Oil-gas separation assembly for compressor, compression mechanism and air conditioning system

A technology for separating components and compression mechanisms, used in machines/engines, pump components, mechanical equipment, etc., can solve problems such as compressor filling, reduce oil discharge rate, and avoid filling the inside of the compressor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

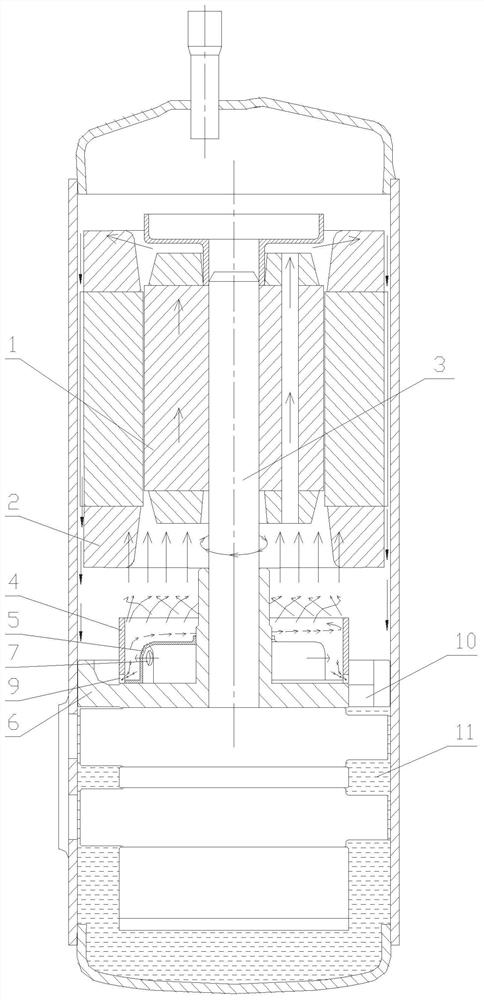

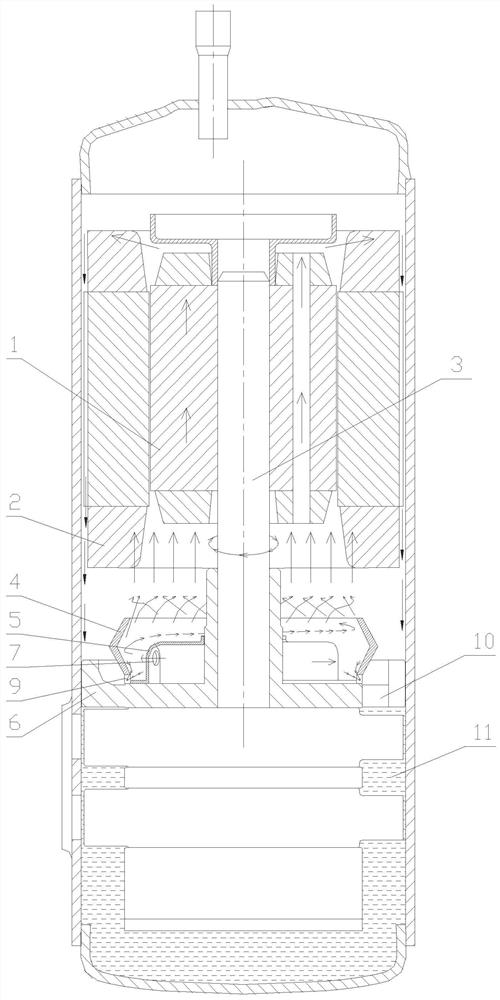

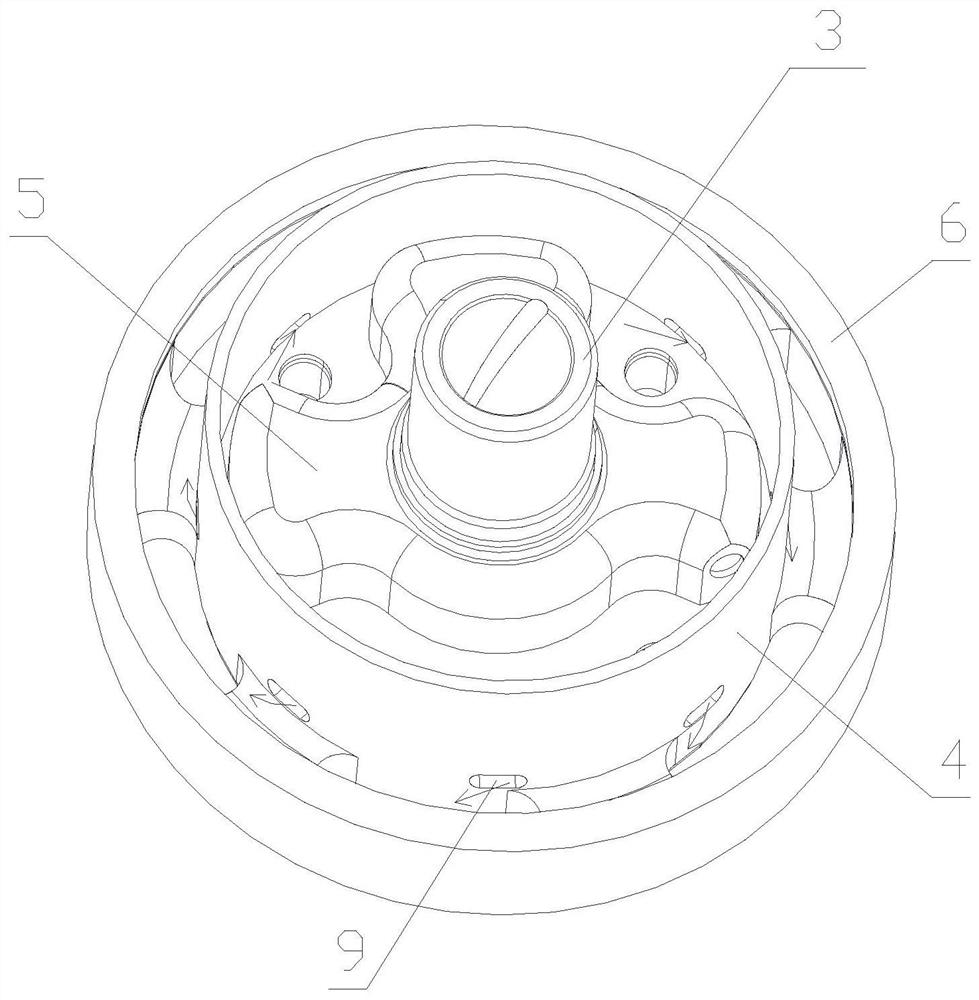

[0037] see in conjunction Figure 1 to Figure 10 As shown, according to an embodiment of the present application, a compressor oil-gas separation assembly is used for oil-gas separation of the discharge gas of the compression chamber of the compressor, including:

[0038] The upper flange 6 and the muffler 5, the muffler 5 is covered on the upper flange 6, and the muffler 5 is provided with an oil gas outlet 7;

[0039] The oil retaining skirt 4 is arranged on the upper flange 6 , and when the oil and gas discharged from the oil and gas outlet 7 pass through one side of the oil retaining skirt 4 , oil and gas separation occurs.

[0040] Based on the fact that the oil and gas outlet 7 of the compressor is arranged on the muffler 5 of the upper flange 6 of the cover buckle, the application sets the oil retaining skirt 4 on the upper flange 6 so that the oil gas discharged from the oil and gas outlet 7 passes through the oil retaining skirt On the side of side 4, there is an imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com