Oil separation device capable of reducing oil discharge rate and rotary compressor

A rotary compressor and oil separation technology, applied in the field of compressors, can solve the problems of reducing oil discharge rate, increasing compressor power consumption, and high oil discharge rate, improving oil separation efficiency, increasing noise reduction effect, and ensuring reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

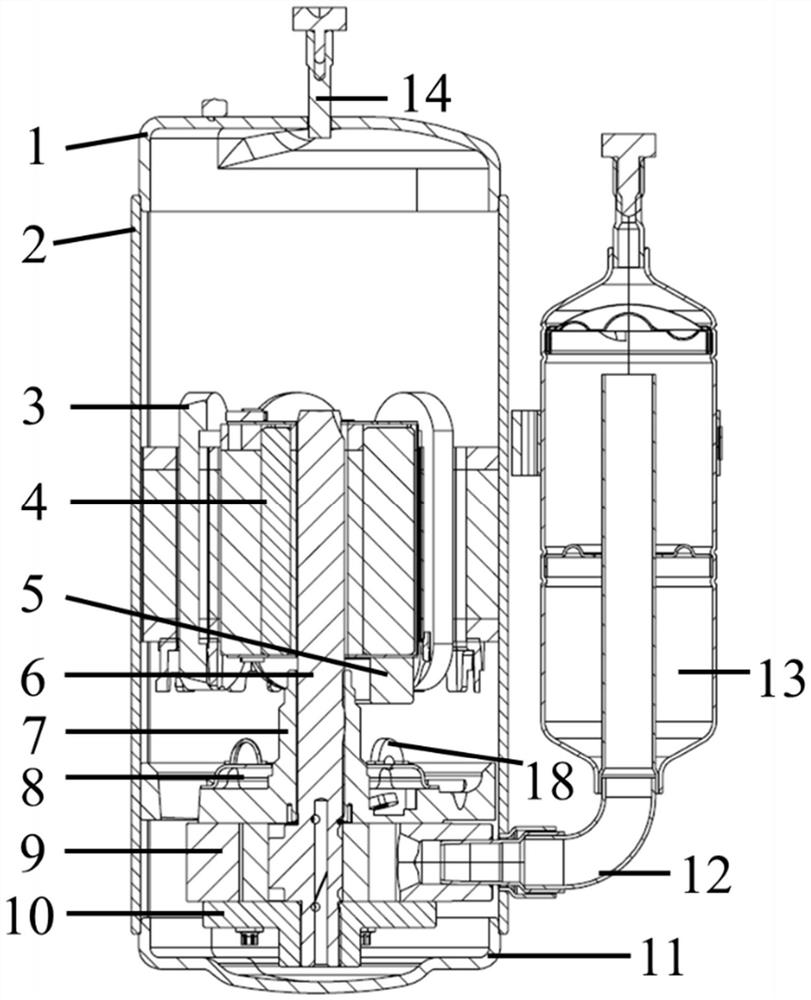

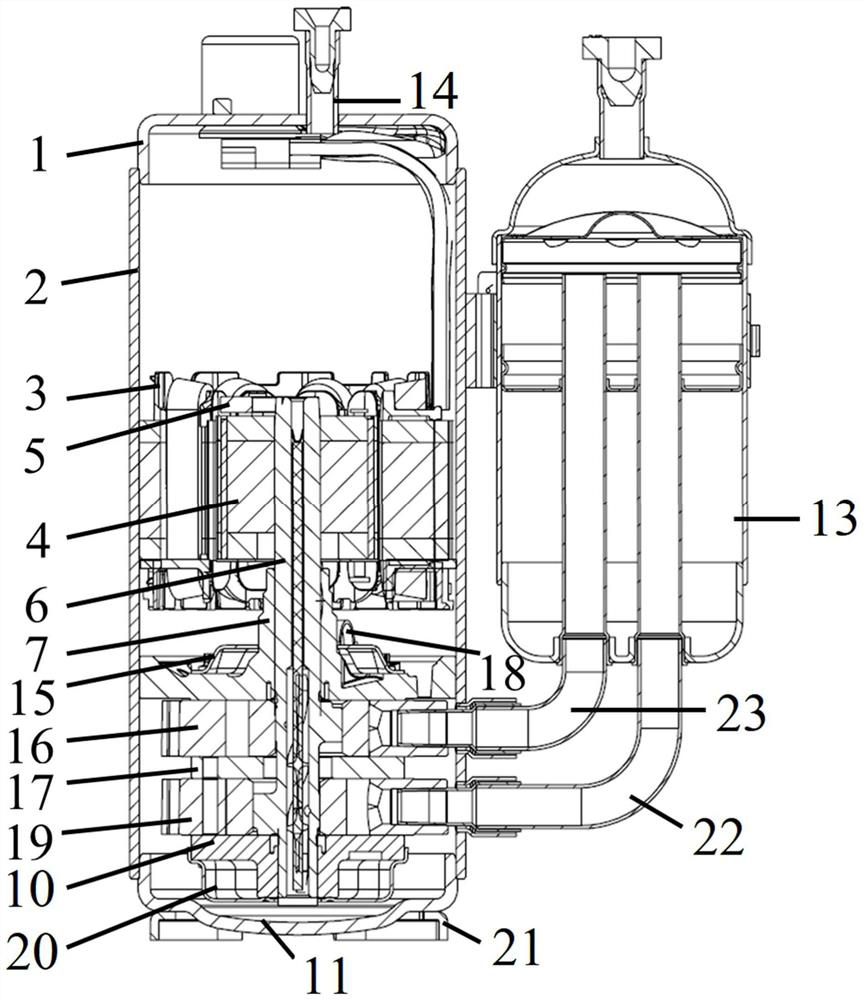

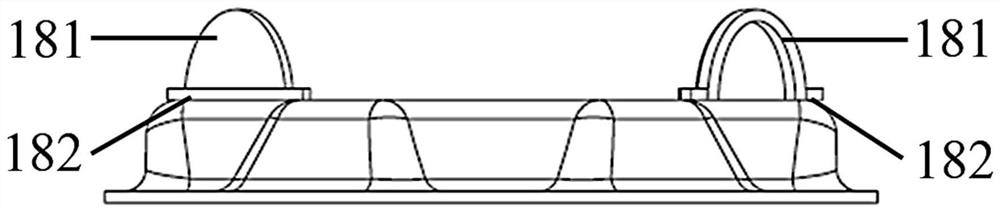

[0029] Such as figure 1 As shown, the single-cylinder rotary compressor in the embodiment of the present invention includes a shell assembly, a motor assembly, a pump body assembly, a crankshaft and an oil separator. The casing assembly is composed of an upper cover 1, a cylinder body 2 and a lower cover 11, and the three are welded together to form a rotary compressor casing. The upper cover 1 is connected with an exhaust pipe 14 for discharging high-temperature and high-pressure refrigerant. The motor assembly is composed of a motor stator 3 and a motor rotor 4 to provide power for the rotation of the crankshaft 6 . After the refrigerant is compressed in the cylinder 9, it passes through the muffler exhaust hole 24 on the muffler 8, and the muffler exhaust hole 24 is equipped with an oil separation device 18 of the present invention to red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com