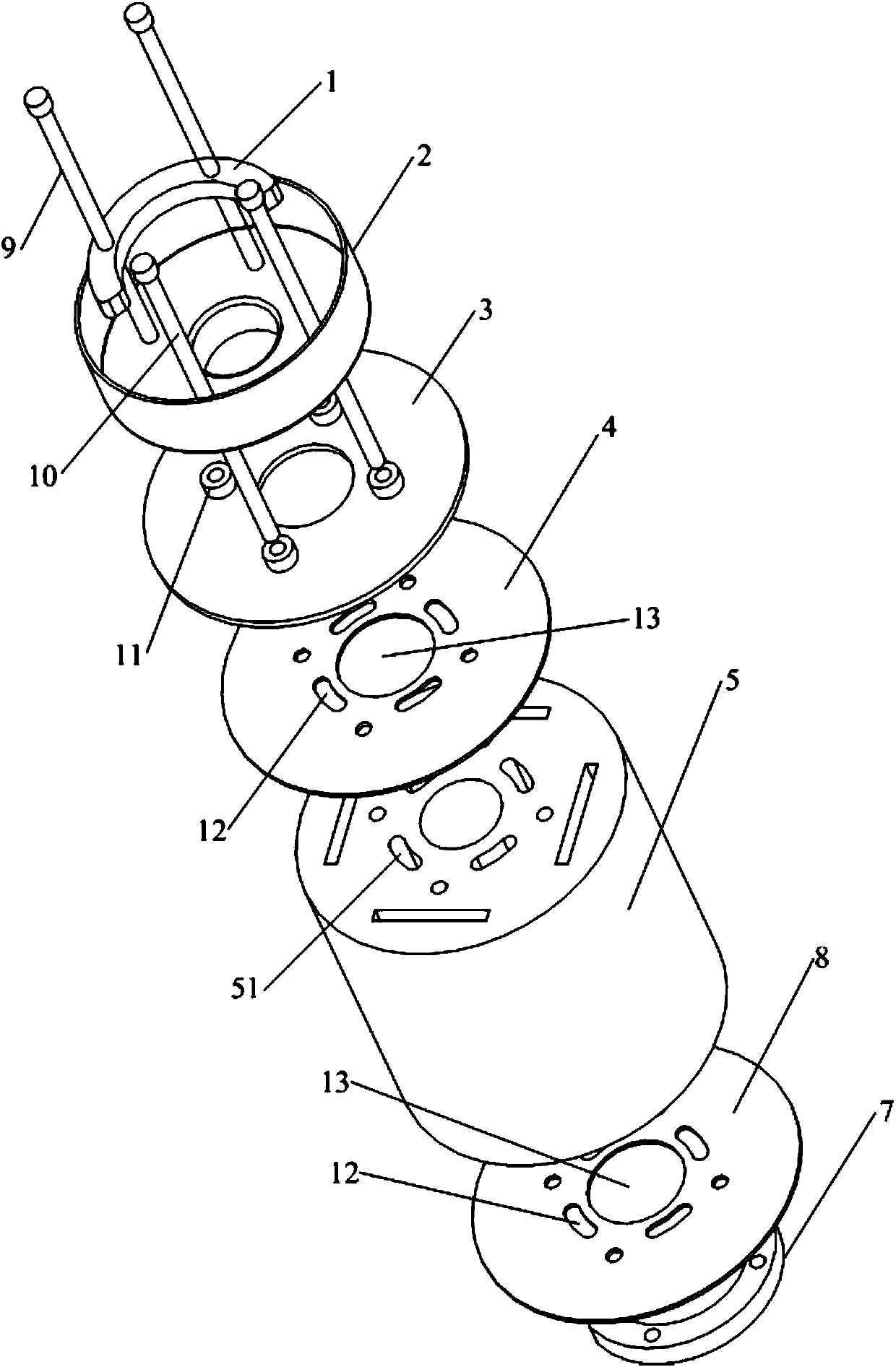

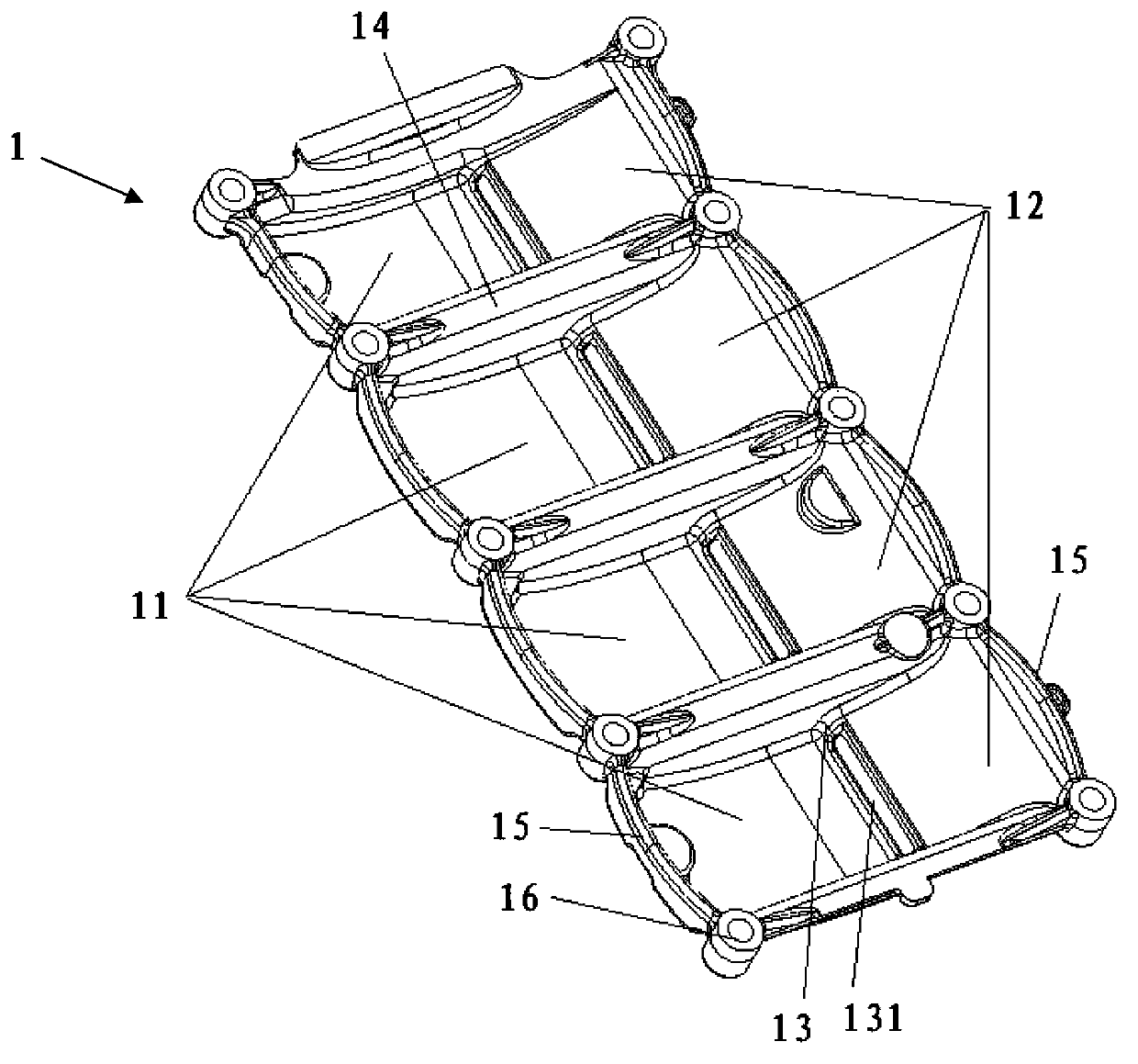

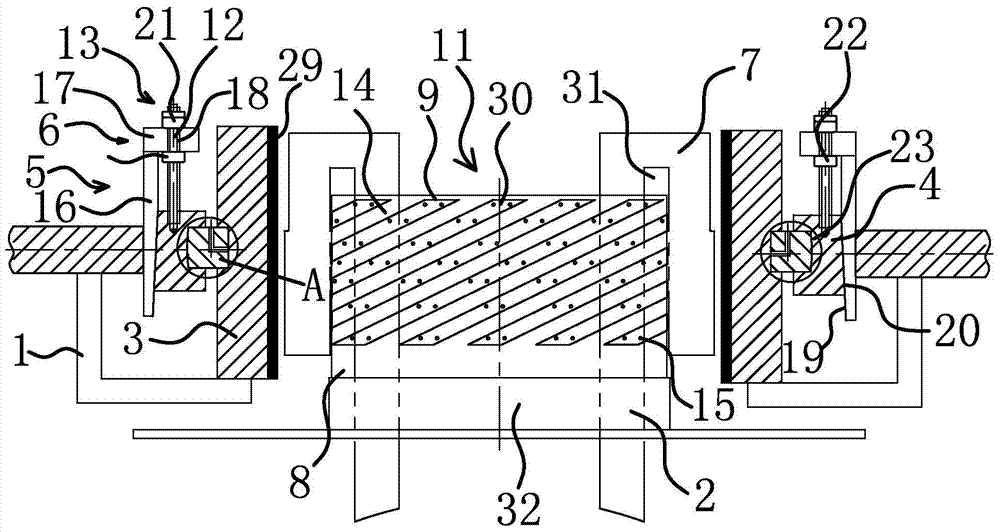

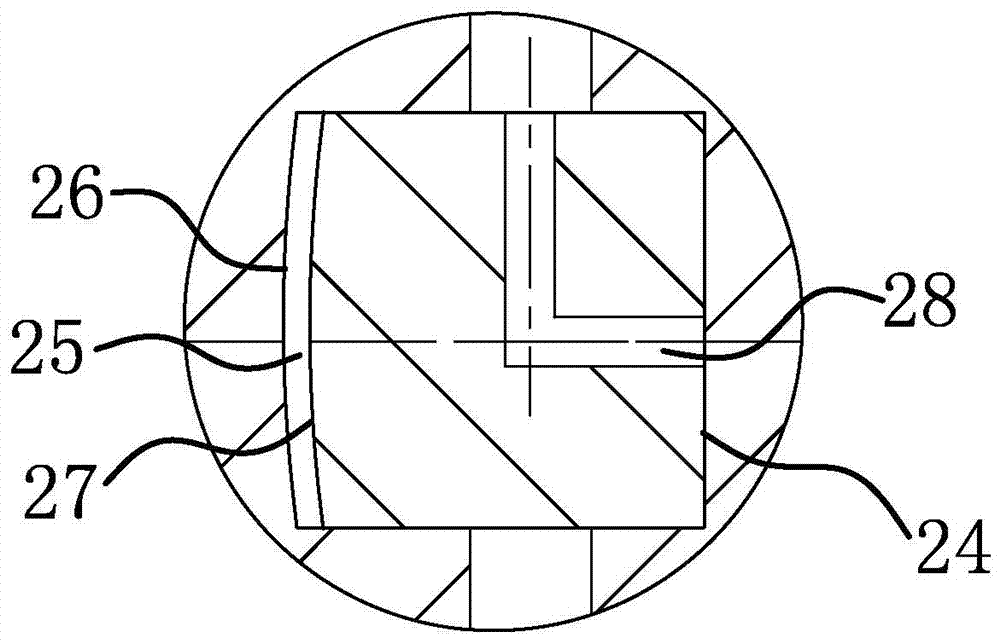

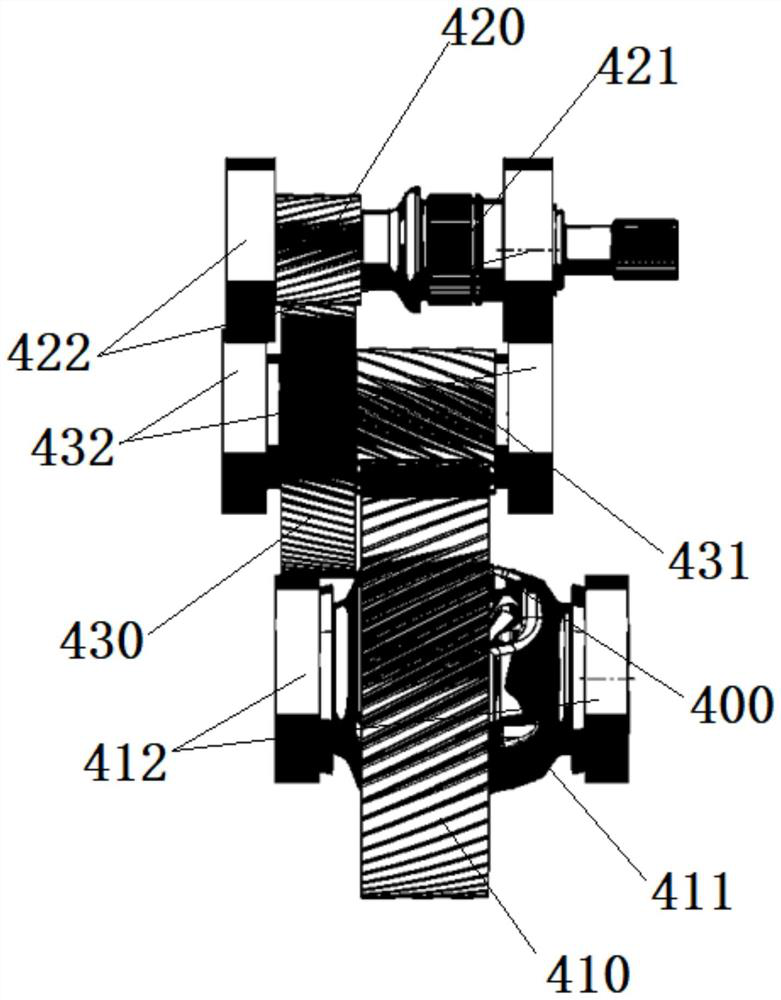

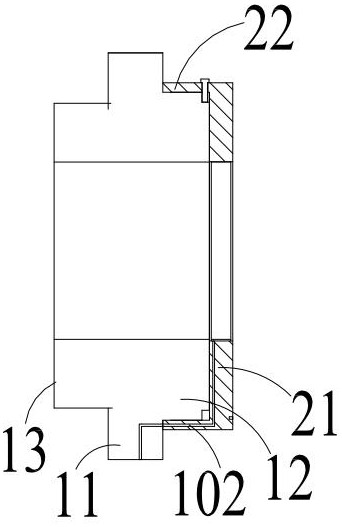

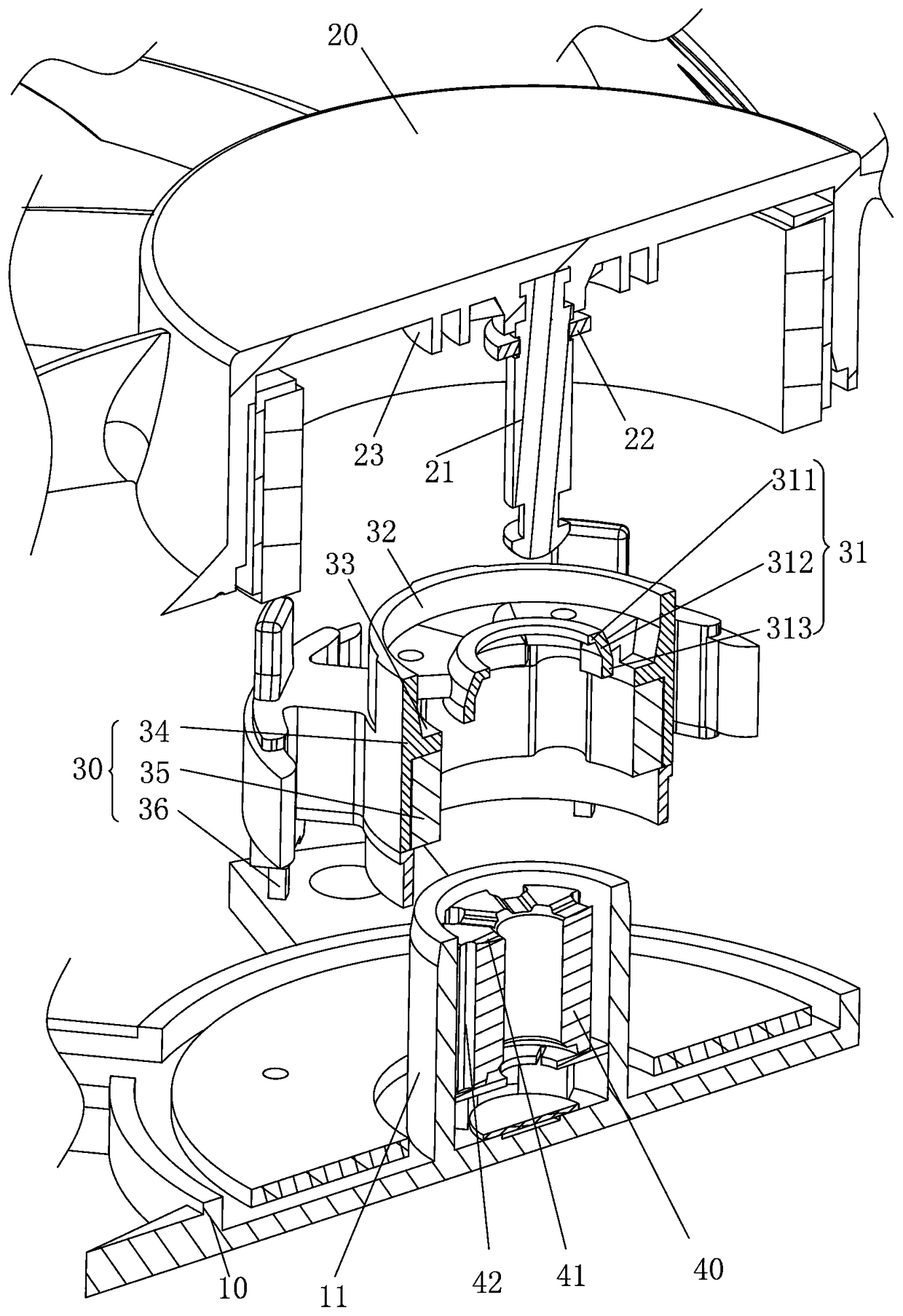

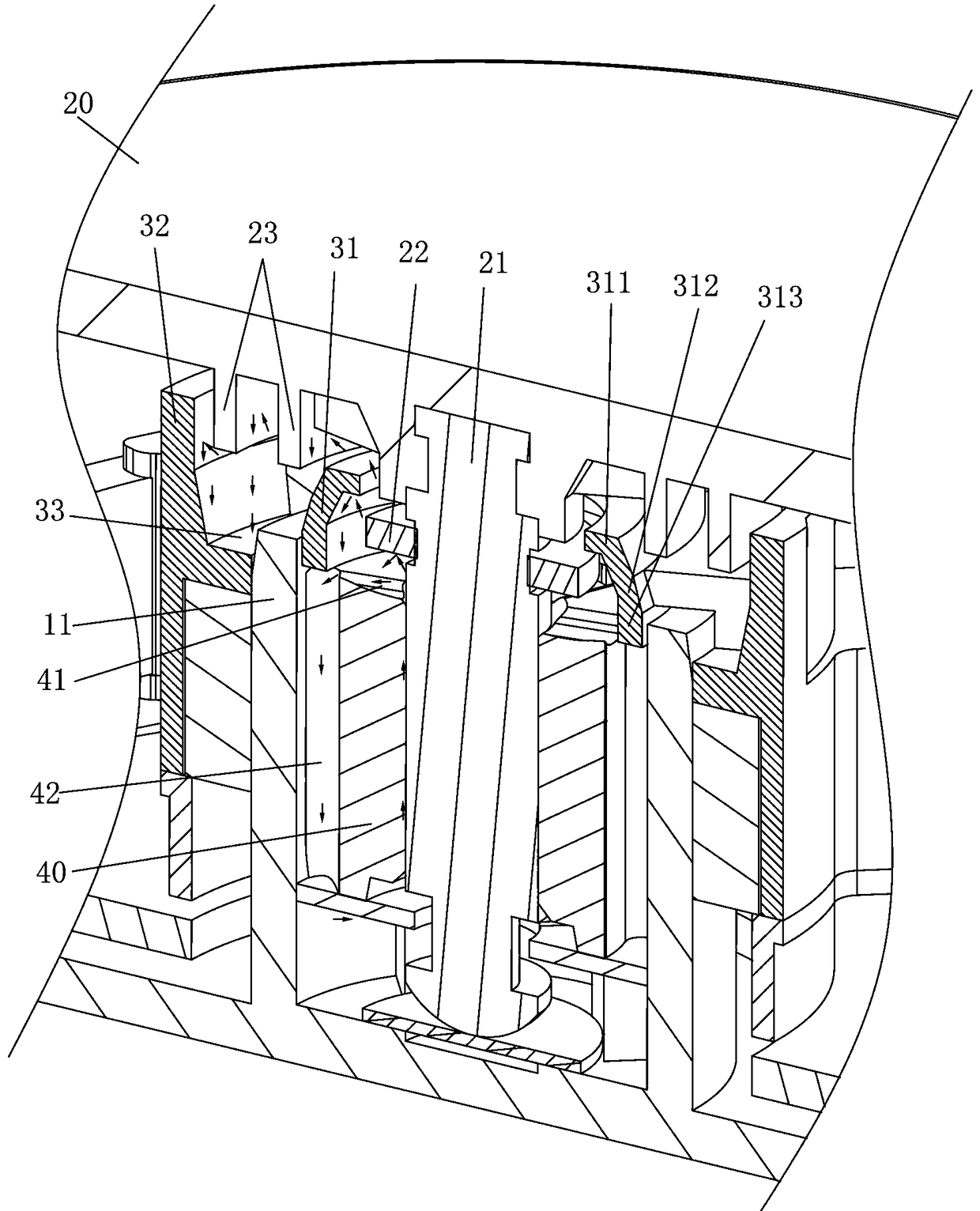

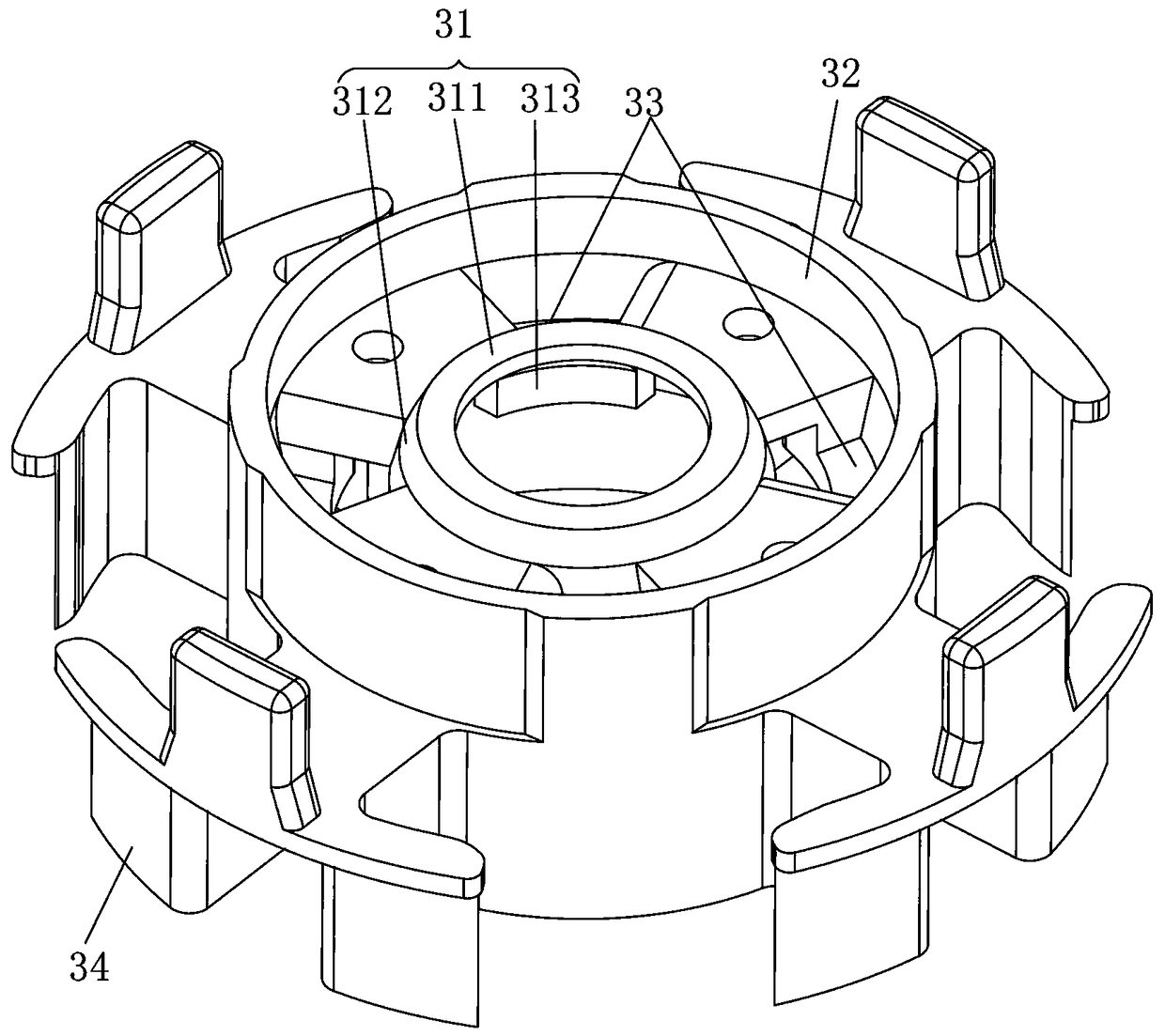

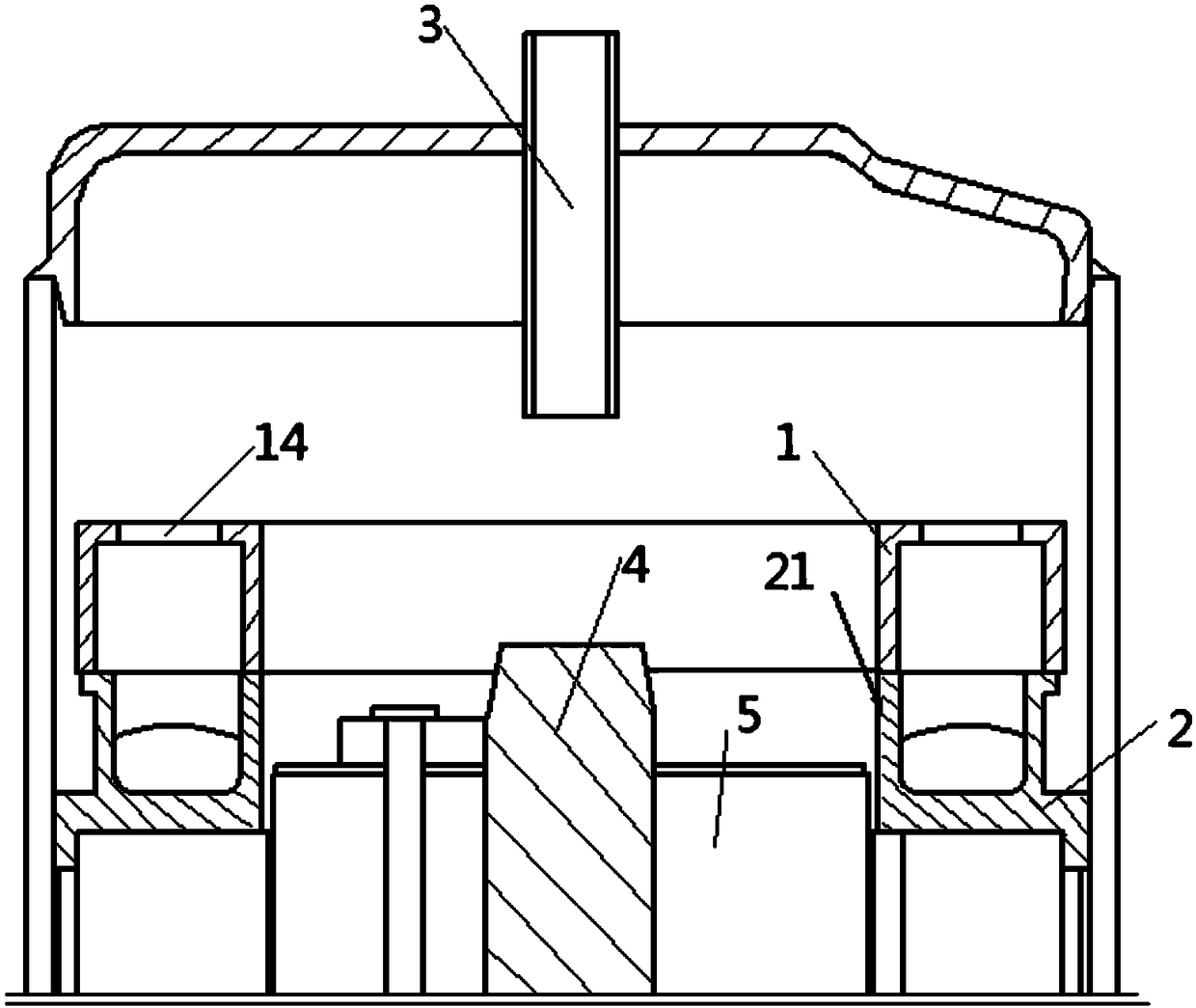

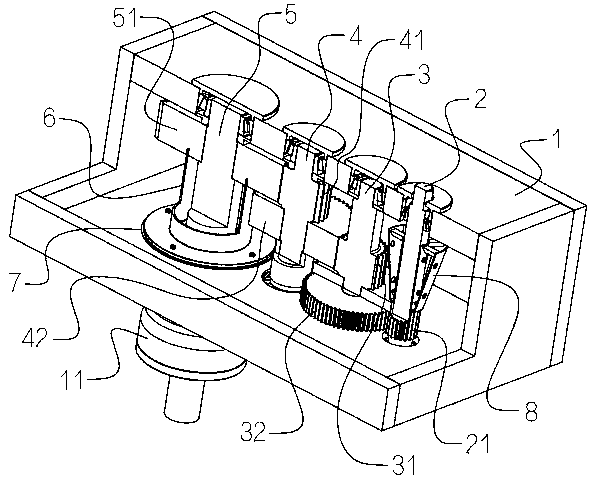

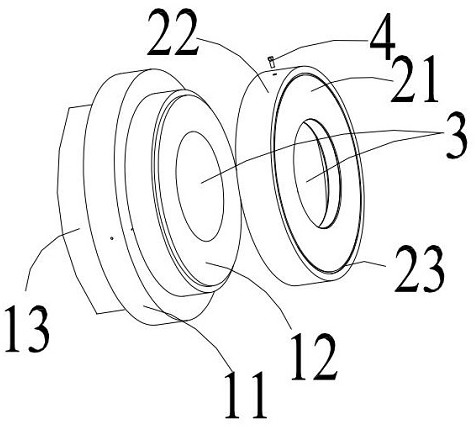

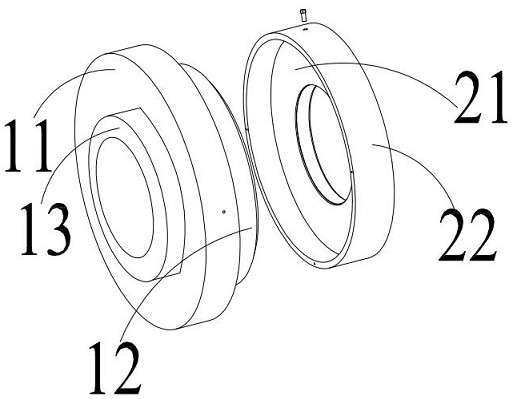

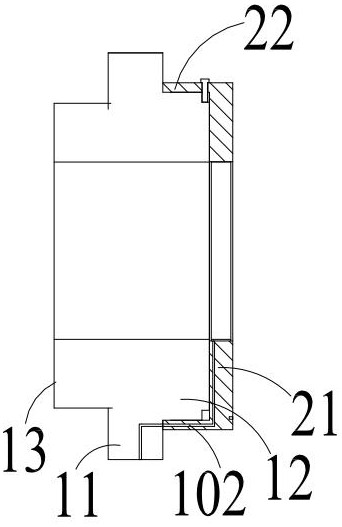

Compressor oil blocking assembly, rotor assembly, compressor and air conditioner system

ActiveCN106014931AReduce oil discharge rateImprove the oil blocking effectPositive displacement pump componentsPositive-displacement liquid enginesBlock effectEngineering

The invention discloses a compressor oil blocking assembly, a rotor assembly, a compressor and an air conditioner system. The compressor oil blocking assembly comprises an oil blocking cap and an oil blocking base which is used for being fixedly connected with the oil blocking cap and can be arranged outside the connecting sleeve in a sleeving manner. A connecting sleeve used for being matched with the tail portion of a bent axle is arranged at the bottom end of the oil blocking cap. A first preset distance is formed between the bottom face of the oil blocking cap and the top face of the oil blocking base, and a second preset distance is formed between the bottom face of the oil blocking base and the bottom end face of the connecting sleeve. The compressor oil blocking assembly is provided with a double-layer oil blocking structure of the oil blocking cap and the oil blocking base, two-time oil blocking is achieved, the oil blocking effect is effectively improved, the oil output rate of the compressor, especially a large-displacement double-cylinder compressor is reduced. According to the air conditioner system applying the compressor oil blocking assembly, the heat exchange efficiency of the air conditioner system is improved, and the performance of the whole air conditioner system is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

