Patents

Literature

33results about How to "Reduce oil discharge rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air conditioner low-temperature heating starting control method, storage medium and air conditioner

ActiveCN113203178AReduce oil discharge rateImprove operational reliabilityMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsFour-way valve

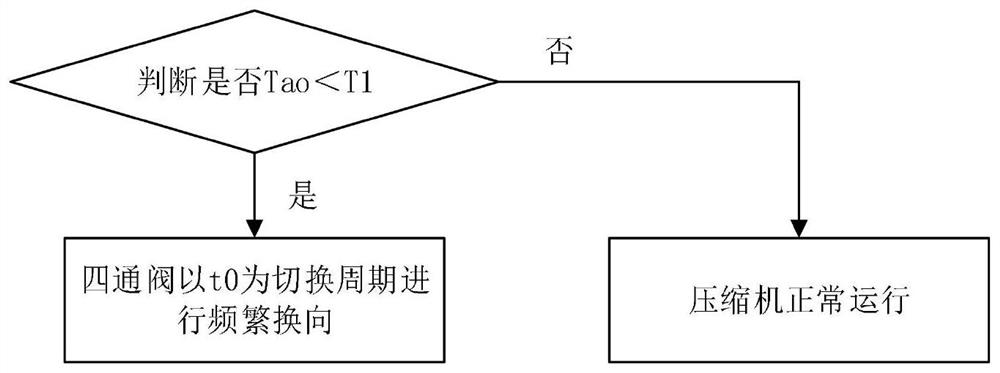

The invention provides an air conditioner low-temperature heating starting control method, an air conditioner and a storage medium. The air conditioner low-temperature heating starting control method comprises the steps that whether the outdoor environment temperature Tao is smaller than a first preset temperature T1 or not is obtained and judged; and if yes, a four-way valve of the air conditioner is controlled to conduct frequent switching with the preset duration t0 as a switching period. By frequently switching the four-way valve, a high-temperature and high-pressure gaseous refrigerant returns to a low-pressure side to enter a compressor, so that the temperature of the compressor is quickly increased; and meanwhile, lubricating oil mixed in the refrigerant quickly returns to the compressor, the oil discharge rate is reduced, and the operation reliability of the compressor is improved.

Owner:NINGBO AUX ELECTRIC +1

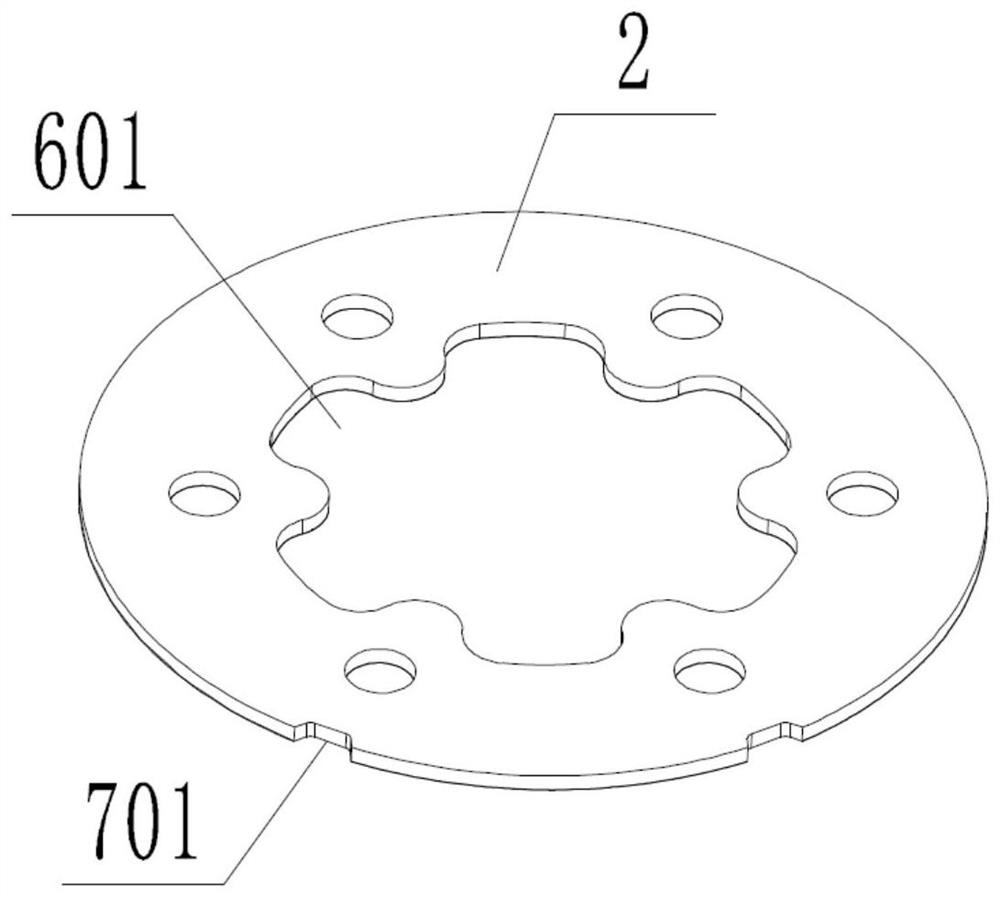

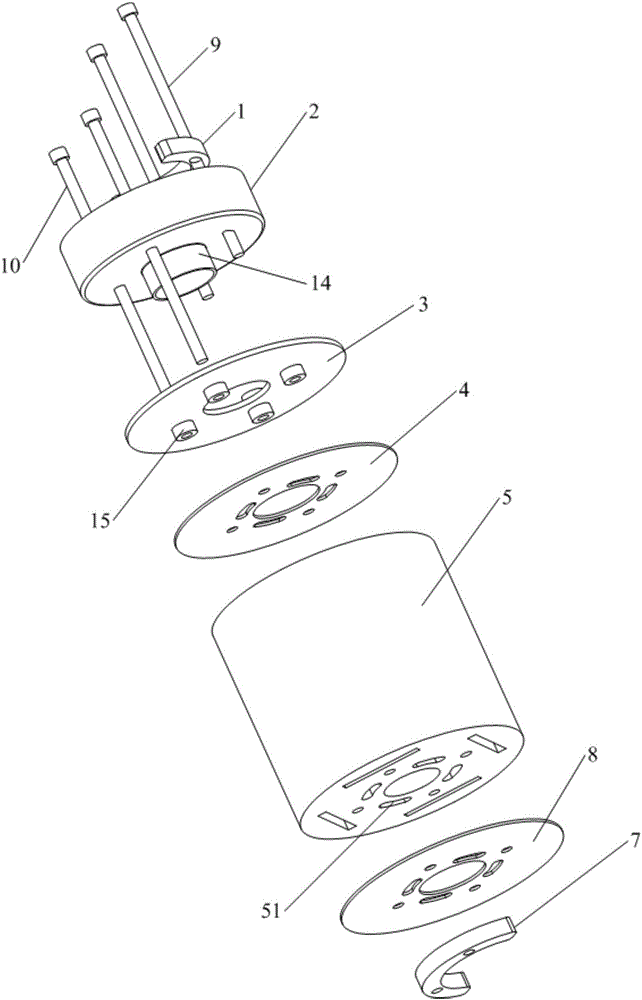

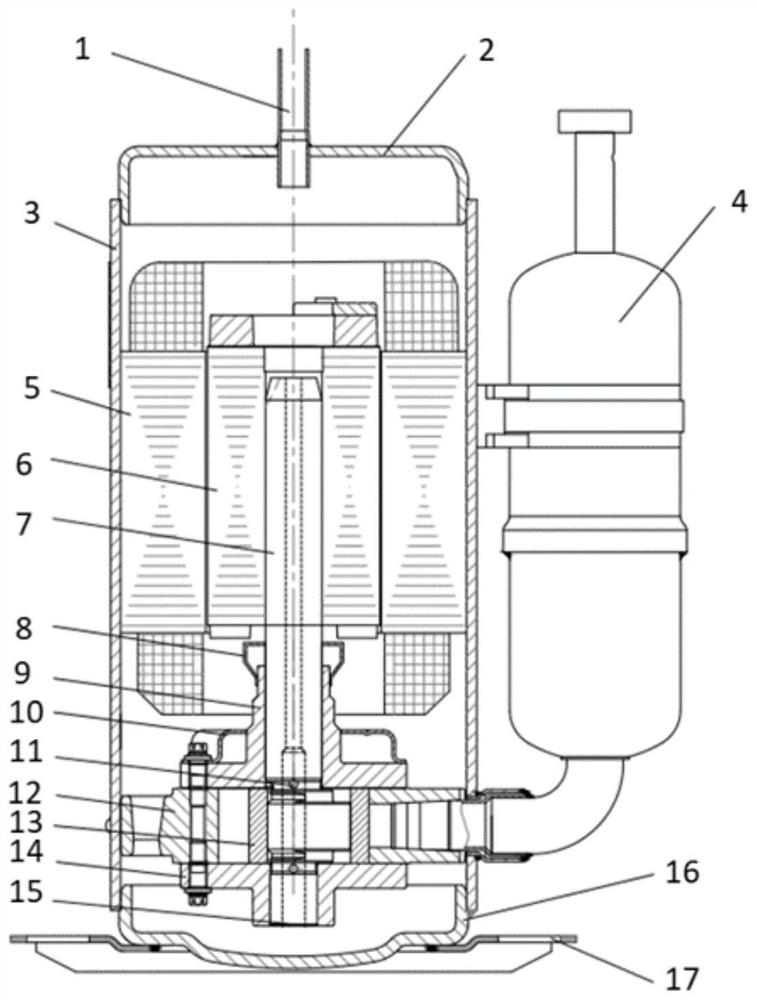

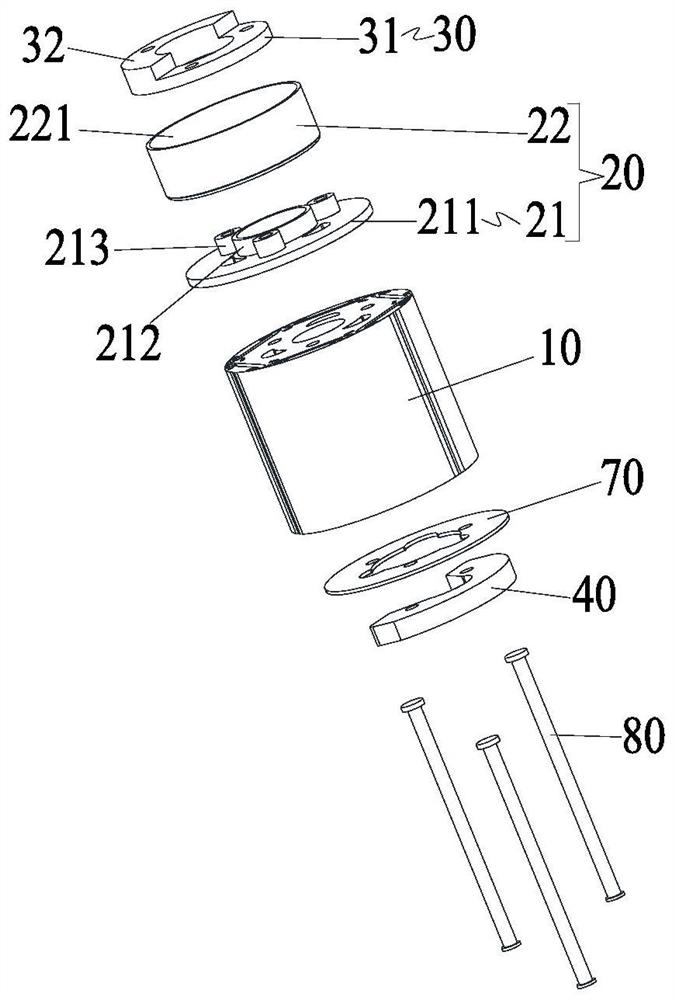

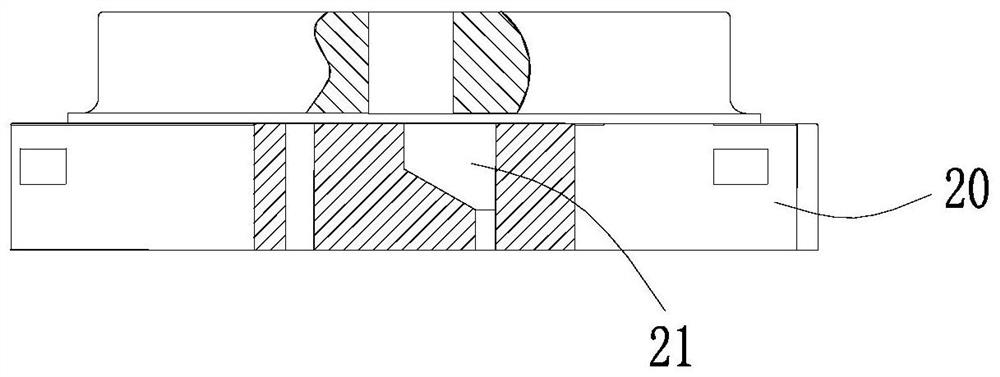

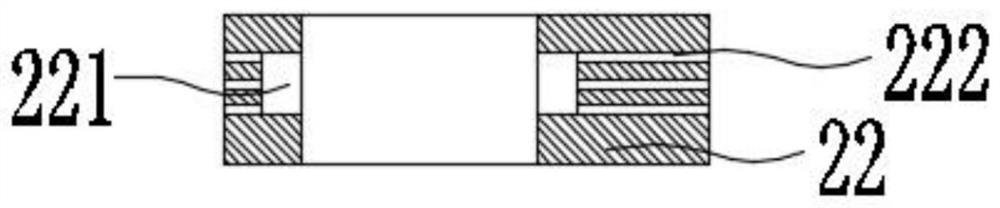

Rotor assembly, compressor and air conditioner

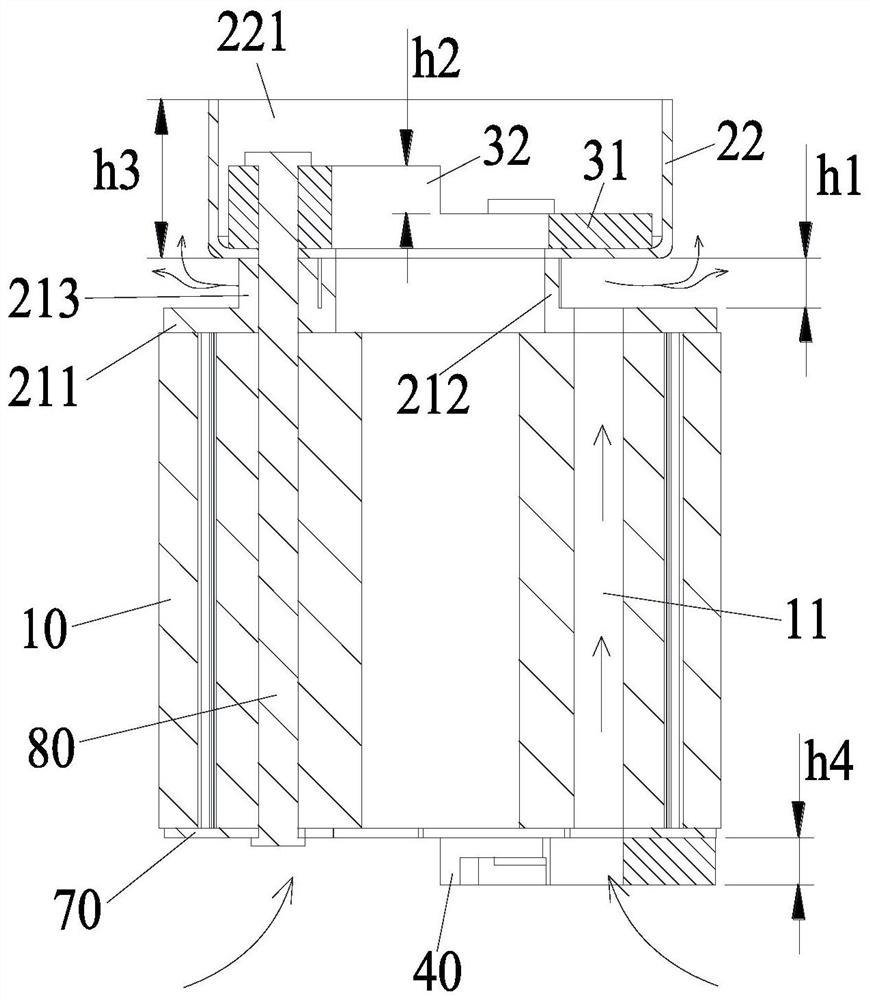

PendingCN112360743AIncreased edge return flowQuality improvementRotary/oscillating piston combinations for elastic fluidsMechanical energy handlingElectric machineryOil separation

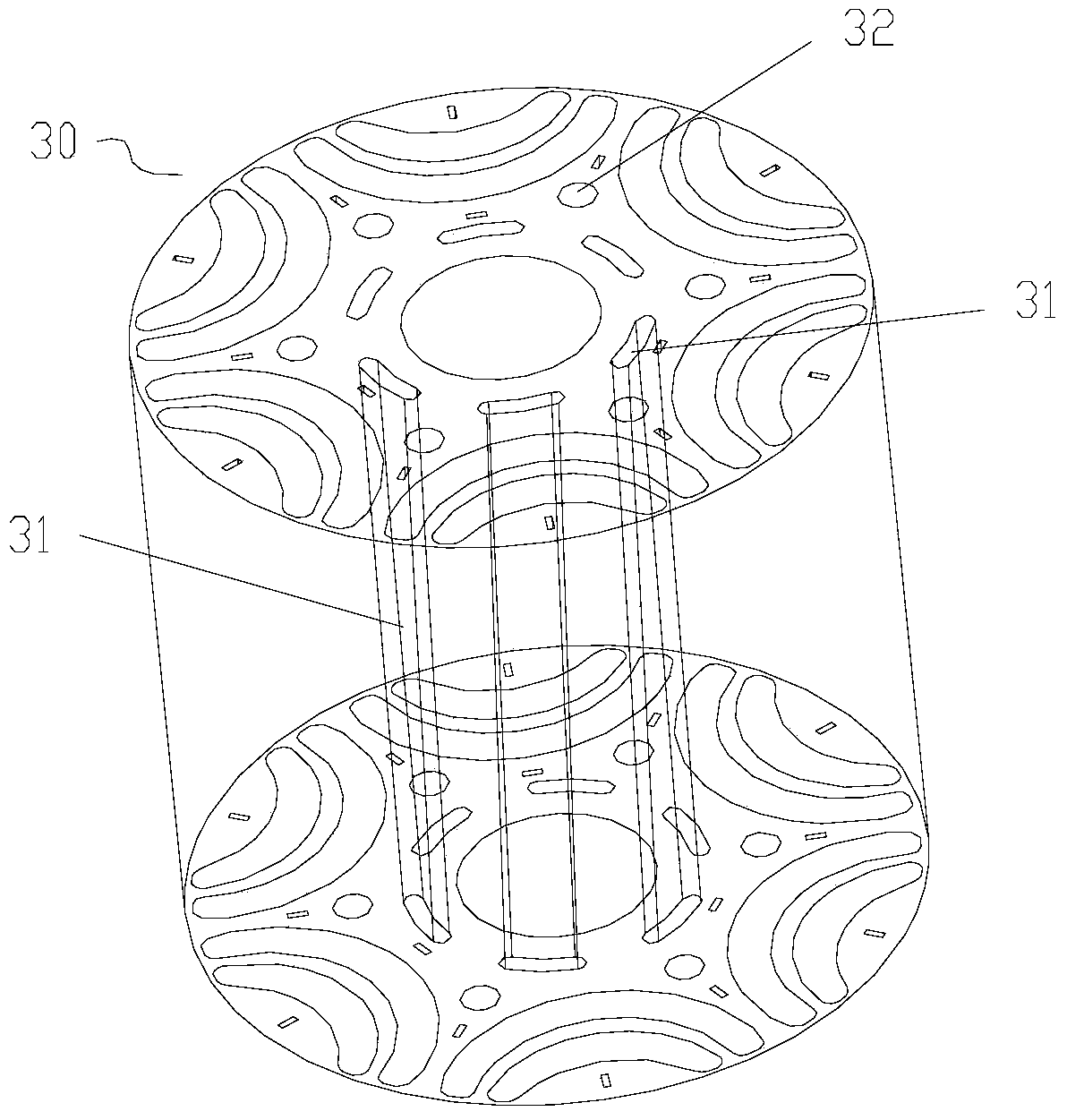

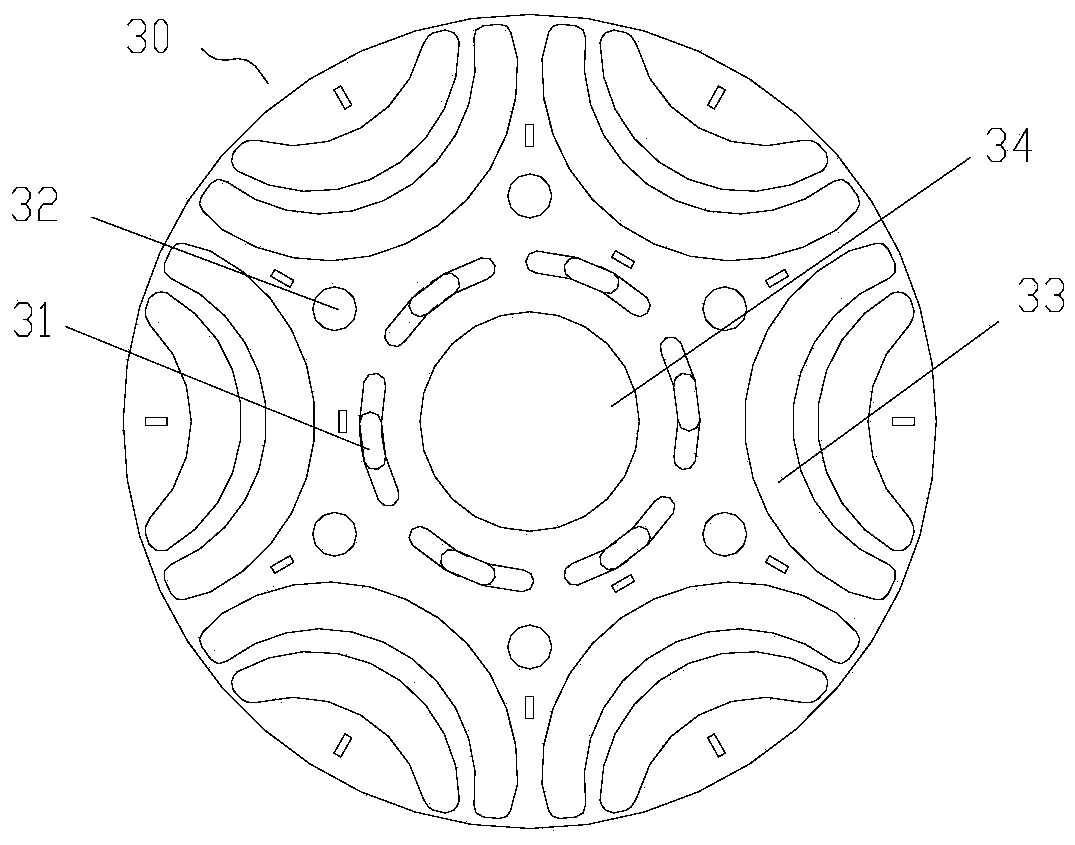

The invention relates to the technical field of gas compression devices, in particular to a rotor assembly, a compressor and an air conditioner. A plurality of main circulation channels are evenly formed in a first magnetic baffle, a rotor iron core and a second magnetic baffle of the rotor assembly around the central axis, auxiliary circulation channels which are through in the axial direction are formed in the first magnetic baffle, the rotor iron core and the second magnetic baffle, a main balance block is located on one side of the central axis, and auxiliary circulation channels are located on the other side of the central axis. The auxiliary circulation channels improve a balance system, the height of the main balance block in the axial direction can be reduced, then the windward area of the main balance block is reduced, the clapping effect on exhaust gas flow is weakened, tiny liquid drops are reduced, and then the amount of oil entering an upper cavity of a motor along with flowing of a refrigerant is reduced. The auxiliary circulation channels increase the flow flowing through the circulation channels, improves the internal circulation of the compressor, increases the stator trimming return flow, and realizes secondary oil separation. The effects of two oil separation are integrated, and the oil spitting rate of the compressor is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

