A pump body muffler, pump body assembly and compressor

A technology of a silencer and a pump body, applied in the field of compressors, can solve the problems of difficulty in dealing with gas pulsation, wide operating range, widening of gas pulsation and excitation range, etc., to reduce the oil discharge rate, expand the application range, and ensure good lubrication. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention by those skilled in the art, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

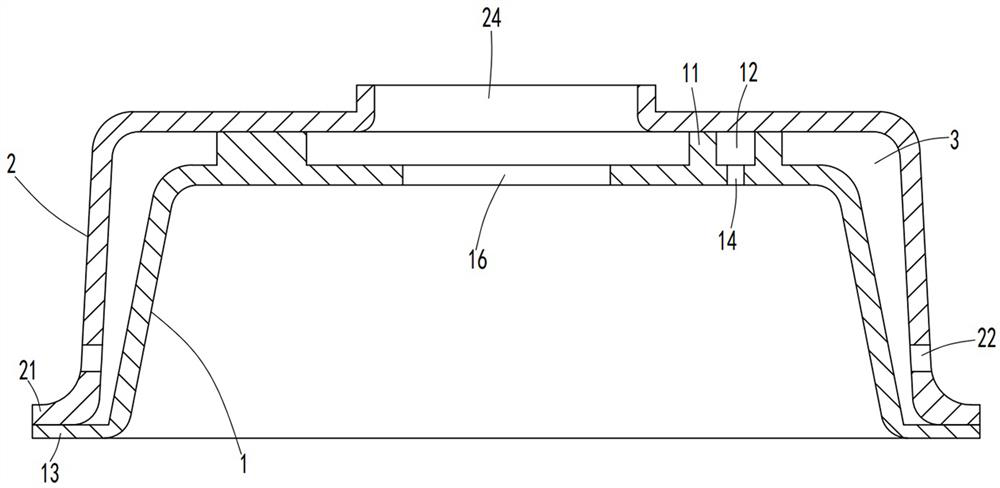

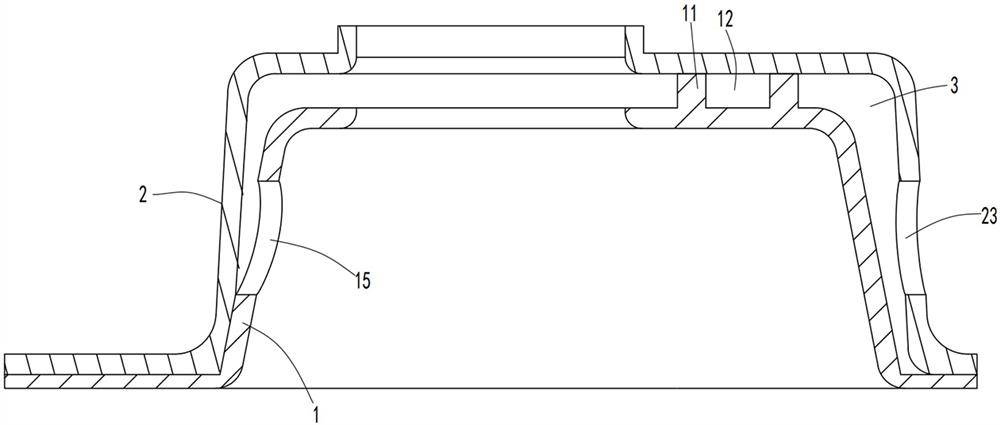

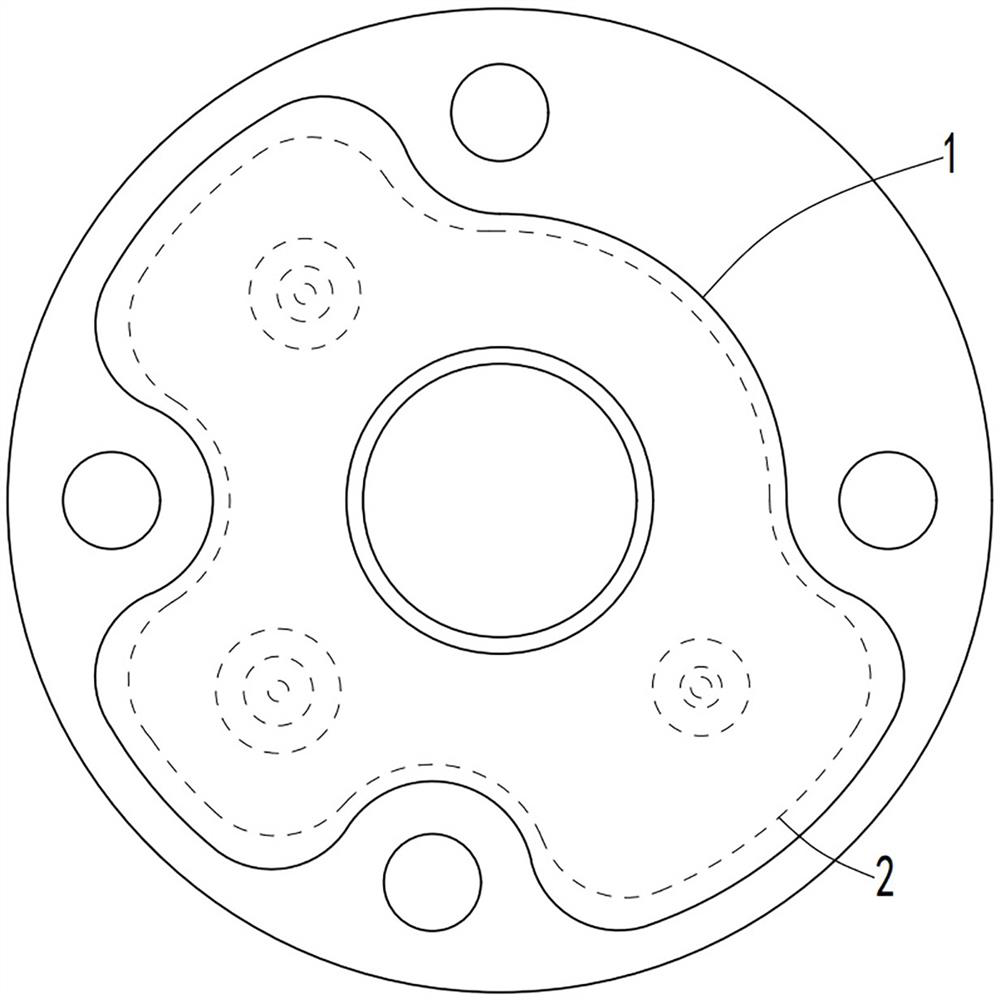

[0025] refer to Figure 1 to Figure 5 , a pump body muffler provided by the present invention is connected with the crankshaft 4 of the pump body assembly of the compressor. The outer muffler cover 2 on the muffler has a space between the inner muffler cover 1 and the outer muffler cover 2, and the space between the inner muffler cover 1 and the outer muffler cover 2 is The gas-liquid separation chamber 3 is formed at intervals, and in this embodiment, the gas-liquid separation chamber 3 is of a structure with a large upper part and a small lower part. A plurality of hollow inner-layer resonators 11 are provided on the side of the top surface of the inner-layer muffler cover 1 facing the outer-layer muffler cover 2 , and the ends of the inner-lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com