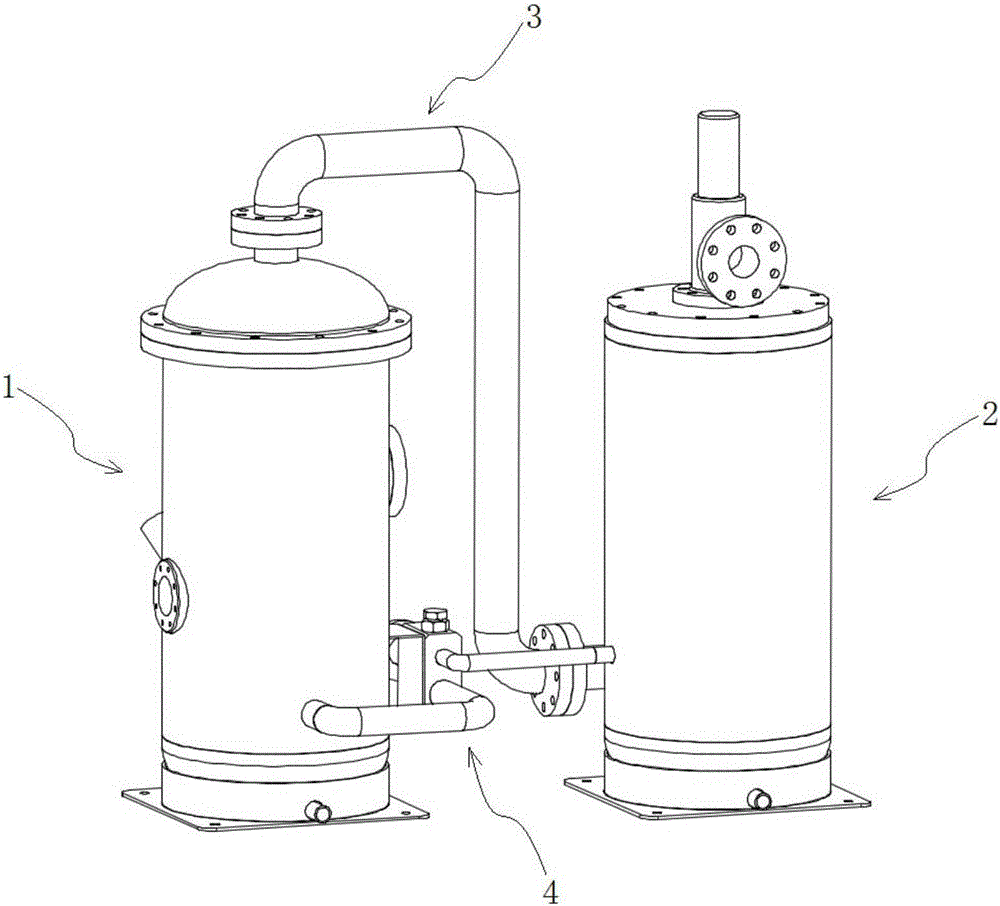

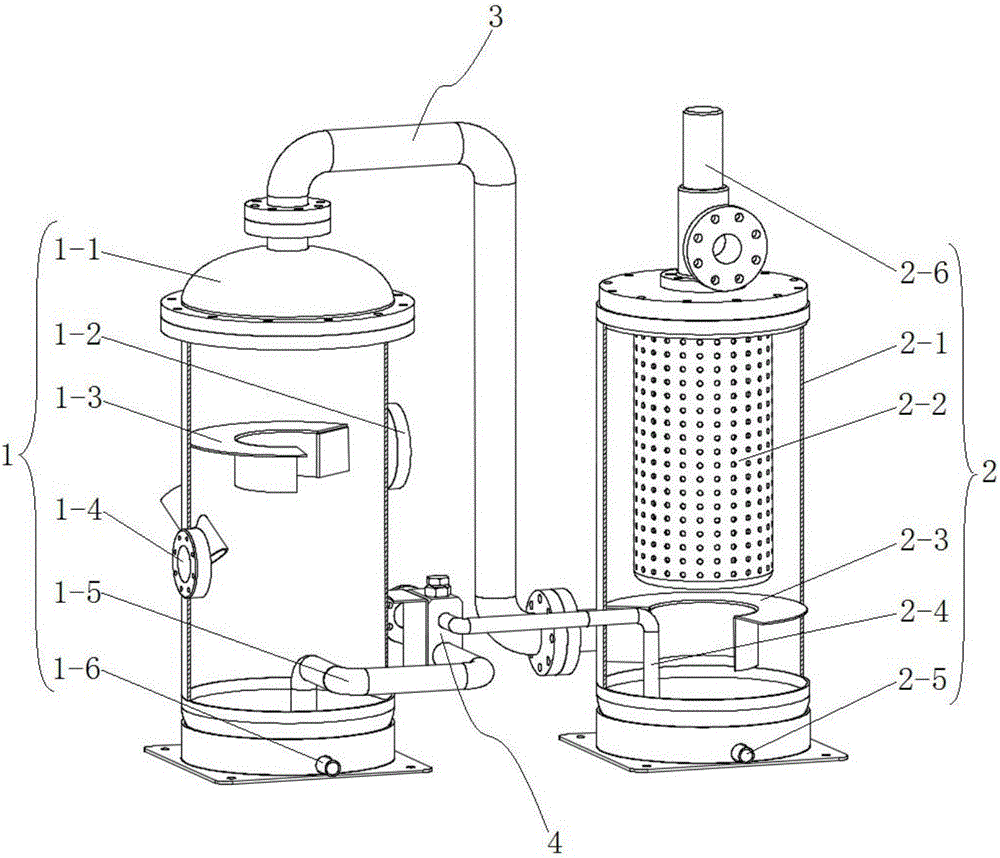

Splitting type three-stage oil and gas separating device of gas compressor

InactiveCN105771521AHigh filtration precisionImprove running stabilityCombination devicesSeparation technologyThree stage

The invention discloses a splitting type three-stage oil and gas separating device of a gas compressor, and belongs to the technical field of oil and gas separating. The splitting type three-stage oil and gas separating device comprises a first oil and gas bucket, a second oil and gas bucket and a flow mixing assembly, wherein a gas outlet of the first oil and gas bucket and a gas inlet of the second oil and gas bucket are communicated by an oil and gas pipeline; the first oil and gas bucket comprises a first cylinder, a first gas inlet, a first gas inlet protecting plate and a first oil return pipe; the second oil and gas bucket comprises a second cylinder, an oil separating core, a second gas inlet protecting plate and a second oil return pipe; the flow mixing assembly is connected with the first oil return pipe and the second oil return pipe respectively, and is used for adjusting the flow rate of the second oil return pipe. The splitting type three-stage oil and gas separating device has the advantages that the three-stage separating of mixing gas is realized by the first oil and gas bucket and the second oil and gas bucket, the first oil and gas bucket is used as an oil storage part, and the second oil and gas bucket is used as a separating part of the oil separating core, and is also used as a buffer gas tank, so that the filtering accuracy and operational stability of the gas compressor are further improved; the size is smaller, the layout of the gas compressor is easy, and the installation and maintenance are more convenient and rapid.