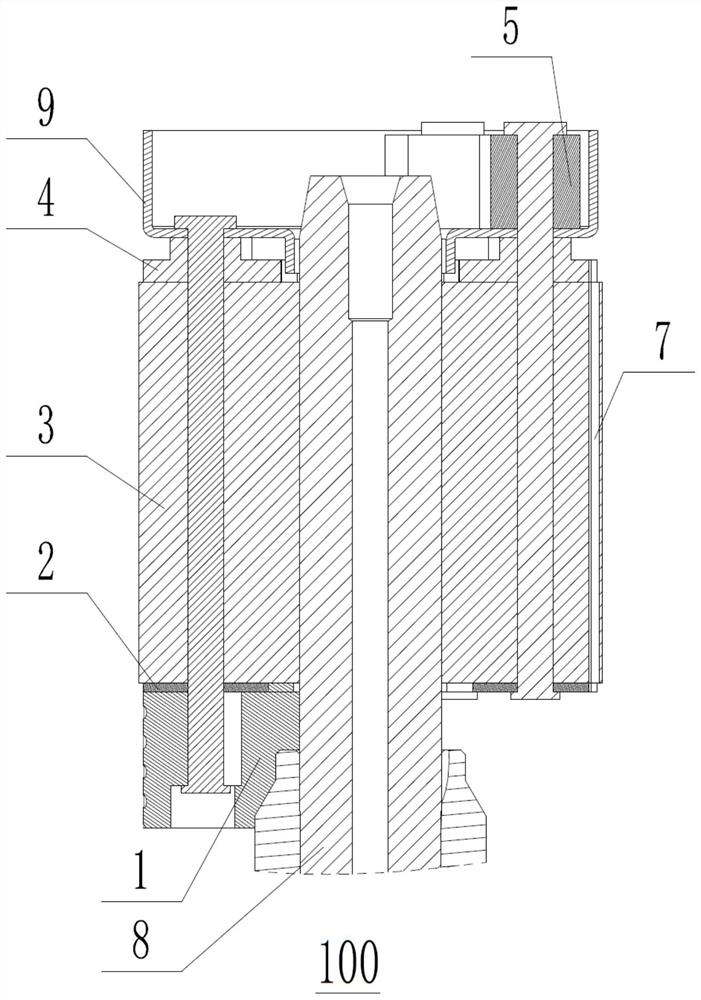

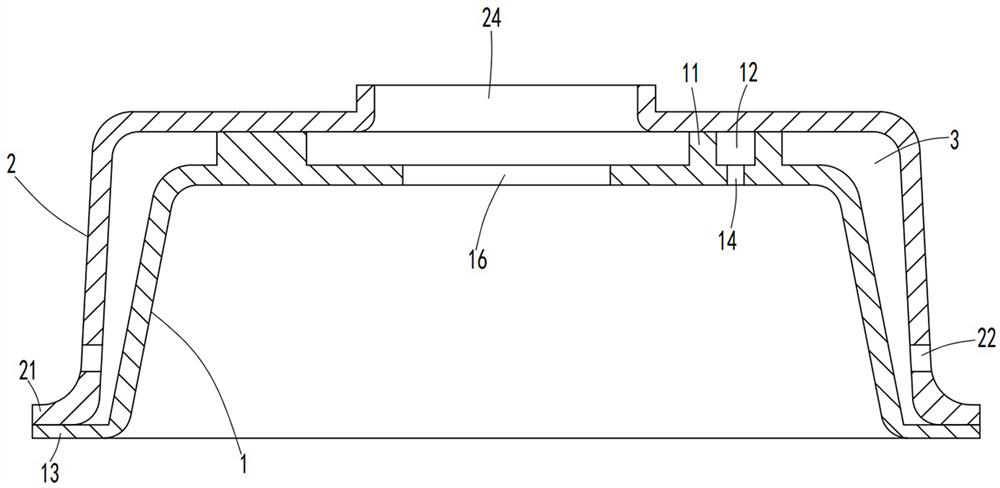

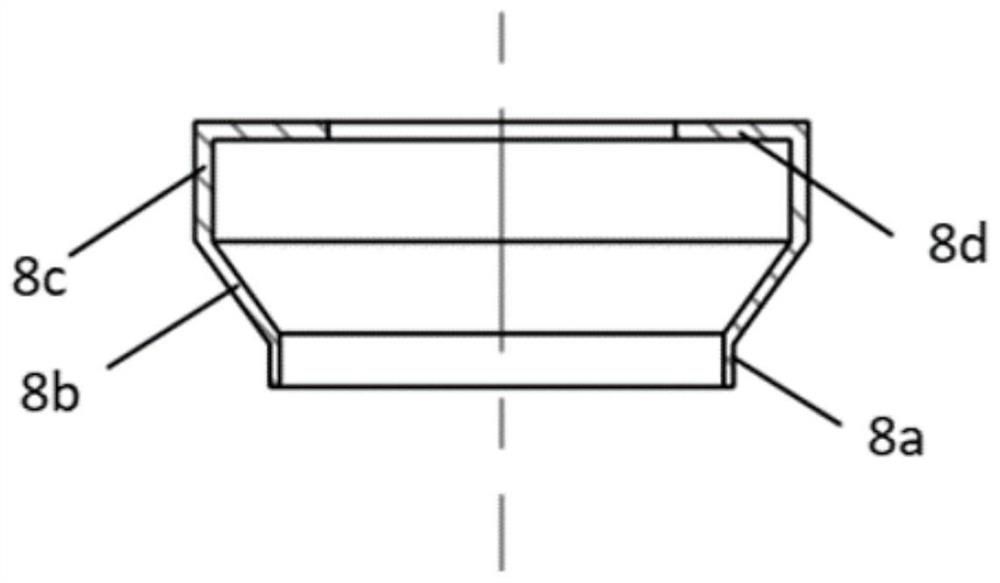

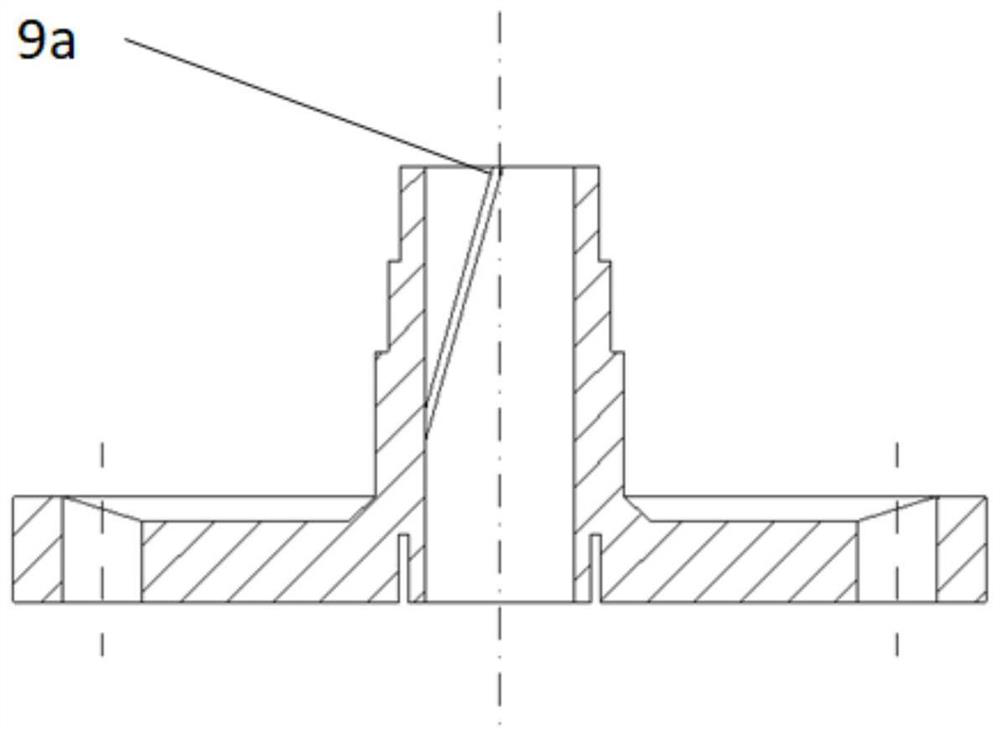

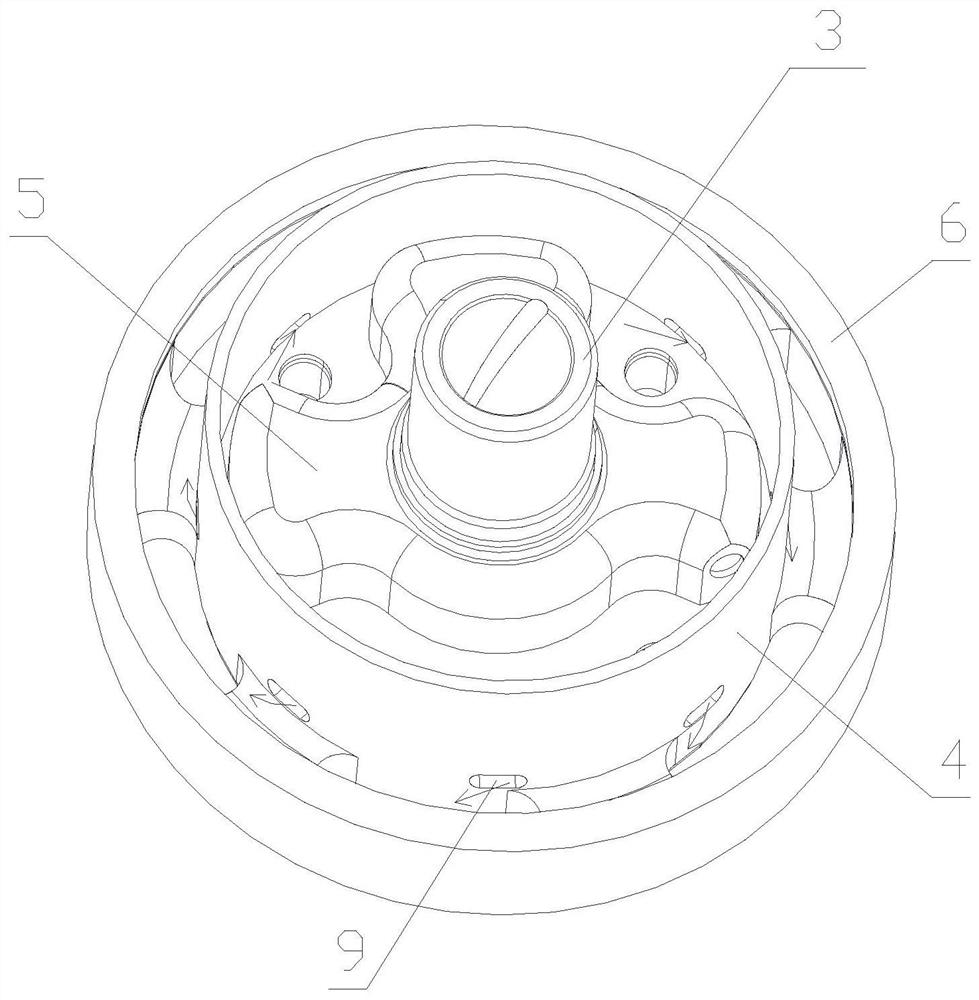

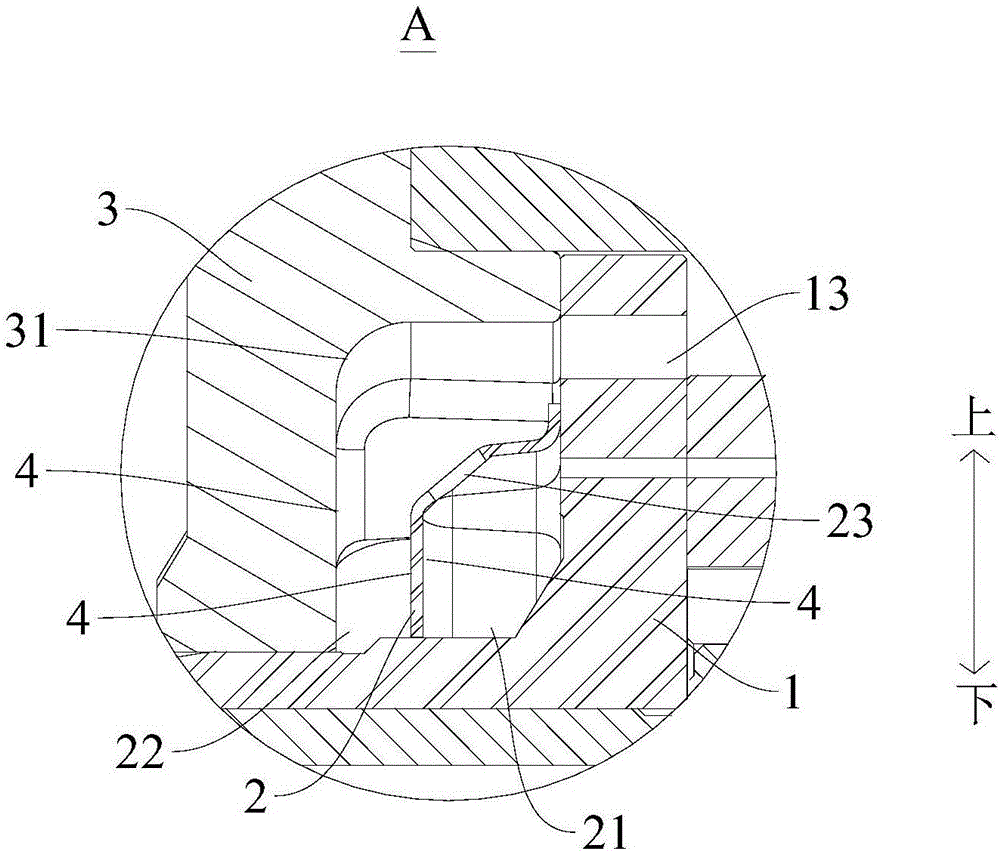

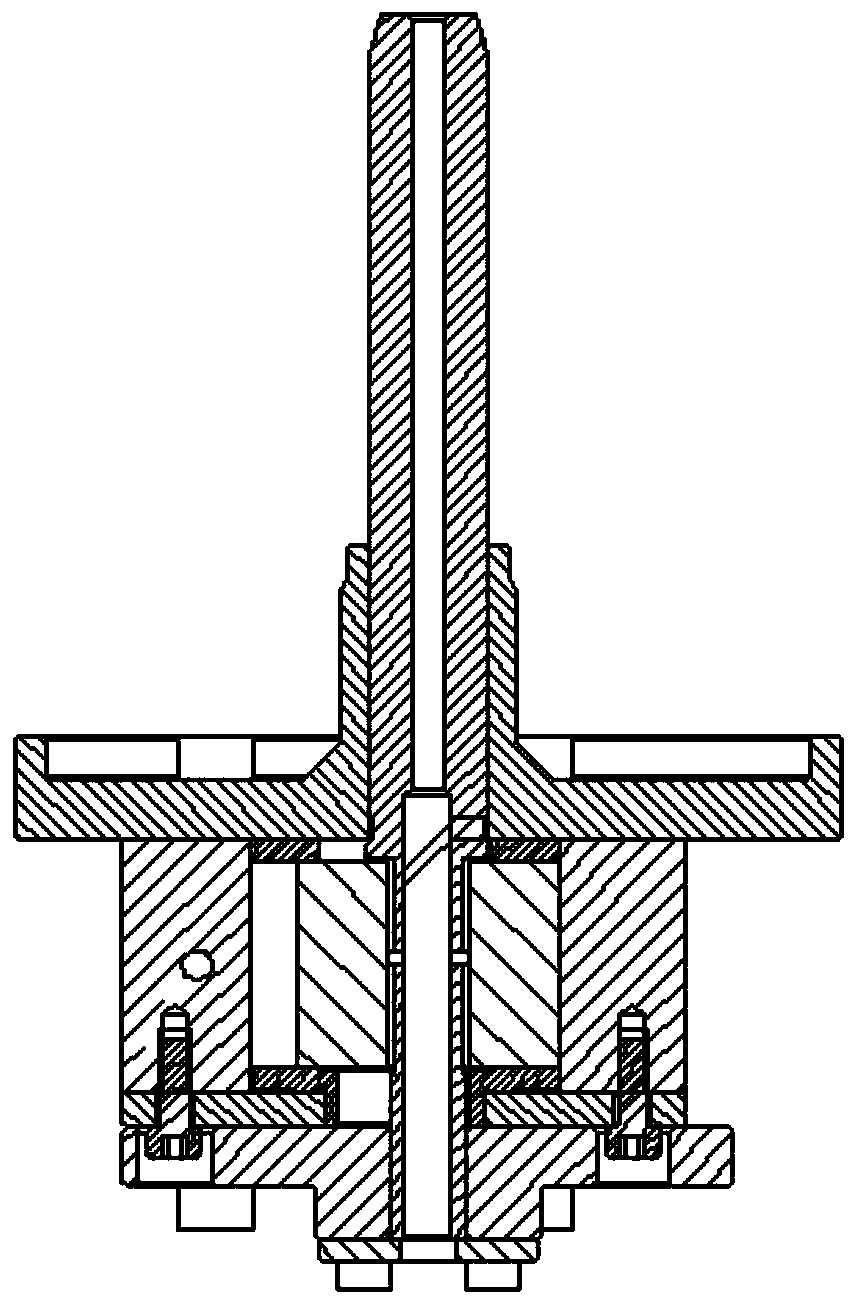

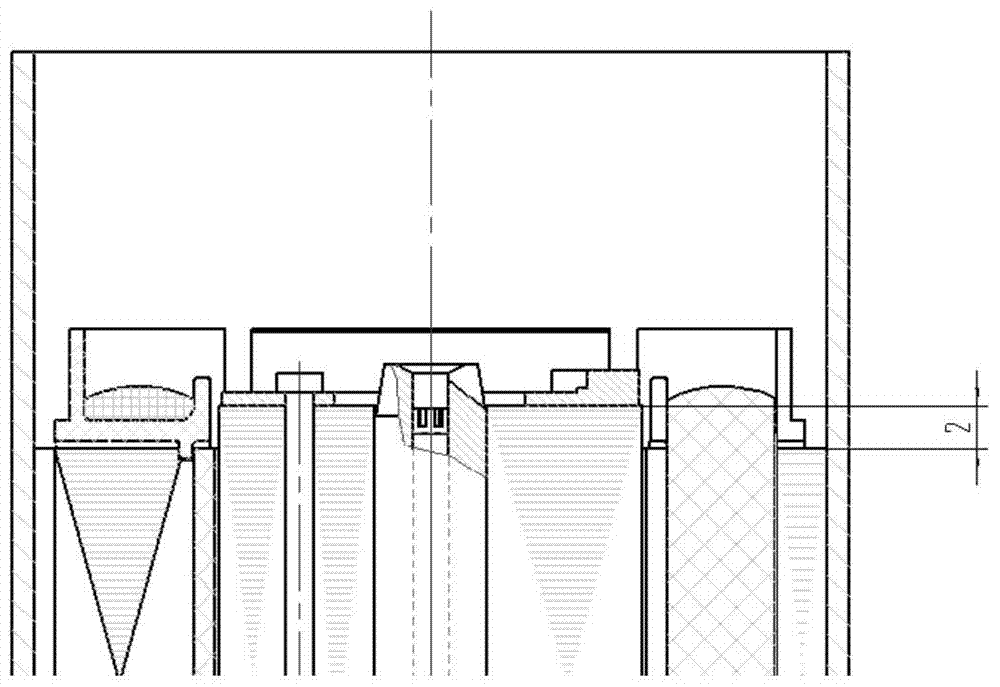

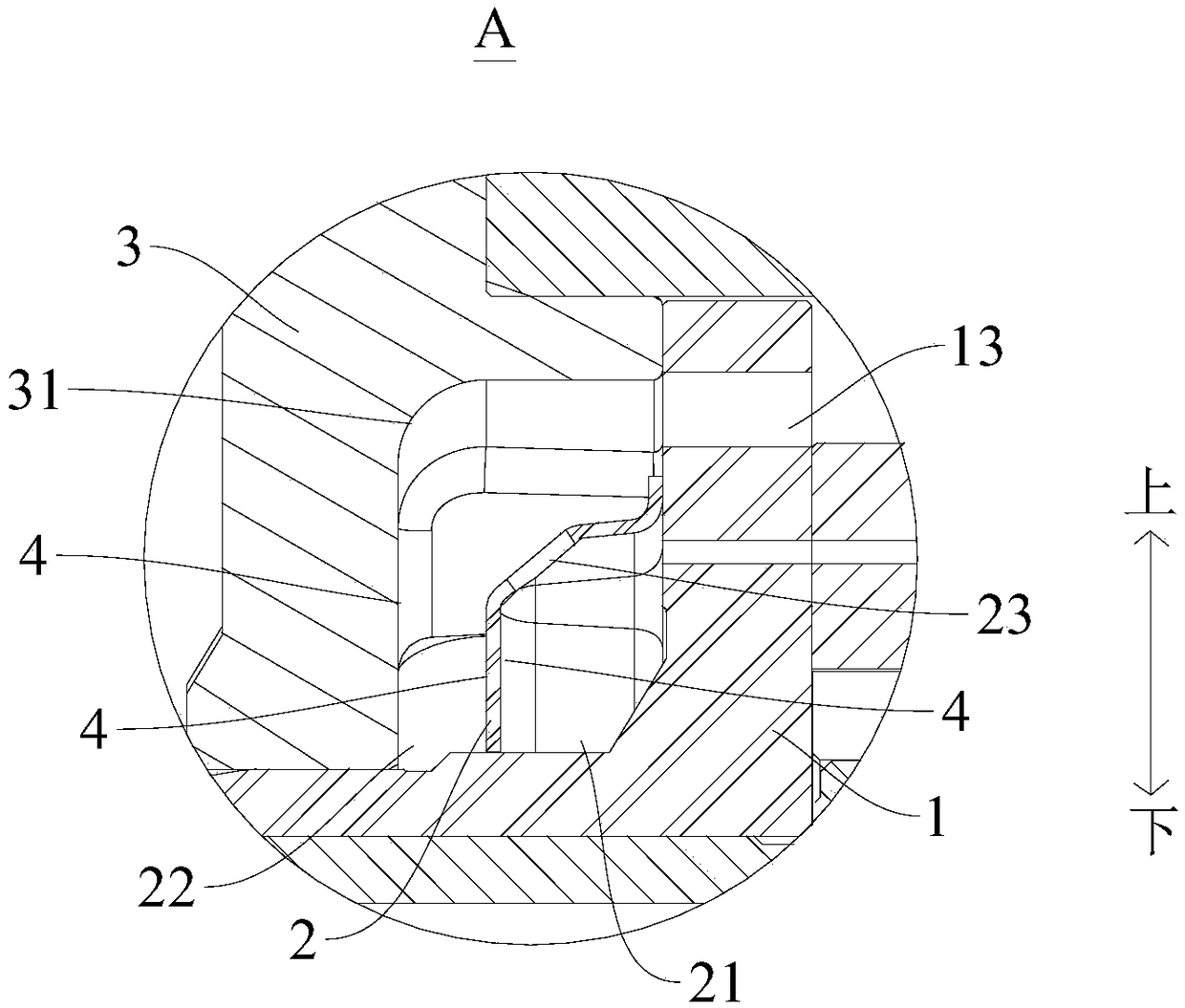

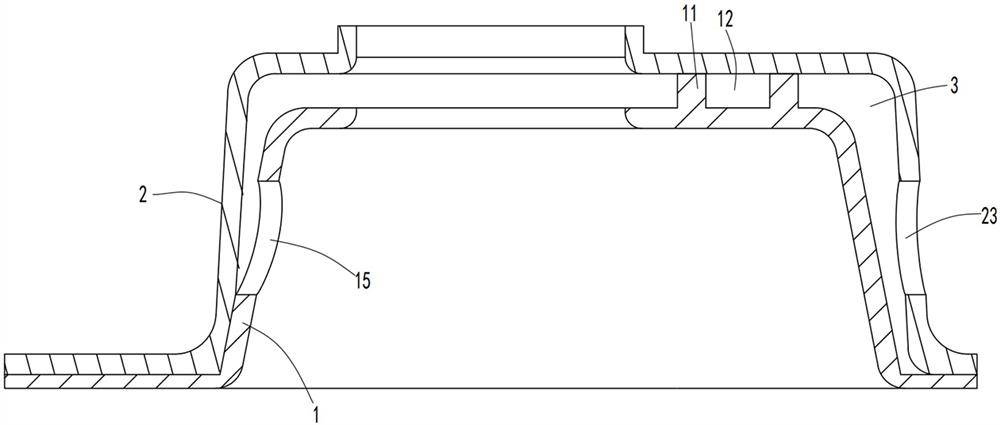

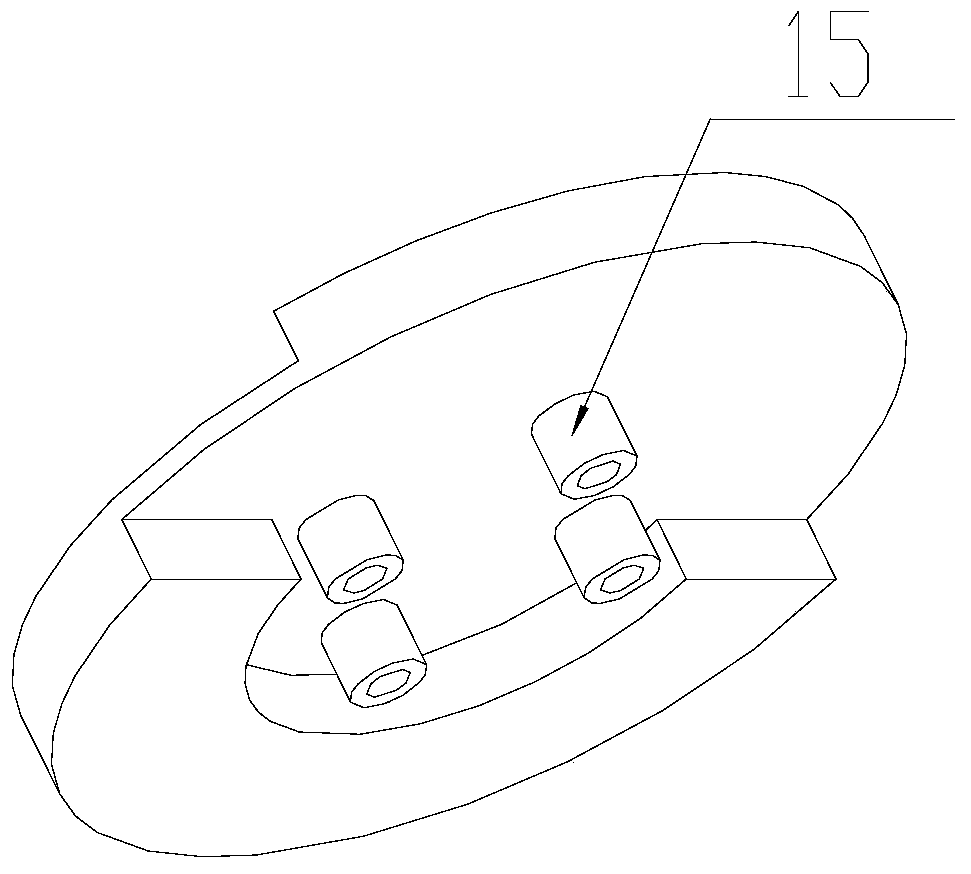

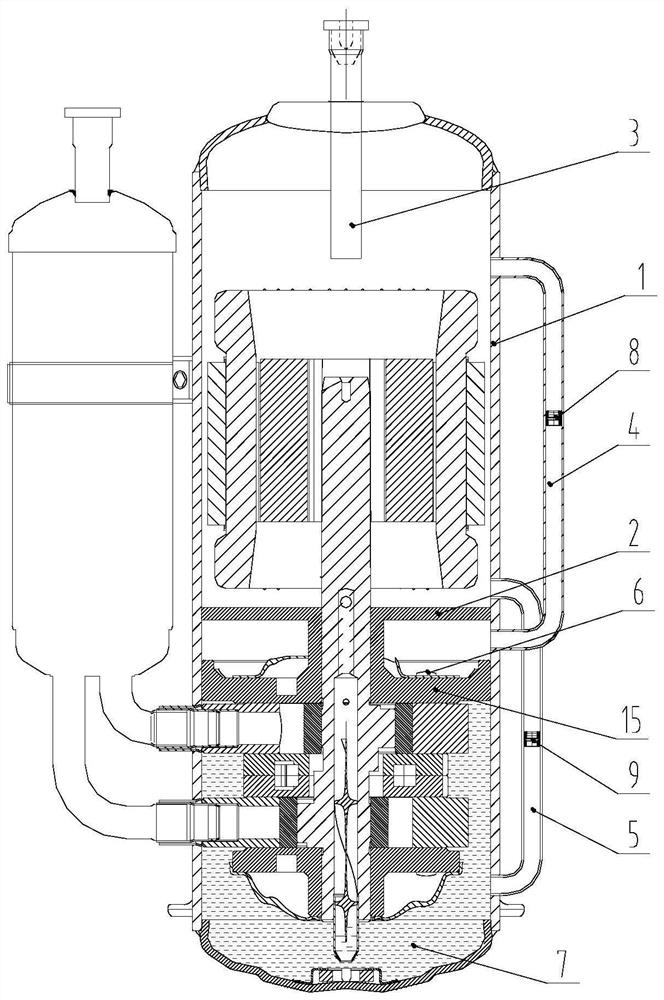

Compressor oil blocking assembly, rotor assembly, compressor and air conditioner system

ActiveCN106014931AReduce oil discharge rateImprove the oil blocking effectPositive displacement pump componentsPositive-displacement liquid enginesBlock effectEngineering

The invention discloses a compressor oil blocking assembly, a rotor assembly, a compressor and an air conditioner system. The compressor oil blocking assembly comprises an oil blocking cap and an oil blocking base which is used for being fixedly connected with the oil blocking cap and can be arranged outside the connecting sleeve in a sleeving manner. A connecting sleeve used for being matched with the tail portion of a bent axle is arranged at the bottom end of the oil blocking cap. A first preset distance is formed between the bottom face of the oil blocking cap and the top face of the oil blocking base, and a second preset distance is formed between the bottom face of the oil blocking base and the bottom end face of the connecting sleeve. The compressor oil blocking assembly is provided with a double-layer oil blocking structure of the oil blocking cap and the oil blocking base, two-time oil blocking is achieved, the oil blocking effect is effectively improved, the oil output rate of the compressor, especially a large-displacement double-cylinder compressor is reduced. According to the air conditioner system applying the compressor oil blocking assembly, the heat exchange efficiency of the air conditioner system is improved, and the performance of the whole air conditioner system is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

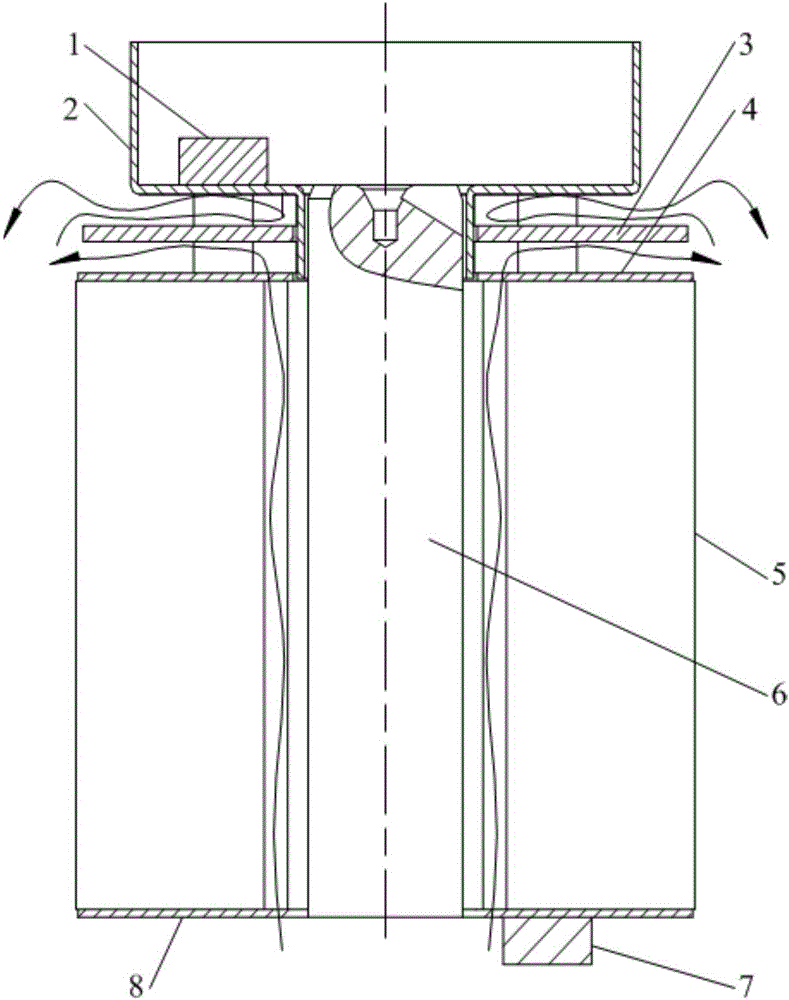

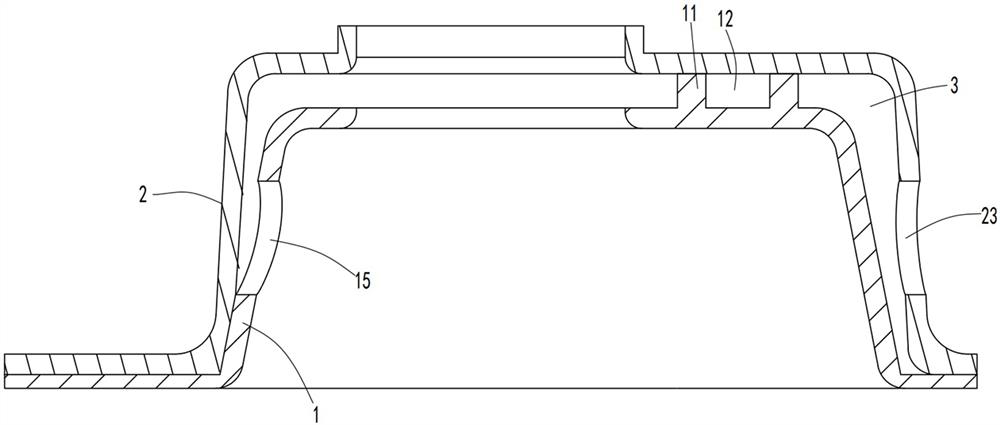

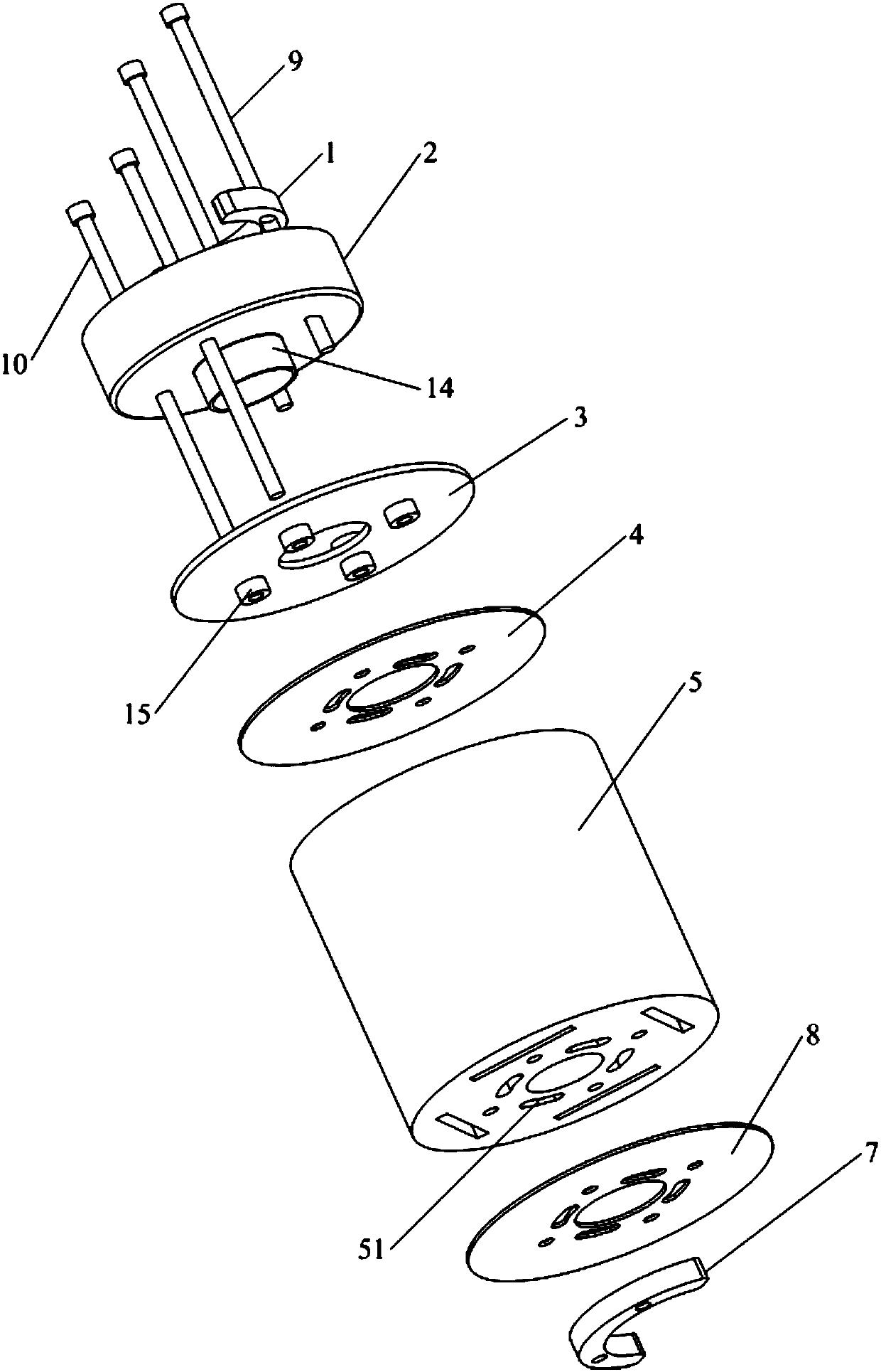

Pump body silencer, pump body assembly and compressor

ActiveCN112196801AImprove the noise reduction effectImprove comfortRotary/oscillating piston pump componentsLiquid fuel engine componentsResonant cavityNoise

