compressor

A compressor and rotor iron core technology, applied in the field of compressors, can solve the problems of reducing compressors and large power consumption of compressors, and achieve the effects of preventing discharge, reducing oil discharge rate, and increasing stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

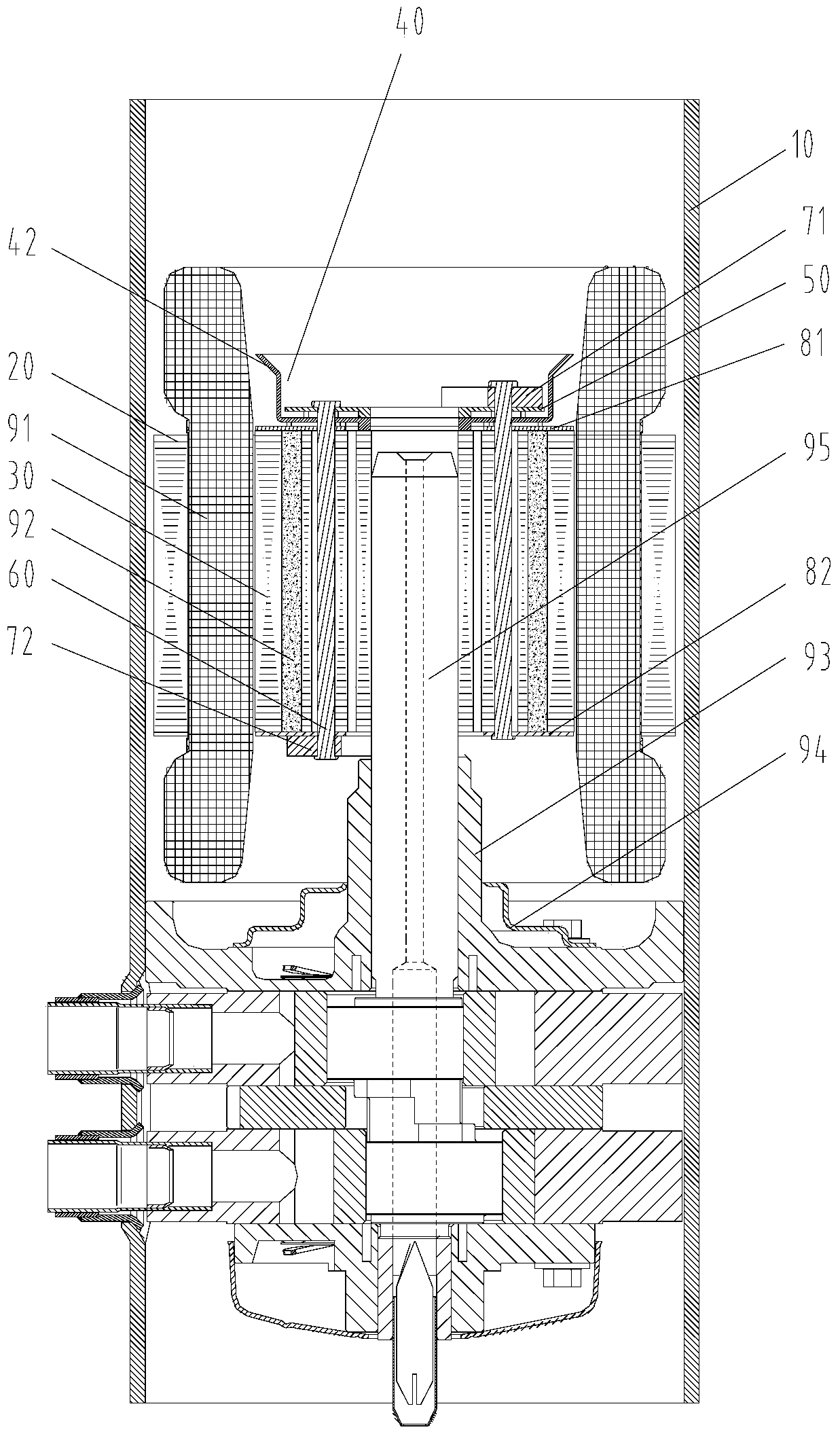

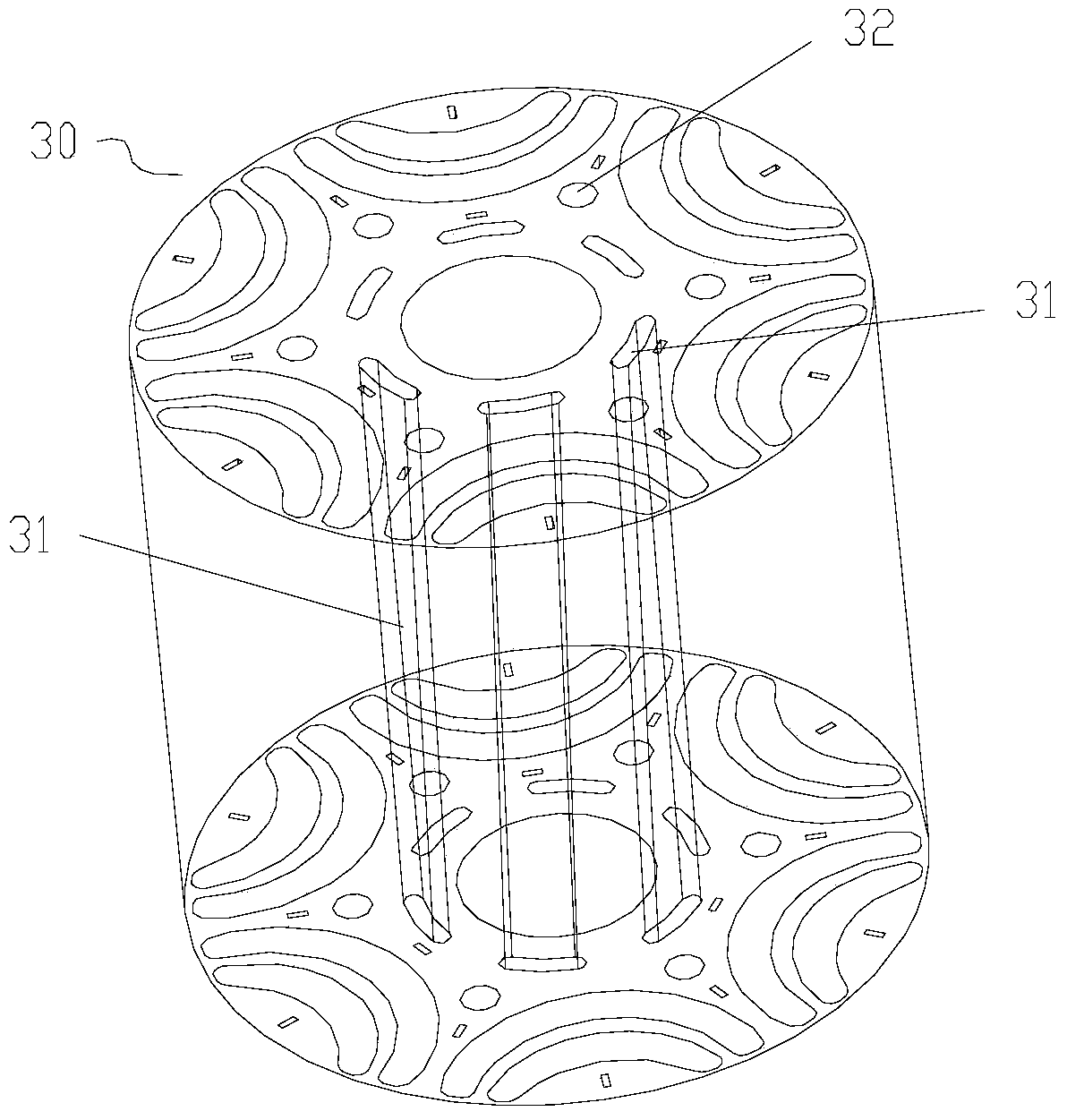