Owner:釜玛机械(江苏)有限公司

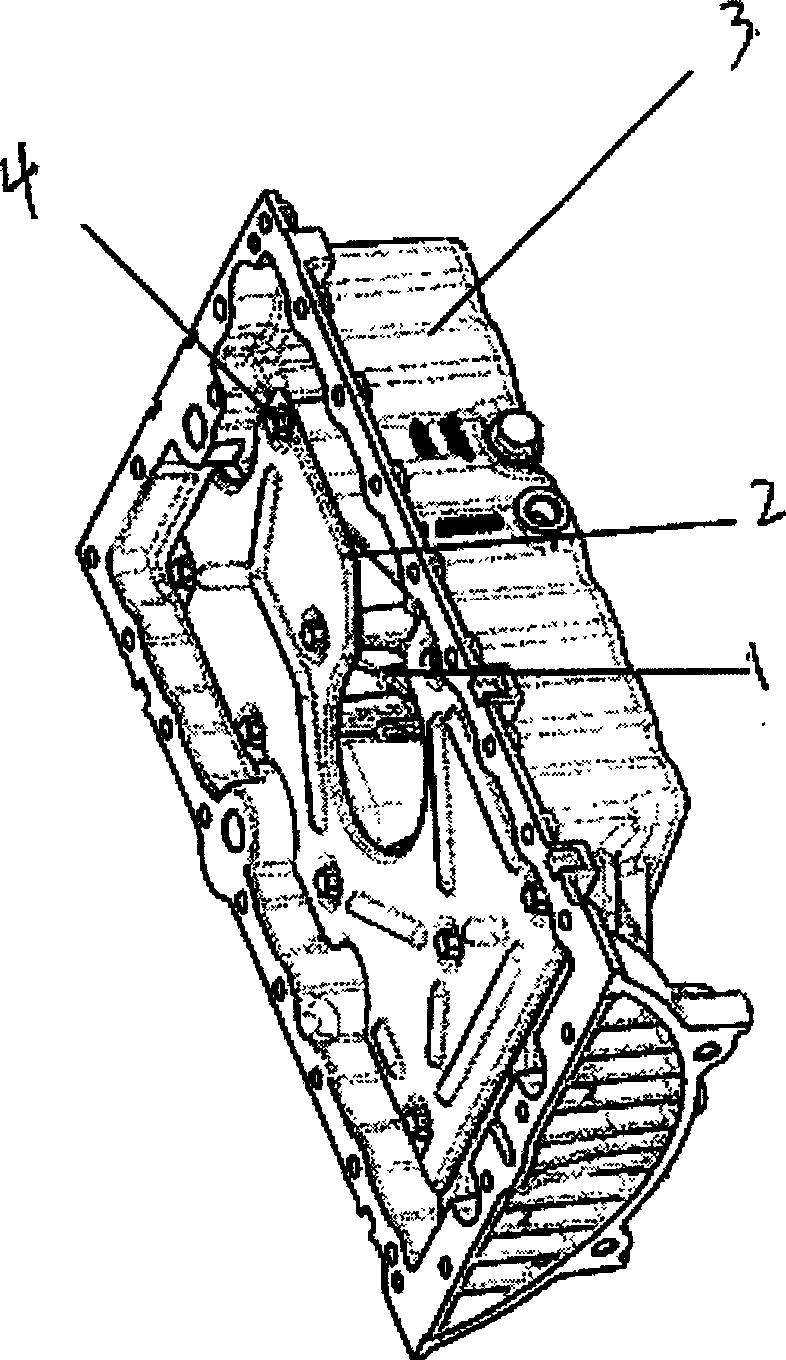

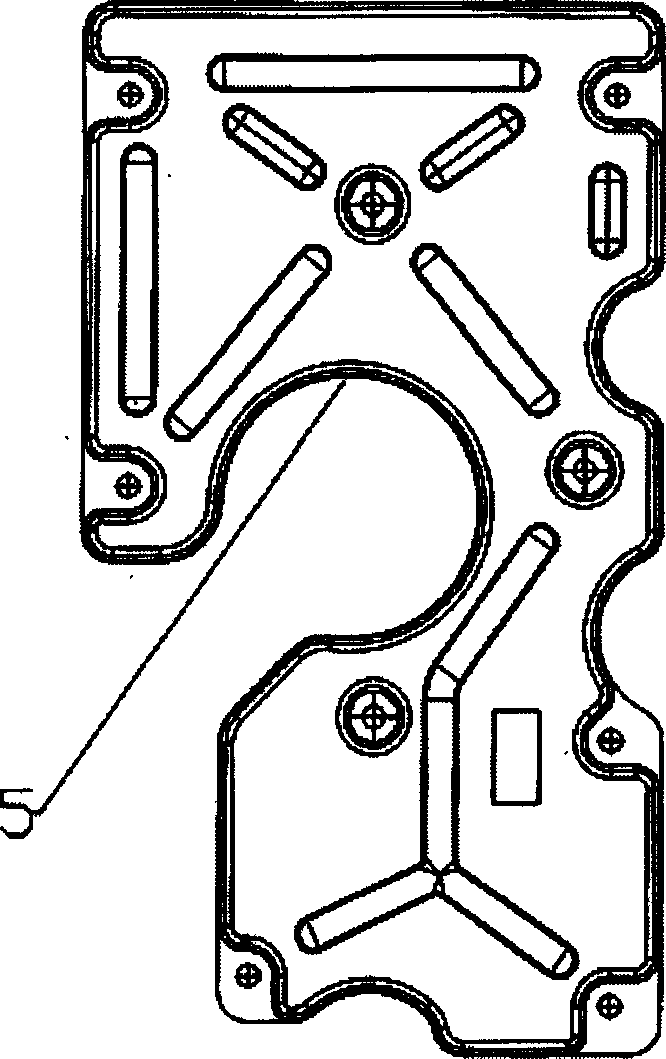

Machine oil collector-insulating board assembly for engine of vehicle

InactiveCN1786428AIncrease oil blocking areaImprove the oil blocking effectMachines/enginesEngine lubricationOil pressureMotor oil

An engine oil collector-bulkhead assembly for the vehicle engine includes an oil sump, an oil collector disposed at the bottom of the oil guard capable of sucking oil from the oil sump, an oil guard being an integrated plate and the oil suction pipe of the oil collector inserted directly into the holes of the oil collector frame.