The invention relates to the technical field of compressors, in particular to a pump body silencer, a pump body assembly and a compressor. The pump body silencer comprises an inner layer silencer cover connected with the pump body assembly and an outer layer silencer cover sleeving an inner layer silencer, wherein a gas-liquid separation cavity is formed between the inner layer silencer cover andthe outer layer silencer cover; a plurality of hollow inner layer resonators are arranged on one side, facing the outer layer silencer cover, of the top surface of the inner layer silencer cover; thetail ends of the inner layer resonators are in contact with the outer layer silencer cover, so that a resonance cavity expansion chamber is formed inside each inner layer resonator; and the resonancefrequencies of the resonance cavity expansion chambers inside the inner layer resonators are different. According to the pump body silencer, the pump body assembly and the compressor, the resonance frequencies of the resonance cavity expansion chambers are different, so that noises with different specific frequencies are eliminated, the silencing effect of the silencer is improved, the compressorand an electric appliance using the compressor are prevented from damaging the sound environment in life of people, the comfort of the compressor and the electric appliance using the compressor is improved, and the application range is expanded.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

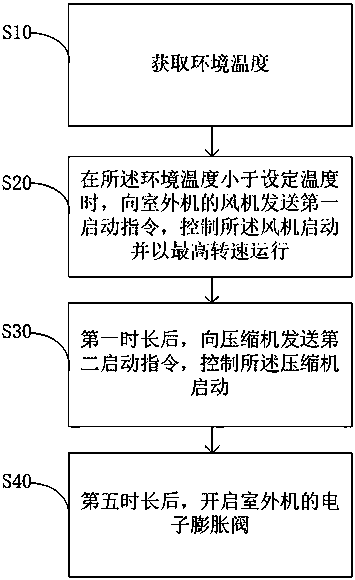

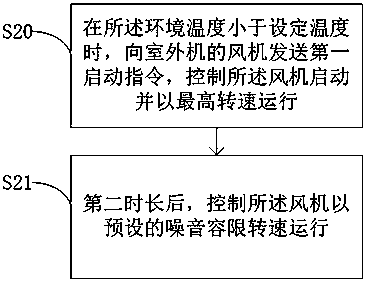

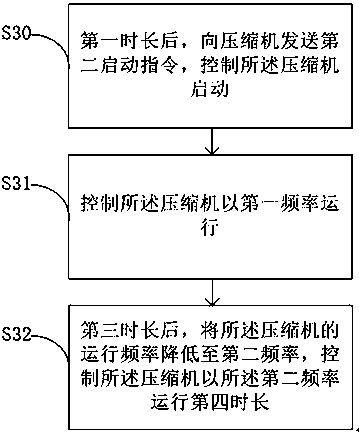

Method and device for controlling low-temperature heating start of air conditioner and air conditioner

ActiveCN110425700AHeating fastReduce oil discharge rateMechanical apparatusSpace heating and ventilation safety systemsEngineeringElectronic expansion valve

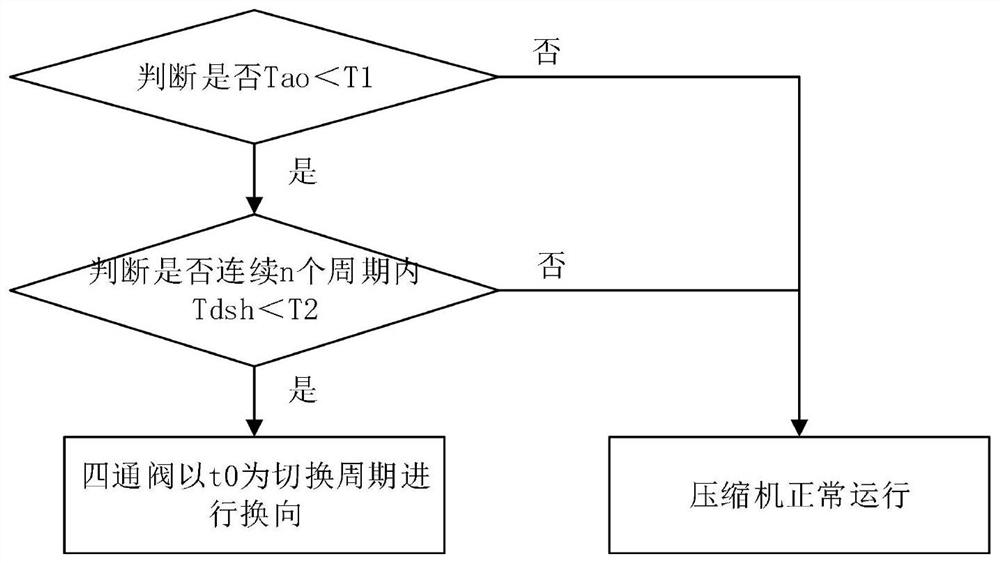

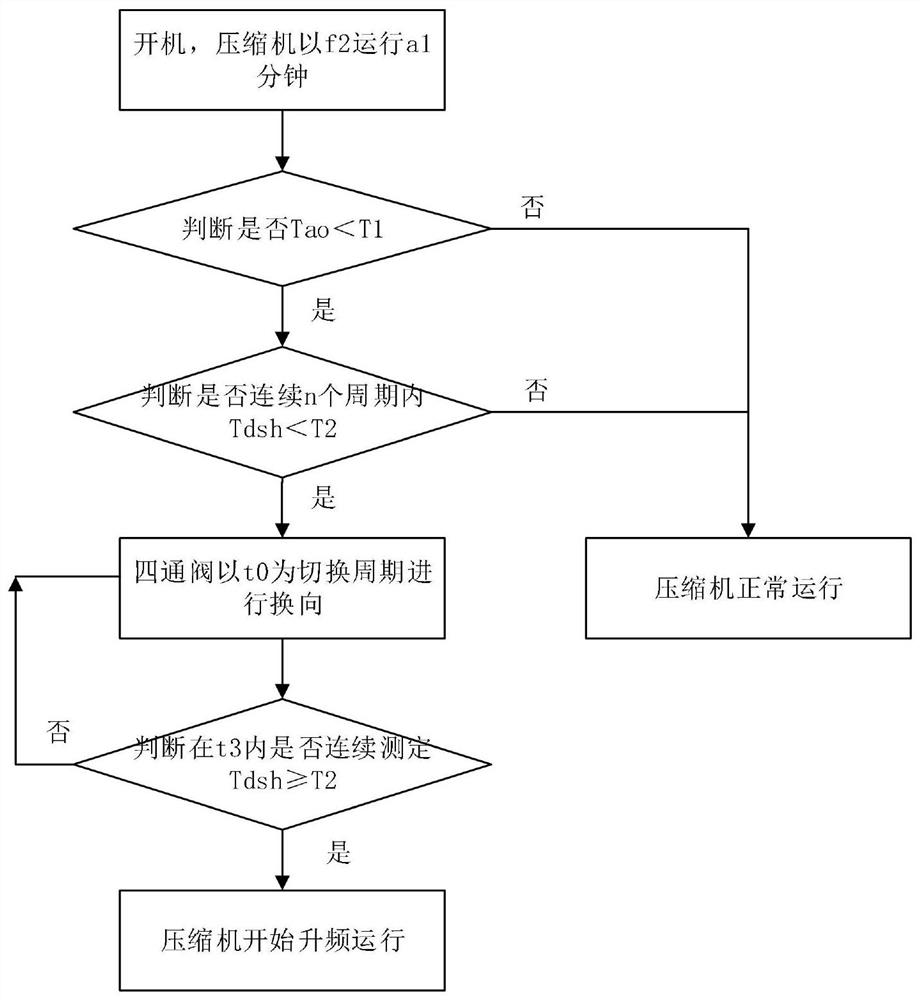

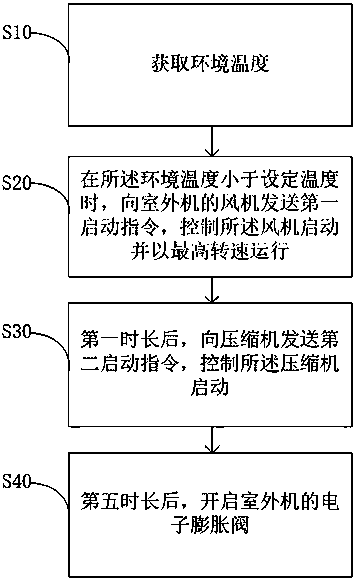

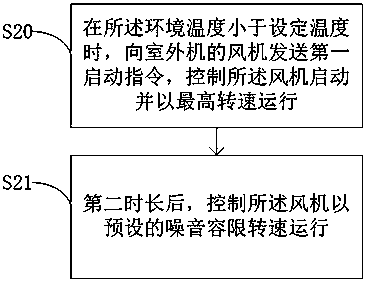

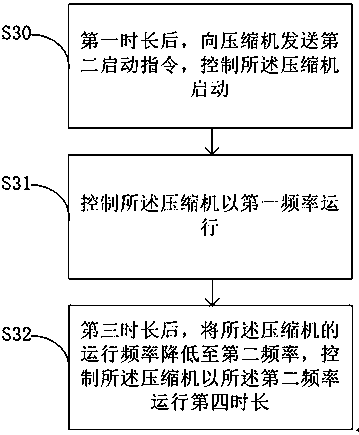

The invention provides a method and device for controlling low-temperature heating start of an air conditioner and the air conditioner. The method comprises the flowing steps: acquiring an ambient temperature; when the ambient temperature is less than a set temperature, sending a first start command to a fan of an outdoor unit to control the fan to start and run at the highest speed; after the third duration, sending a second start command to a compressor to control the compressor to start; after the fifth duration, turning on an electronic expansion valve of the outdoor unit. The method for controlling low-temperature heating start of the air conditioner can rapidly establish the system superheat degree under the premise of ensuring low oil discharge of the system, improve the heat exchange effect, enable the compressor to heat quickly, reduce the oil discharge amount, ensure the reliability of the system and realize rapid heating of the air conditioner during low-temperature heatingstart.

Owner:NINGBO AUX ELECTRIC

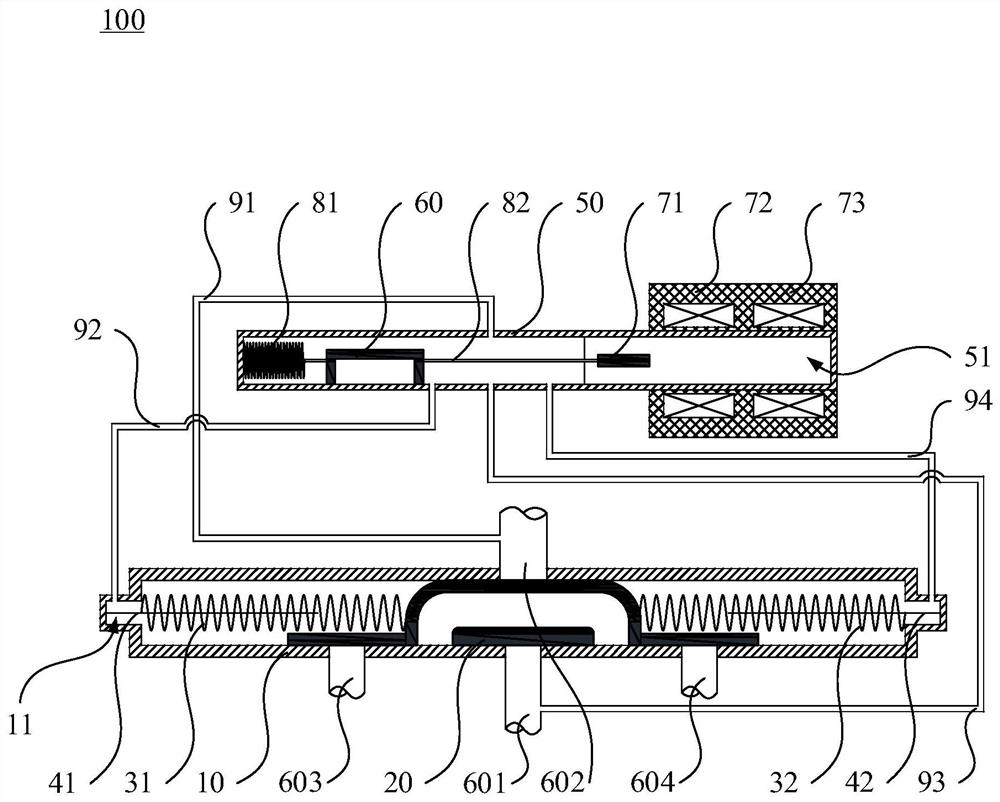

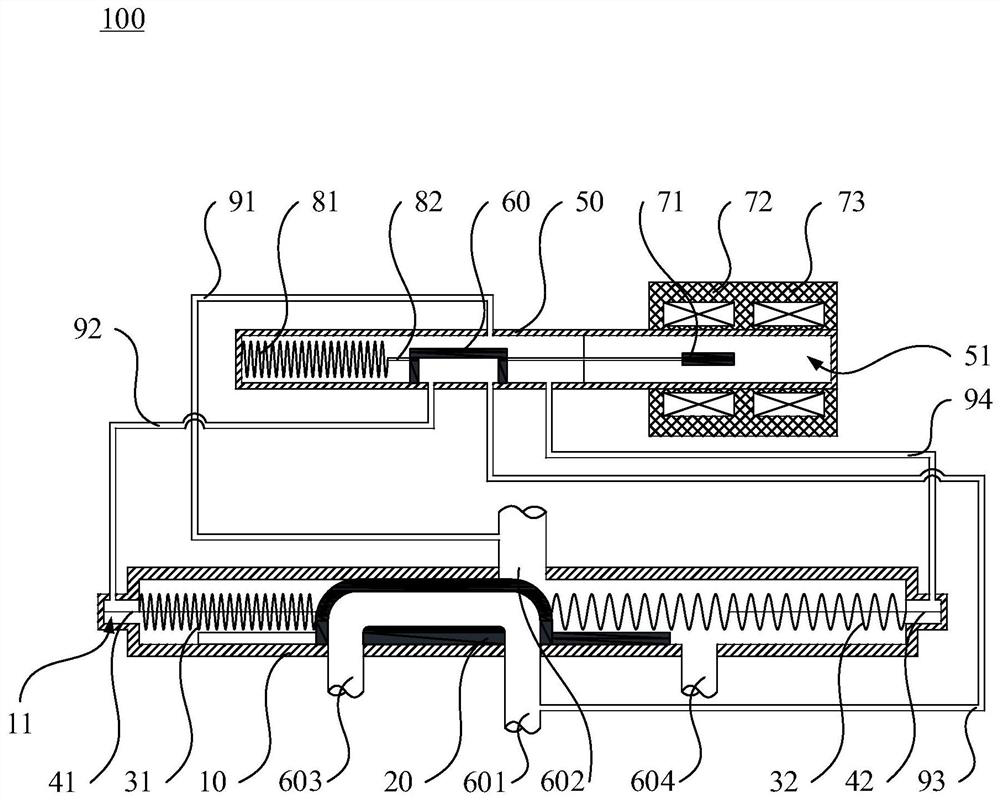

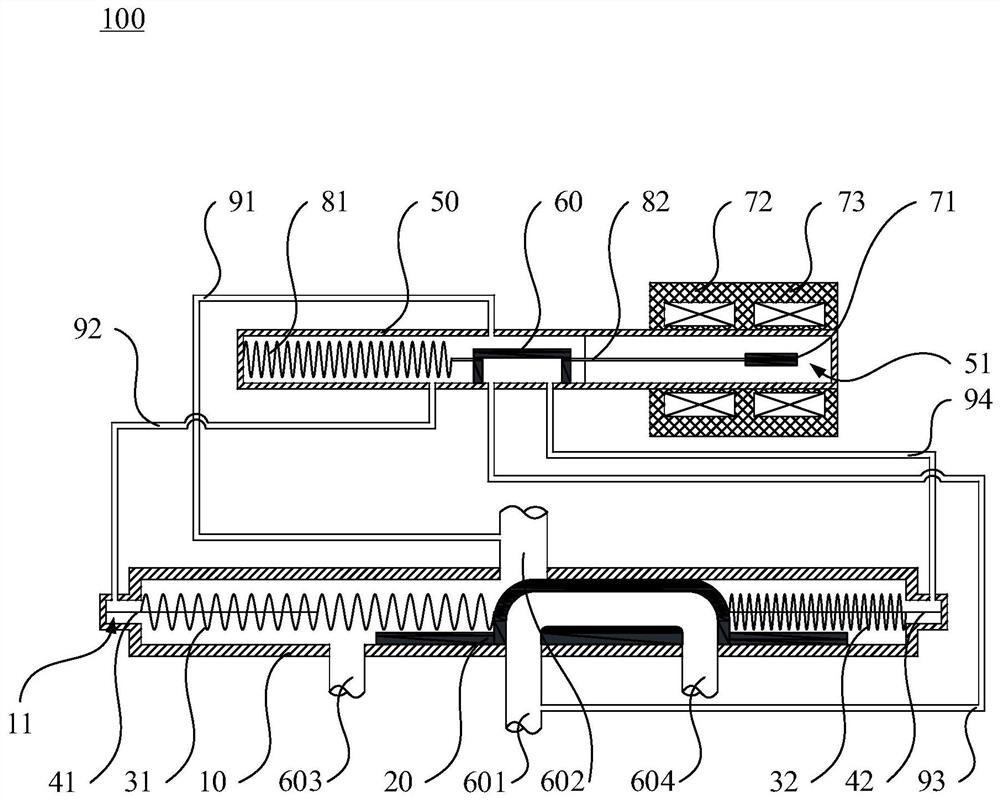

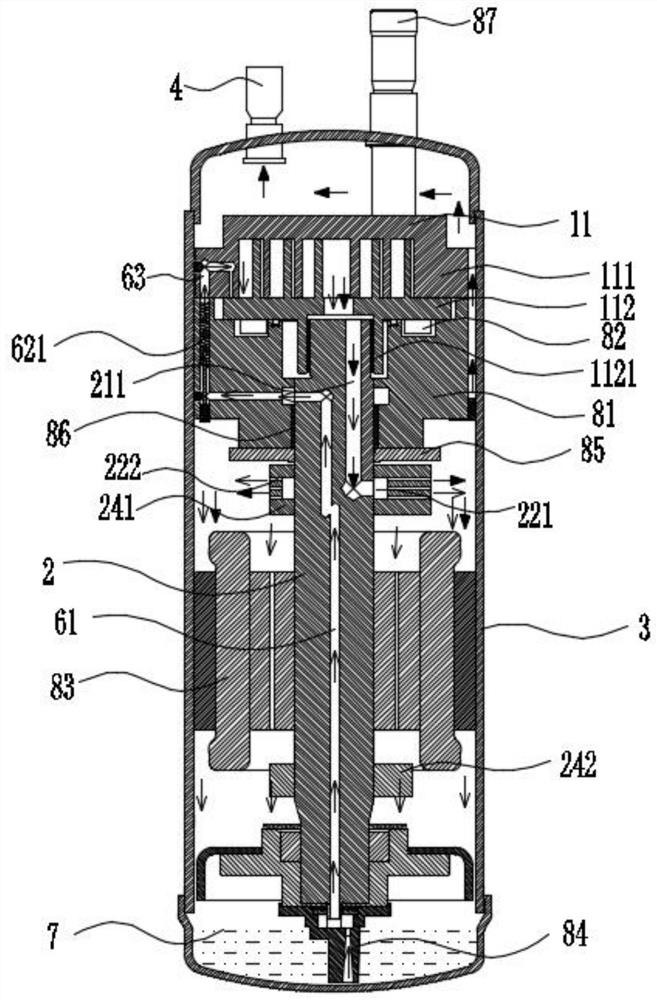

Oil separation device for rotary compressor and compressor with same

ActiveCN113074114AReduce oil discharge rateDoes not increase power consumptionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectric machineryOil separation

The invention discloses an oil separation device for a rotary compressor and a compressor with same. The oil separation device comprises an oil separation device body, wherein the oil separation device body comprises a first fixing part connected with an upper bearing, the first fixing part is connected with a first oil separation part, an oil hole is formed in the first oil separation part, and is in a horn mouth shape, the upper outer edge of the first oil separation part is connected with a second oil separation part in the axial direction, the second oil separation part is in a cylindrical shape, the second oil separation part is connected with a third oil separation part, and the third oil separation part points to a crankshaft to be in a circular ring shape. The oil separation device solves the problem that oil drops are broken and the oil discharge amount is increased due to the fact that lubricating oil is sprayed out of a spiral oil groove outlet to collide with a motor rotor is solved, and does not influence compressor power consumption.

Owner:XI AN JIAOTONG UNIV

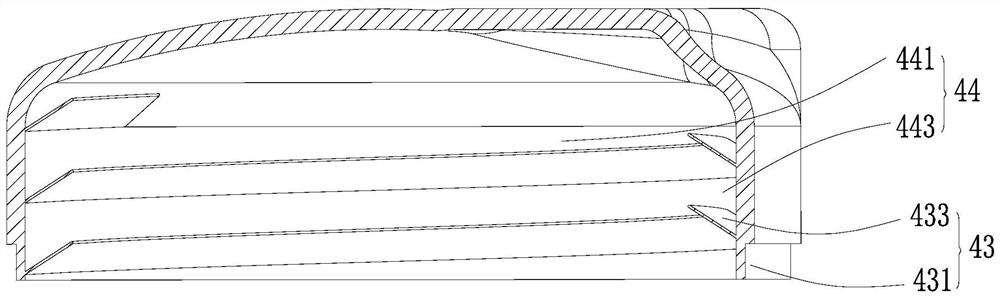

Oil-gas separation assembly for compressor, compression mechanism and air conditioning system

ActiveCN113446226APrevent fullReduce oil discharge rateRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringAir conditioning

The invention provides an oil-gas separation assembly for a compressor, a compression mechanism and an air conditioning system. The oil-gas separation assembly for the compressor comprises an upper flange, a silencer, and an oil baffle skirt edge, wherein the silencer covers the upper flange, and an oil-gas discharging port is formed in the silencer; and the oil baffle skirt edge is arranged on the upper flange, and oil-gas separation occurs when oil-gas flow discharged from the oil-gas discharging port flow through one side surface of the oil baffle skirt edge. The oil baffle skirt edge is arranged on the upper flange, when an oil-gas mixture flowing out of the oil-gas discharging port in the silencer flows through the side surface of the oil baffle skirt edge, oil drops in gas make contact with the side surface of the oil baffle skirt edge to be gathered on the side surface, and the oil drops are separated from the gas so that the situation that the compressor is filled with the oil drops can be avoided, and the oil discharge rate is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