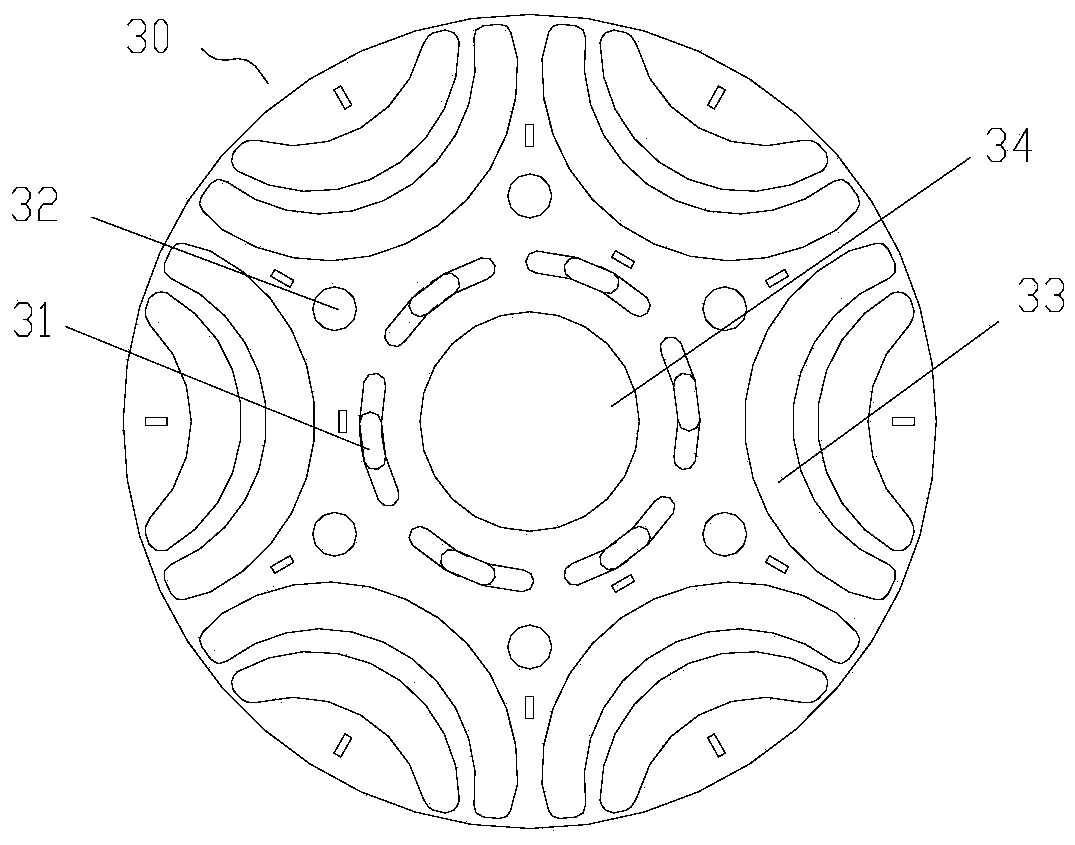

[0031] The present invention provides a compressor, please refer to Figure 1 to Figure 5 , the compressor includes a housing 10 and a stator core 20 and a rotor core 30 arranged in the housing 10, and the stator core 20 is arranged around the rotor core 30, and the rotor core 30 is provided with The compressor also includes: a first baffle plate 40, the first baffle plate 40 includes a bottom plate portion 41 and an oil baffle side edge 42 arranged on the upper side of the bottom plate portion 41, the first baffle plate 40 and the rotor core 30 The upper end surfaces of the upper faces are oppositely arranged so that the refrigerant flowing out from the circulation hole 31 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com