Owner:CHERY AUTOMOBILE CO LTD

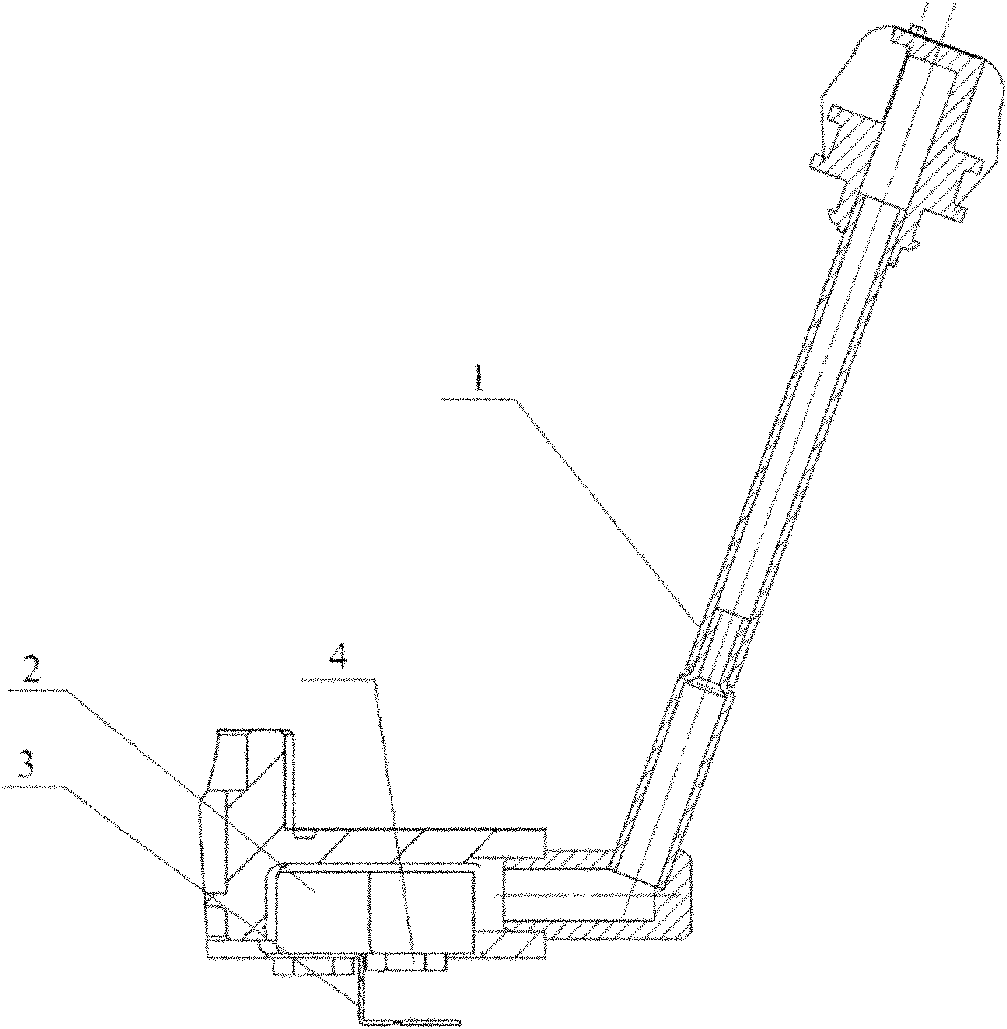

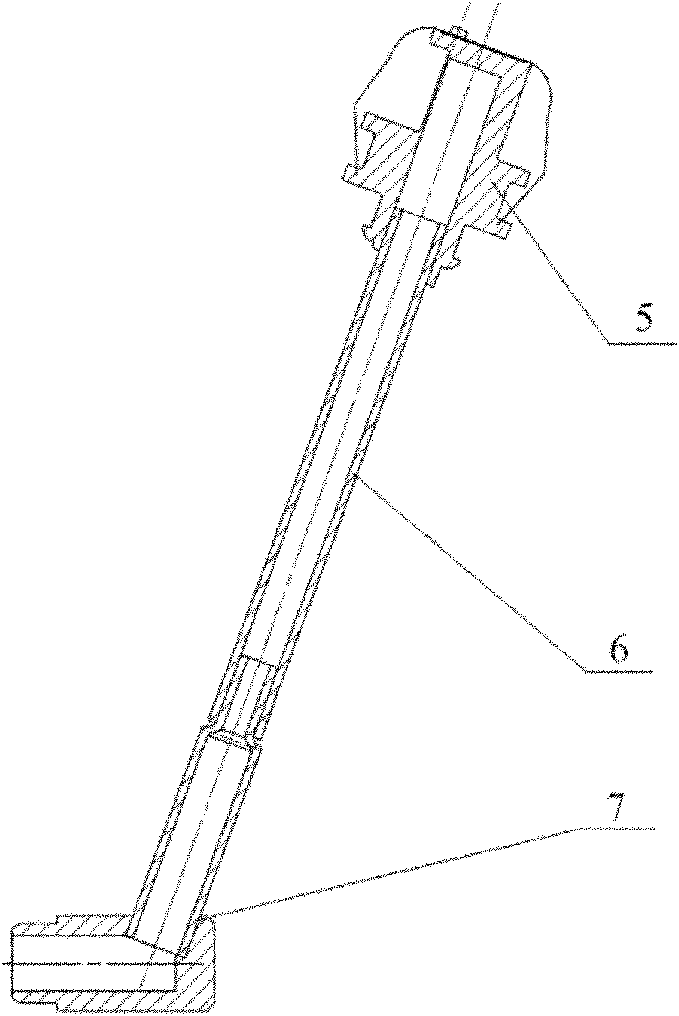

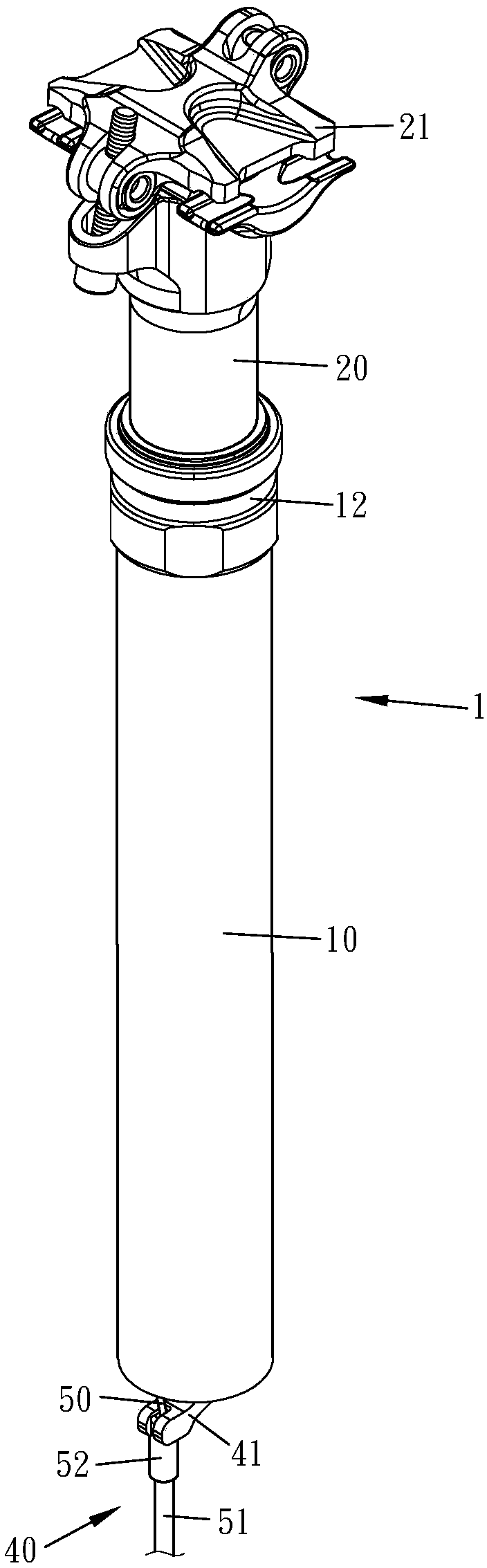

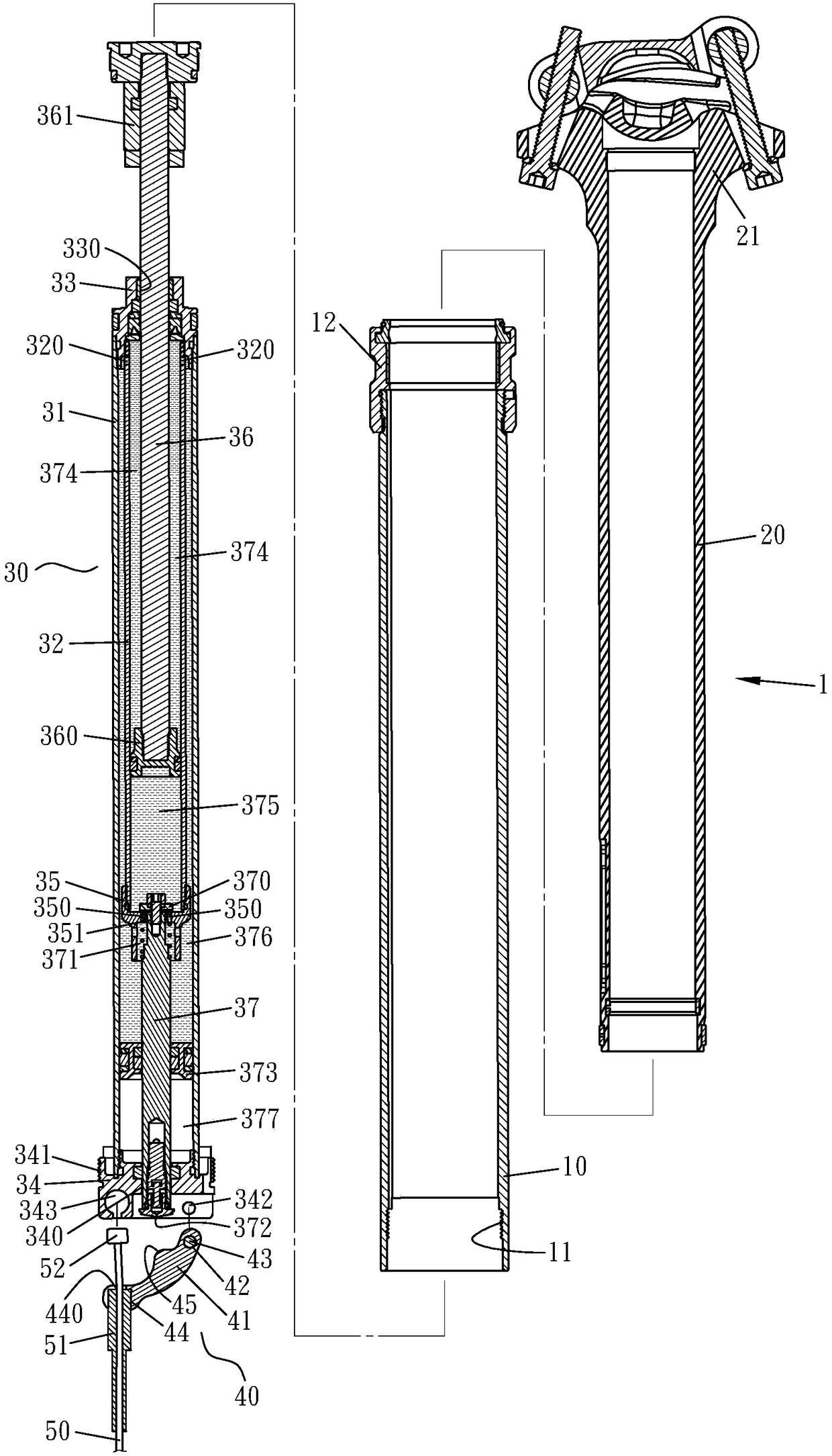

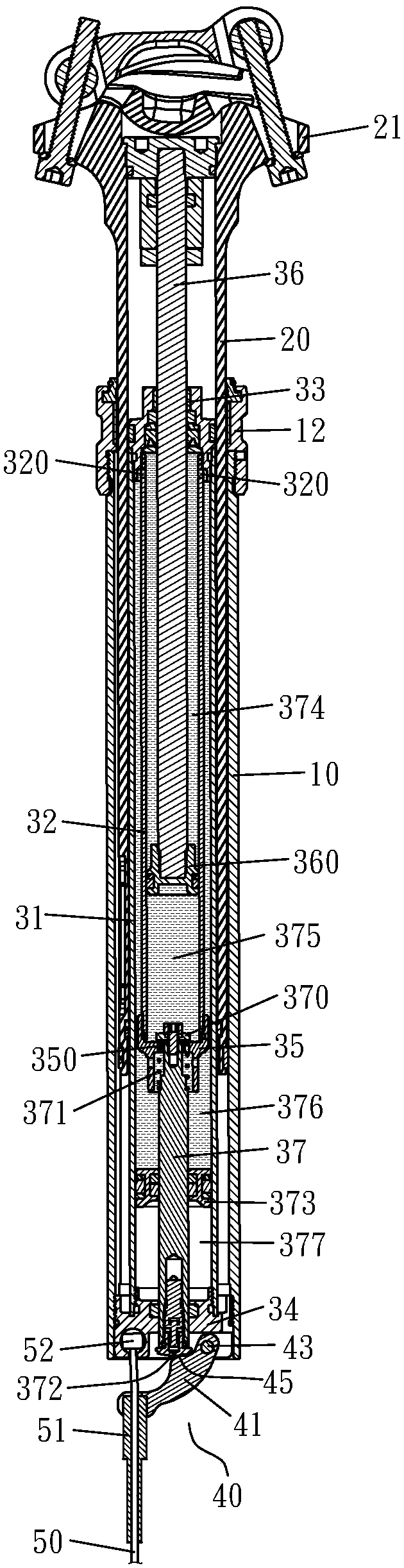

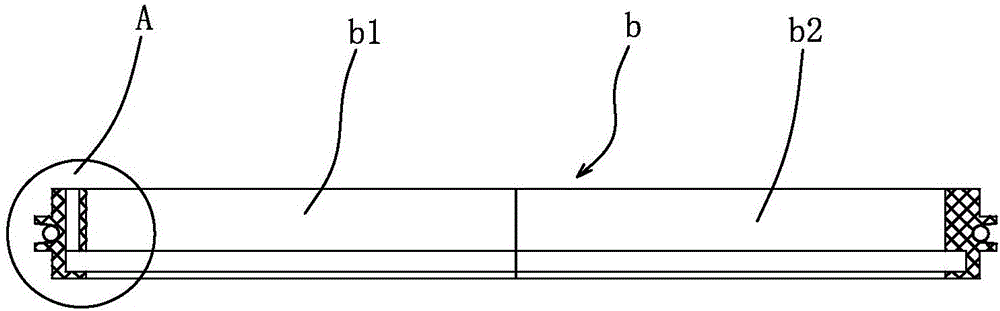

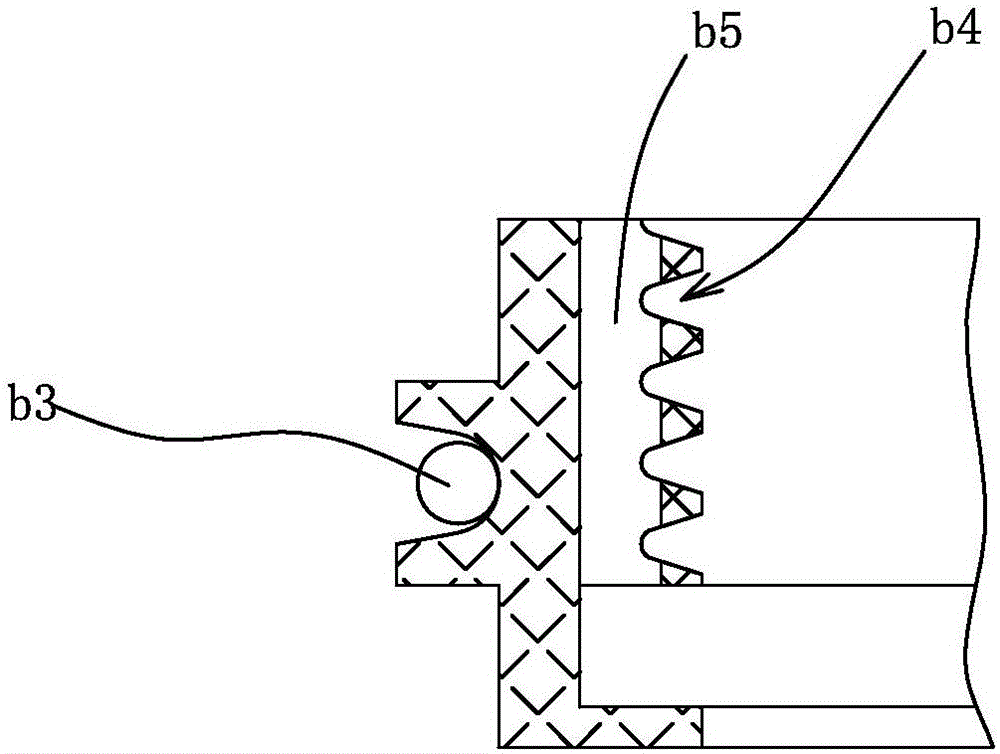

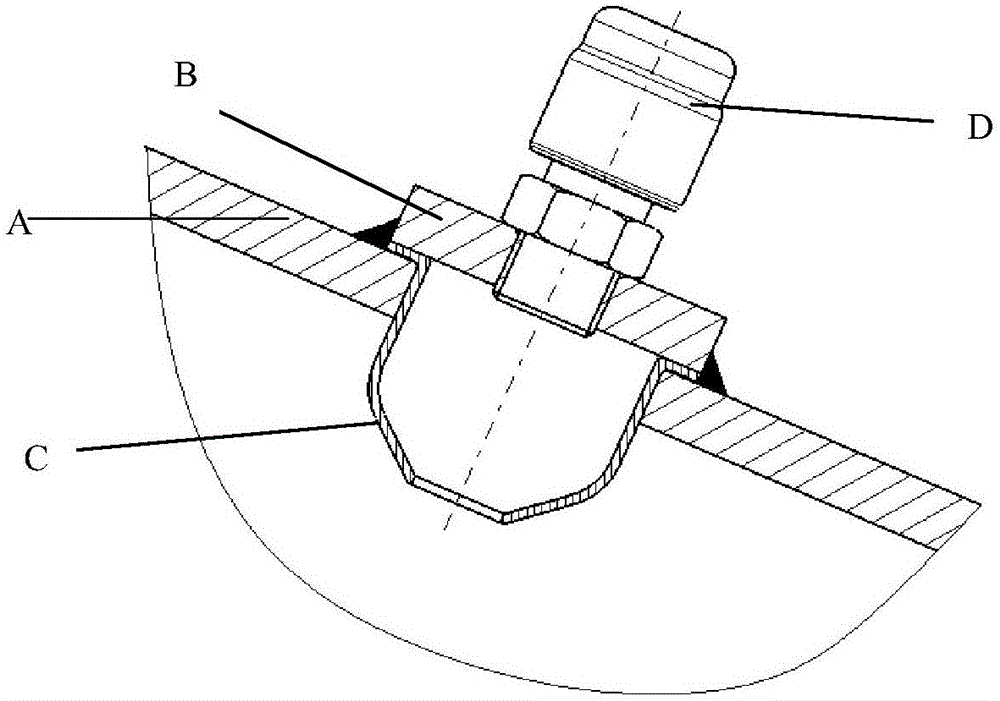

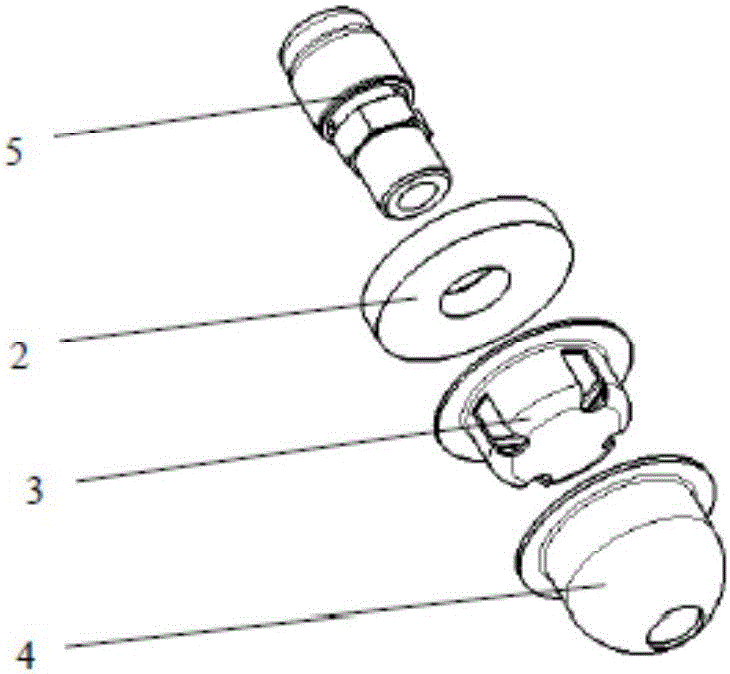

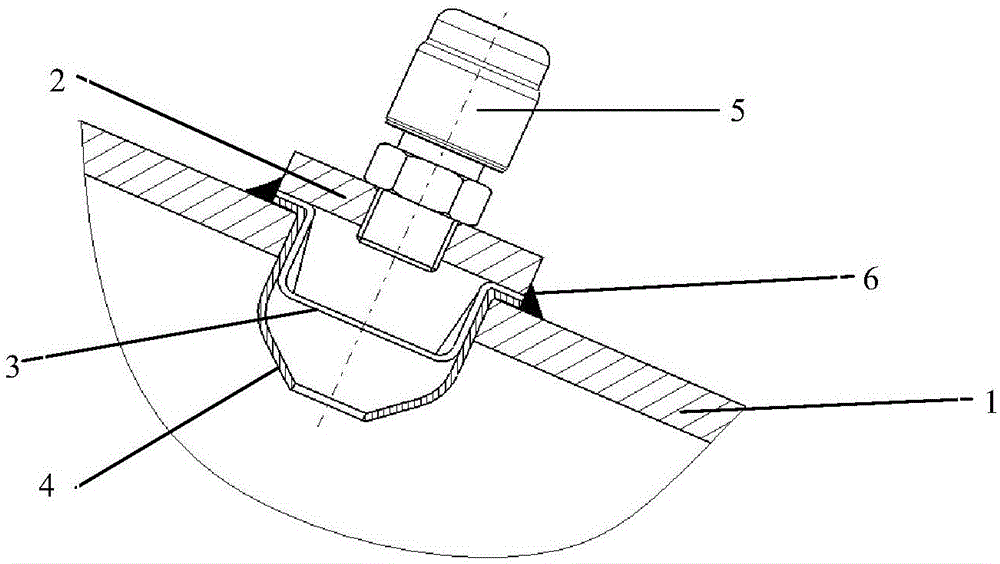

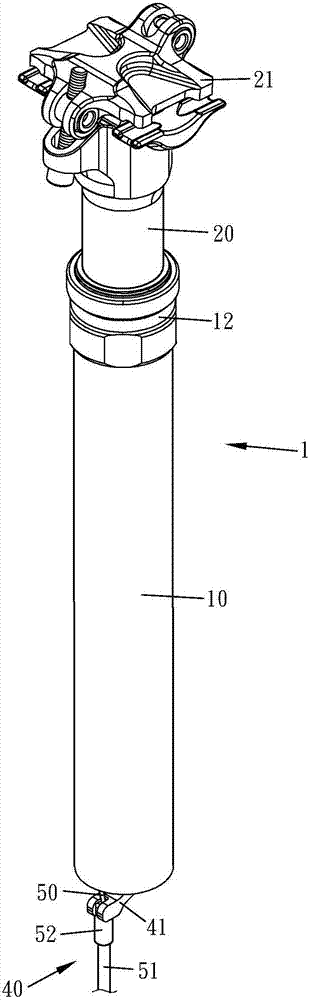

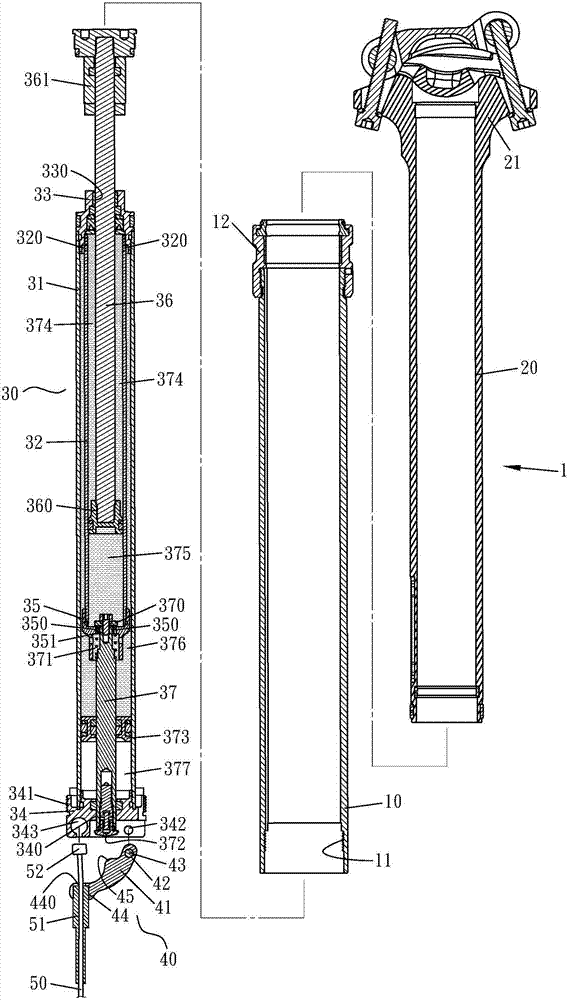

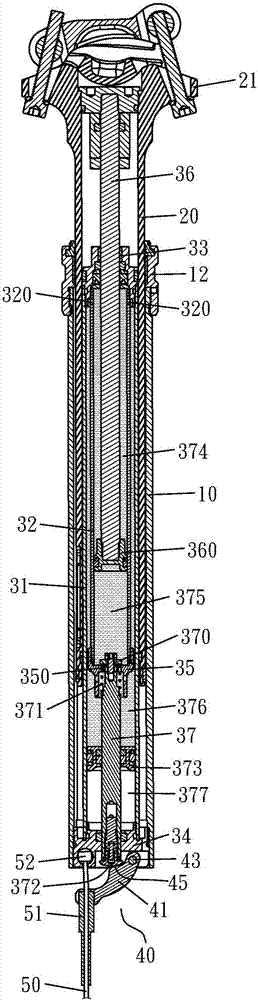

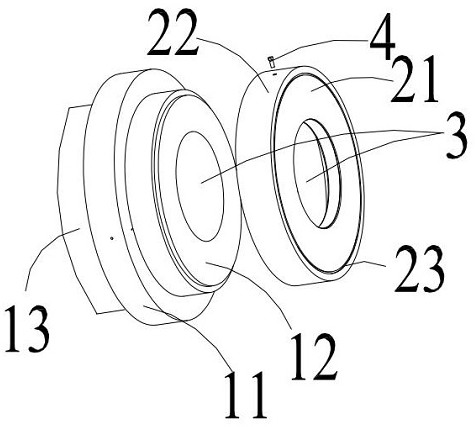

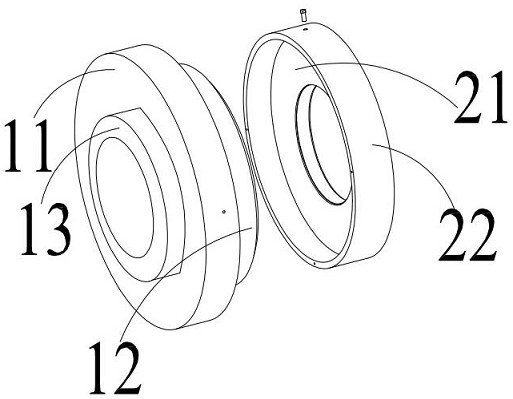

Height adjustment mechanism of bicycle seat tube

The invention provides a bicycle seat tube height adjusting mechanism. Mainly, oil way switches of the bicycle seat tube height adjusting mechanism are all located in a lifting adjusting unit, and valve ports of the oil way switches and an oil baffle are jointed in a vertical attachment mode for blockage. Thus, during maintenance, it is only needed to pull and replace the lifting adjusting unit, and the effects of being convenient to maintain and assemble are achieved. The valve ports and the oil baffle are in surface attachment in the vertical setting relationship, the oil baffle effect is good, at the moment a user sits on a seat cushion, the oil baffle does not bear shear force, and therefore the service life is prolonged.

Owner:TAIWAN HODAKA INDAL

End bracket type bearing

InactiveCN106286606AAvoid enteringExtended service lifeBearing unit rigid supportAtmospheric pressureMechanical engineering

The invention provides an end bracket type bearing which comprises a seat. A bearing pad connected with a rotating shaft is arranged in the seat, an end bracket sealing component is arranged on one side of the seat, an air seal cover with a sealed air cavity is arranged on the other side of the seat, an air pipe seat communicated with the sealed air cavity is fixedly arranged on the air seal cover, an air pipe component capable of balancing air pressure in the sealed air cavity and external air pressure is connected onto the air pipe seat, one end of the air pipe component is fixedly connected with the air pipe seat, the other end of the air pipe component is communicated with the outside of the seat, a positioning structure capable of preventing the bearing pad from moving relative to the seat is arranged between the seat and the bearing pad, and an oil ring structure is arranged in the bearing pad. The end bracket type bearing has the advantages of good sealing effect and capabilities of preventing oil or oil mists from entering a motor and prolonging the service life of the motor.

Owner:诸暨市鸿源电力机械有限公司

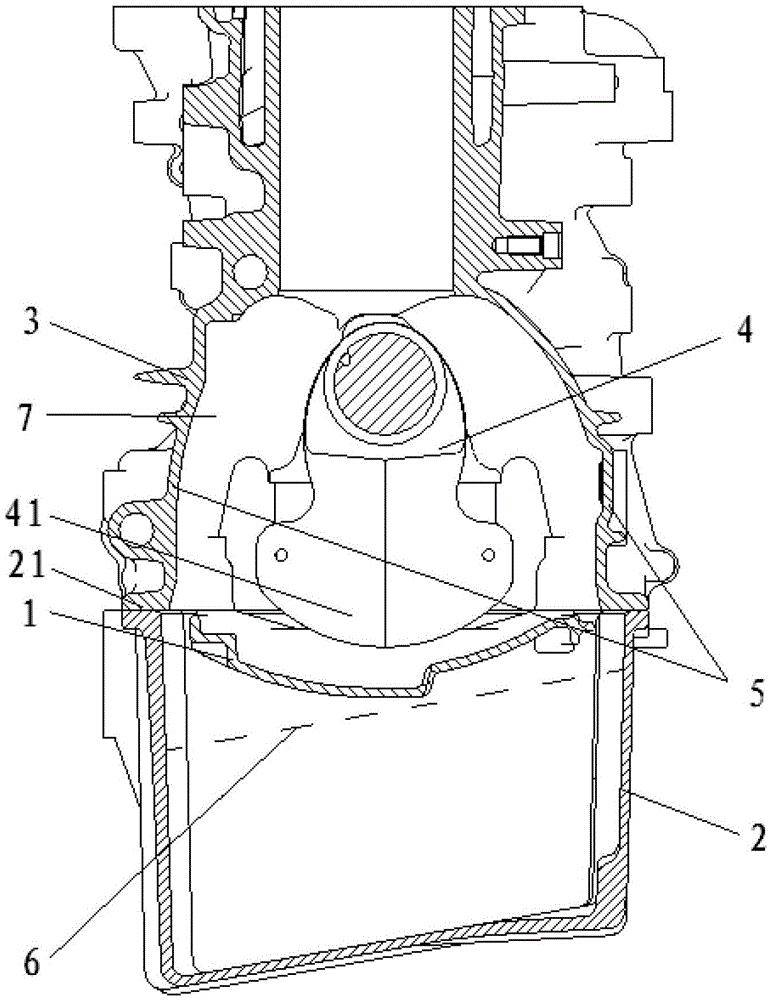

Inner oil blocking structure of compressor and compressor with oil blocking structure

ActiveCN106401966AReduce outflowImprove the oil blocking effectRotary/oscillating piston pump componentsLiquid fuel engine componentsBlock effectAir compressor

The invention relates to the field of air compressors, in particular to an inner oil blocking structure of a compressor and the compressor with the oil blocking structure. The inner oil blocking structure comprises an oil blocking component, the oil blocking component is arranged at the position where the refrigerant circulation area in the compressor is large, and the oil blocking component is used for stopping flowing of refrigerant fluid carrying refrigeration oil. The technical problem that in the prior art, the oil blocking effect of an oil baffle in the prior art is not good needs to be solved, and accordingly the inner oil blocking structure of the compressor and the compressor with the oil blocking structure are provided, wherein the inner oil blocking structure is better in oil blocking effect.