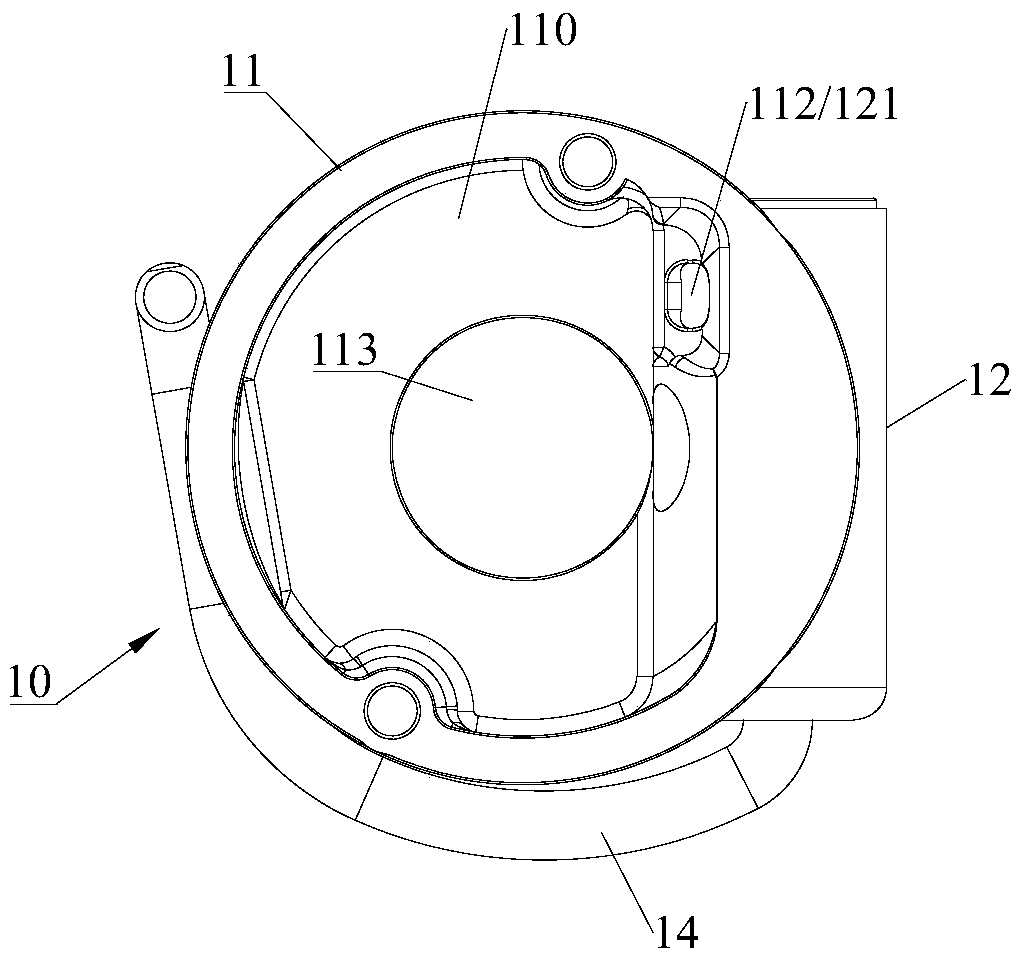

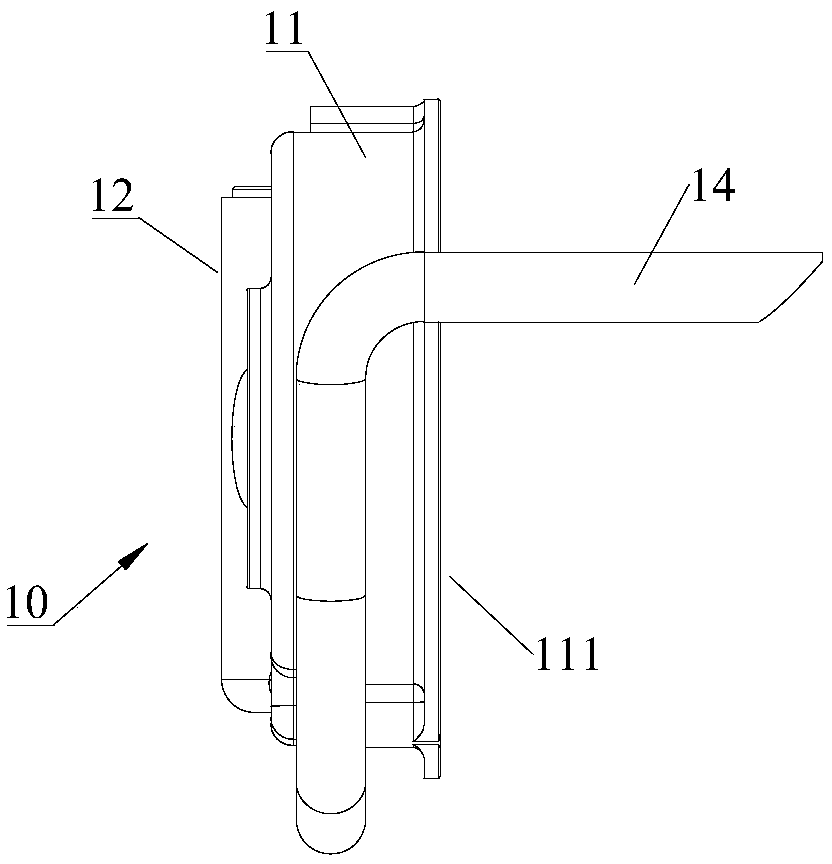

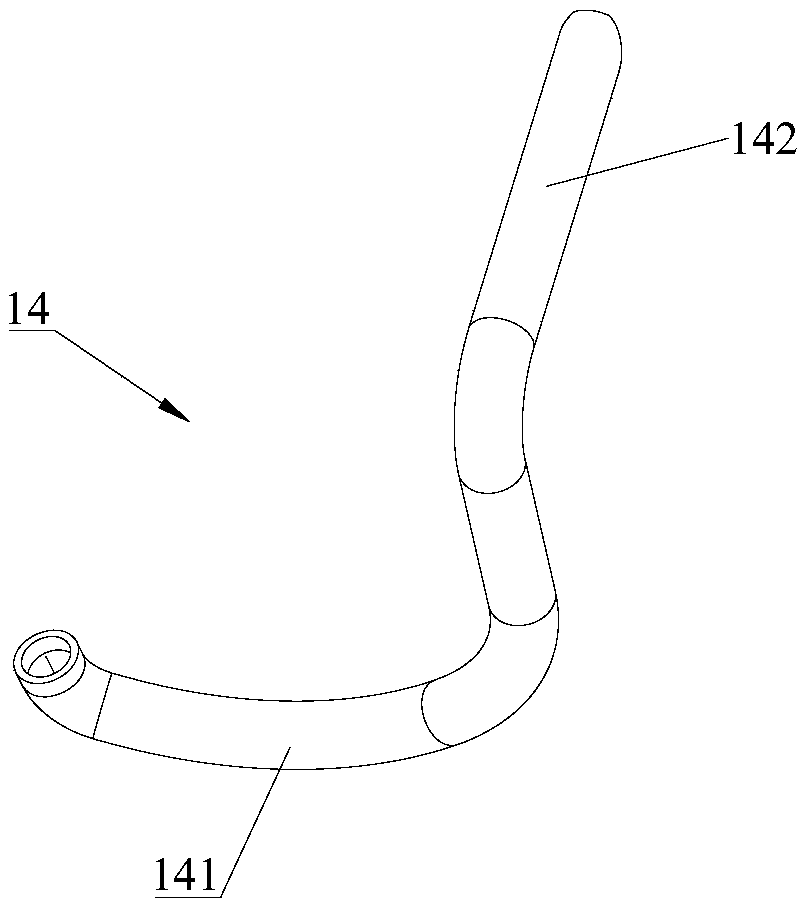

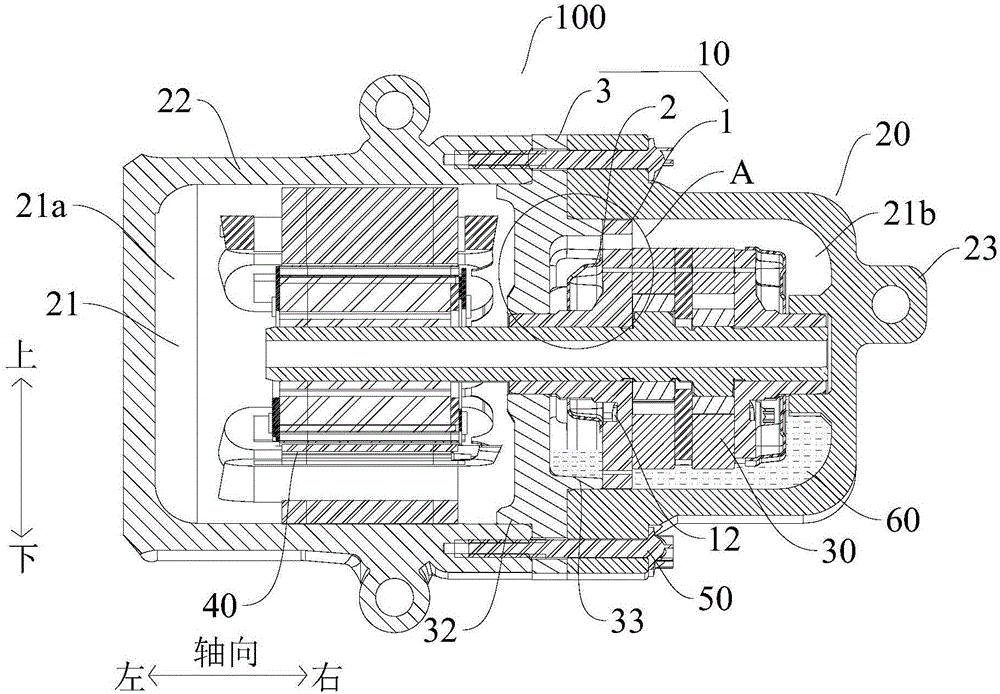

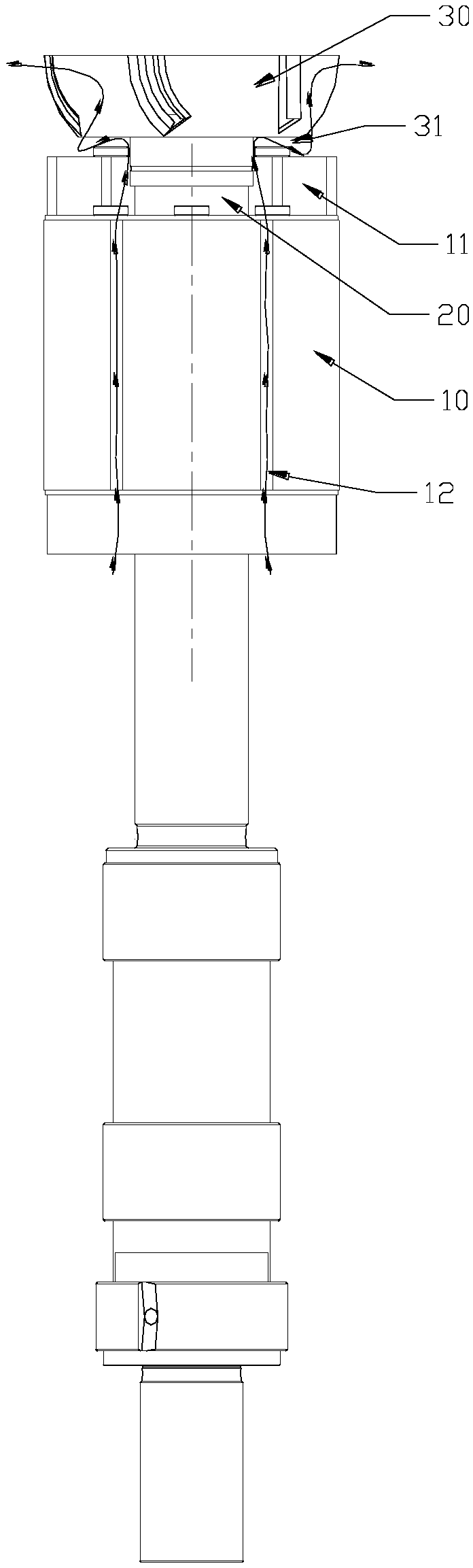

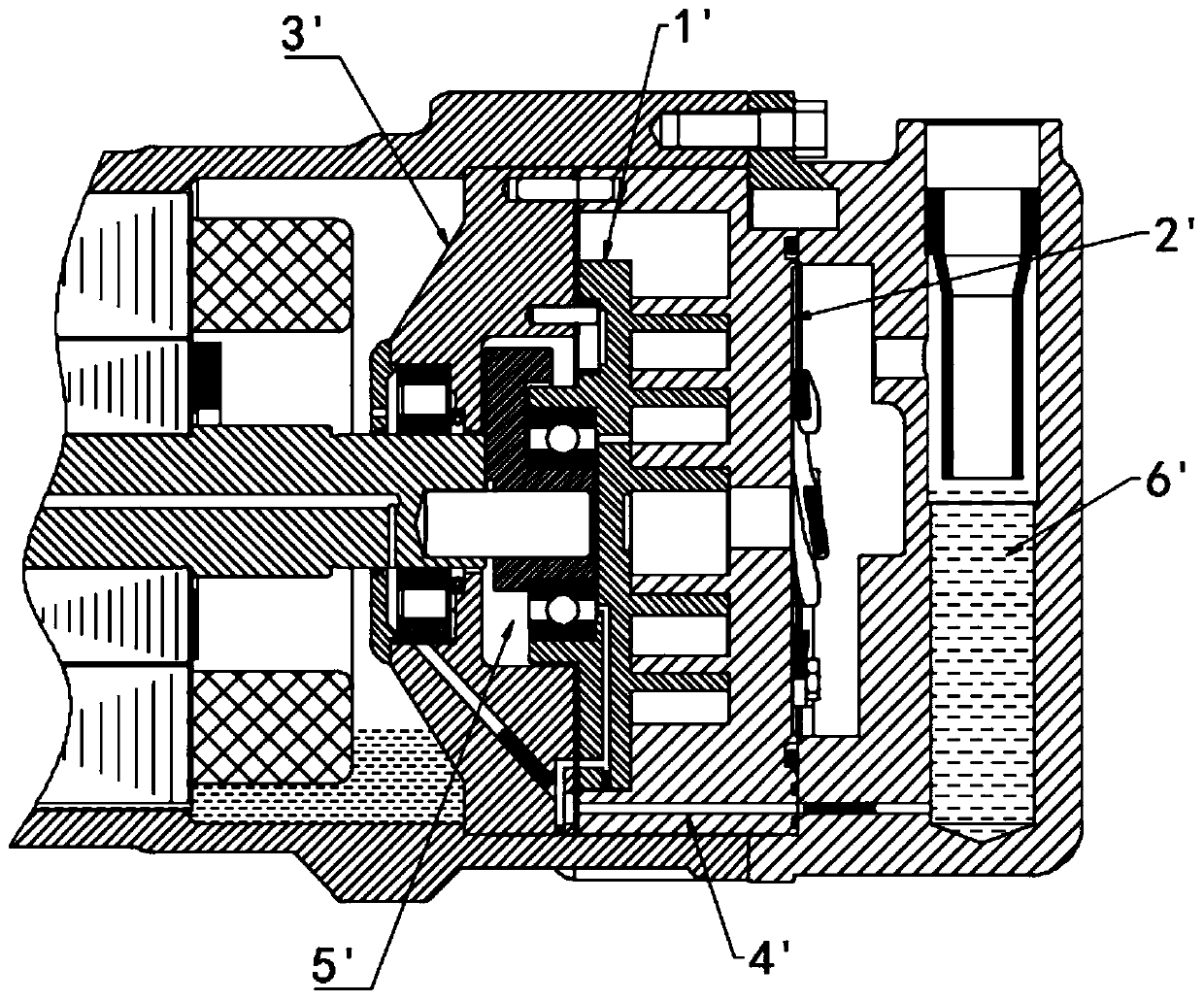

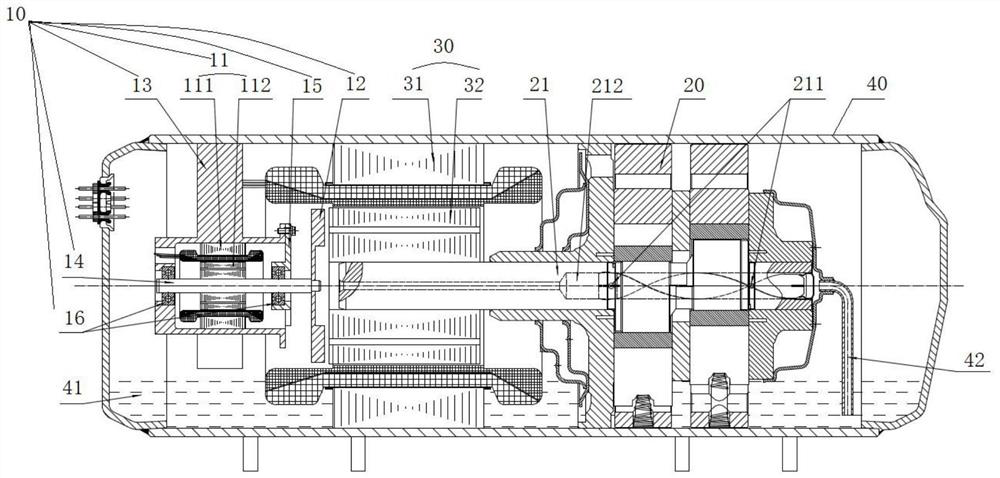

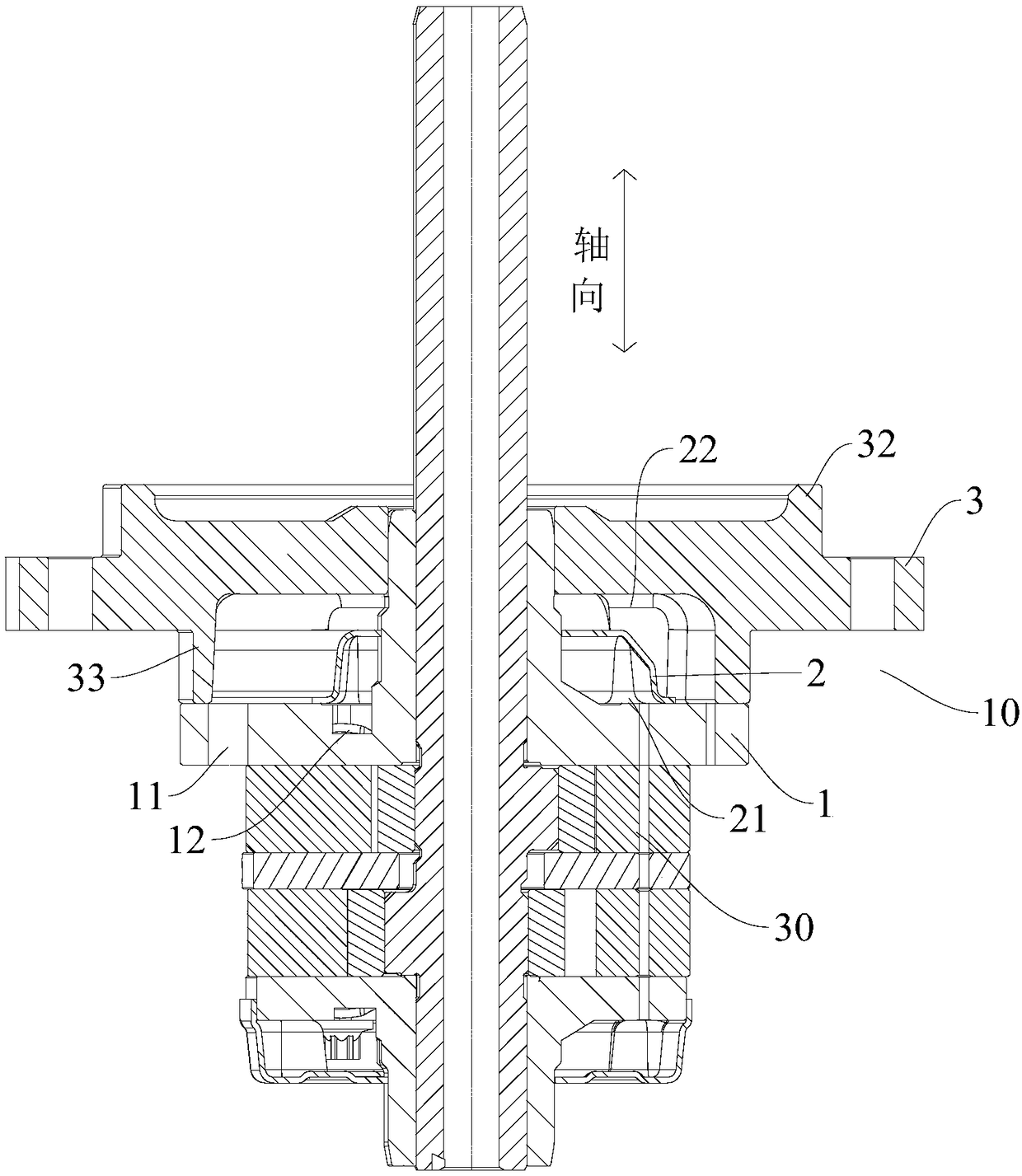

Oil separator used for compressor, compressor and refrigeration system

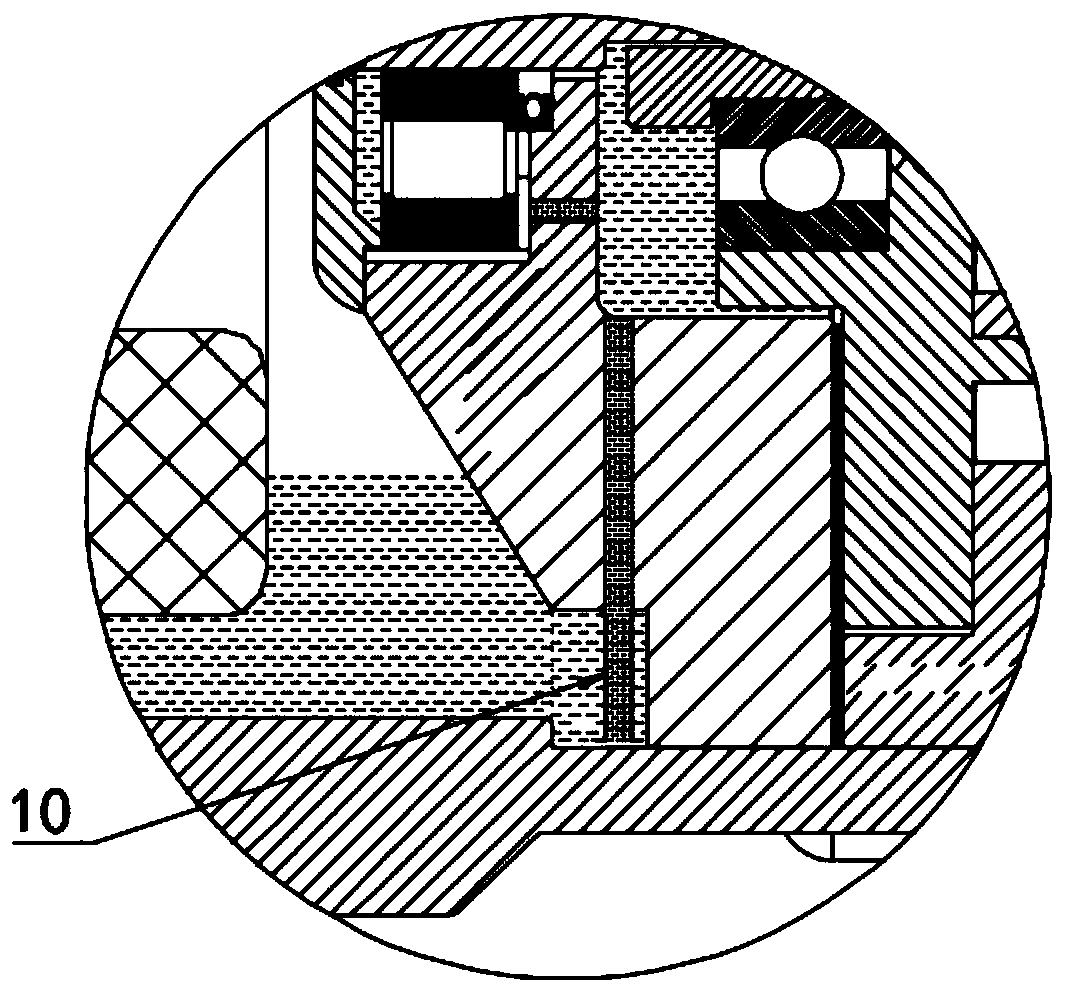

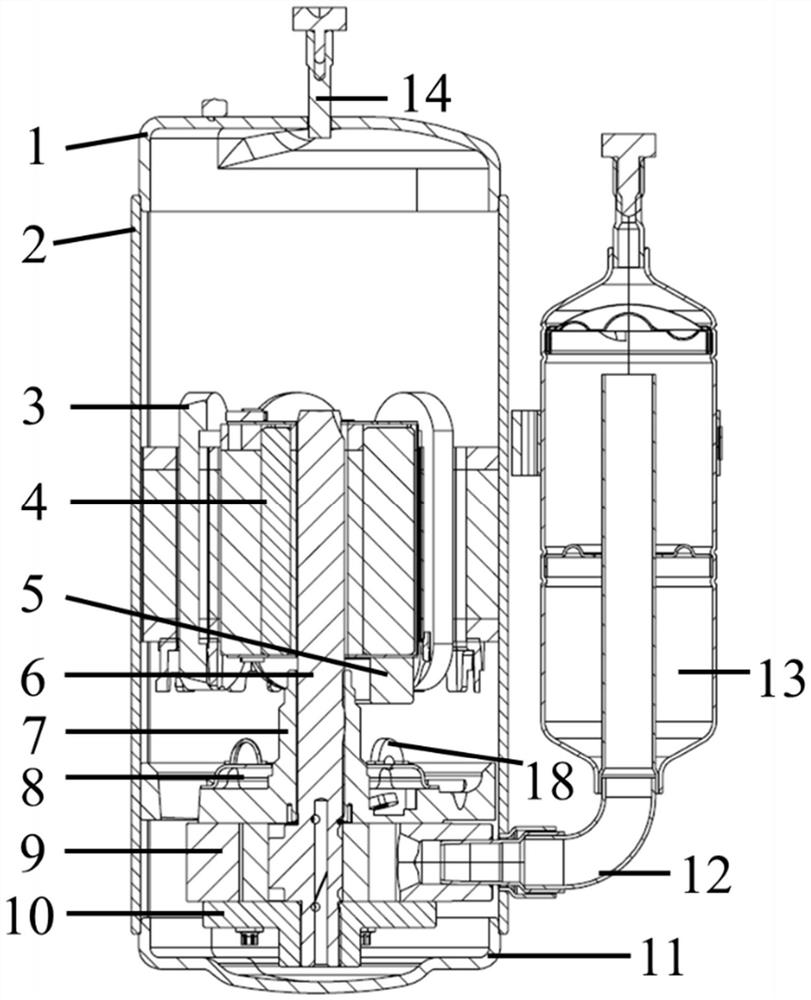

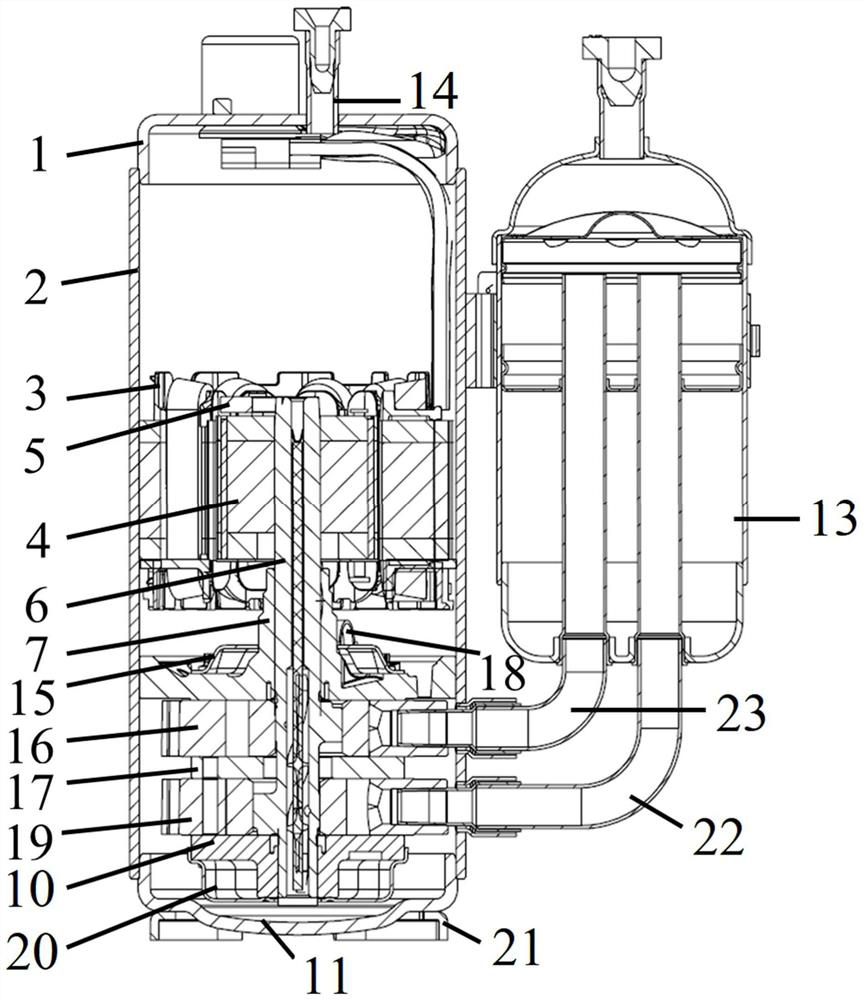

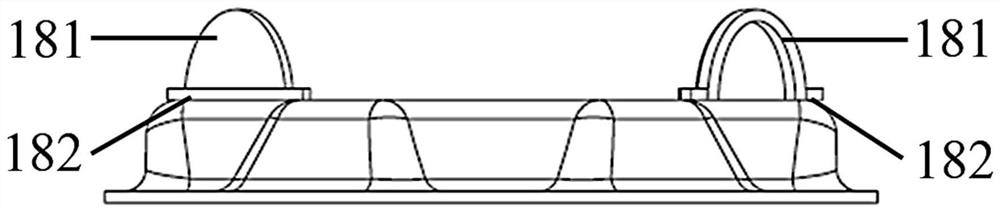

PendingCN110966812AImprove oil and gas separation efficiencyReduce oil discharge rateCompressorOil separationGas separation

The invention relates to the technical field of refrigeration, and discloses an oil separator used for a compressor, the compressor and a refrigeration system. The oil separator (10) is arranged in the compressor and comprises an oil separation chamber (120), an oil liquid outlet (122) and a gas outlet (123), wherein the oil liquid outlet (122) and the gas outlet (123) communicate with the oil separation chamber (120); the oil liquid outlet (122) is positioned on the bottom of the oil separation chamber (120); the gas outlet (123) is positioned on the top of the oil separation chamber (120); the oil separator (10) comprises an oil returning pipe (14) connected to the oil liquid outlet (122); and the outlet pressure of the oil returning pipe (14) is equal to the pressure of the gas outlet (123). By use of the oil separator, oil and gas separation efficiency can be improved, an oil discharging rate is lowered, and the performance of the compressor is improved.

