Pump body silencer, pump body assembly and compressor

A muffler and pump body technology, which is applied in the field of compressors, can solve the problems of wide operating range, widened gas pulsation and excitation range, and difficulty in dealing with gas pulsation, so as to achieve the effects of expanding the application range, ensuring good lubrication, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

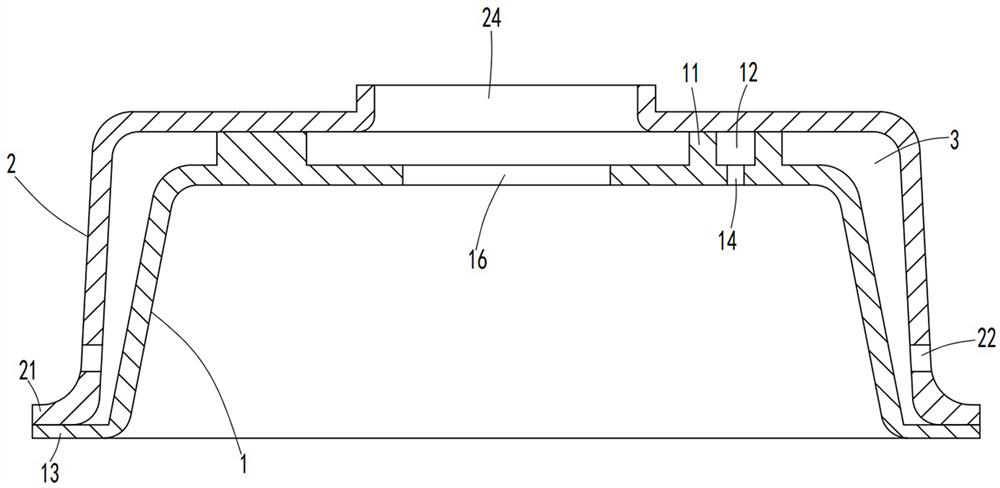

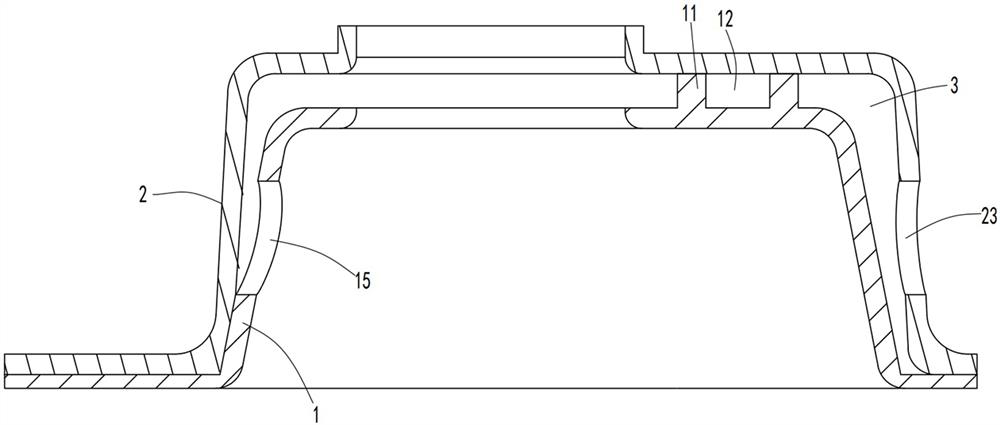

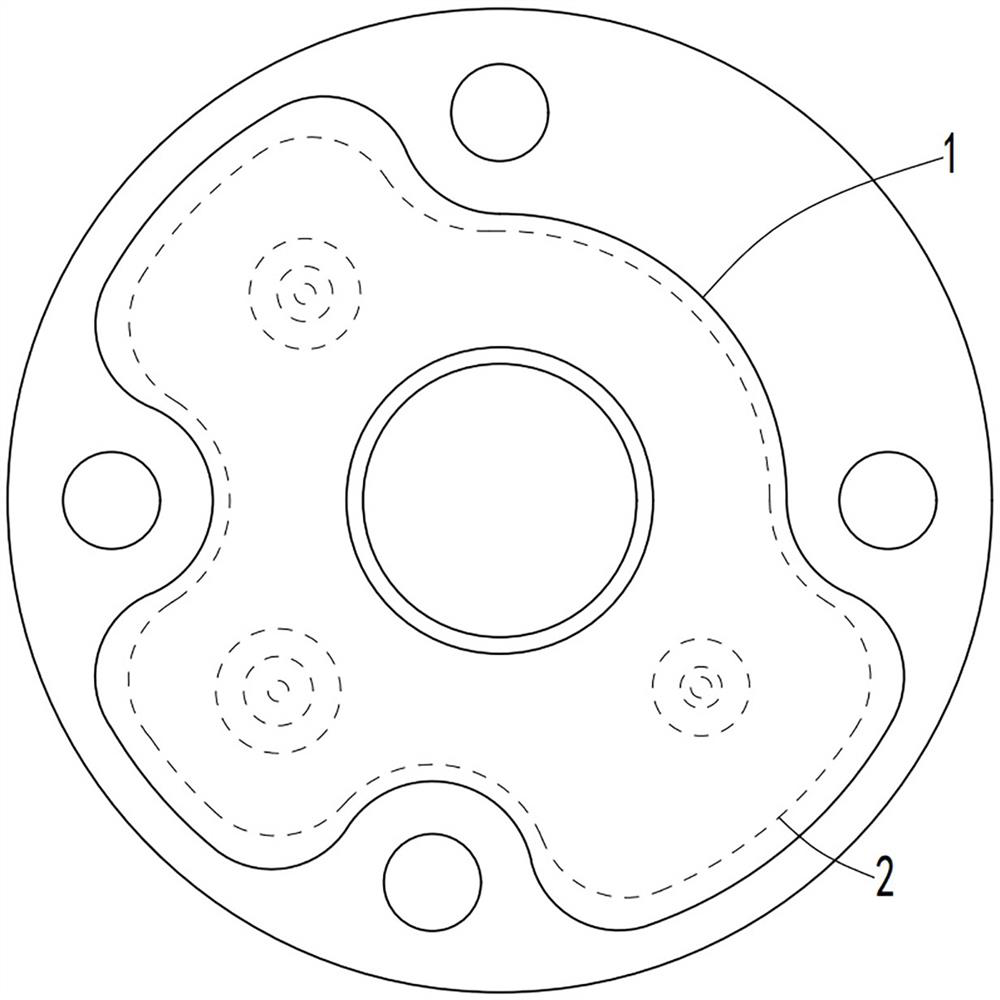

[0025] refer to Figure 1 to Figure 5 , a pump muffler provided by the present invention is connected to the crankshaft 4 of the pump body assembly of the compressor. The pump muffler includes an inner layer muffler cover 1 connected to the pump body assembly, which is sleeved on the inner layer muffler The outer layer muffling cover 2 on the device, there is a space between the inner layer muffling cover 1 and the outer layer muffling cover 2, and the interval between the inner layer muffling cover 1 and the outer layer muffling cover 2 A gas-liquid separation chamber 3 is formed. In this embodiment, the gas-liquid separation chamber 3 is a structure with a large top and a small bottom. A plurality of hollow inner resonators 11 are arranged on the top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com