Owner:GREE ELECTRIC APPLIANCES INC +1

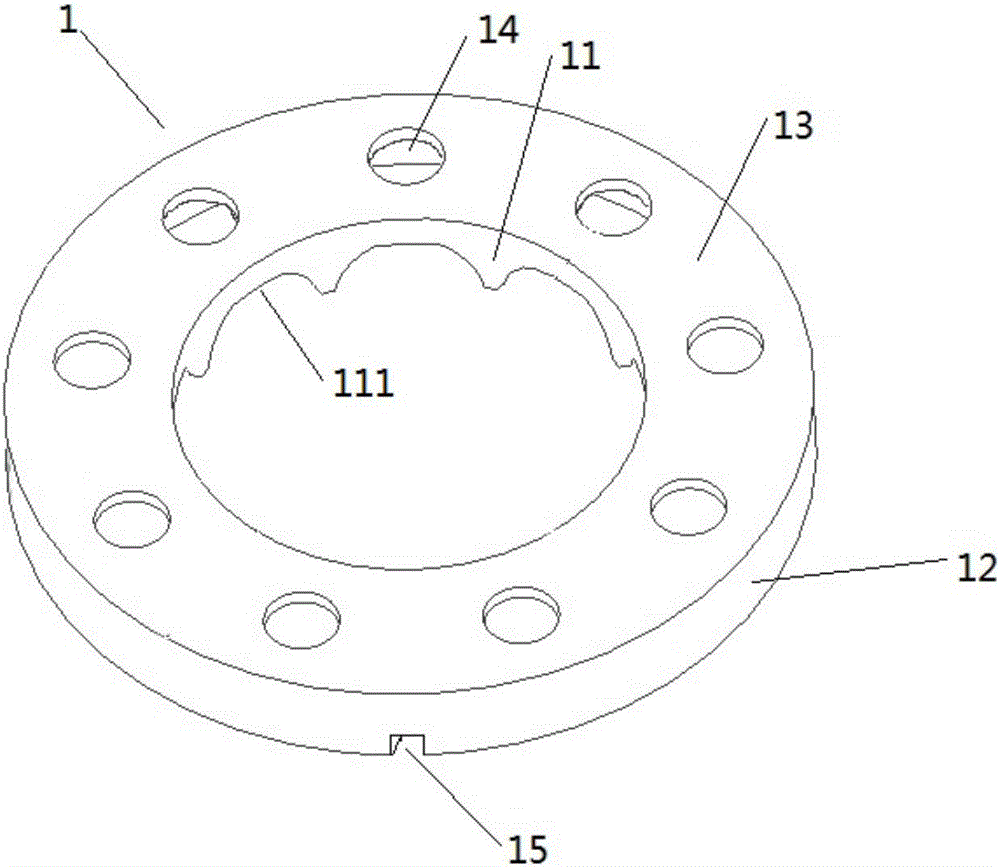

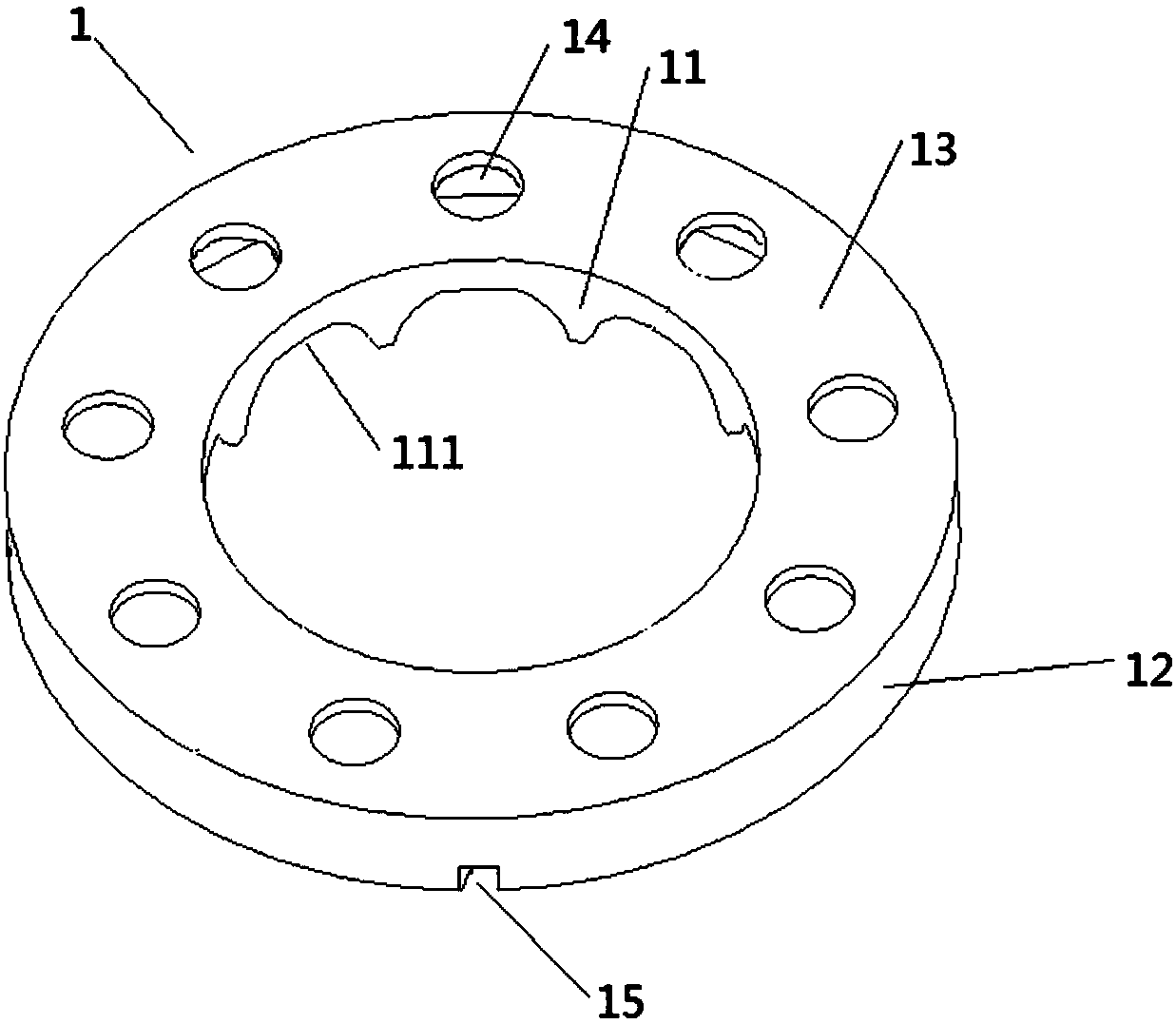

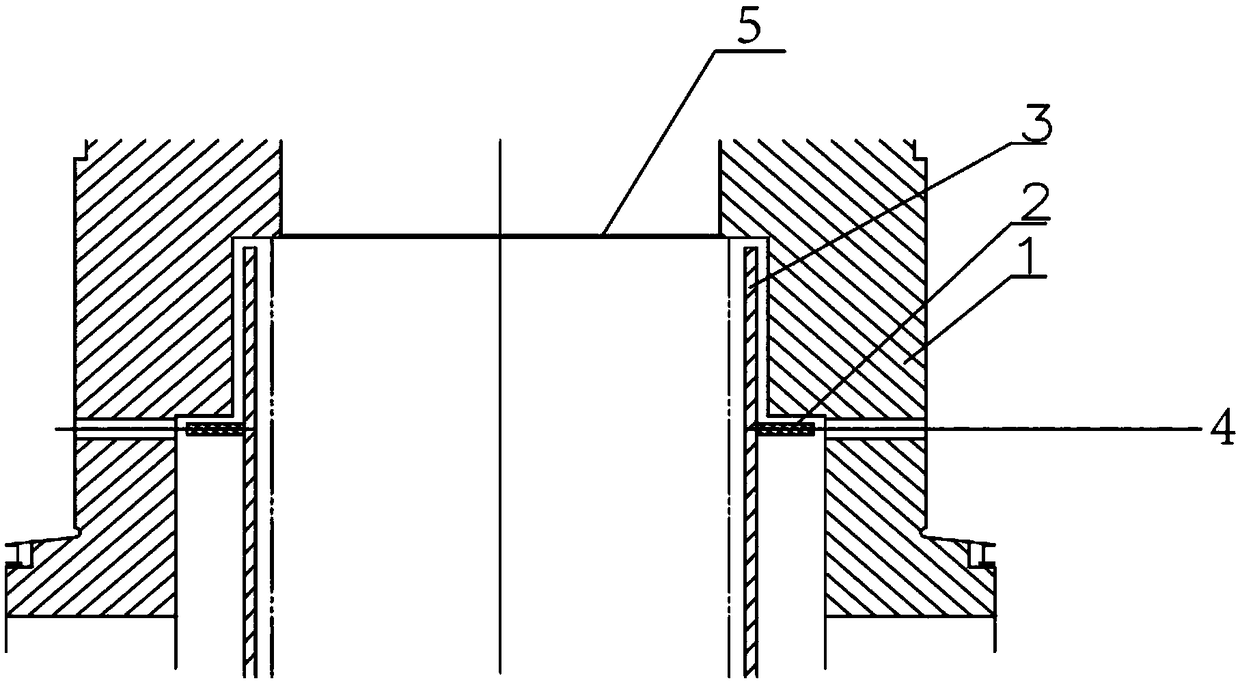

Detachable oil baffle sealing ring

PendingCN109372990AGuaranteed tightnessGuaranteed clearanceEngine sealsCorrosion resistantNuclear power plant

The invention belongs to the technical field of nuclear power plant steam turbine maintenance, and particularly relates to a detachable oil baffle sealing ring, and aims to develop a reliable oil baffle sealing ring. The oil baffle sealing ring has the advantages of being convenient to assemble and disassemble, good in fixing performance, corrosion-resistant, good in sealing performance, high in oil blocking capability and the like. End face sealing and clearance can be effectively guaranteed after installation, and lubricating oil can be prevented from being thrown out along with the shaft. The oil baffle sealing ring is characterized by comprising a probe mounting sealing hole and a hoisting hole, an upper positioning hole, an upper mounting bolt hole and a middle split surface positioning pin, a middle split surface fastener, an upper oil retaining ring, a lower oil retaining ring, a lower positioning hole and a lower mounting bolt hole.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Compressor oil retaining components, rotor components, compressors and air conditioning systems

ActiveCN106014931BReduce oil discharge rateImprove the oil blocking effectPositive displacement pump componentsPositive-displacement liquid enginesBlock effectAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC +1

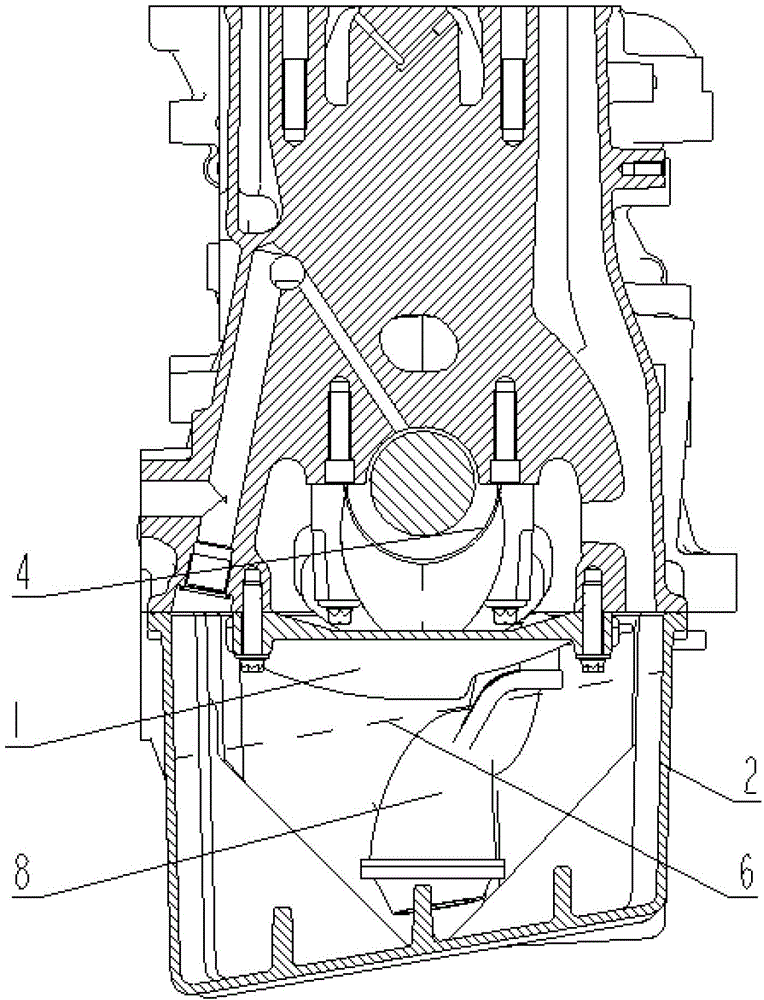

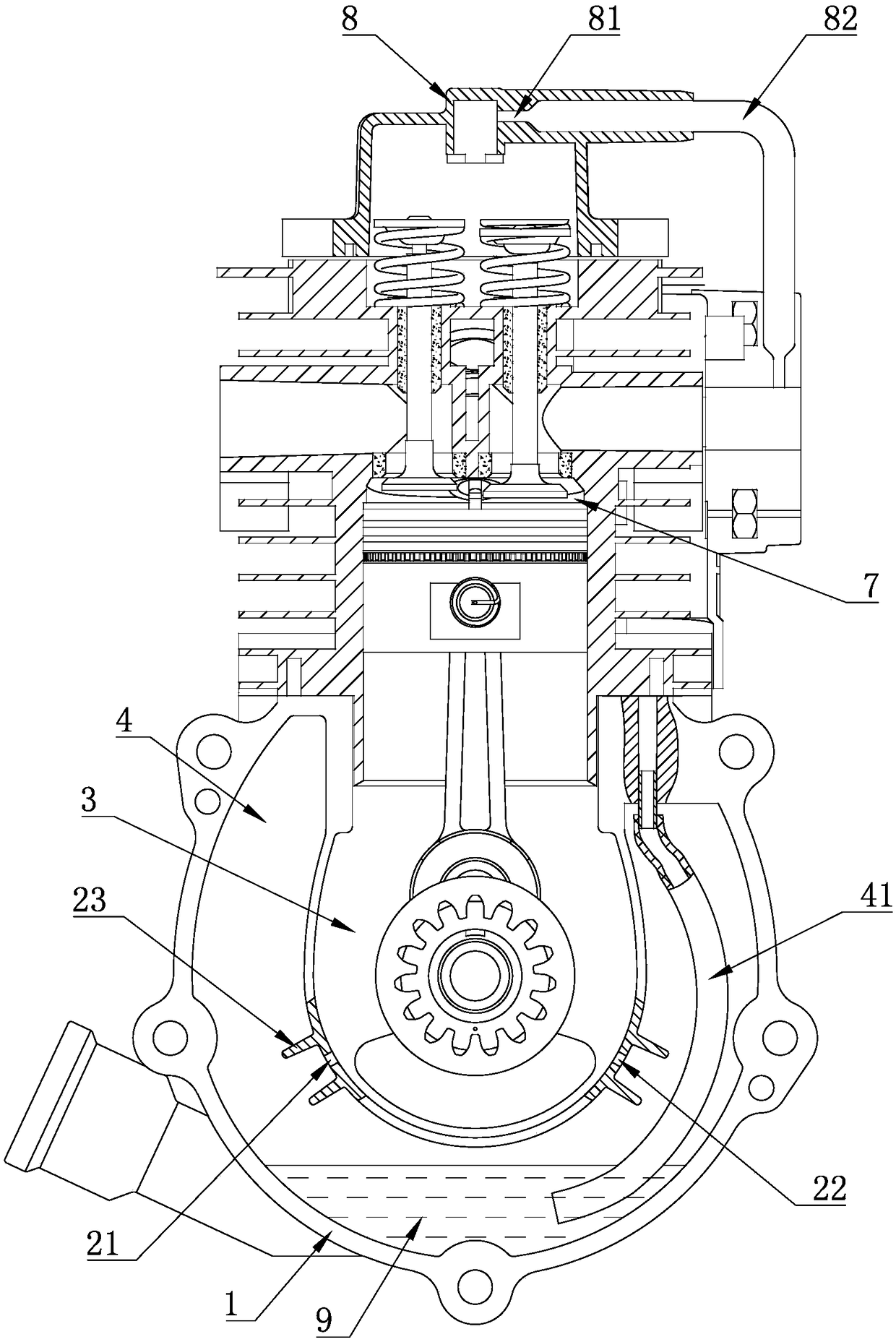

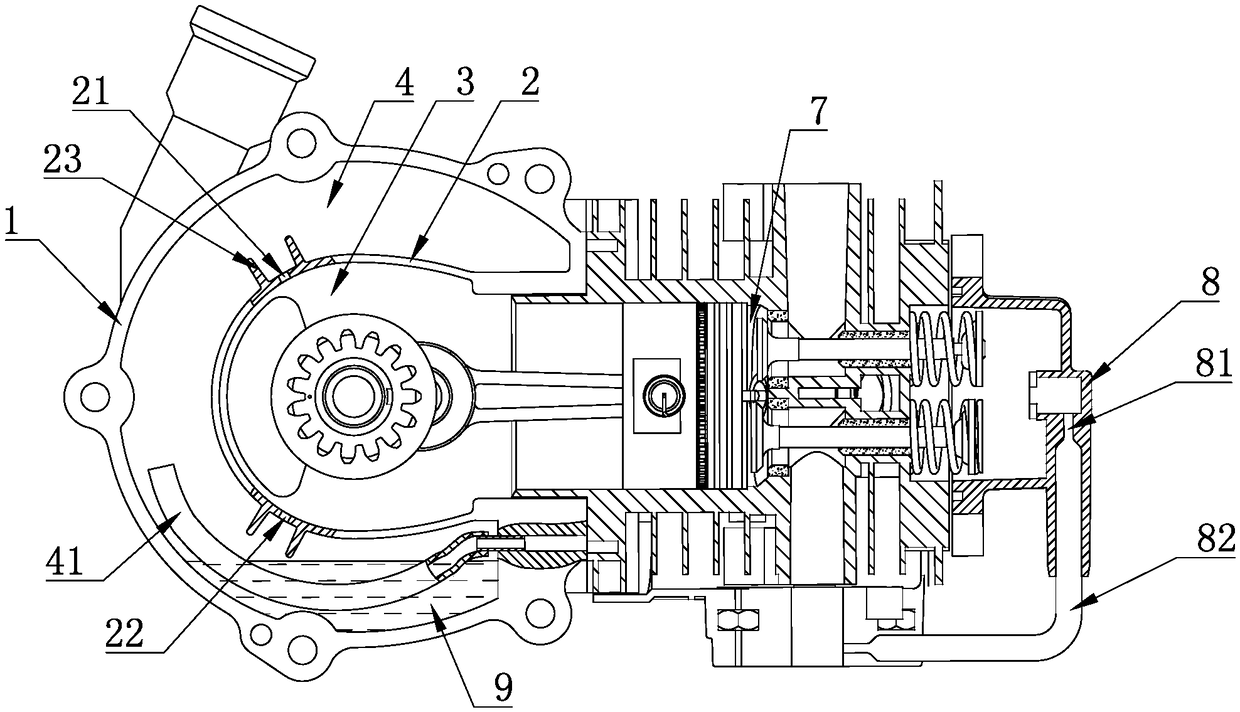

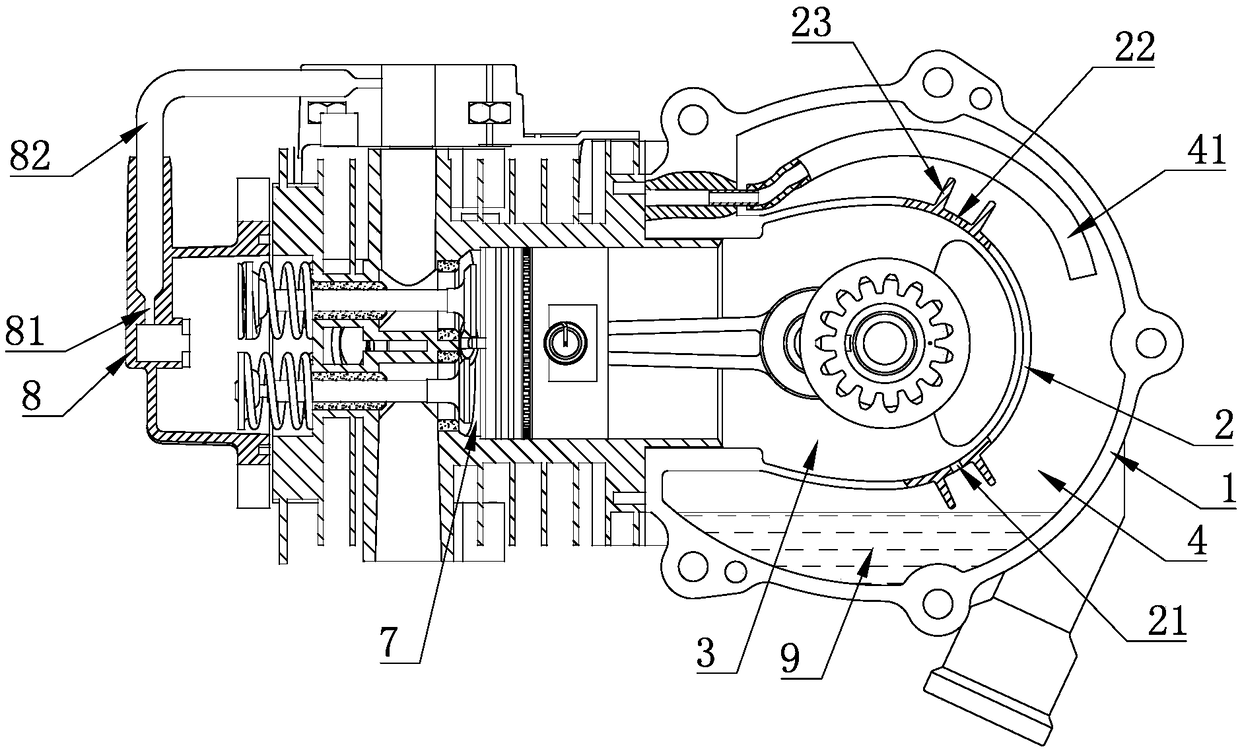

Engine oil baffle

ActiveCN103362594ADelay agingDifficult to enterMachines/enginesEngine lubricationVibration attenuationReturn function

The invention provides an engine oil baffle which is connected to the two sides of a crank case and located below a balance block of a crank shaft. The engine oil baffle is located above an engine oil liquid level in an oil pan and an engine oil strainer. The engine oil baffle comprises a first arc slab, a second arc slab and a transition board. The transition board is provided with a strip-shaped oil drainage hole and connected with the first arc slab and the second arc slab. The oil drainage hole is located in the lowermost position of the engine oil baffle. The included angle between the transition board and the vertical direction is less than or equal to 60 degrees. The engine oil baffle has good oil blocking and returning functions and can play a good role in vibration attenuation, thereby achieving the purposes of cost reduction and light weight.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

an oil baffle

ActiveCN103362594BDelay agingDifficult to enterMachines/enginesEngine lubricationVibration attenuationReturn function

The invention provides an engine oil baffle which is connected to the two sides of a crank case and located below a balance block of a crank shaft. The engine oil baffle is located above an engine oil liquid level in an oil pan and an engine oil strainer. The engine oil baffle comprises a first arc slab, a second arc slab and a transition board. The transition board is provided with a strip-shaped oil drainage hole and connected with the first arc slab and the second arc slab. The oil drainage hole is located in the lowermost position of the engine oil baffle. The included angle between the transition board and the vertical direction is less than or equal to 60 degrees. The engine oil baffle has good oil blocking and returning functions and can play a good role in vibration attenuation, thereby achieving the purposes of cost reduction and light weight.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Lubricating system of four-stroke engine and tool equipment with four-stroke engine

PendingCN109268101AStable pressureTimely lubricationLubrication of auxillariesMachines/enginesFour-stroke engineCrankcase

The invention discloses a lubricating system of a four-stroke engine. The lubricating system comprises a crankcase, a lubricating oil tank and a cam chamber, the crankcase is provided with a crank chamber, the lubricating oil tank is positioned outside the crankcase, and the cam chamber is used for storage of a cam. A lubricating oil chamber for storage of lubricating oil is formed between the lubricating oil tank and the crankcase. The crankcase is provided with front oil taking holes in communication with the crank chamber and the lubricating oil chamber, and an oil pipe is connected betweenthe cam chamber and the lubricating oil chamber. By communication between the cam chamber and the lubricating oil chamber through the oil pipe, in operation of the four-stroke engine, vertical movement of a cylinder piston enables lubricating oil to enter the cam chamber through the oil pipe without passing through the crank chamber, and sufficient lubricating oil can enter the cam chamber to timely lubricate structures of the cam and the like to prevent abrasion. The invention further provides tool equipment with the four-stroke engine. The tool equipment comprises the four-stroke engine which adopts the lubricating system.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

Wide strip foil rolling equipment

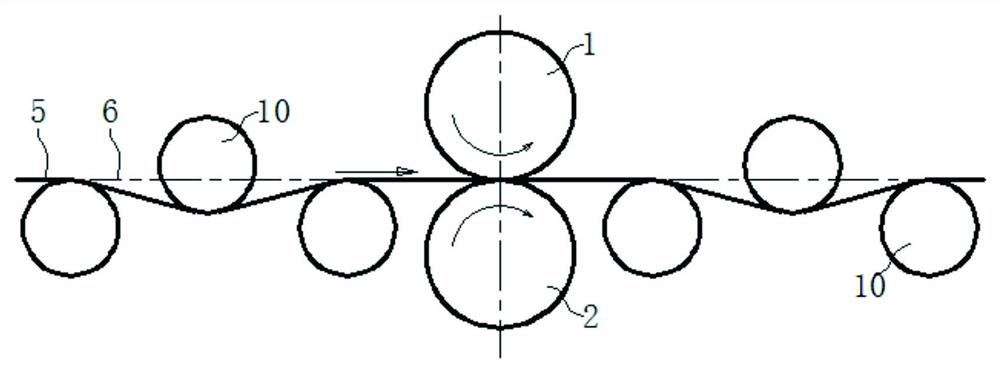

ActiveCN113118215AAchieving spread rollingSolve curl deformationMetal rolling stand detailsGuiding/positioning/aligning arrangementsRolling millPhysics

Wide strip foil rolling equipment comprises a rolling mill, a front adjusting roller set and a rear adjusting roller set. In a pair of working rollers of the rolling mill, the roller diameter of one working roller is larger than that of the other working roller. In the front adjusting roller set or the rear adjusting roller set, the roller diameter of an adjusting roller close to the rolling mill is larger than the roller diameter of the other adjusting rollers, and by adjusting the height of the adjusting roller with the larger roller diameter, strip foil is wrapped on the roller surface of one working roller to form a wrapping arc. According to the wide strip foil rolling equipment, the rolling mill with the working rollers with unequal diameters is adopted to roll the strip foil, and the front tension is uniformly distributed on the cross section of the wrapping arc on the inlet side through the wrapping arc. By means of the wide strip foil rolling equipment, thinning of the strip foil is facilitated, obtaining of a good plate shape is facilitated, uniform rolling of the strip foil is achieved, the bottleneck restricting development of the strip foil towards the wider, thinner and more ideal plate shape is broken through, and the technical problems in the industry are solved. In addition, the adjusting rollers with unequal diameters are favorable for eliminating the original defects of residual oil and strip foil.