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

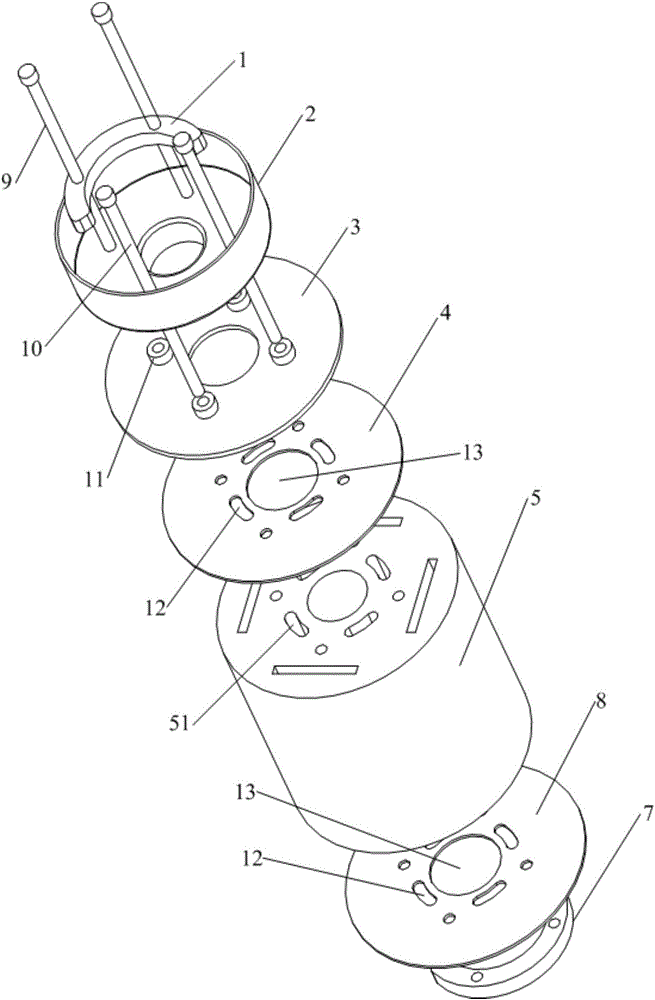

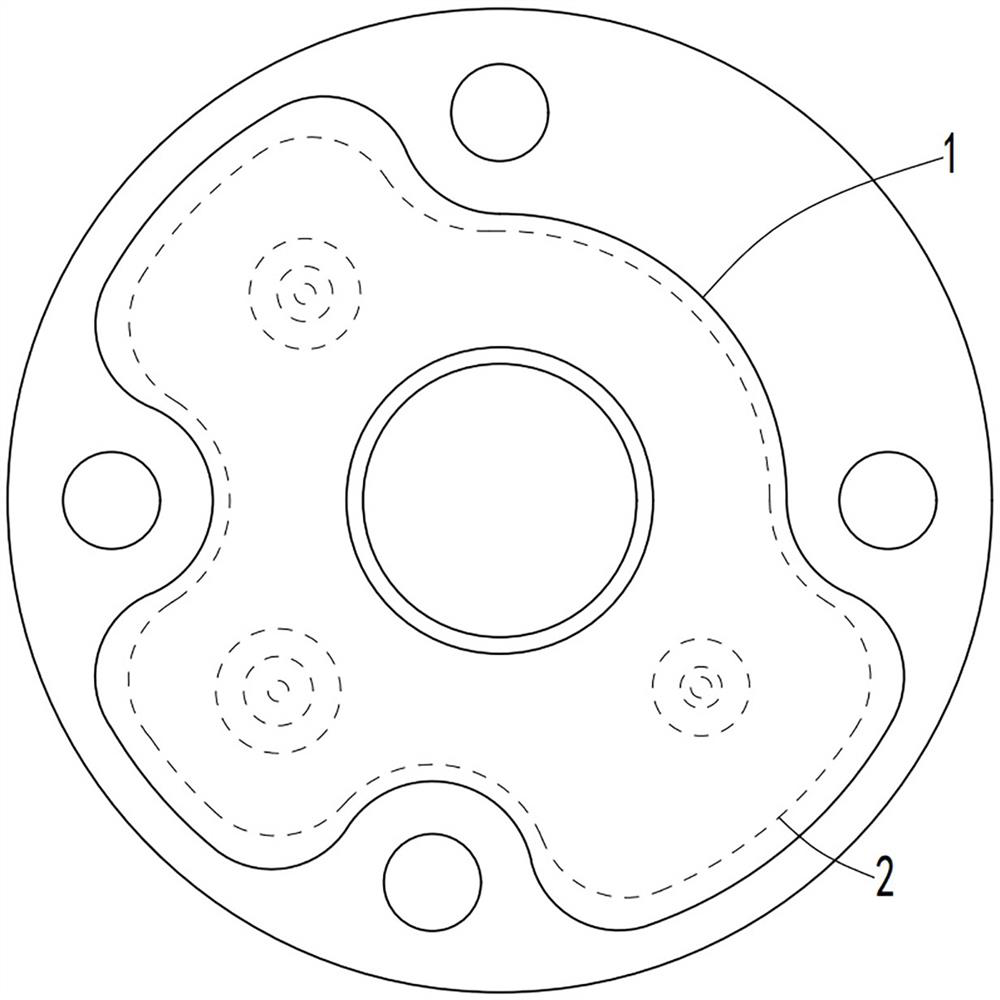

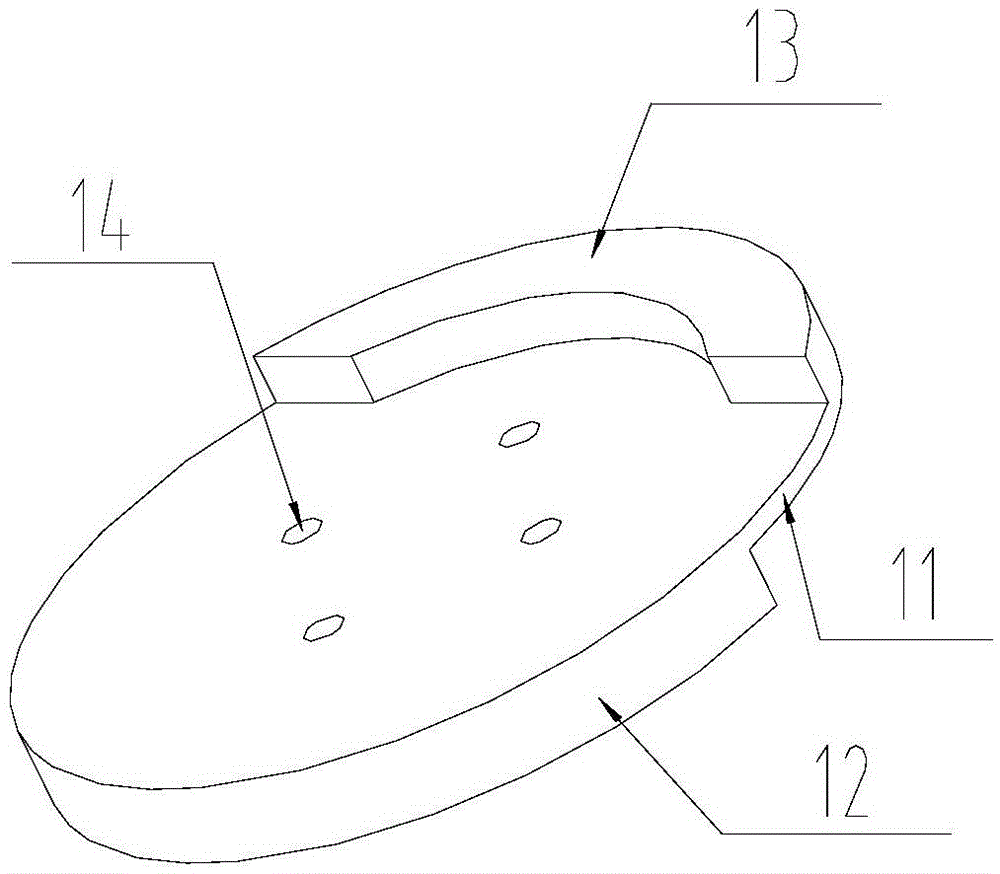

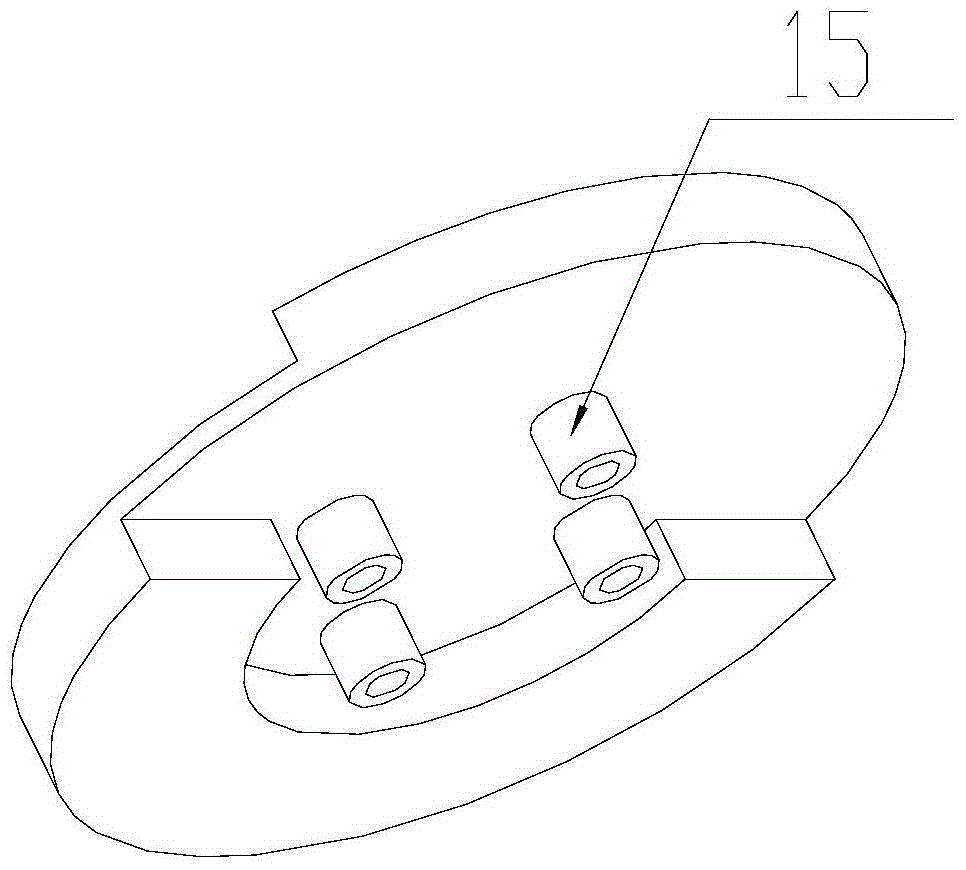

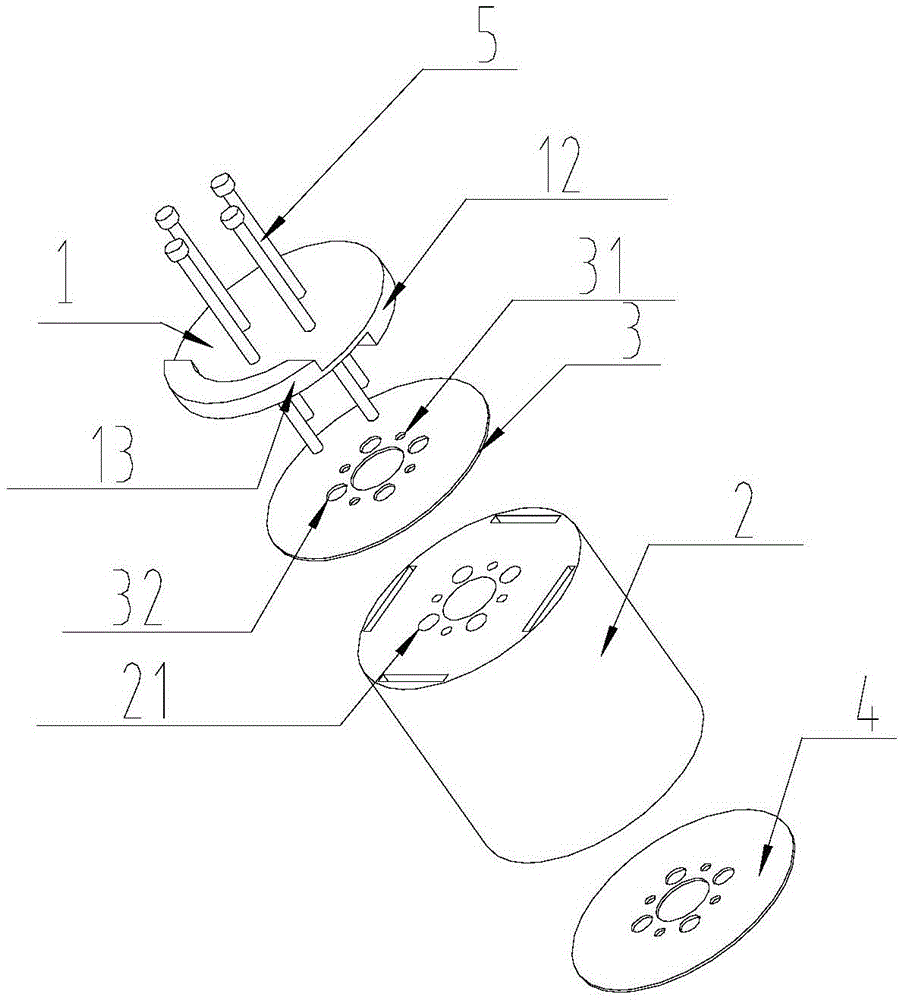

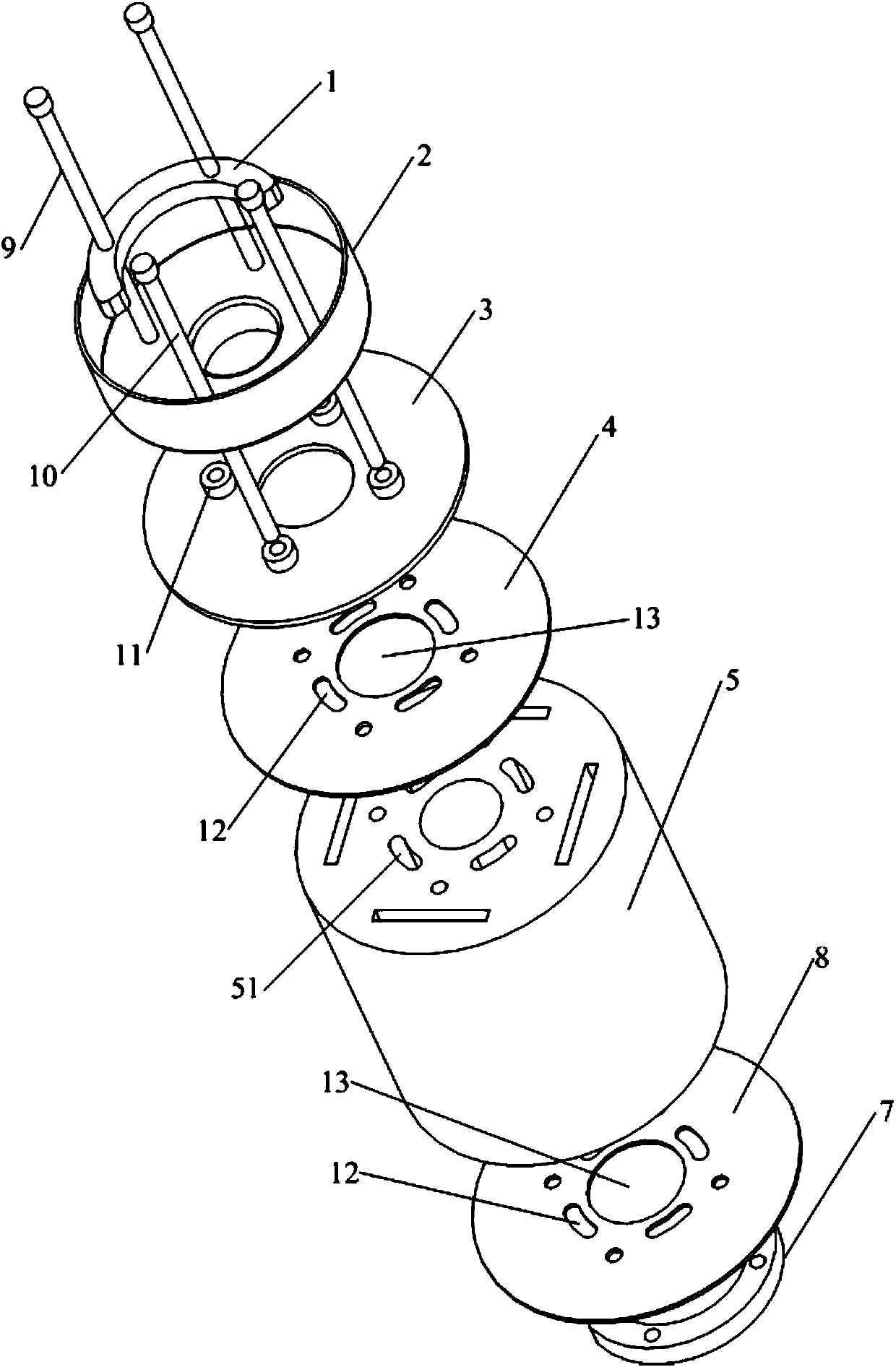

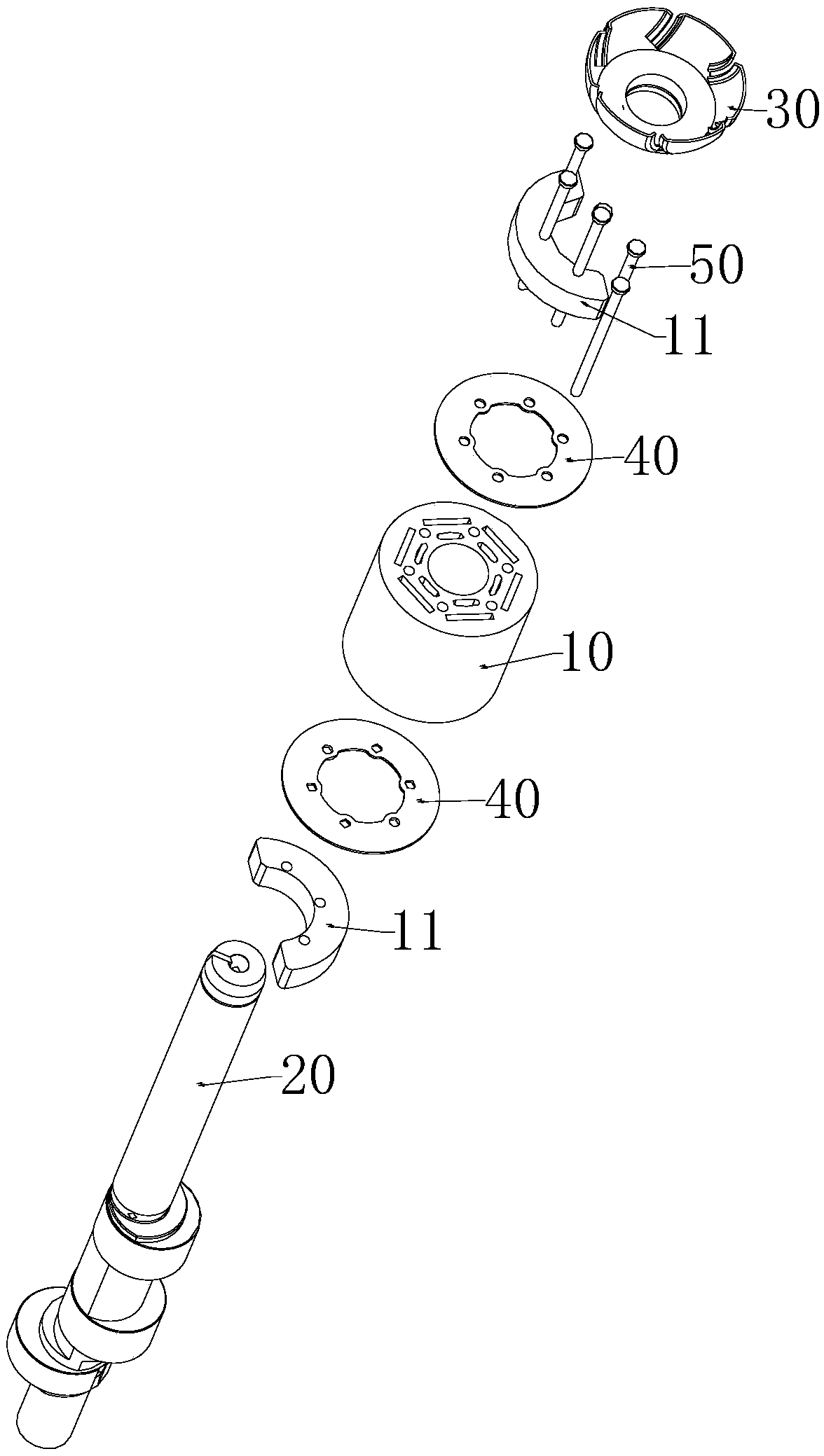

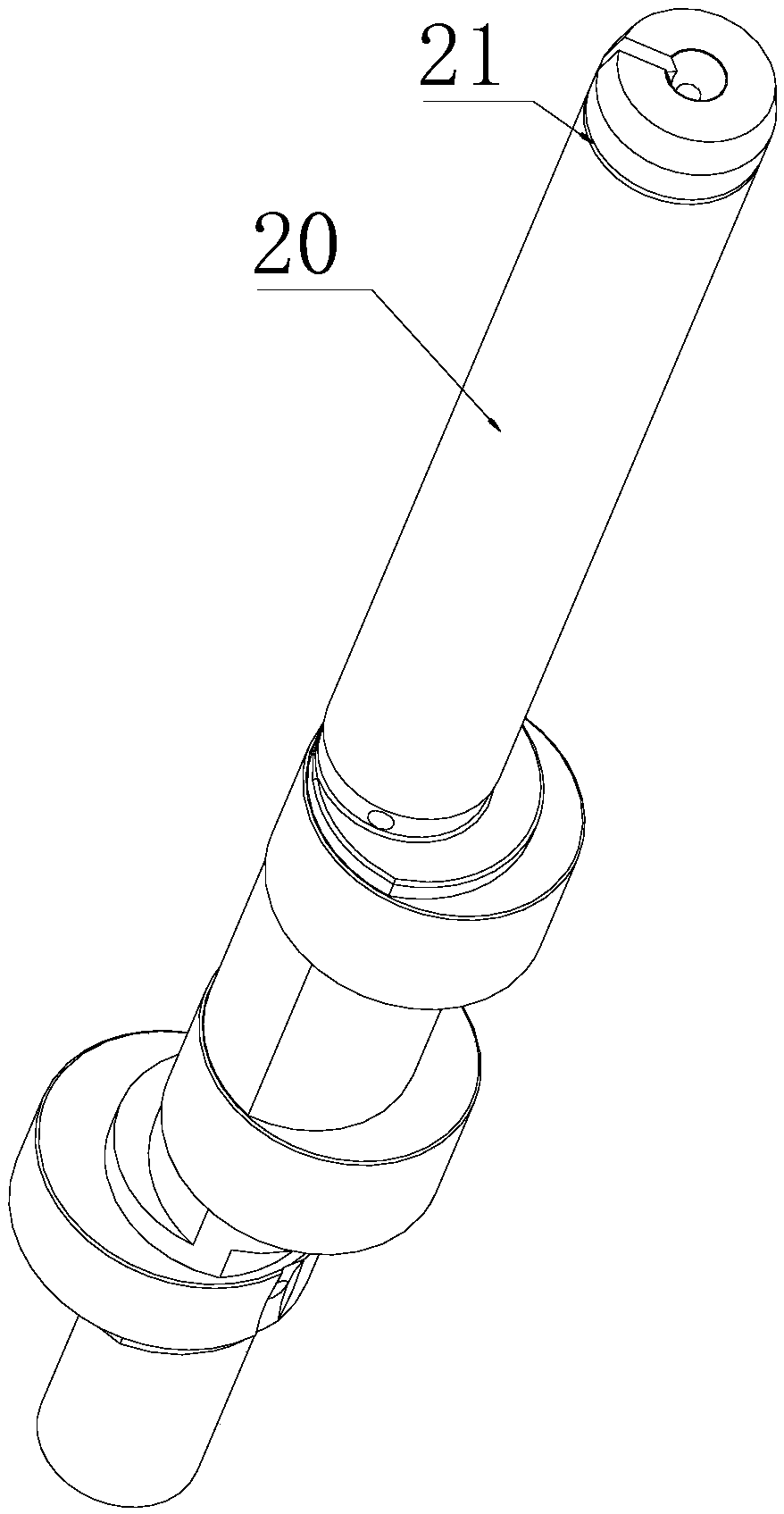

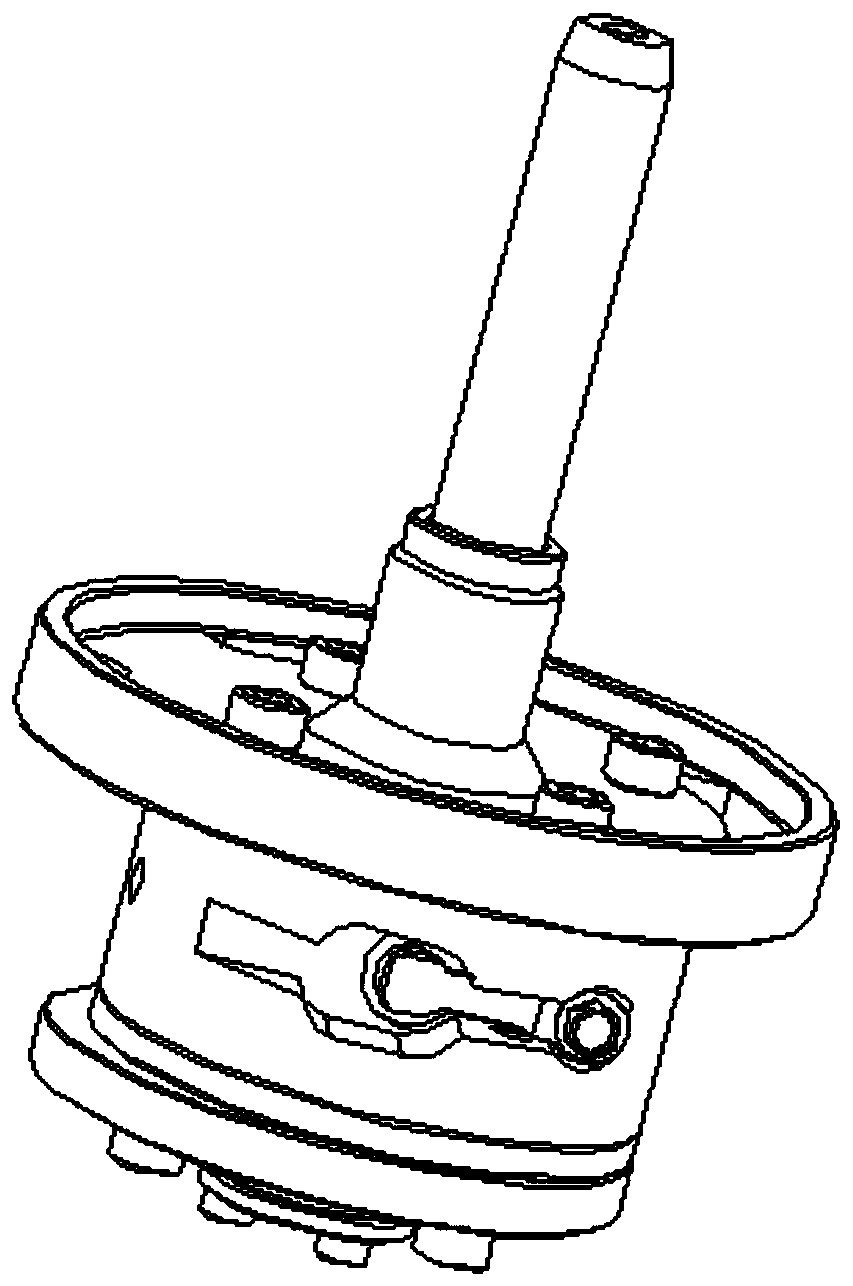

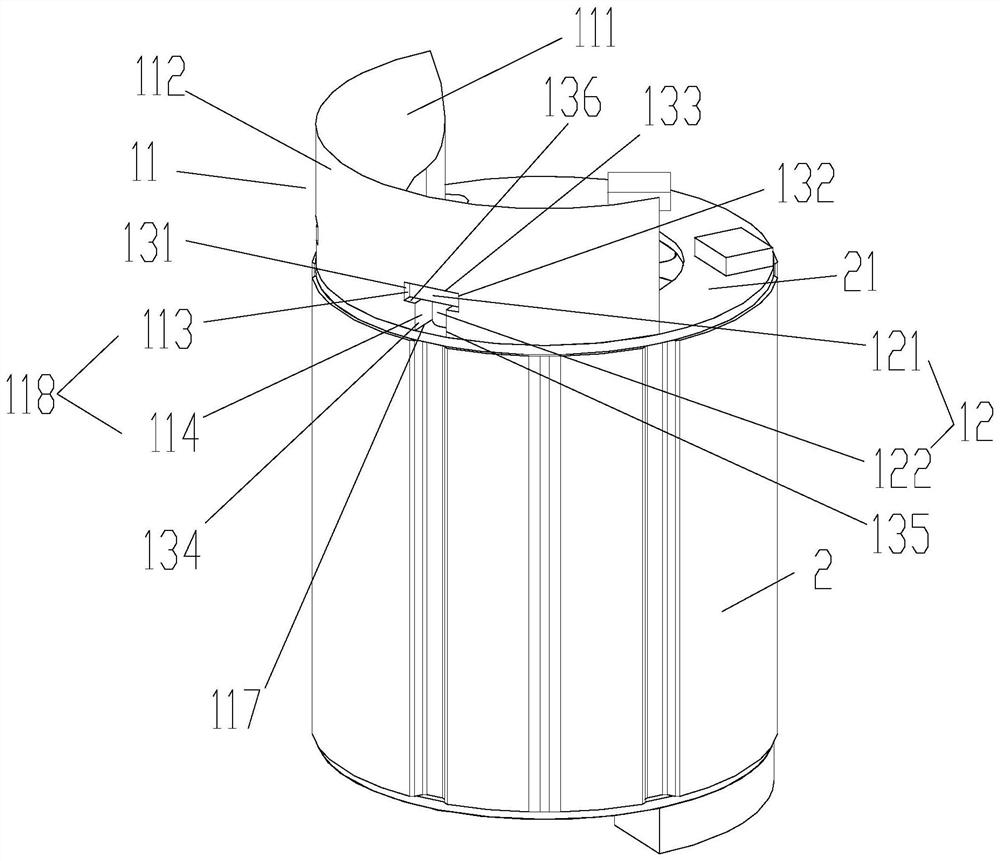

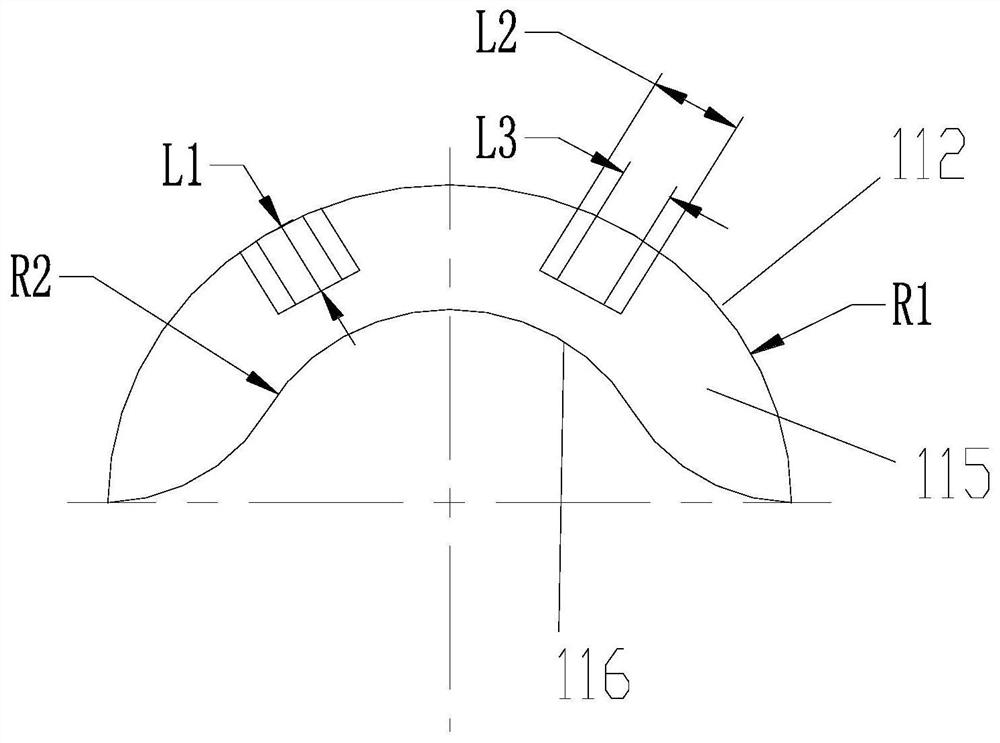

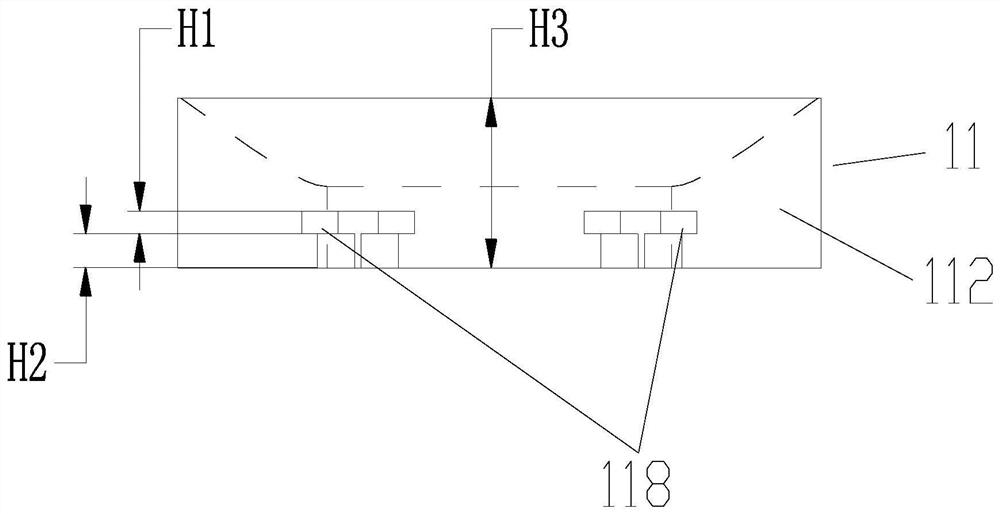

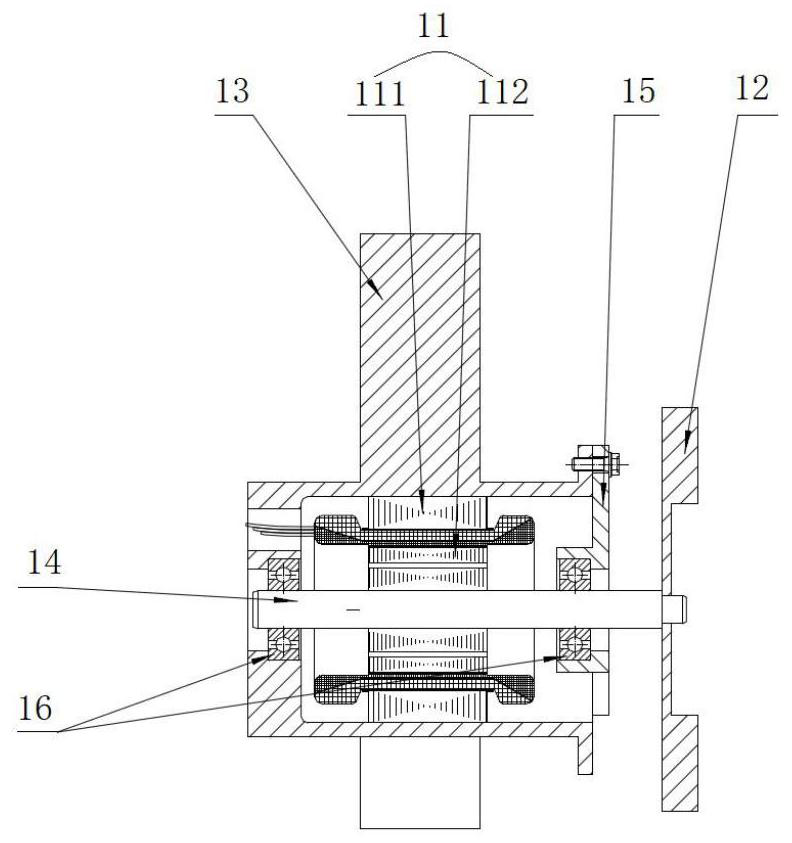

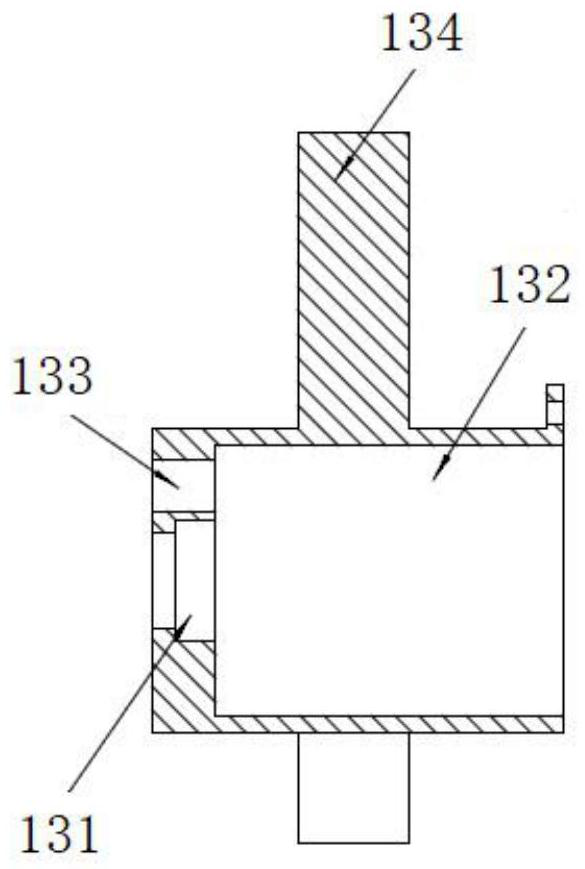

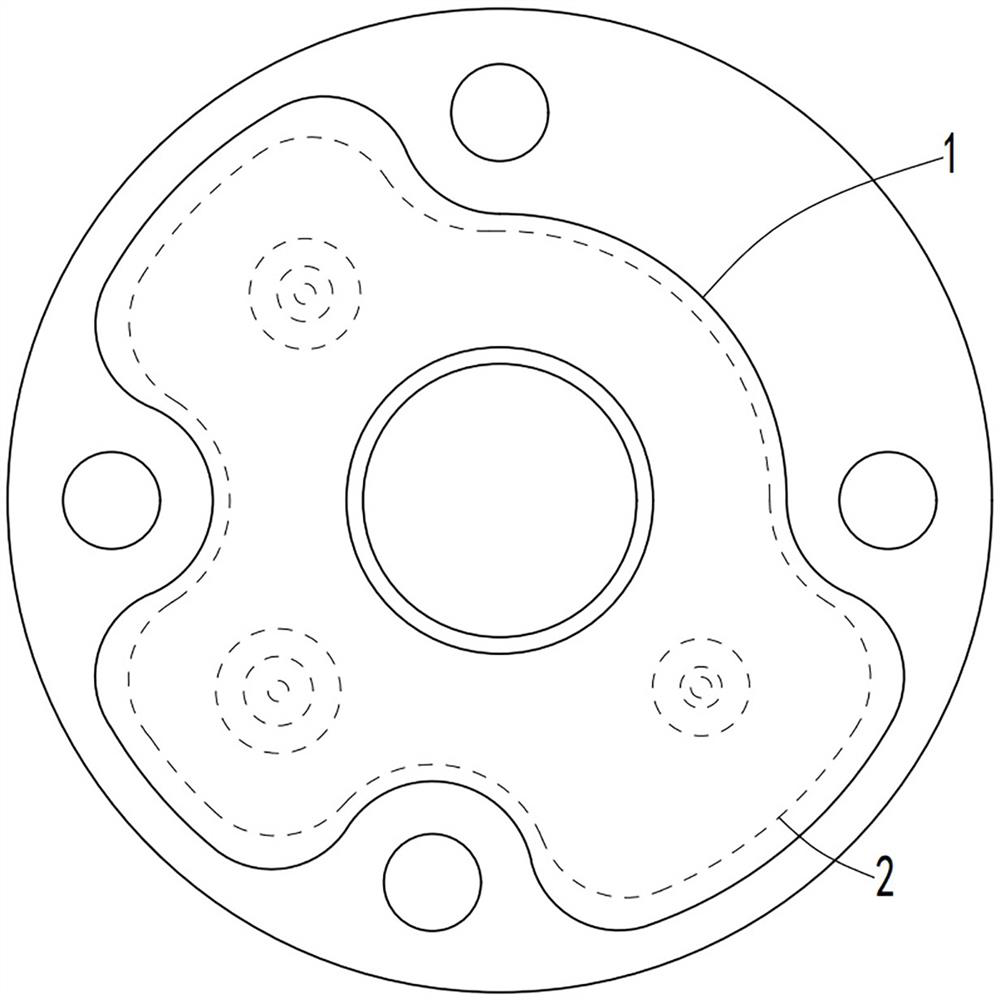

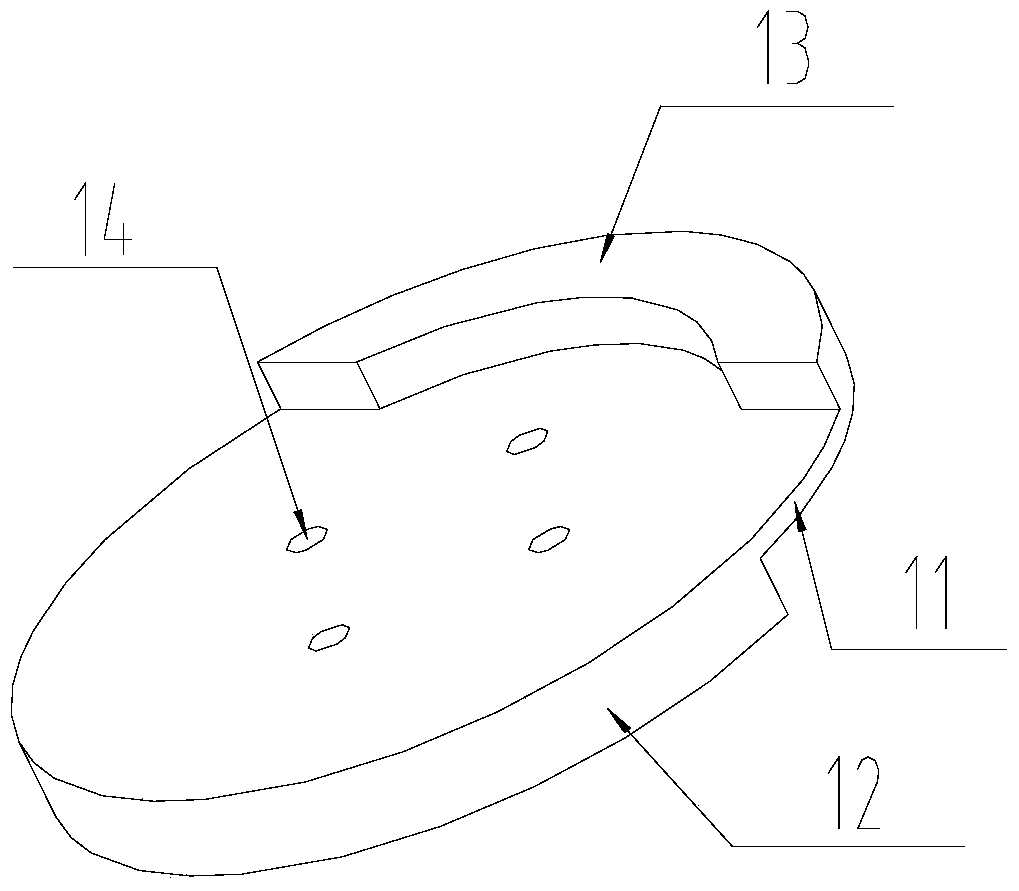

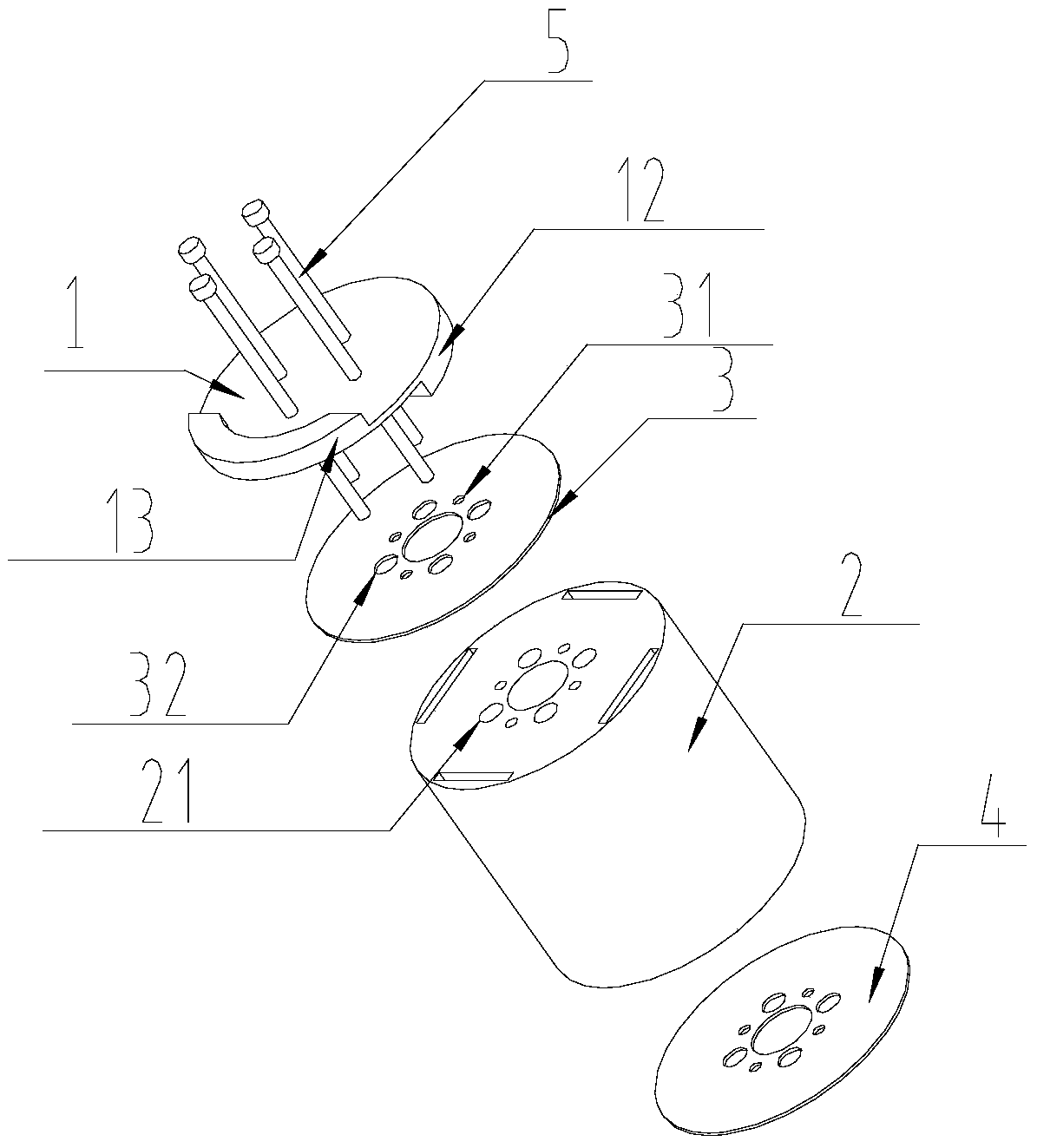

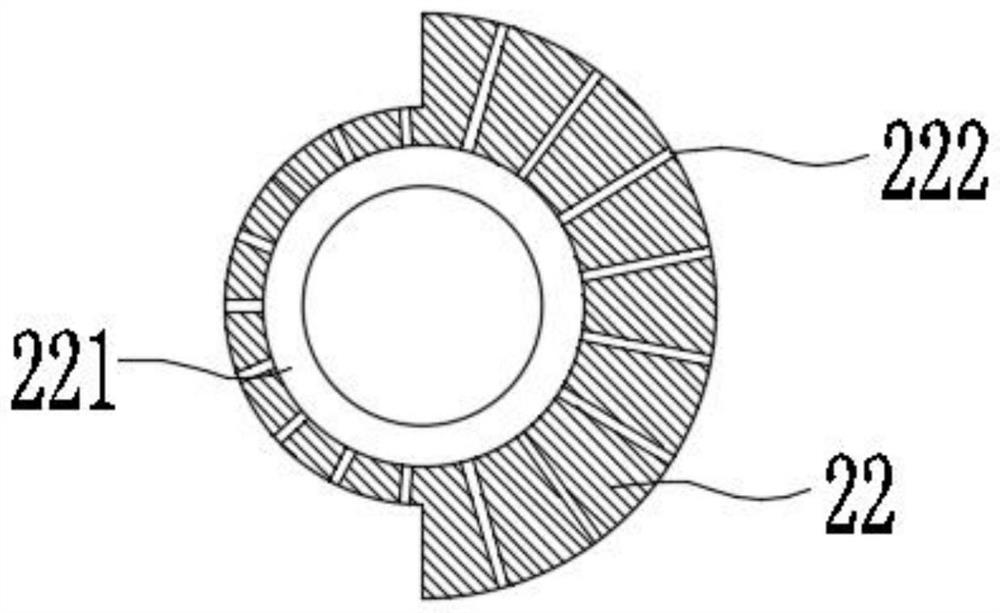

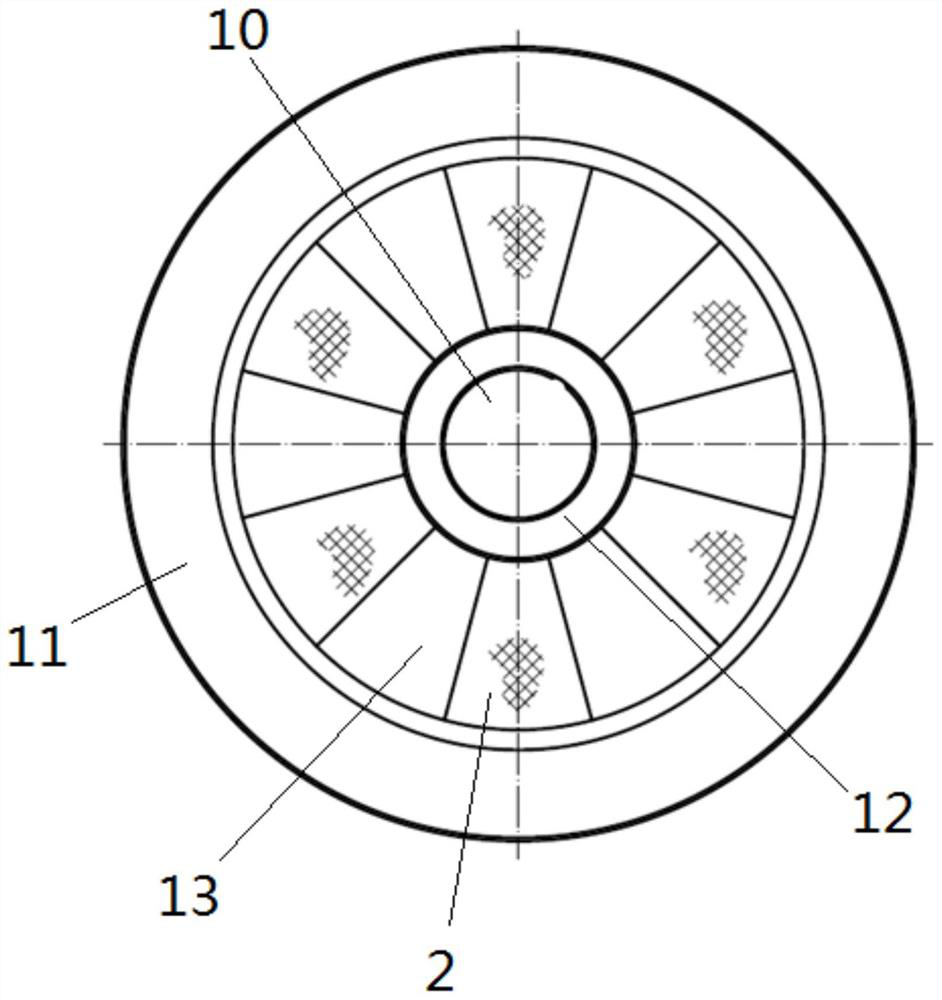

Balancing weight of rotary compressor and double-cylinder double-stage compressor with balancing weight

ActiveCN105526170ALow costVibration and Noise GuaranteeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringCircular surface

The invention provides a balancing weight (1) of a rotary compressor. The balancing weight comprises a balancing weight base plate (11), wherein the balancing weight base plate is of a flat disc shape, and comprises an upper circular surface and a lower circular surface. A balancing weight main eccentric portion (12) and a balancing weight auxiliary eccentric portion (13) are arranged on the upper circular surface and the lower circular surface respectively, and are oppositely arranged by circling the circle center of the disc-shaped balancing weight base plate (11). The balancing weight base