Rotary fluid machine

A fluid mechanical and rotary technology, applied in the field of compressors, can solve problems such as abnormal wear and reliability of the rotating shaft, achieve the effects of reducing stress deformation, improving deflection deformation, and reducing oil discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

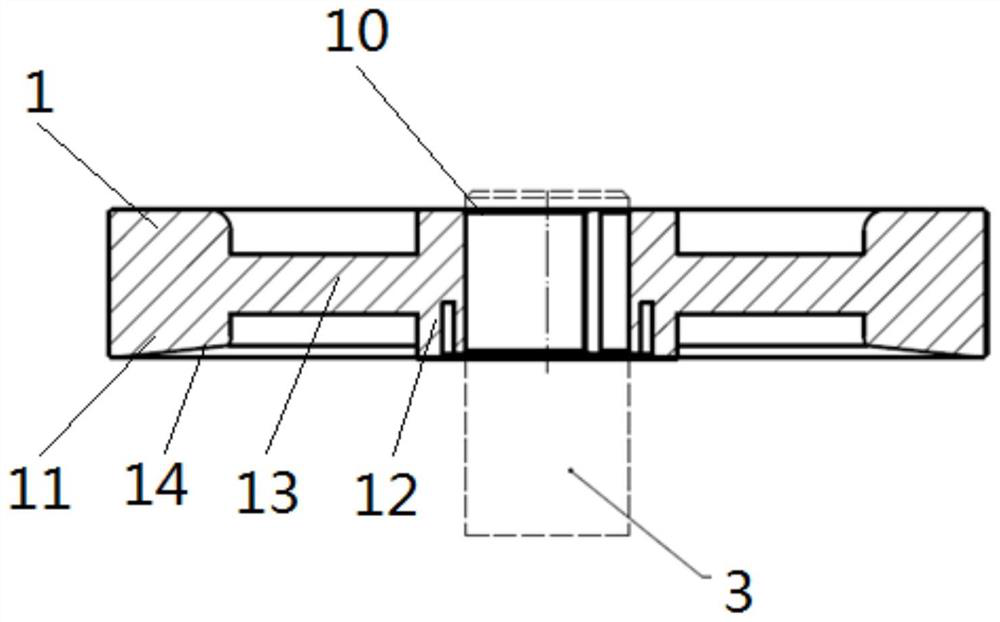

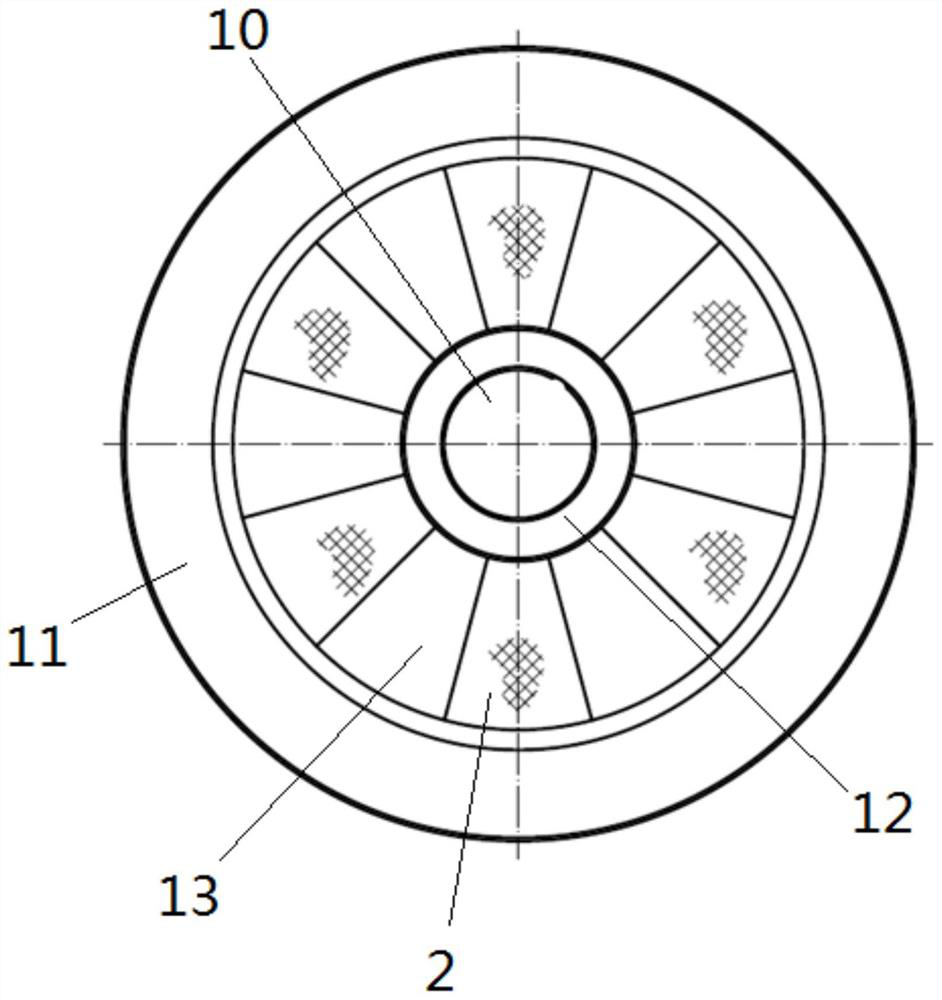

[0026] Such as Figure 1-2 As shown, the present invention also provides a rotary fluid machine, which includes:

[0027] Motor, pump body assembly and crankshaft bracket 1, said pump body assembly includes crankshaft 3, cylinder, first bearing and second bearing, one end of said crankshaft 3 passes through said cylinder, said first bearing and said second bearing Two bearings can support the crankshaft 3, the other end of the crankshaft 3 passes through the motor, and the crankshaft support 1 is also arranged on the part of the shaft section extending out of the motor on the crankshaft 3, the The radially outer end of the crankshaft bracket 1 is fixed, and the radially inner side of the crankshaft bracket 1 has a shaft hole 10 , and the other end of the crankshaft 3 passes through the shaft hole 10 and is supported on the crankshaft bracket 1 . Preferably, the motor is located between the crankshaft bracket 1 and the pump body assembly.

[0028] In the present invention, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com