Owner:SHANGHAI WUXING COPPER CO LTD +1

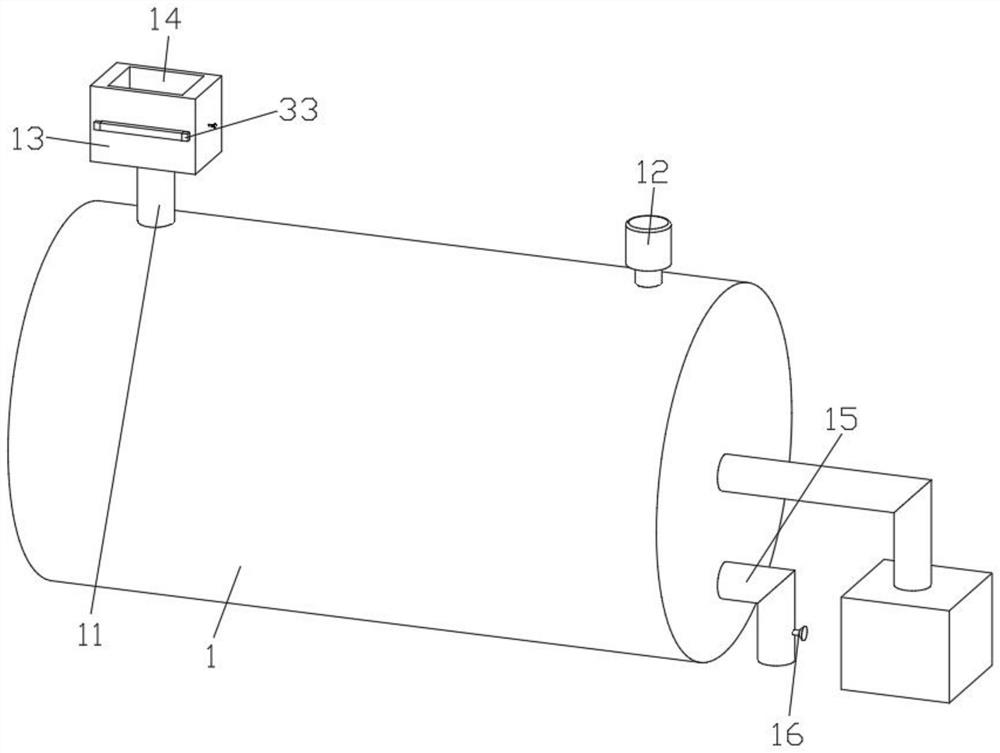

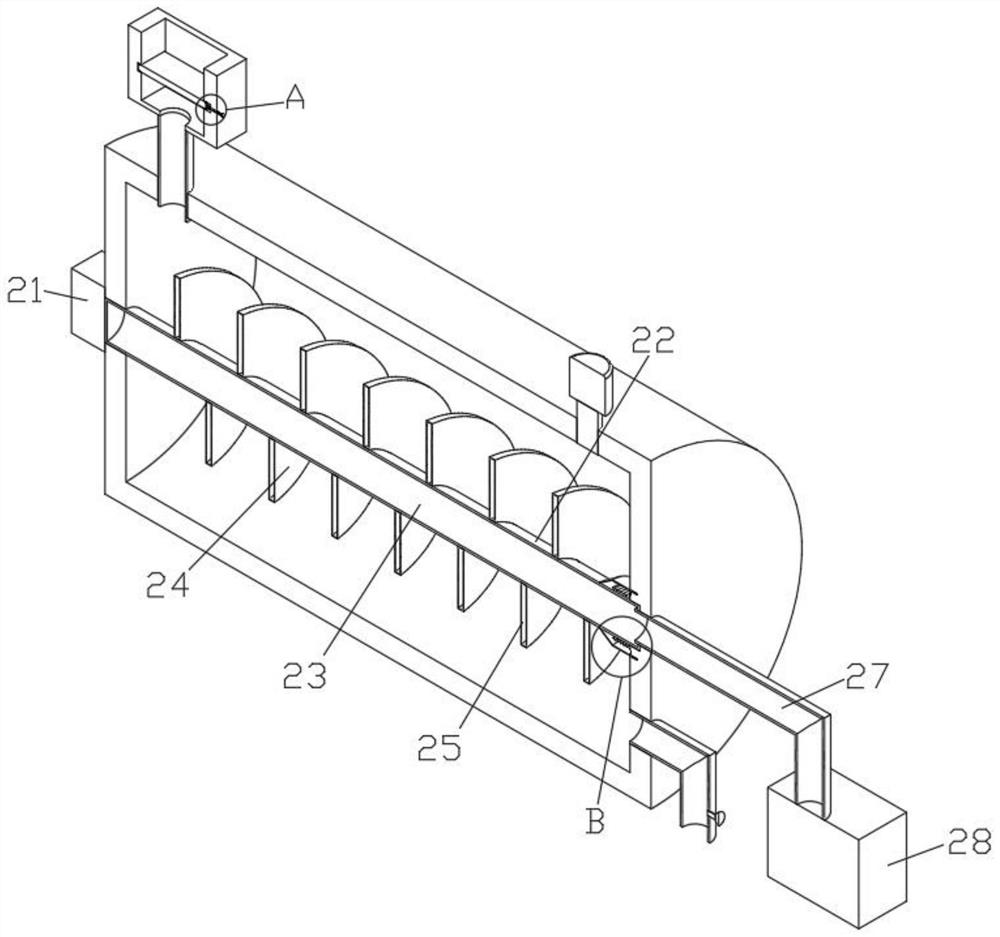

Extraction mechanism for petrochemical production buffer tank

ActiveCN112915923AAvoid spillingAchieve heating effectFiltration separationFeed devicesBuffer tankElectric machinery

The invention discloses an extraction mechanism for a petrochemical industry production buffer tank. The extraction mechanism comprises an extraction cylinder, an extraction pipe is arranged on the upper left portion of the extraction cylinder, a square block is arranged at the top of the extraction pipe, a liquid inlet groove is formed in the square block, a filtering component is arranged in the liquid inlet groove, and a heating component is arranged in the extraction cylinder. Through cooperative use of the extraction cylinder, the extraction pipe, an oil pump, the square block, the liquid inlet groove, a filtering part, a motor, a rotating shaft, a first groove, a spiral blade, a hollow groove, a circular opening, an exhaust pipe, a heater and a sealing part, the problems that an existing extraction mechanism is not provided with a heating device, the oil extraction efficiency is reduced, impurities in oil are not filtered, and impurities are left in the buffer tank are solved.

Owner:JIANGXI TONGJIAN MACHINERY DEV

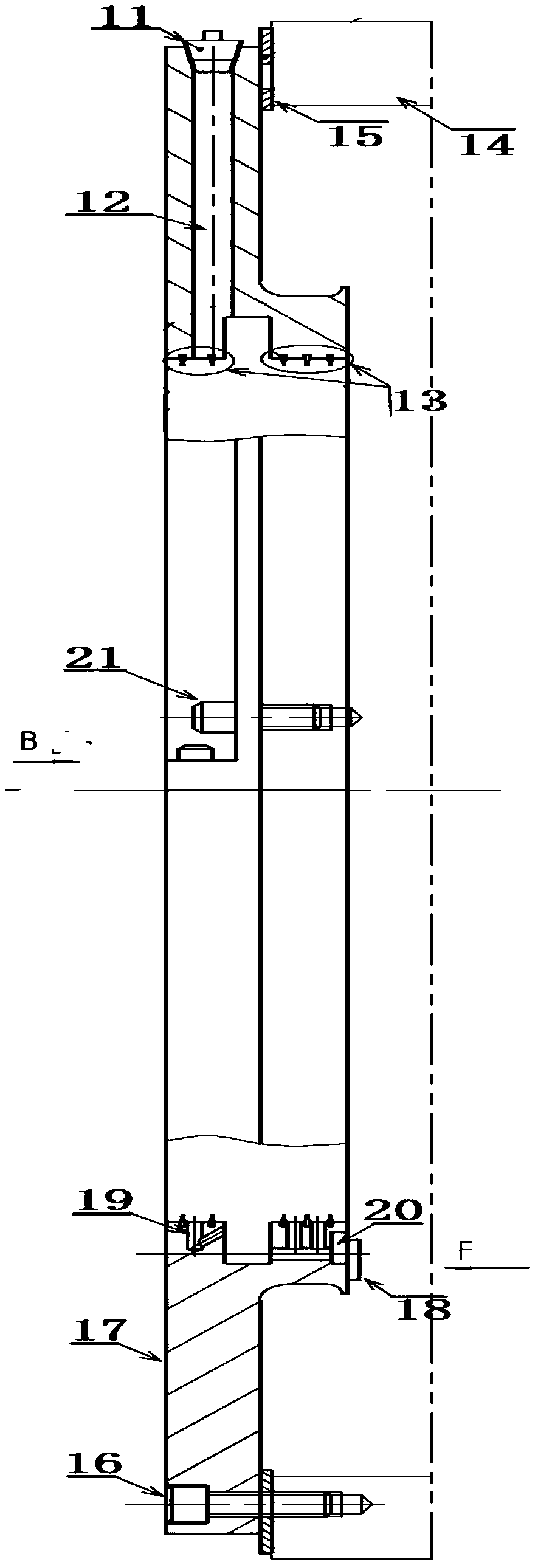

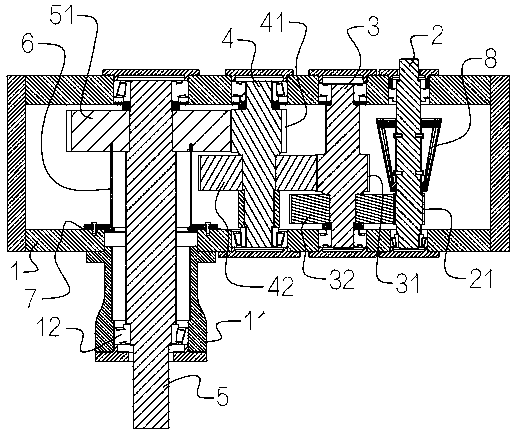

Water guide bearing

InactiveCN105065448BBest design valueEasy maintenanceHydro energy generationBearing componentsPositive pressureEngineering

The invention belongs to the technical field of hydraulic turbine parts and particularly relates to a turbine guide bearing. The turbine guide bearing comprises a bearing block and a spindle, wherein the outside of the spindle is sleeved with a water guide block; the water guide block is rotatably connected with the spindle; a water guide block adjusting device is arranged between the water guide block and the bearing block; an oil retaining mechanism is arranged between the water guide block and the spindle. The turbine guide bearing is characterized in that the oil retaining mechanism comprises a cylindrical body which is arranged at the spindle provided with a guide bearing collar and is positioned in an annular space formed between the spindle and the guide bearing collar; the guide bearing collar is externally sleeved with the water guide block; the water guide block is rotatably connected with the spindle; a pressure forming structure which can form positive pressure when the spindle rotates to prevent lubricating oil from being lost is arranged on the body. The turbine guide bearing has the advantages that a clearance between a shaft bush and a shaft is favorably adjusted, and a good oil retaining effect is realized.

Owner:ZHEJIANG ZHENGSHENG BEARING

compressor

ActiveCN105782053BReduce oil discharge rateReduce power consumptionRotary/oscillating piston pump componentsLiquid fuel engine componentsMechanical engineeringThroughput

The invention provides a compressor comprising a shell, a stator core, a rotor core and a first baffle, wherein the stator core and the rotor core are arranged in the shell; the stator core is arranged around the rotor core; circulating holes formed along the axial direction of the rotor core are formed in the rotor core; and the first baffle comprises a bottom plate part and an oil retaining side edge arranged at the upper side of the bottom plate part, and the first baffle is opposite to the upper end surface of the rotor core, so that lubricating oil carried by a refrigerant comes into collision with the oil retaining side edge to form oil drops falling back below the rotor core after the refrigerant flowing out of the circulating holes passes through the bottom plate part. By using the compressor, the refrigerant can return from the upside to the downside of a motor of the compressor, so that the stroke of the refrigerant is increased; in addition, due to the adoption of the design of the non-swirl baffle located above the rotor core, an extremely good oil retaining effect is taken while no wind resistance is generated, and the condition that the lubricating oil is discharged from the compressor is avoided, so that the oil throughput rate of the compressor is effectively reduced, the performance of a unit is improved, and the power consumption of the compressor is reduced.