plate (11), the balancing weight main eccentric portion (12) and the balancing weight auxiliary eccentric portion (13) are of an integrally formed structure. By the adoption of the balancing weight, only one mold needs to be opened, and the balancing weight main eccentric portion and the balancing weight auxiliary eccentric portion can be manufactured, so that compared with the cost of respective mold opening manufacturing in the prior art, the cost is greatly reduced. In addition, due to the fact that the angle between the balancing weight main eccentric portion and the balancing weight auxiliary eccentric portion is relatively fixed, the assembling process is simple, the assembling efficiency is remarkably improved, the phenomenon of assembling errors cannot exist, and the vibration noise of the compressor can be guaranteed. The invention further relates to a double-cylinder double-stage compressor with the balancing weight.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Compressor oil retaining components, rotor components, compressors and air conditioning systems

ActiveCN106014931BReduce oil discharge rateImprove the oil blocking effectPositive displacement pump componentsPositive-displacement liquid enginesBlock effectAir conditioning

Owner:GREE ELECTRIC APPLIANCES INC +1

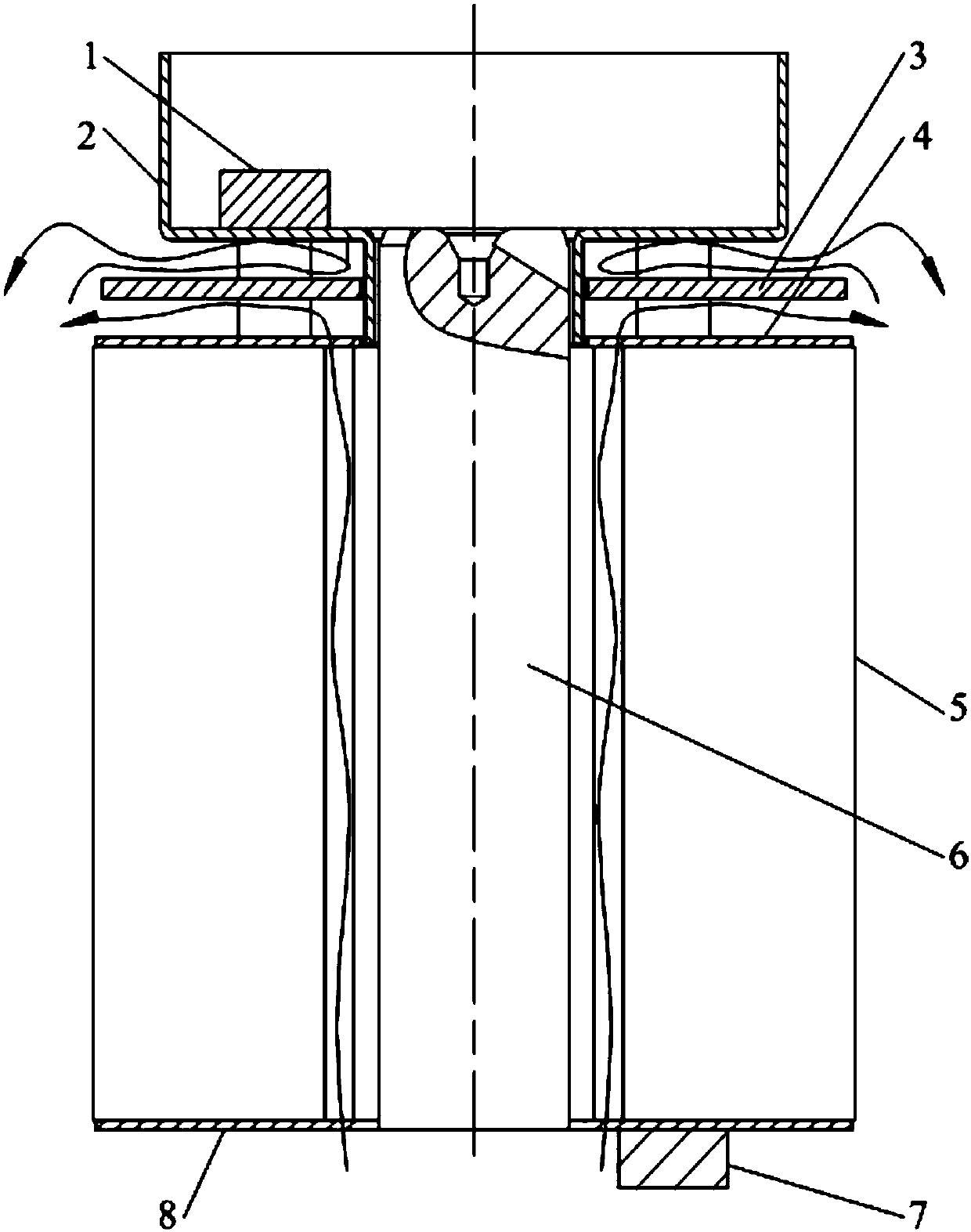

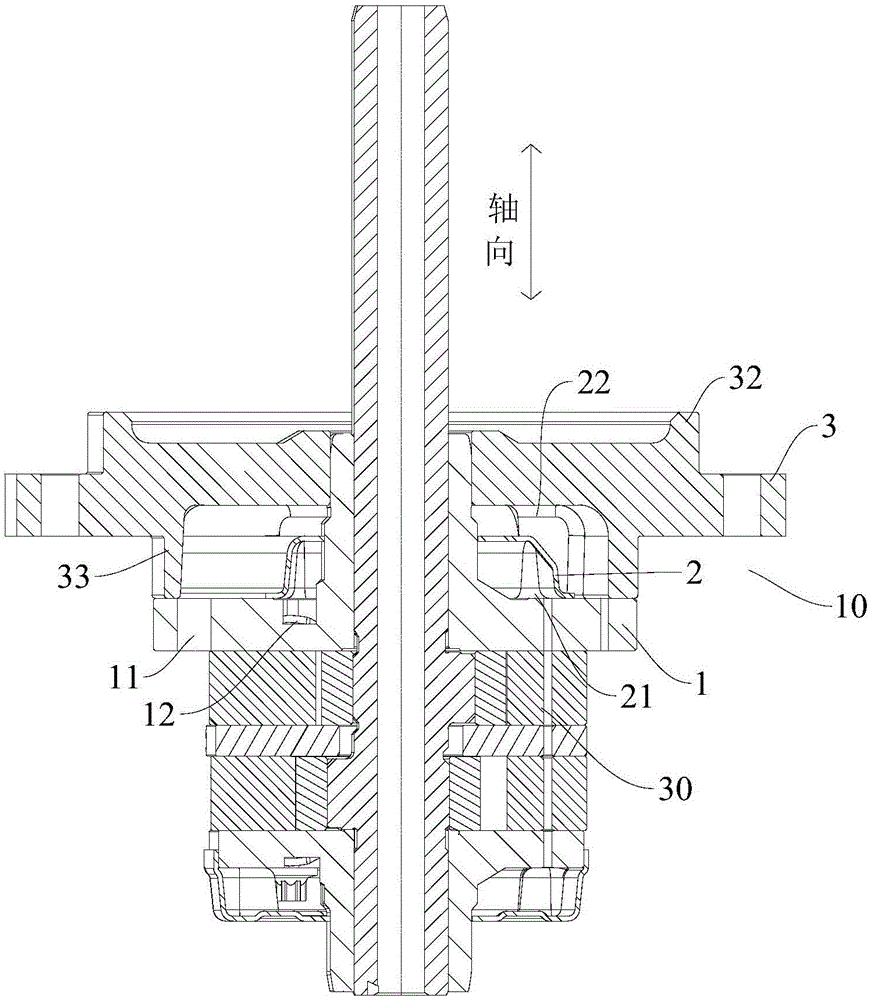

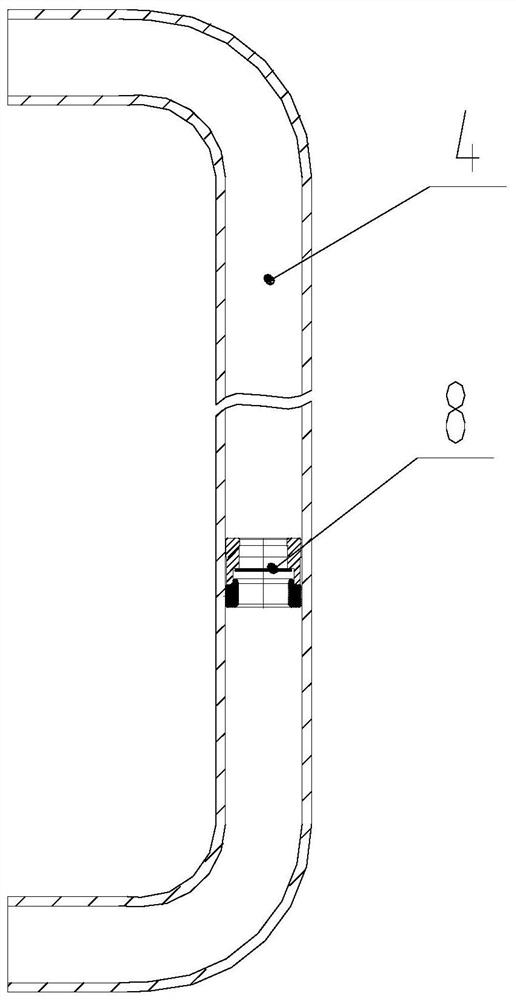

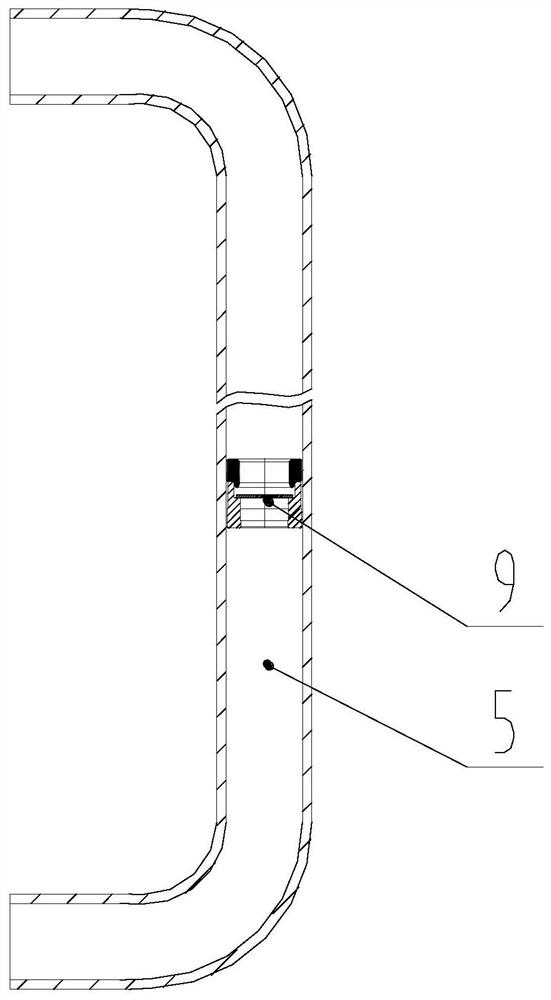

Air discharging assembly of compressor, and rotation type compressor

ActiveCN106837802AReduce oil discharge rateEnsure stabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsRotary compressorOil distribution