Owner:GREE ELECTRIC APPLIANCES INC +1

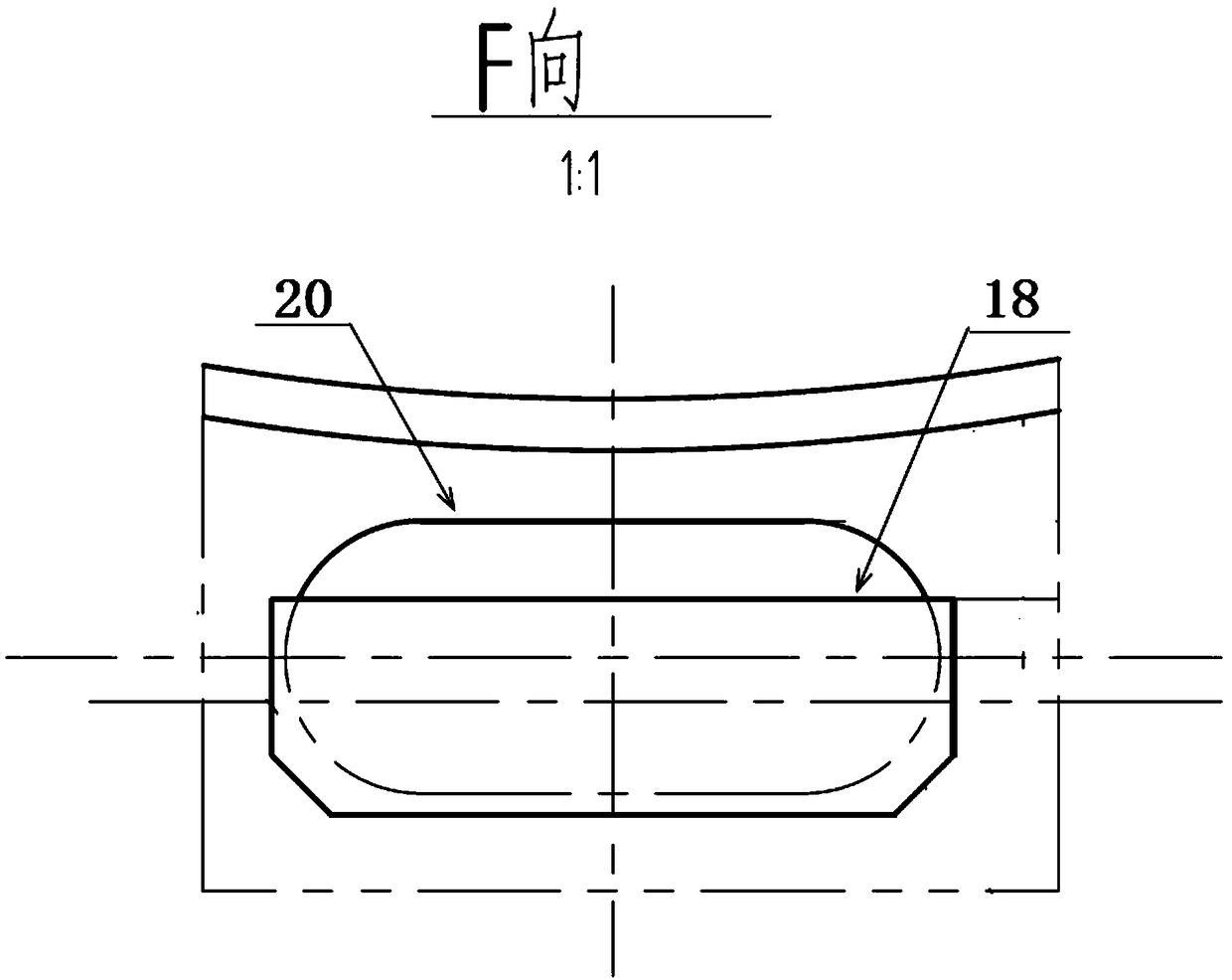

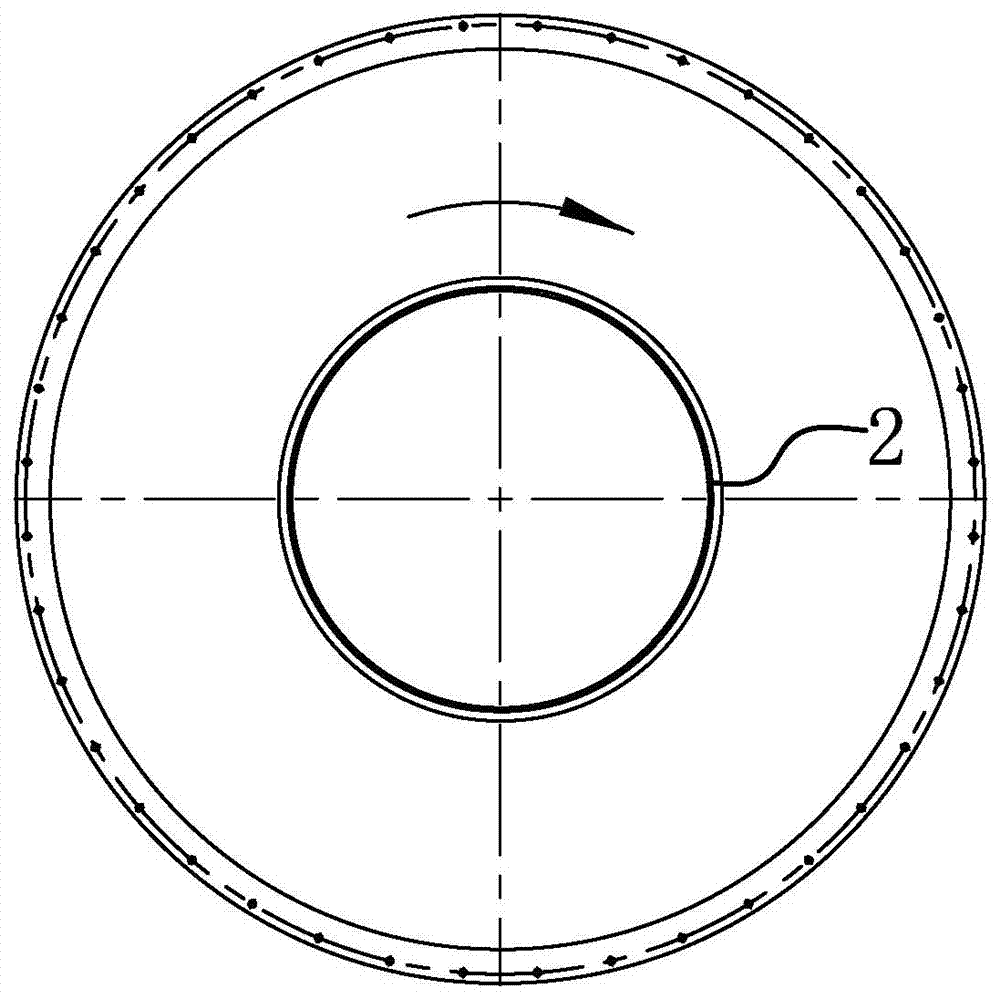

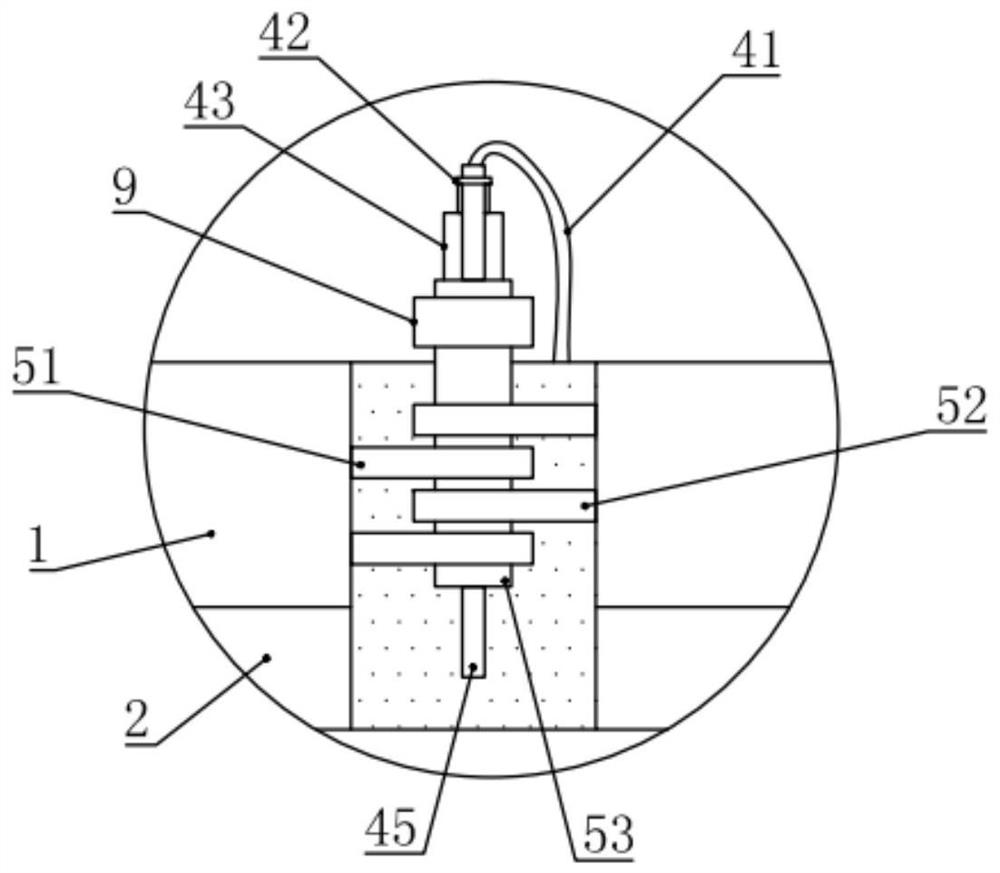

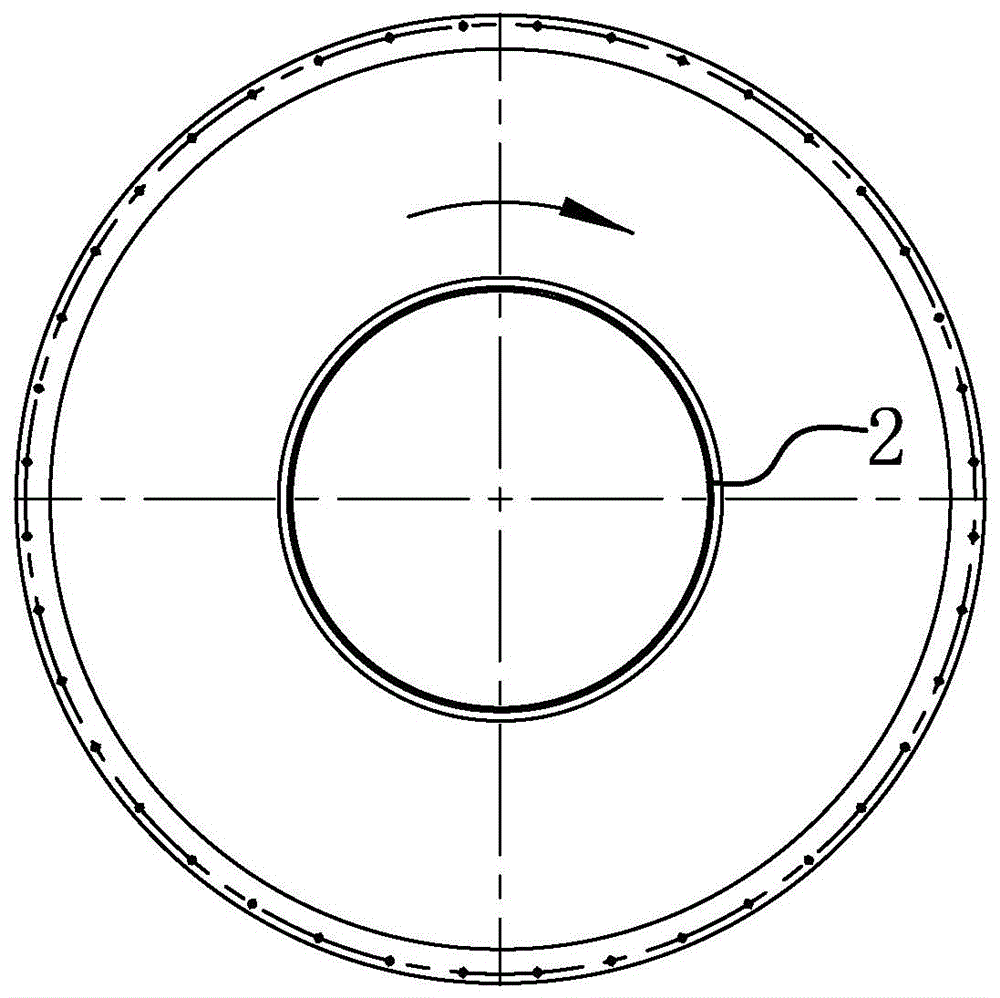

Water guide bearing oil retaining mechanism

InactiveCN105065175BPrevent leakageReduce leakageHydro energy generationMachines/enginesShaft collarTurbine

The invention belongs to the technical field of bearing parts, and particularly relates to an oil stopping mechanism of a turbine guide bearing. The oil stopping mechanism of the turbine guide bearing comprises a cylindrical body which is arranged at a main shaft provided with a shaft collar and located in an annular space formed between the main shaft and the shaft collar, the main shaft is fixed on a main shaft seat, the bearing arranged on the shaft collar in a sleeving mode is arranged between the main shaft and the main shaft seat, and the bearing is rotatably connected with the main shaft. The oil stopping mechanism of the turbine guide bearing is characterized in that the body is provided with a pressure forming structure which can form positive pressure to prevent lubricating oil from running off when the main shaft is rotated. The oil stopping mechanism of the turbine guide bearing has the advantages that the pressure forming structure can form the positive pressure on the main shaft, therefore, the lubricating oil is prevented from leaking, the oil stopping effect is good, the overall design is reasonable, and the structure is simple; the lubricating oil can be contained in a spiral groove in the rotating process of the main shaft, therefore, the lubricating oil leakage is reduced, and the oil stopping effect is good; the oil stopping mechanism is beneficial for the lubricating oil to be evenly distributed on the surface of the main shaft, and lubricating is facilitated.

Owner:ZHEJIANG ZHENGSHENG BEARING

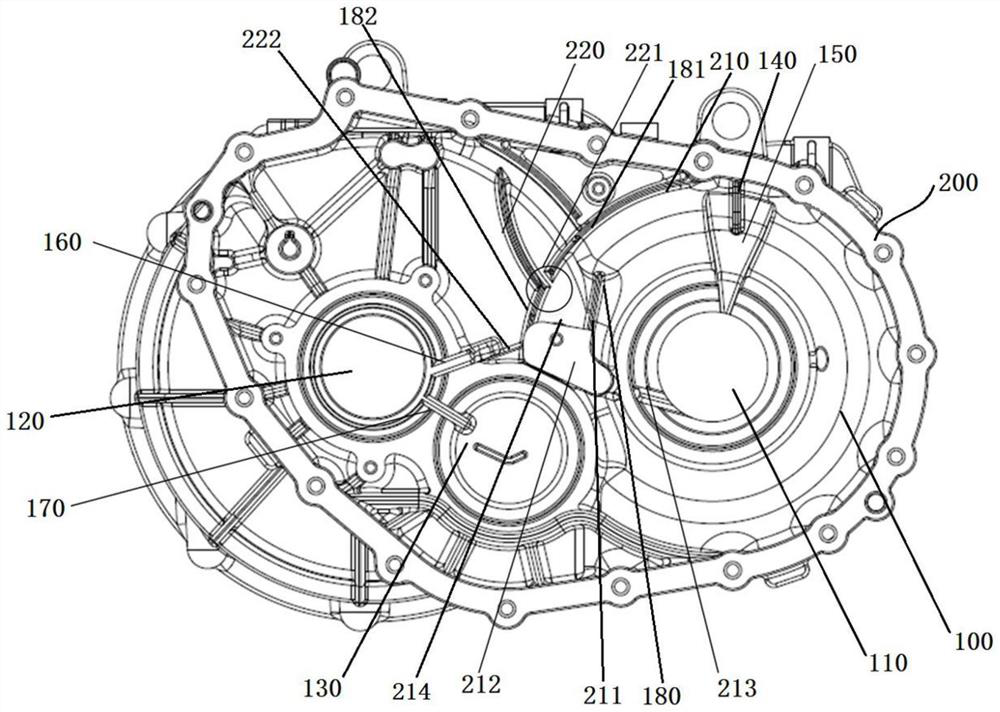

Automobile reduction gearbox and automobile

PendingCN114370494AIncrease the amount of oil guideImprove the lubrication effectGear lubrication/coolingToothed gearingsOil canGear wheel

The invention discloses an automobile reduction gearbox and an automobile, the automobile reduction gearbox comprises a shell and a gear set arranged in the shell, the shell comprises a mounting wall used for bearing the gear set, the gear set comprises an output gear, the mounting wall is provided with a first bearing chamber correspondingly used for bearing the output gear, and the first bearing chamber is provided with a second bearing chamber correspondingly used for bearing the output gear. The mounting wall is further provided with an oil collecting groove internally provided with a first blocking rib, the oil collecting groove extends downwards and is communicated with the first bearing chamber, the first blocking rib can block oil thrown out by the output gear, and the blocked oil can flow into the first bearing chamber along the oil collecting groove. According to the oil guide device, thrown-out oil liquid can be drained, the oil guide efficiency and the oil guide amount are improved, and therefore the lubricating effect is enhanced.

Owner:SHANGHAI ELECTRICGROUP CORP

Ventilation plug oil baffle structure for driving axle and driving axle

InactiveCN106274292AImprove the oil blocking effectImprove reliabilityAxle unitsEngineeringBreathing

Owner:BAIC GRP ORV CO LTD

Bicycle seat tube height adjusting mechanism

The invention provides a bicycle seat tube height adjusting mechanism. Mainly, oil way switches of the bicycle seat tube height adjusting mechanism are all located in a lifting adjusting unit, and valve ports of the oil way switches and an oil baffle are jointed in a vertical attachment mode for blockage. Thus, during maintenance, it is only needed to pull and replace the lifting adjusting unit, and the effects of being convenient to maintain and assemble are achieved. The valve ports and the oil baffle are in surface attachment in the vertical setting relationship, the oil baffle effect is good, at the moment a user sits on a seat cushion, the oil baffle does not bear shear force, and therefore the service life is prolonged.

Owner:TAIWAN HODAKA INDAL

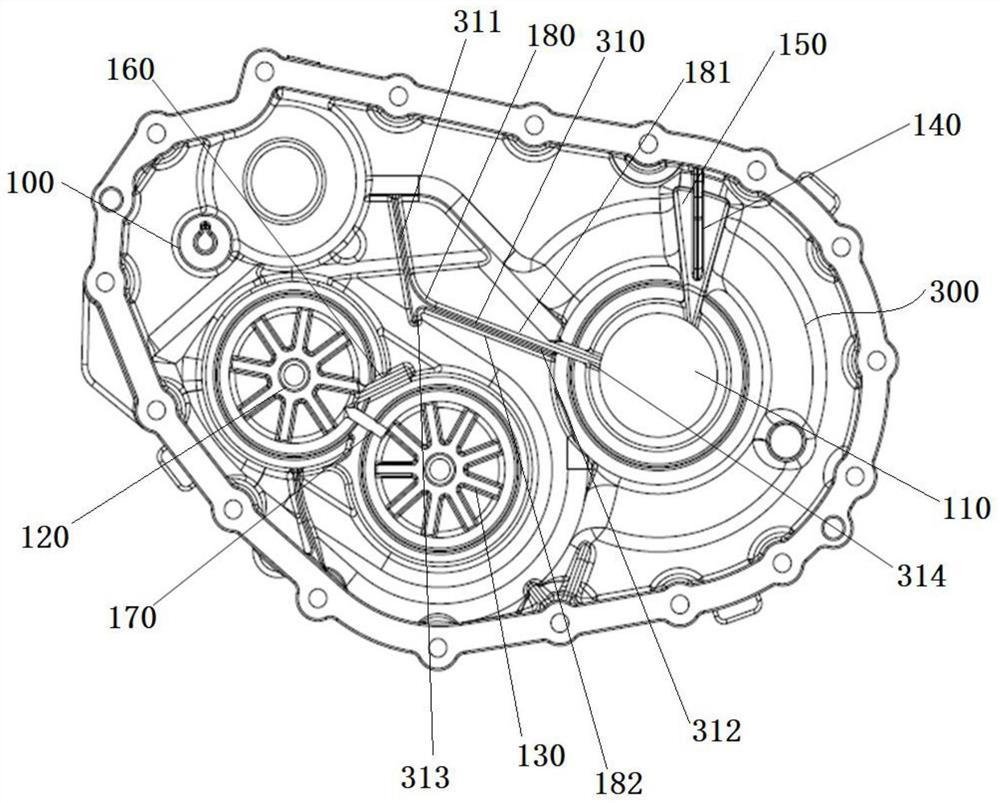

gear reducer

The invention discloses a gear reducer, which comprises a gear box and a reduction gear assembly arranged in the gear box; wherein the reduction gear assembly includes a pair of transmission shafts passing through the side wall of the gear box at intervals and sleeved on the transmission shaft respectively. There are several gears on the shaft; and on the side wall of the gear case, there is a matching hole that is rotatably matched with the transmission shaft; and an oil baffle is set on the transmission shaft; the oil baffle includes a large The eccentric wheel and the small eccentric wheel; the outer diameter of the large eccentric wheel is larger than the outer diameter of the small eccentric wheel; and the large eccentric wheel and the small eccentric wheel are provided with through holes that pass through but are not coaxial; and are respectively arranged on the large eccentric wheel and the small eccentric wheel The apertures of the through holes of the wheels are the same. The invention can effectively improve the transmission stability of the transmission shaft.

Owner:常州市天磊传动机械有限公司 +1

Heat dissipation fan with multiple oil return functions

PendingCN109488624AReduce throwRealize oil return functionPump componentsPump installationsReturn functionFan blade

The invention provides a heat dissipation fan with multiple oil return functions. The heat dissipation fan comprises a fixed seat, a fan blade and a stator, wherein a shaft sleeve is arranged in the center of the fixed seat, an inserting hole is formed in the center of the stator, the shaft sleeve is inserted into the inserting hole to enable the stator to sleeve outside the shaft sleeve, and therotating shaft of the fan blade is installed in the shaft sleeve through a bearing; the inner wall of the inserting hole is connected with an oil baffle ring, and the oil baffle ring is positioned above the shaft sleeve and sleeves outside the rotating shaft; and a plurality of oil return top grooves are formed in the top surface of the bearing, a plurality of oil return side grooves are formed inthe side face, the inner ends of the oil return top grooves communicate with bearing holes of the bearings, and the outer ends of the oil return top grooves communicate with the upper ends of the oilreturn side grooves. According to the heat dissipation fan, the oil baffle ring can block most lubricating oil thrown out from the opening of the shaft sleeve, the blocked lubricating oil falls backto the surface of the bearing and reenters the gap between the bearing and the rotating shaft sequentially along the bottom gaps among the oil return top grooves, the oil return side grooves, the bearing and the shaft sleeve, so that the oil return function is realized, and the lubricating oil is reduced from being thrown out.

Owner:SHENZHEN GAO YU ELECTRONIC TECHNOLOGY CO LTD

Internal oil blocking structure of compressor and compressor with the oil blocking structure

ActiveCN106401966BReduce outflowImprove the oil blocking effectRotary/oscillating piston pump componentsLiquid fuel engine componentsBlock effectBlock structure

Owner:GREE ELECTRIC APPLIANCES INC +1

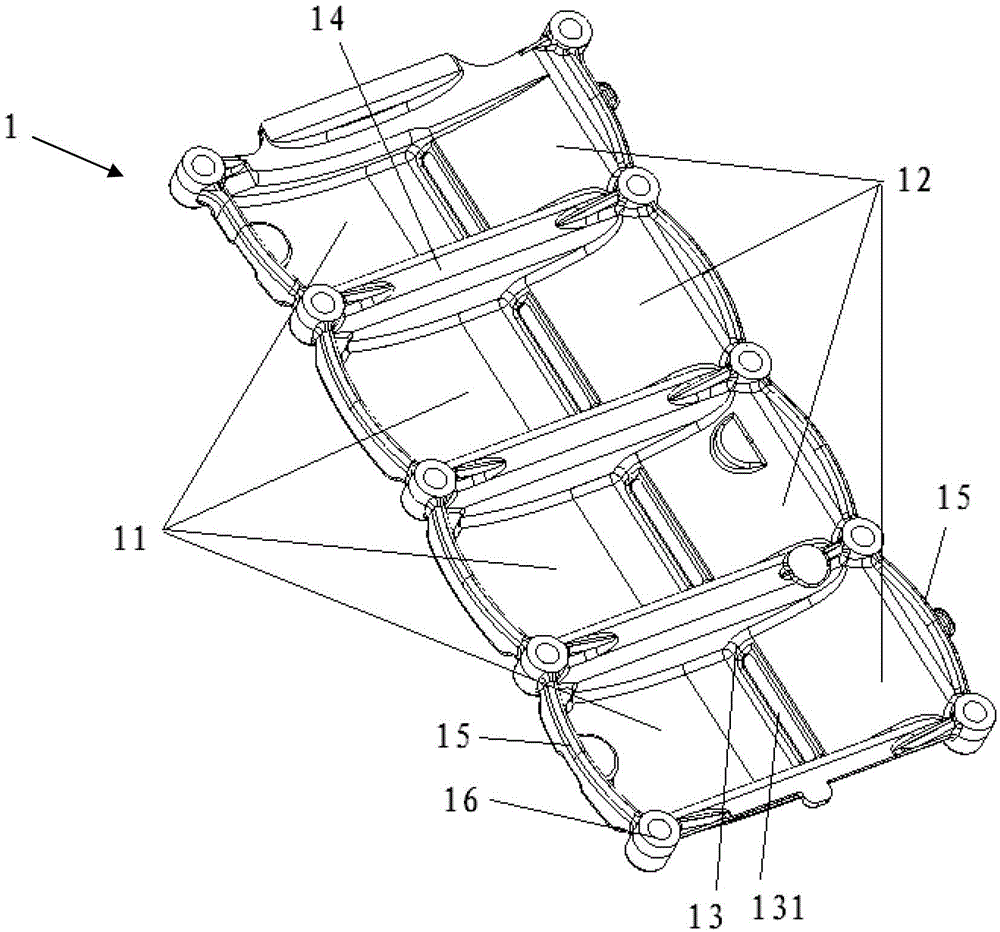

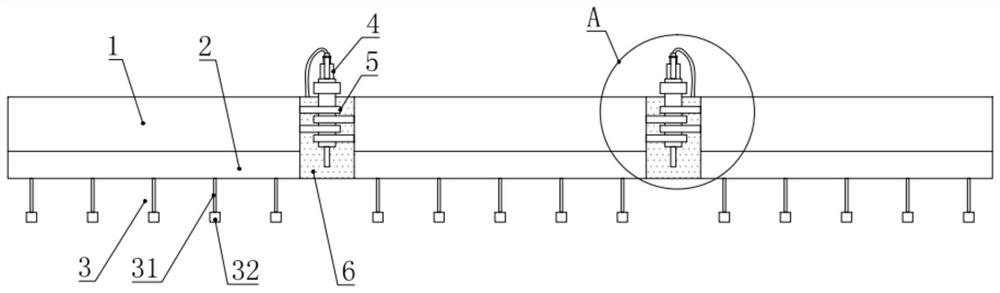

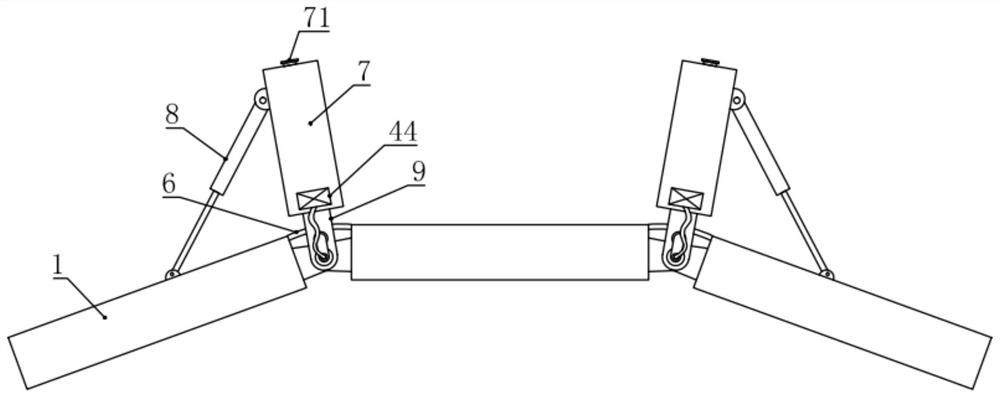

An oil boom facility with crude oil recovery function

InactiveCN111979992BGood oil containment effectImprove the oil blocking effectWater cleaningGeneral water supply conservationBuoyOil pump

The invention relates to the technical field of environmental protection, in particular to an oil containment boom facility with crude oil recovery function, comprising three buoys, the three buoys are sequentially connected by hinge components, and two adjacent buoys are also connected There is an elastic plate, and the rear side between two adjacent buoys is also provided with an oil storage buoy, and the oil storage buoy is also connected and fixed with the hinge assembly through the fixing plate, and the oil storage buoy is also installed on the oil storage buoy. The oil pumping device for crude oil extraction between two adjacent buoys, the rear side of the two buoys at both ends is also hinged with a second telescopic cylinder, and the other end of the second telescopic cylinder is hinged to the oil storage buoy the side of the buoy; the underside of the buoy is also equipped with an oil baffle, and the underside of the oil baffle is equipped with a number of counterweight assemblies. The invention has good stability, is convenient to use and adjust, has better crude oil recovery function, and is beneficial to popularization and application.

Owner:郭雅心

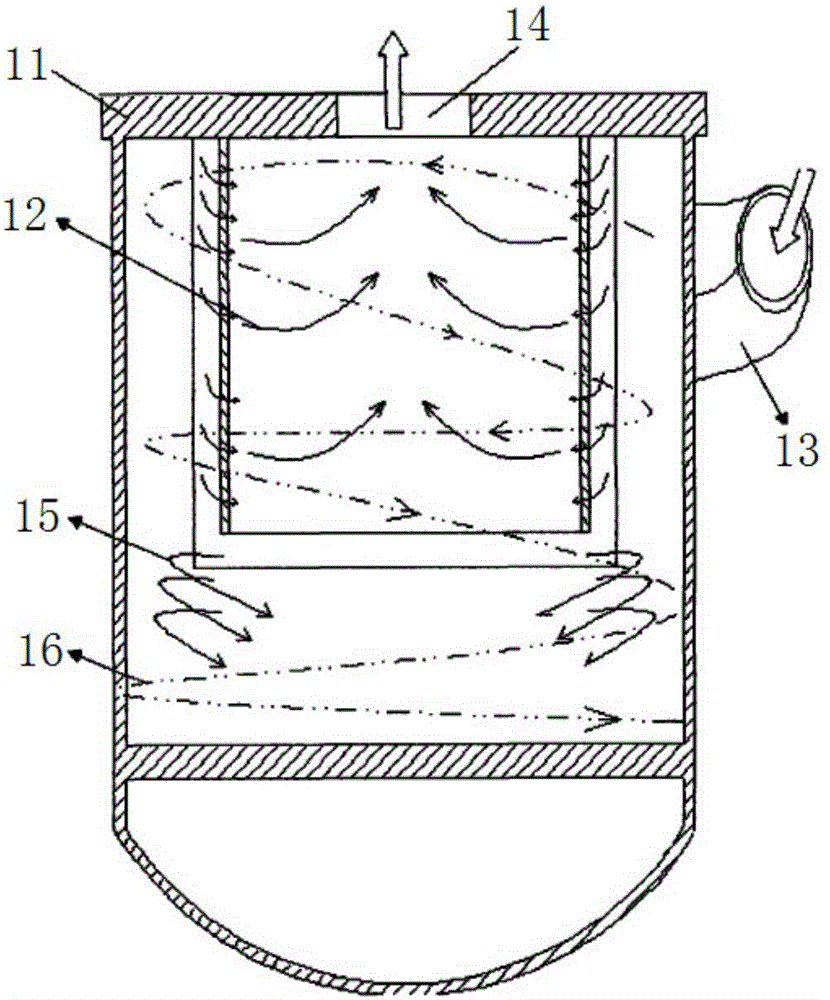

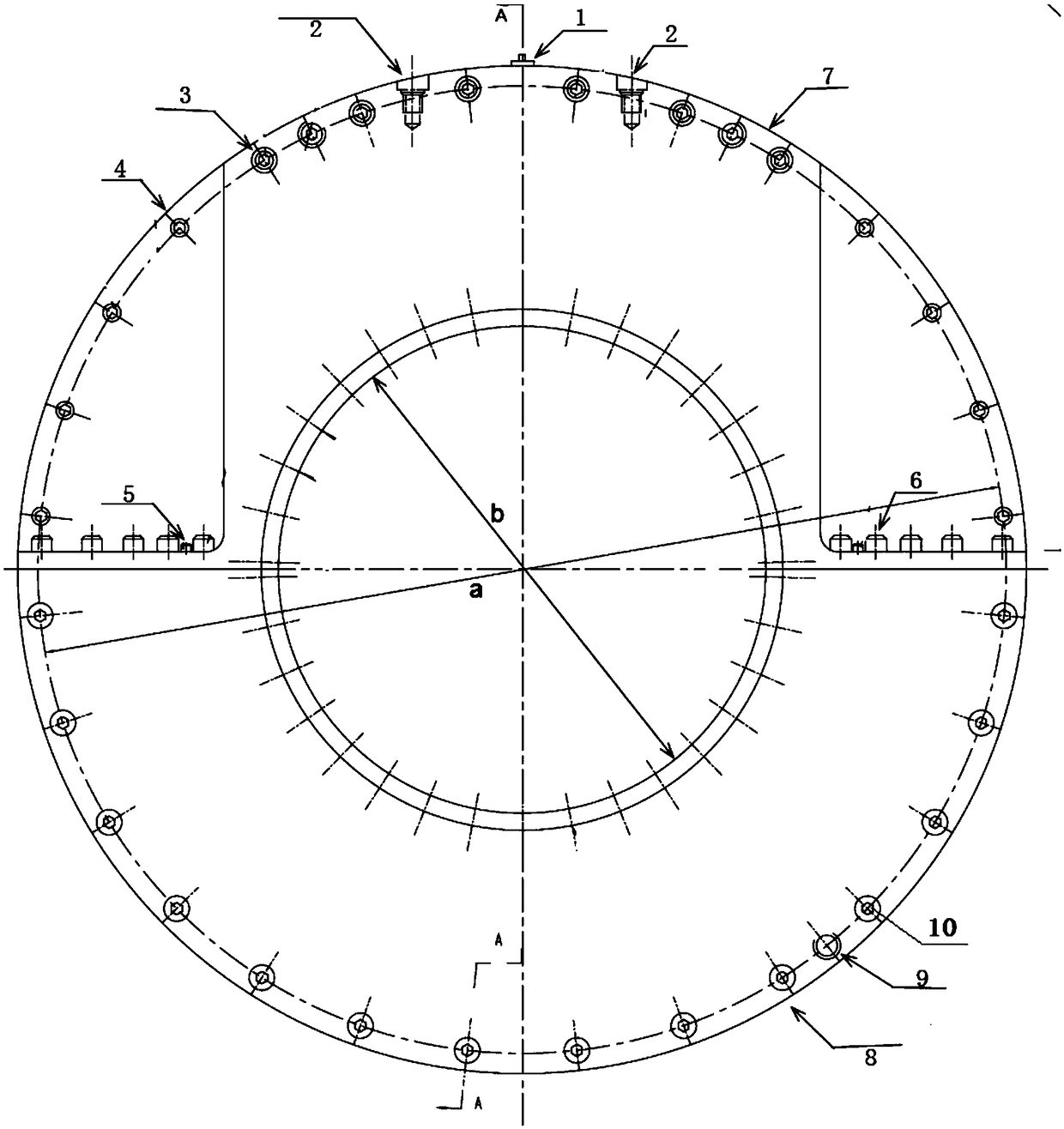

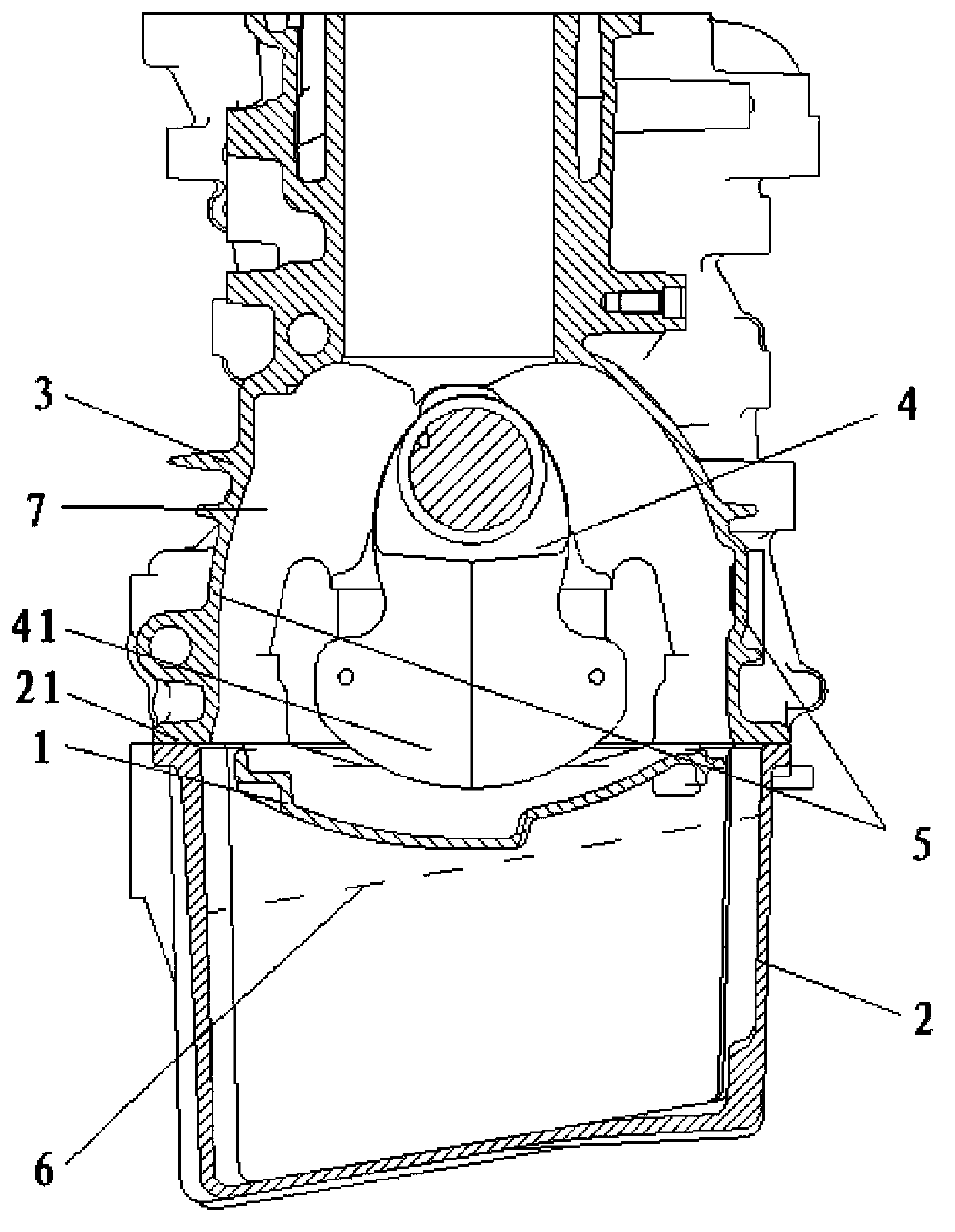

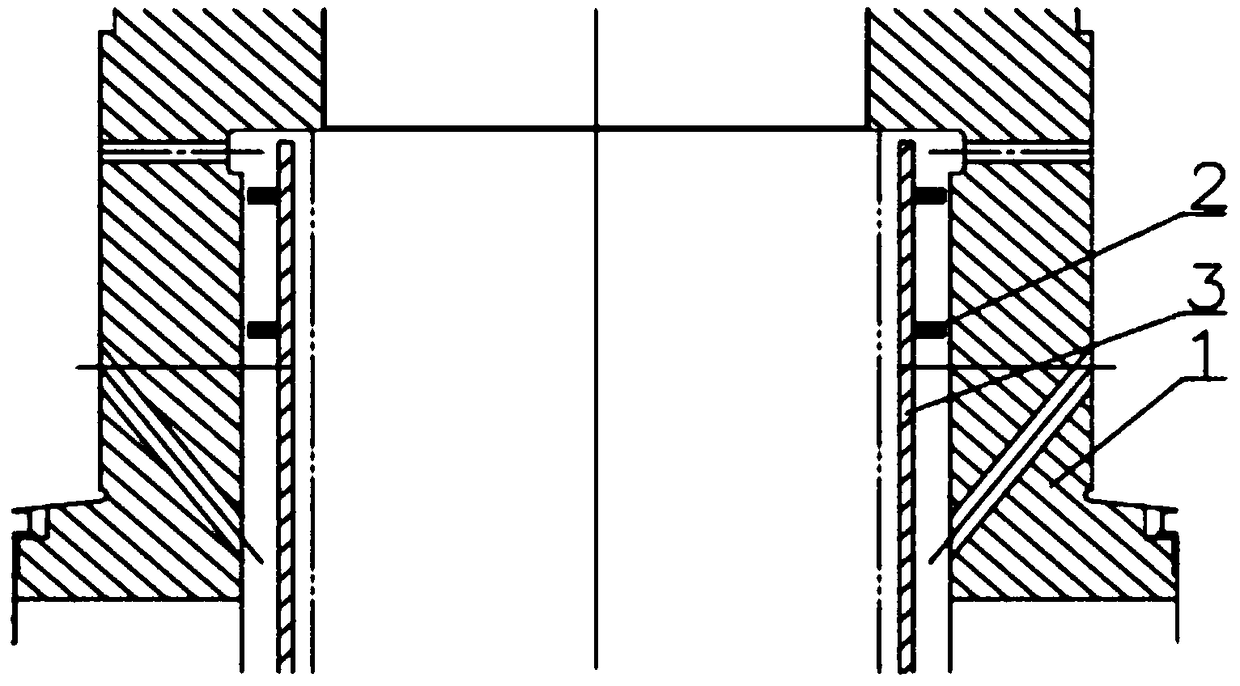

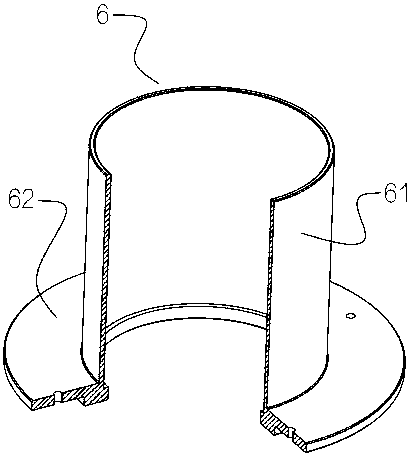

A new type of plate pump type oil retaining cylinder oil retaining structure for vertical hydro-generator

ActiveCN105317617BStop the leakSolve the oil spill problemHydro energy generationMachines/enginesBlock structureThrust block

The invention discloses a novel plate pump type oil blocking barrel oil blocking structure of a vertical hydraulic generator. The oil blocking structure comprises a thrust block, a ring, an oil blocking barrel and an upper rack, and is characterized in that the oil blocking barrel is arranged on the upper rack, and the oil blocking barrel and the upper rack are mutually and fixedly welded; the ring is arranged on one side of the oil blocking barrel, the ring and the oil blocking barrel are mutually and fixedly welded, and the ring is flush with a pilot bearing bush central line; a circle of holes are evenly formed in the thrust block at the height of a guide shoe central line. According to the novel plate pump type oil blocking barrel oil blocking structure, the circle of holes are formed in the thrust block at the height of the guide shoe central line, the thrust block plays a role of a pump when rotating, and with blocking of the ring, oil can difficultly climb; even if a little oil climbs, the upper oil blocking barrel plays the role of double-layer oil blocking pipes, and leakage of the oil is completely prevented; the oil leakage problem of bearings of the upper rack of the vertical hydraulic generator is solved, and the oil blocking structure has the advantages of being good in oil blocking effect, simple, and easy to machine.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Oil stopping mechanism of turbine guide bearing

InactiveCN105065175APrevent leakageReduce leakageHydro energy generationMachines/enginesEngineeringShaft collar

The invention belongs to the technical field of bearing parts, and particularly relates to an oil stopping mechanism of a turbine guide bearing. The oil stopping mechanism of the turbine guide bearing comprises a cylindrical body which is arranged at a main shaft provided with a shaft collar and located in an annular space formed between the main shaft and the shaft collar, the main shaft is fixed on a main shaft seat, the bearing arranged on the shaft collar in a sleeving mode is arranged between the main shaft and the main shaft seat, and the bearing is rotatably connected with the main shaft. The oil stopping mechanism of the turbine guide bearing is characterized in that the body is provided with a pressure forming structure which can form positive pressure to prevent lubricating oil from running off when the main shaft is rotated. The oil stopping mechanism of the turbine guide bearing has the advantages that the pressure forming structure can form the positive pressure on the main shaft, therefore, the lubricating oil is prevented from leaking, the oil stopping effect is good, the overall design is reasonable, and the structure is simple; the lubricating oil can be contained in a spiral groove in the rotating process of the main shaft, therefore, the lubricating oil leakage is reduced, and the oil stopping effect is good; the oil stopping mechanism is beneficial for the lubricating oil to be evenly distributed on the surface of the main shaft, and lubricating is facilitated.

Owner:ZHEJIANG ZHENGSHENG BEARING

Upper input and lower output type speed reduction gear box

InactiveCN108180257AReasonable layoutReduce in quantityToothed gearingsGear lubrication/coolingThree stageEngineering

The invention relates to the technical field of drive devices, and discloses an upper input and lower output type speed reduction gear box. The upper input and lower output type speed reduction gear box comprises a box body, wherein the box body forms a three-stage gear speed reduction mechanism through a first-grade rotating shaft, a second-grade rotating shaft, a third-grade rotating shaft, a fourth-grade rotating shaft and gears on the shafts; a three-grade gearwheel is arranged on the fourth-grade rotating shaft; an oil baffle cover, comprising cylindrical sidewalls of which two ends are opened, is fixedly connected into the box body; the cylindrical sidewalls sleeve the outside of the fourth-grade rotating shaft; lower end ports of the cylindrical sidewalls are in sealing connectionwith the inner surface of the lower wall of the box body; a first circular ring slot is formed in the lower end of the third-grade gearwheel; upper end ports of the cylindrical sidewalls extend into the first circular ring slot. According to the upper input and lower output type speed reduction gear box, an oil baffle disc in the prior art is replaced by the improved oil baffle cover; the gear arraignment mode in the scheme enables good oil baffle effect; a bearing at the lower part of the fourth-grade rotating shaft can be lubricated through semi-solid lubricating grease, and thus the risk that liquid lubricating oil leaks from the box body is avoided.

Owner:张萍

Gear reducer

The invention discloses a gear reducer which comprises a gear box body and a reduction gear assembly arranged in the gear box body, wherein the reduction gear assembly comprises a pair of transmission shafts penetrating through the side wall of the gear box body at intervals and a plurality of gears arranged on the transmission shafts in a sleeving mode, wherein a matching hole which is in running fit with the transmission shafts is formed in the side wall of the gear box body; an oil baffle plate is sleeved on the transmission shaft; the oil baffle plate comprises a large eccentric wheel and a small eccentric wheel which are matched and fixed; the outer diameter of the large eccentric wheel is larger than that of the small eccentric wheel; the large eccentric wheel and the small eccentric wheel are provided with through holes which are communicated but not coaxial; and the through holes respectively formed in the large eccentric wheel and the small eccentric wheel have the same aperture. The transmission stability of the transmission shaft can be effectively improved.

Owner:常州市天磊传动机械有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com