The present invention discloses an air discharging assembly of a compressor, and a rotation type compressor. The air discharging assembly of the compressor comprises a bearing, a silencer, a high-low pressure separation plate, and an oil distribution structure, wherein the silencer is arranged on the bearing and defines a first air discharging cavity together with the bearing; the high-low pressure separation plate defines a second air discharging cavity with the bearing and the silencer respectively; the second air discharging cavity is communicated with the first air discharging cavity; the oil distribution structure is arranged in the first air discharging cavity and / or the second air discharging cavity; an oil return hole communicated with the second air discharging cavity and an oil pool is formed in the bearing. In the air discharging assembly of the compressor, the oil distribution structure can be used for distributing oil to separate oil liquid from a coolant; separated oil liquid can gather to the oil return hole and then flows to the oil pool by the oil return hole, so that the oil liquid can be used in a cycling manner, the oil discharging rate is reduced, the stabilization of the oil level of the oil pool is ensured, and the reliability of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

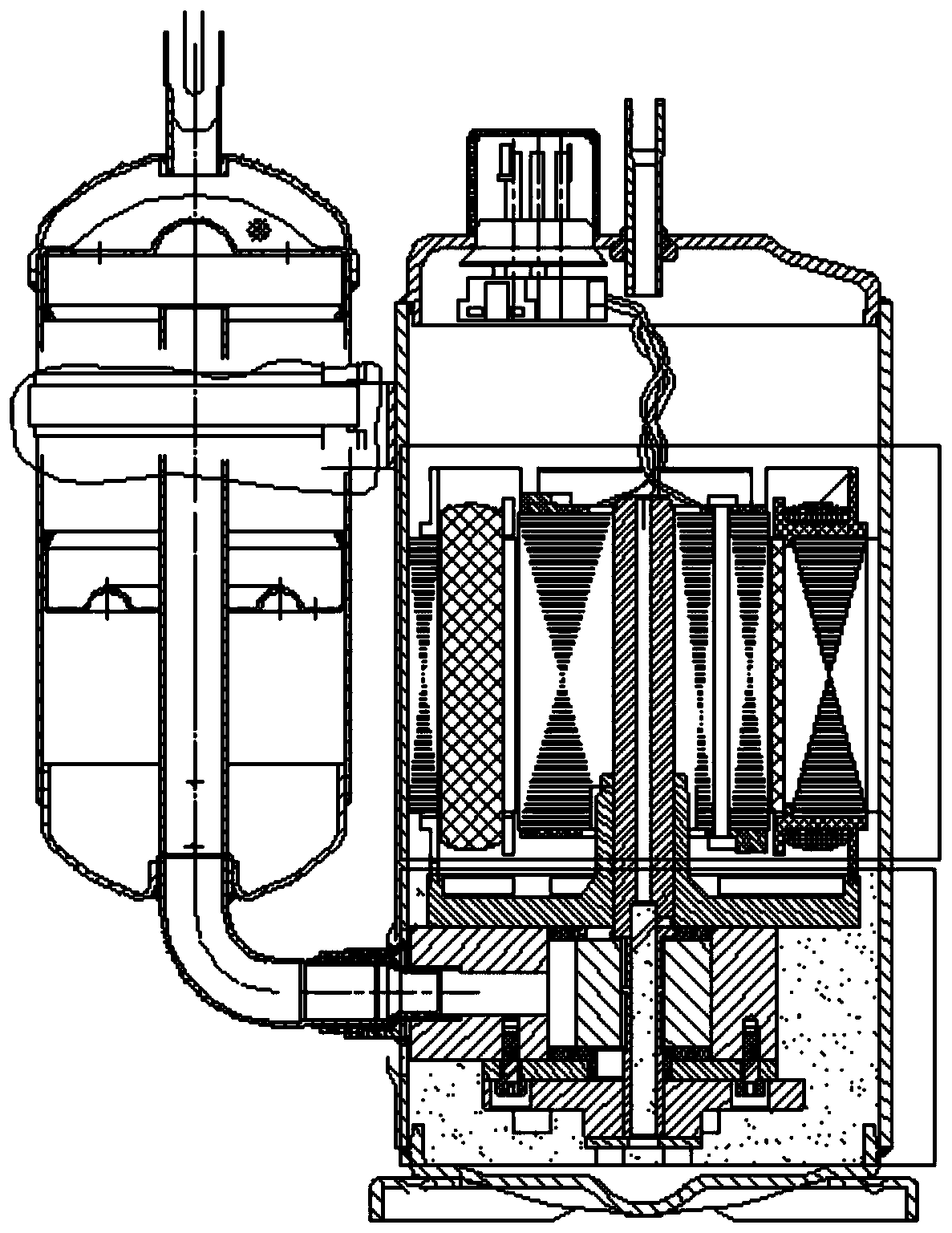

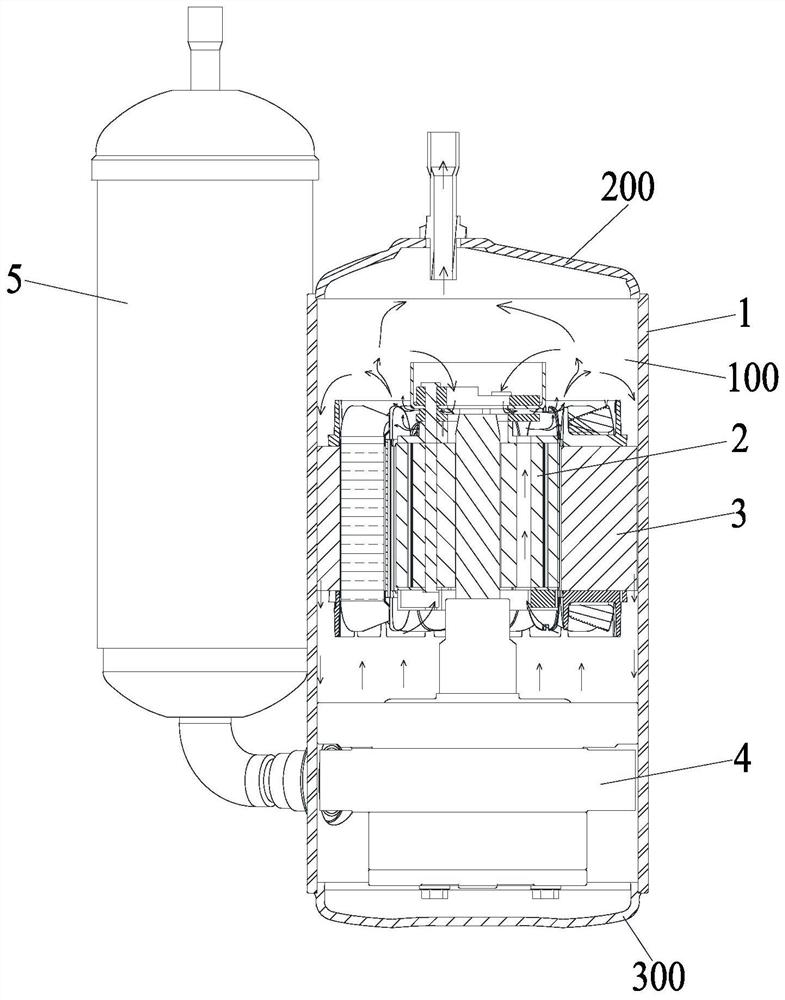

Compressor and heat exchange device

PendingCN109667756AReduce oil discharge rateAvoid dischargeRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsEngineeringMechanical engineering

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Compressor pump body and compressor

InactiveCN110966203AReduce oil discharge rateReasonable structural designSealing arrangement for pumpsRotary/oscillating piston pump componentsEngineeringMechanical engineering

The invention provides a compressor pump body. The pump body comprises a rotating shaft, a piston, a flange, a limiting plate, a cylinder and another cylinder, wherein an cylinder, a piston and a rotating shaft are arranged in the cylinder, an air suction channel is arranged on the cylinder, the limiting plate and the flange are respectively mounted on upper and lower sides of the cylinder, a first exhaust passage is arranged on a side edge of the cylinder, a cover plate for sealing the first exhaust passage is arranged on the side edge of the cylinder, the limiting plate and the flange at anupper portion of the cylinder are provided with second exhaust passages, the first exhaust channel is communicated with the second exhaust channels. The pump body solves a problem of side exhaust of the compressor pump body and prevents compressed refrigerant from being directly discharged into refrigerant oil. The compressor comprises the compressor pump body, and the compressor pump body is thecompressor pump body. Problems that side exhaust resistance is large, and compression efficiency is affected are solved, the oil spitting rate of the compressor is effectively prevented from being increased, and energy efficiency of an air-conditioning system is prevented from being affected.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

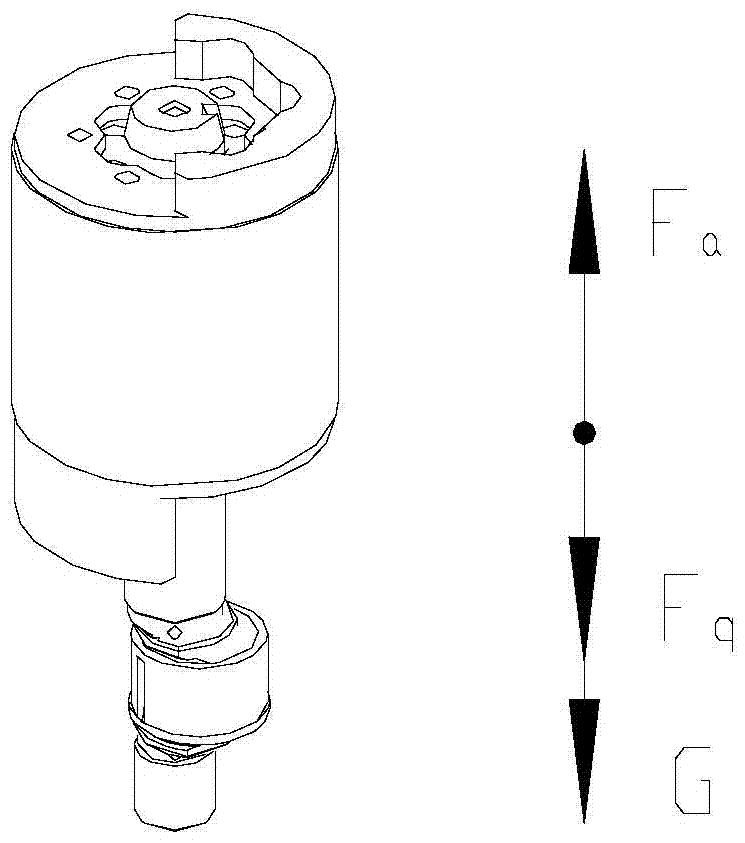

a compressor

ActiveCN105201850BPrevent movementLow efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsImpellerElectric machine

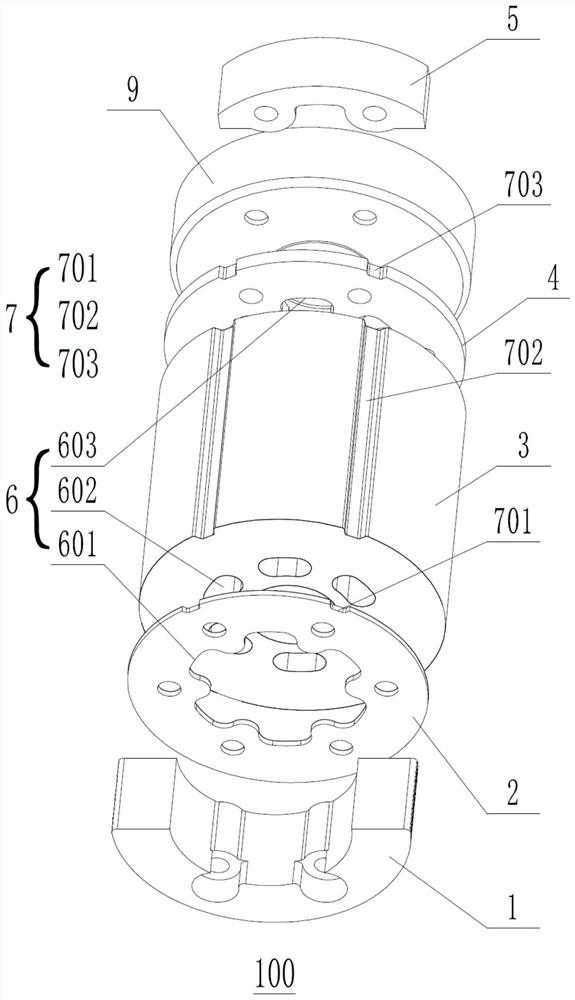

The invention provides a compressor, comprising a crankshaft (7), a motor rotor assembly and an impeller (4) or blade arranged on the upper part of the crankshaft (7). The impeller (4) or blade can rotate under the driving of the rotation of the crankshaft (7) and can produce an axial force on the crankshaft (7) during rotation, wherein the direction of the axial force is opposite to the direction of a gas force on the crankshaft and the motor rotor assembly. According to the compressor provided by the invention, displacement of the crankshaft and the motor rotor assembly can be effectively suppressed; mechanical loss of the compressor and loss of exhausting channels can be reduced; an oil discharging rate can be decreased; and reliability and service life of the compressor can be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Rotor assembly, motor and compressor

PendingCN112564342AGuarantee working reliabilityReduce oil discharge rateRotary/oscillating piston combinations for elastic fluidsMagnetic circuit rotating partsThermodynamicsElectric machine

The invention provides a rotor assembly, a motor and a compressor, the rotor assembly comprises a rotor iron core and an oil blocking part, the rotor iron core is provided with a flow channel, and theflow channel is used for an oil-gas mixture to flow in; the oil blocking part comprises a first oil blocking base and an oil blocking cap, the first oil blocking base is connected with the end face of the rotor iron core, and the end face of the side, facing the rotor iron core, of the oil blocking cap abuts against the first oil blocking base so as to block a gap between the oil blocking cap andthe first oil blocking base. The problem that in the prior art, the oil spitting rate of a compressor is too large is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

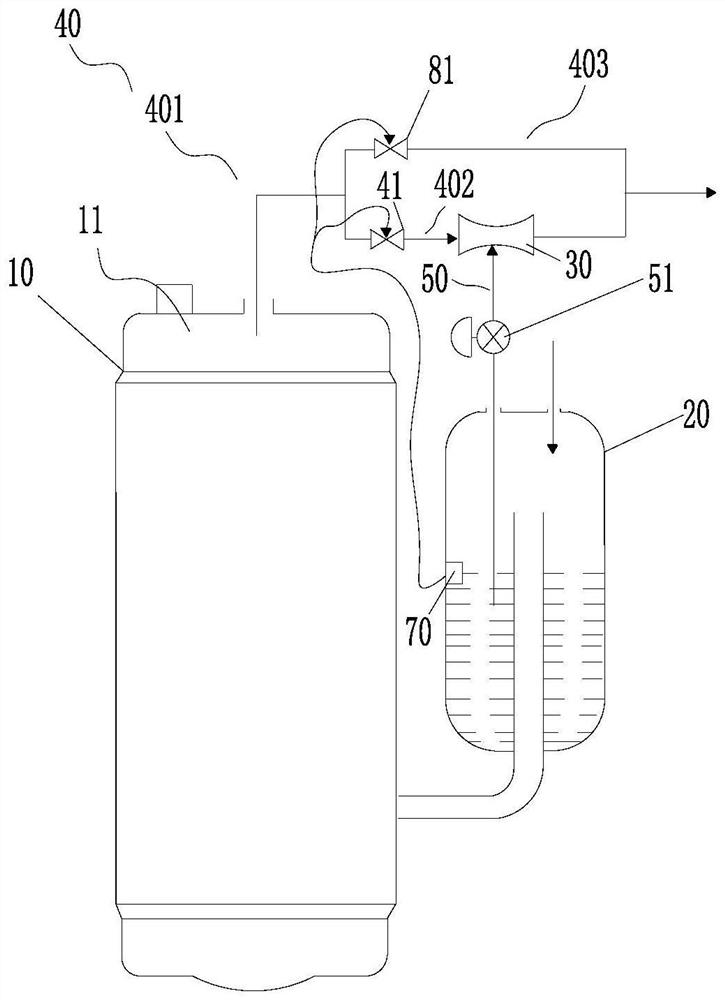

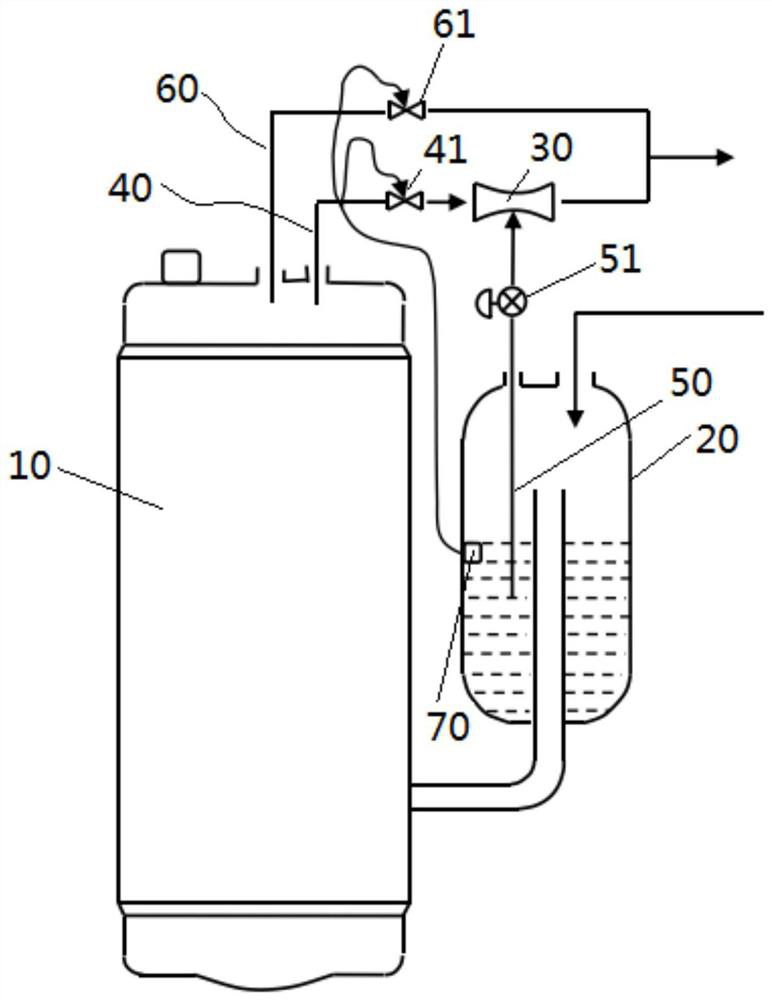

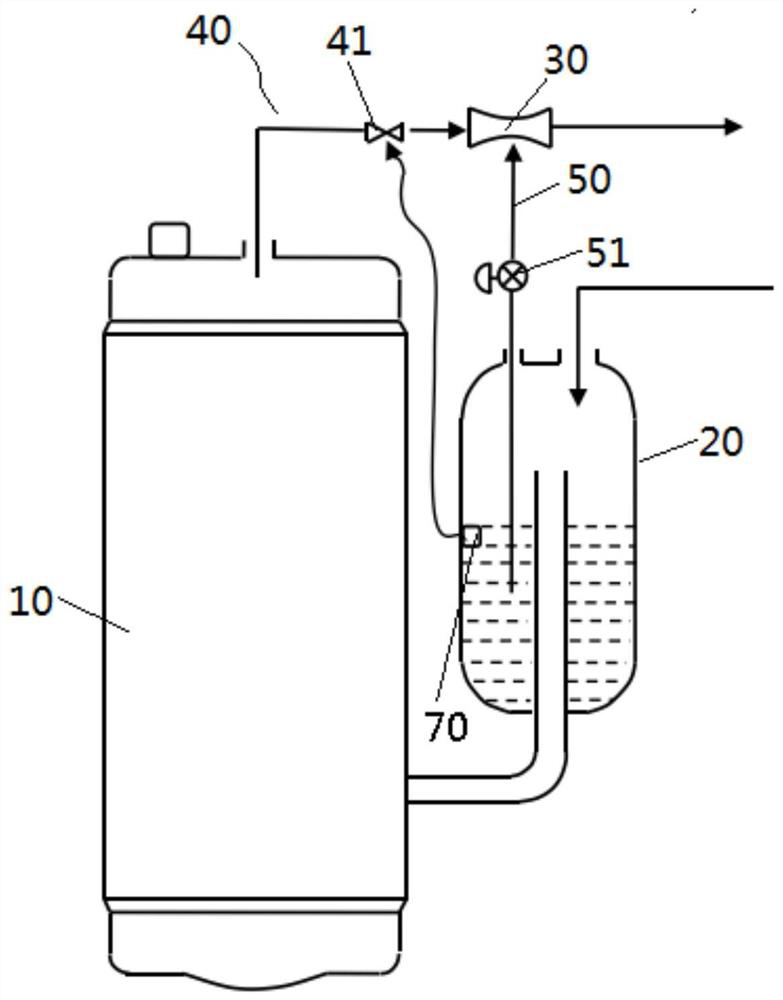

Air conditioner system, air conditioner and control method of air conditioner

InactiveCN112013558AControl suction drynessCases to prevent liquid hammerCompressorCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention provides an air conditioner system, an air conditioner and a control method of the air conditioner. The air conditioner system comprises a compressor, a gas-liquid separator and an ejection device, wherein the compressor is provided with an exhaust cavity; an exhaust port of the gas-liquid separator communicates with a gas suction port of the compressor; a jet flow inlet of the ejection device communicates with the exhaust cavity, a receiving chamber inlet of the ejection device communicates with the gas-liquid separator, and a jet flow outlet of the ejection device communicateswith a heat exchanger. When the liquid level in the gas-liquid separator reaches the preset height, the ejection device can suck the liquid level in the gas-liquid separator into the ejection device through the receiving chamber inlet.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

An air conditioner low temperature heating start control method, device and air conditioner

ActiveCN110425700BHeating fastReduce oil discharge rateMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsElectronic expansion valve

A method and a device for controlling low-temperature heating startup of an air conditioner, an air conditioner, and a storage medium. The method comprises: acquiring an ambient temperature; if the ambient temperature is less than a set temperature, sending a first startup instruction to a fan of an outdoor unit, and controlling the fan to start up and run at the highest rotation speed; after a first duration, sending a second startup instruction to a compressor to control the compressor to start up; and after a fifth duration, turning on an electronic expansion valve of the outdoor unit. The method for controlling low-temperature heating startup of an air conditioner can quickly establish the degree of superheat of a system while ensuring a low amount of oil discharged from the system, thereby improving the heat exchange effect, enabling the compressor to be heated quickly, reducing the amount of oil discharged, ensuring the reliability of the system, and achieving the quick heating for low-temperature heating startup of the air conditioner.

Owner:NINGBO AUX ELECTRIC

Balance weight structure, motor and compressor

ActiveCN113037004BReduce breakageReduce oil discharge rateMechanical energy handlingClassical mechanicsElectric machinery

The invention provides a balance block structure, a motor and a compressor. The balance weight structure includes: a balance weight body, the balance weight body has a first end and a second end oppositely arranged; the second end of the balance weight body is used to connect with the rotor; the balance weight body has a windward side and a leeward side, and the leeward side A mounting groove is provided, and the balance weight body is connected with the rotor through a fastener inserted in the mounting groove. The balance weight structure of the present invention solves the problem of wind wear loss of the compressor motor caused by the balance weight in the prior art.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

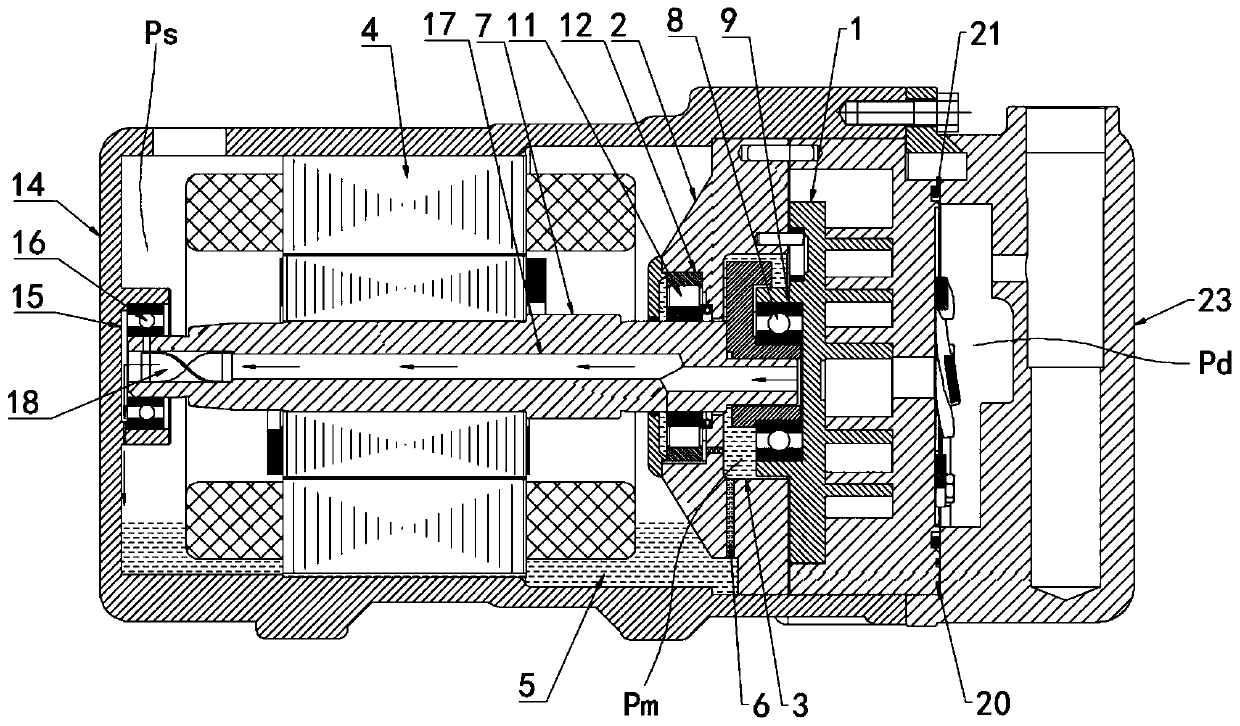

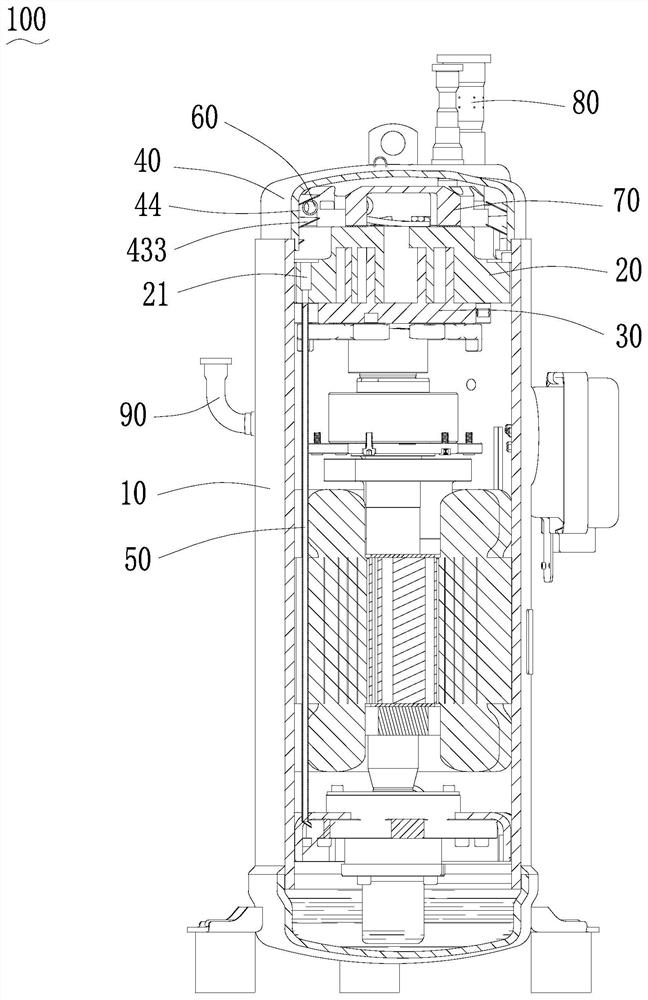

Oil way structure and scroll compressor

PendingCN110701048AImprove reliabilityReduce oil discharge rateRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsElectric machineryEngineering

The invention provides an oil way structure and a scroll compressor. A dynamic scroll disc, a support frame structure and a motor assembly are included. A backpressure cavity is formed between the dynamic scroll disc and the support frame structure. An oil storage area is arranged in a cavity where the motor assembly is located. The support frame structure is provided with a first oil introducingchannel. The oil storage area communicates with the backpressure cavity through the first oil introducing channel. The first oil introducing channel is used for introducing oil in the oil storage areainto the backpressure cavity. According to the oil way structure and the scroll compressor, the dynamic scroll disc, a static scroll disc and a bearing part can all achieve oil film lubrication, friction power consumption is lowered, and reliability of the compressor is improved. The oil introducing channel is simple in structure, high and low pressure throttling is not needed, and the risk of high and low pressure leakage does not exist. An oil way channel and a gas way are relatively separated, the oil discharge rate of the compressor can be lowered, and a system heat exchange effect is improved. A circulation oil way is formed, recycling of a lubricant in the compressor can be facilitated better, part machining and design are simplified, the process is simple, and safety and reliability are achieved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Oil separation device capable of reducing oil discharge rate and rotary compressor

ActiveCN114294232AImprove separation efficiencyGuaranteed reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsThermodynamicsOil separation

An oil separation device for reducing oil discharge rate and a rotary compressor, the oil separation device comprises a guide part for changing airflow direction and a fixing part connected with a silencer, the guide part is composed of an arc-shaped surface and an extending flange, the arc-shaped surface extends towards the upper part of the silencer exhaust hole along the periphery of the silencer exhaust hole, and the extending flange is arranged on the arc-shaped surface. The extending flange is connected with the edge of the arc-shaped surface; the fixing part is used for connecting the arc-shaped surface and the extending flange with the outer surface of the silencer; and air flow exhausted from the silencer exhaust hole is horizontally exhausted through a channel formed by the arc-shaped surface and the extending flange. The rotary compressor is provided with the oil separation device, so that the air flow direction of a refrigerant is changed, the oil-gas separation efficiency is improved, and the oil discharge rate is lower; and during unsteady-state operation such as cold start, the amount of lubricating oil in the oil pool can be ensured, so that the mixed viscosity of the refrigerant / lubricating oil in the oil pool and the reliability of the compressor are ensured. The oil separation device does not affect the silencing effect and increase the power consumption of the compressor.

Owner:XI AN JIAOTONG UNIV

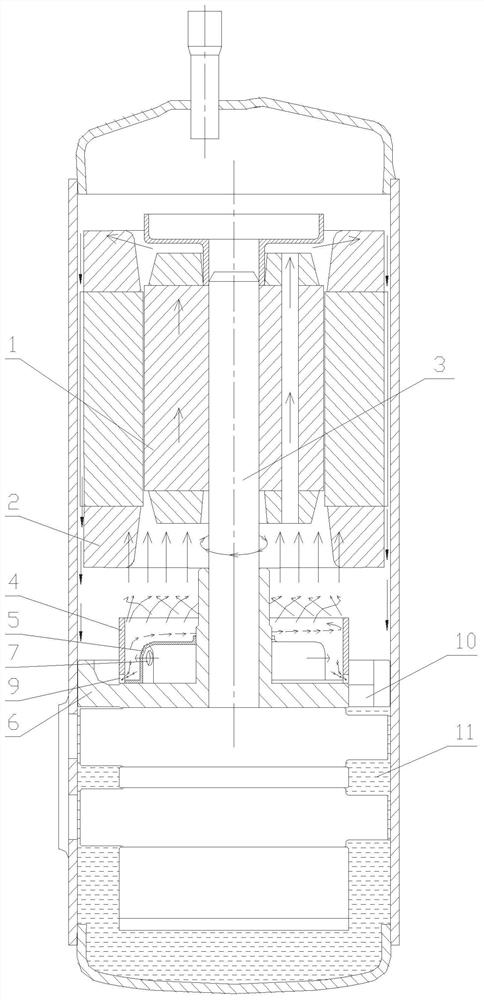

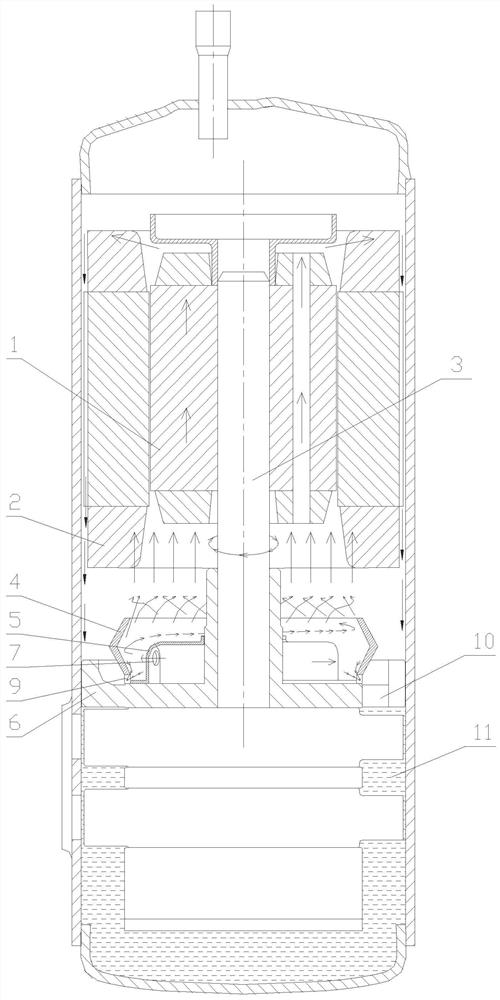

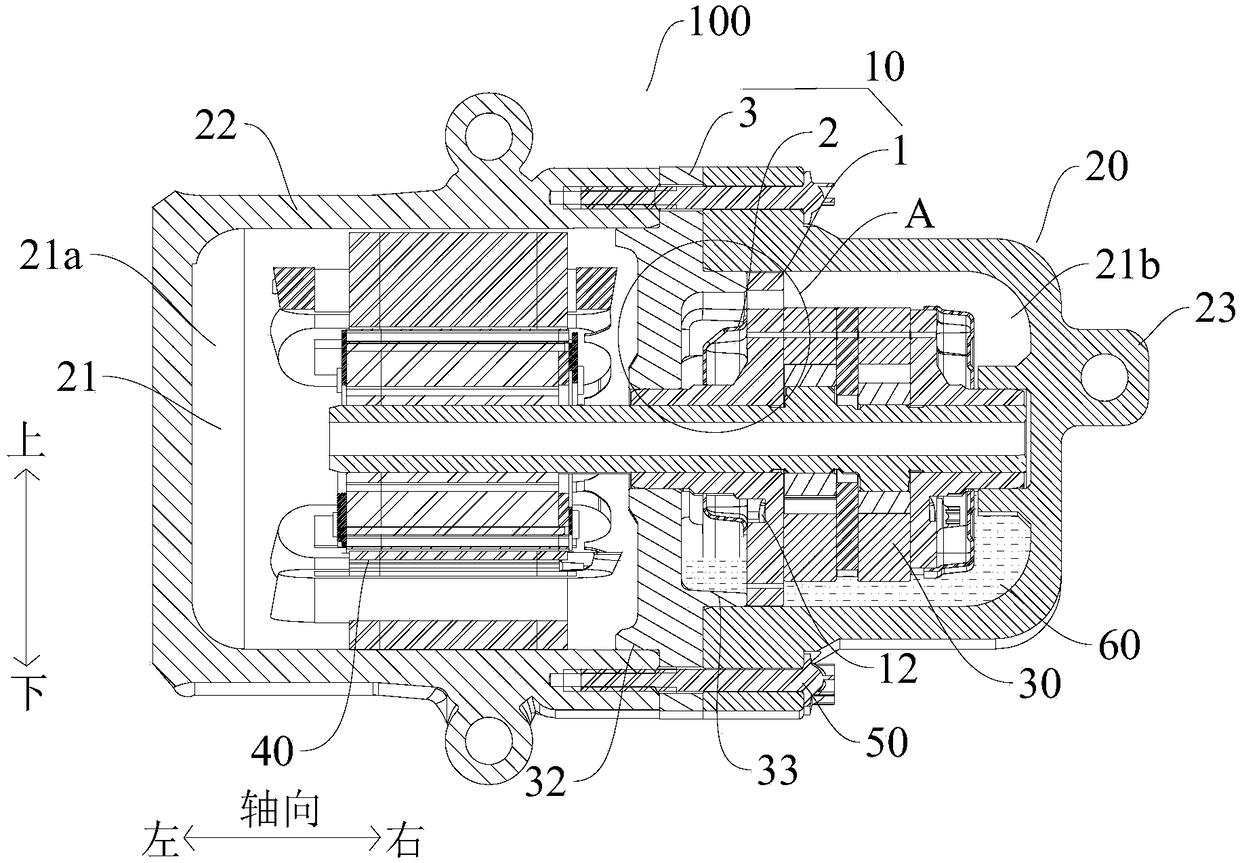

compressor

ActiveCN105782053BReduce oil discharge rateReduce power consumptionRotary/oscillating piston pump componentsLiquid fuel engine componentsMechanical engineeringThroughput

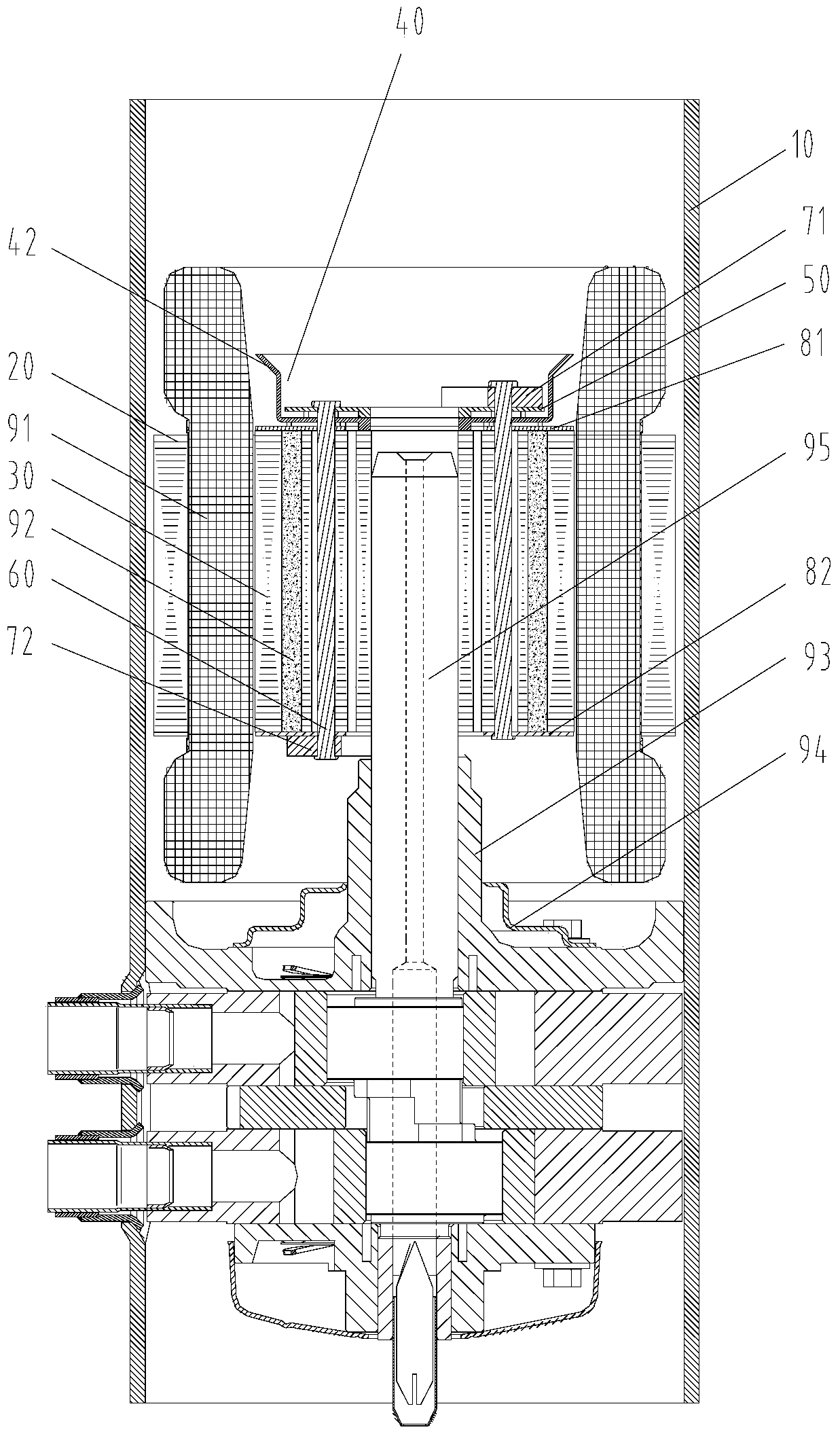

The invention provides a compressor comprising a shell, a stator core, a rotor core and a first baffle, wherein the stator core and the rotor core are arranged in the shell; the stator core is arranged around the rotor core; circulating holes formed along the axial direction of the rotor core are formed in the rotor core; and the first baffle comprises a bottom plate part and an oil retaining side edge arranged at the upper side of the bottom plate part, and the first baffle is opposite to the upper end surface of the rotor core, so that lubricating oil carried by a refrigerant comes into collision with the oil retaining side edge to form oil drops falling back below the rotor core after the refrigerant flowing out of the circulating holes passes through the bottom plate part. By using the compressor, the refrigerant can return from the upside to the downside of a motor of the compressor, so that the stroke of the refrigerant is increased; in addition, due to the adoption of the design of the non-swirl baffle located above the rotor core, an extremely good oil retaining effect is taken while no wind resistance is generated, and the condition that the lubricating oil is discharged from the compressor is avoided, so that the oil throughput rate of the compressor is effectively reduced, the performance of a unit is improved, and the power consumption of the compressor is reduced.

Owner:GREE ELECTRIC APPLIANCES INC +1

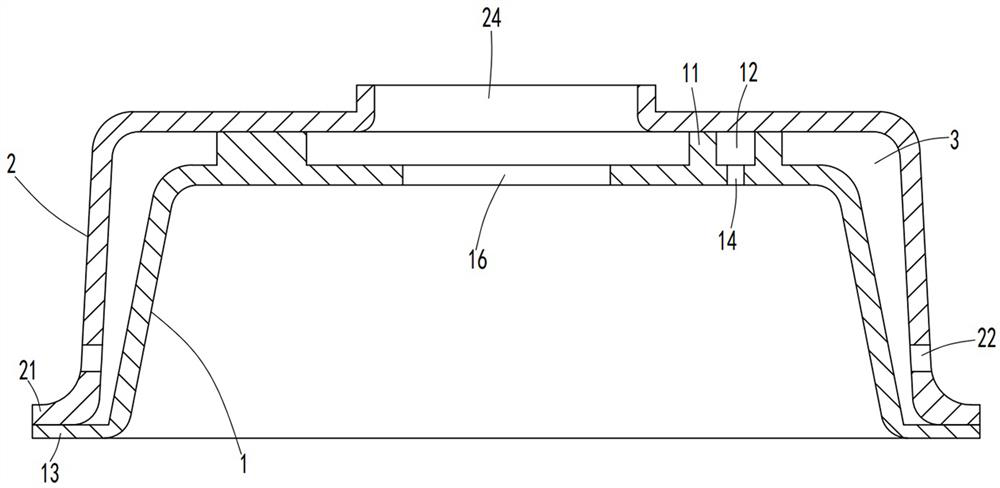

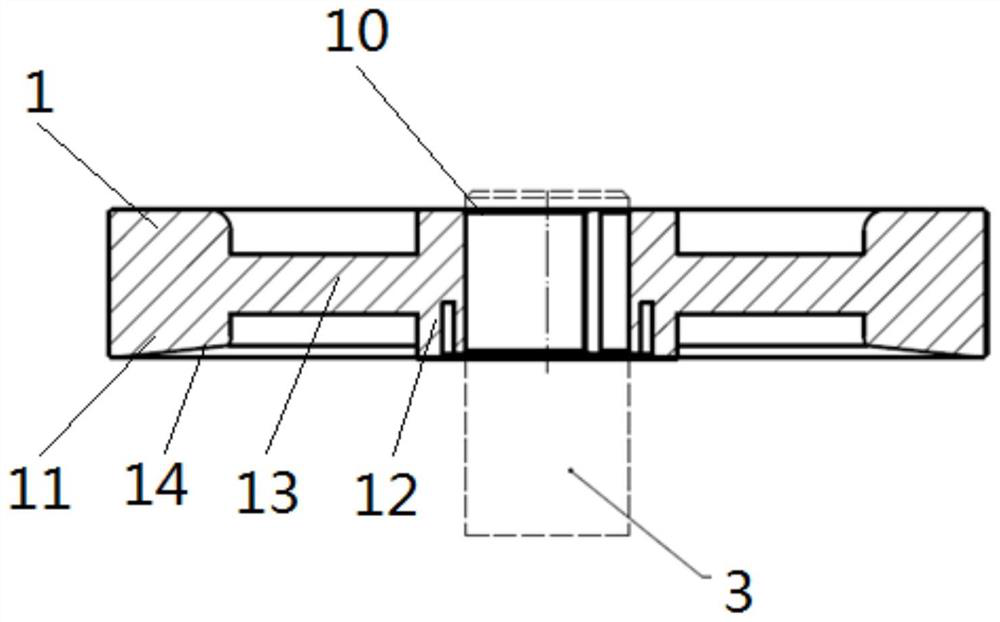

Compressor upper cover and compressor

ActiveCN112283103AReduce noiseReduce oil discharge rateRotary piston pumpsRotary piston liquid enginesPhysicsLubrication

The invention relates to a compressor and a compressor upper cover. The compressor upper cover comprises a top wall and side walls, the top wall and the side walls are connected in an intersecting mode and define an accommodating cavity, and a guide groove is formed in the inner surfaces, facing the accommodating cavity, of the side walls; wherein the guide groove is provided with a head section and a tail section which communicate with each other, and the head section is close to the top wall and is bent; and the tail section is far away from the top wall, and the tail section is obliquely arranged in the direction far away from the top wall in the direction parallel to the top wall. The bent guide groove is formed in the inner side of the compressor upper cover, so that gas flowing to the compressor upper cover is guided to flow along the guide groove in a bent mode, impact between gas flow and the compressor upper cover is relieved, and noise of the compressor is further reduced. Moreover, when the air flow flows from the head section to the tail section in the guide groove from top to bottom, oil liquid doped in the air flow can be retained on the inner wall of the guide groove, and finally the retained oil liquid flows out from the obliquely downward tail section, so that the oil liquid in the air flow can be separated and recycled, the oil spitting rate of the compressoris reduced, and reliable lubrication of the compressor is guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Oil supply assembly, compressor and control method

PendingCN113833660AWide speed rangeReduce oil discharge rateRotary/oscillating piston combinations for elastic fluidsPump controlElectric machineryAutomotive engineering

The invention provides an oil supply assembly, a compressor and a control method. The oil supply assembly comprises a fan, and the fan is configured to adjust the pressure difference between the two ends of a crankshaft center oil hole according to the real-time rotating speed of a compressor motor so that the crankshaft center oil hole can be normally oiled when the compressor motor runs. The technical problems that the rotating speed of a fan of an oil supply assembly of a compressor is consistent with the rotating speed of a crankshaft of the compressor, the oil supply amount is limited by the rotating speed of a crankshaft, and consequently oil supply is not smooth during operation of the compressor are solved, the rotating speed range of the compressor motor is widened, and on the other hand, the oil spitting rate of the compressor can be reduced.

Owner:ZHUHAI LANDA COMPRESSOR +1

Compressor discharge assemblies and rotary compressors

ActiveCN106837802BReduce oil discharge rateImprove reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsOil distributionDischarge rate

Owner:GUANGDONG MEIZHI COMPRESSOR

Four-way reversing valve, air conditioning system and control method of four-way reversing valve

InactiveCN113310253APrevent backflowChange directionMechanical apparatusEfficient regulation technologiesRefrigerantElectrical and Electronics engineering

The invention relates to the technical field of four-way reversing valves, in particular to a four-way reversing valve, an air conditioning system and a control method of the four-way reversing valve. The air conditioning system comprises the four-way reversing valve, a compressor, an indoor unit and an outdoor unit, wherein the four-way reversing valve comprises a main valve body with a first inner cavity and a valve element movably arranged in the first inner cavity; a first valve port, a second valve port, a third valve port and a fourth valve port which are communicated with the first inner cavity are formed in the main valve body; the first valve port is communicated with an air suction port of the compressor; the second valve port is communicated with an exhaust port of the compressor; the third valve port is communicated with the indoor unit; the fourth valve port is communicated with the outdoor unit; the valve element has a first position, a second position and a third position in the moving process; when the valve element is located at the first position or the second position, all the valve ports are communicated differently; and when the valve element is located at the third position, the first valve port and the second valve port are disconnected with the third valve port, and the first valve port and the second valve port are disconnected with the fourth valve port, so that refrigerants in the indoor unit and the outdoor unit can be prevented from flowing back to the compressor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

A pump body muffler, pump body assembly and compressor

ActiveCN112196801BImprove the noise reduction effectImprove comfortRotary/oscillating piston pump componentsLiquid fuel engine componentsResonant cavityNoise

The present invention relates to the technical field of compressors, in particular to a pump muffler, a pump body assembly and a compressor. The pump muffler includes an inner muffler cover connected with the pump body assembly, and is sheathed on the inner muffler cover. The outer layer anechoic cover, the gas-liquid separation chamber is formed between the inner layer anechoic cover and the outer layer anechoic cover, the top surface of the inner layer anechoic cover facing the side of the outer layer anechoic cover is provided with a plurality of hollow The inner resonator, the end of the inner resonator is in contact with the outer muffler so that the inside of the inner resonator forms a resonant cavity expansion chamber, and the resonance frequency of the resonant cavity expansion chamber inside the multiple inner resonators different. The resonant frequency of each expansion chamber of the resonant cavity in the present invention is different, so that the noise of different specific frequencies can be eliminated, the noise reduction effect of the muffler is improved, and the compressor and the electrical appliances using the compressor are prevented from causing damage to the acoustic environment in people's lives. , improve the comfort of the compressor and the electrical appliances using the compressor, and expand its application range.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Balance weight of a rotary compressor and a two-cylinder two-stage compressor having the same

ActiveCN105526170BLow costVibration and Noise GuaranteeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringCircular surface

The invention provides a balancing weight (1) of a rotary compressor. The balancing weight comprises a balancing weight base plate (11), wherein the balancing weight base plate is of a flat disc shape, and comprises an upper circular surface and a lower circular surface. A balancing weight main eccentric portion (12) and a balancing weight auxiliary eccentric portion (13) are arranged on the upper circular surface and the lower circular surface respectively, and are oppositely arranged by circling the circle center of the disc-shaped balancing weight base plate (11). The balancing weight base plate (11), the balancing weight main eccentric portion (12) and the balancing weight auxiliary eccentric portion (13) are of an integrally formed structure. By the adoption of the balancing weight, only one mold needs to be opened, and the balancing weight main eccentric portion and the balancing weight auxiliary eccentric portion can be manufactured, so that compared with the cost of respective mold opening manufacturing in the prior art, the cost is greatly reduced. In addition, due to the fact that the angle between the balancing weight main eccentric portion and the balancing weight auxiliary eccentric portion is relatively fixed, the assembling process is simple, the assembling efficiency is remarkably improved, the phenomenon of assembling errors cannot exist, and the vibration noise of the compressor can be guaranteed. The invention further relates to a double-cylinder double-stage compressor with the balancing weight.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

compressor, air conditioner

ActiveCN110863990BReduce oil discharge rateAvoid oil shortageRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigerantMechanical engineering

The present application provides a compressor and an air conditioner, including a housing and a pump body assembly. A partition is provided in the housing to isolate the interior of the housing into a first chamber and a second chamber. The pump body assembly is located in the first chamber , the wall of the second chamber is provided with an exhaust channel, the compressor also includes a first communication pipe and a second communication pipe, the first communication pipe and the second communication pipe respectively communicate the first chamber with the second chamber, the second One end of a connecting pipe set on the second chamber is set at a non-zero angle to the exhaust passage, the refrigerant and oil discharged from the pump body assembly enter the second chamber through the first connecting pipe, and the refrigerant passes through the exhaust passage At least a part of the oil flows into the first chamber through the second connecting pipe, which can effectively reduce the oil discharge rate of the compressor, prevent the bottom of the compressor from lack of oil, and prevent the pump body components from being worn due to lack of oil.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Compressor and air conditioner with same

ActiveCN113700650AImprove oil separation abilityReduce oil discharge rateRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention provides a compressor and an air conditioner with the same. The compressor comprises a pump body assembly and a rotating shaft assembly, the pump body assembly comprises a compression structure, and the compression structure is provided with an exhaust port; and a separation cavity is formed in the rotating shaft assembly, the exhaust port communicates with the separation cavity, and the separation cavity is used for carrying out oil-gas separation on fluid discharged out of the exhaust port. According to the compressor and the air conditioner with the same, the oil spitting rate of the compressor can be effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

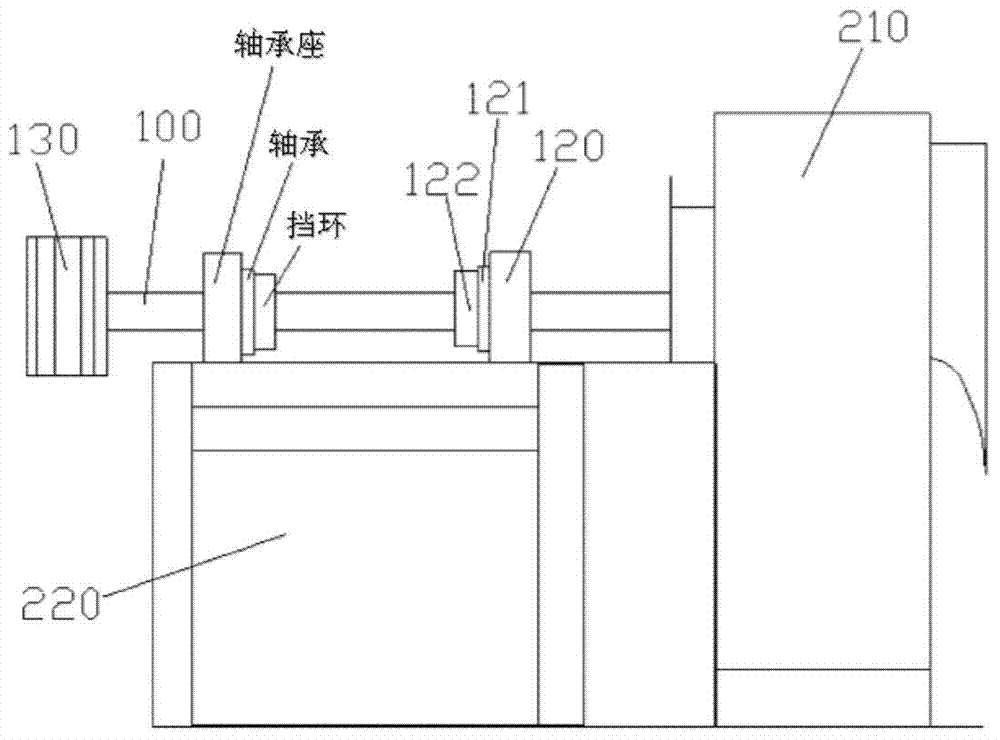

Rotary fluid machine

PendingCN114087177AIncrease deflectionEasy to operateRotary piston pumpsRotary piston liquid enginesFriction lossElectric machinery

The invention provides a rotary fluid machine which comprises a motor, a pump body assembly and a crankshaft support; the pump body assembly comprises a crankshaft, an air cylinder, a first bearing and a second bearing; one end of the crankshaft penetrates through the air cylinder, the first bearing and the second bearing and can support the crankshaft, and the other end of the crankshaft penetrates through the motor; a crankshaft support is further arranged on a part of the shaft section, extending out of the motor, of the crankshaft; the radial outer end of the crankshaft support is fixed; a shaft hole is formed in the radial inner side of the crankshaft support; and the other end of the crankshaft penetrates through the shaft hole and is supported on the crankshaft support. The crankshaft support is converted into a bridge structure from a cantilever beam structure and supports the crankshaft to operate together with the upper flange and the lower flange, so that the compressor operates more stably, the stress deformation of a crankshaft shaft system after the rotating speed of the compressor is increased is greatly reduced, the bending deformation of the crankshaft is improved, the friction loss of the compressor is reduced, the failure of compressor parts is avoided, and the reliability of the compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com