Compressor and air conditioner with same

A technology for compressors and components, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of increased oil discharge rate and reduced reliability of compressors, and achieve the goal of reducing oil discharge rate and enhancing oil separation capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

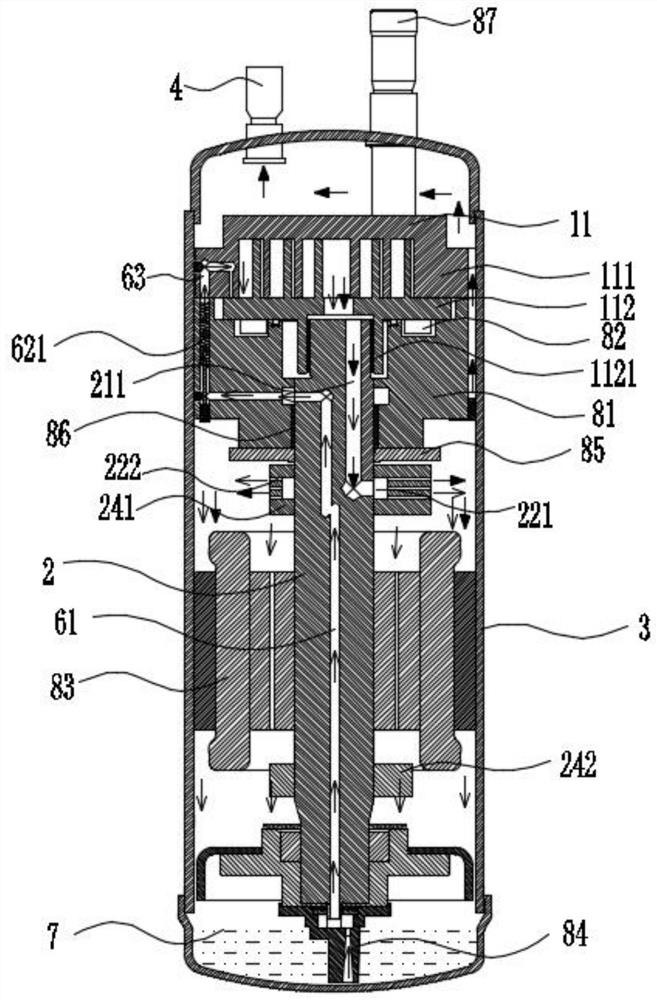

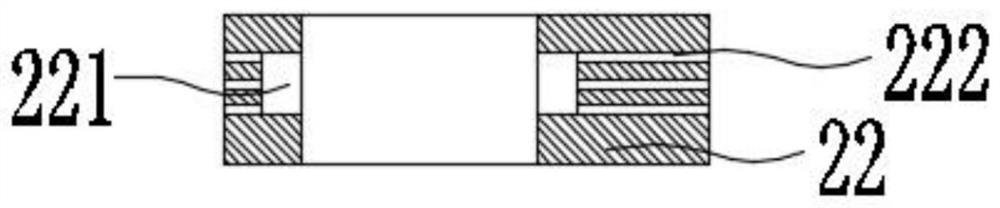

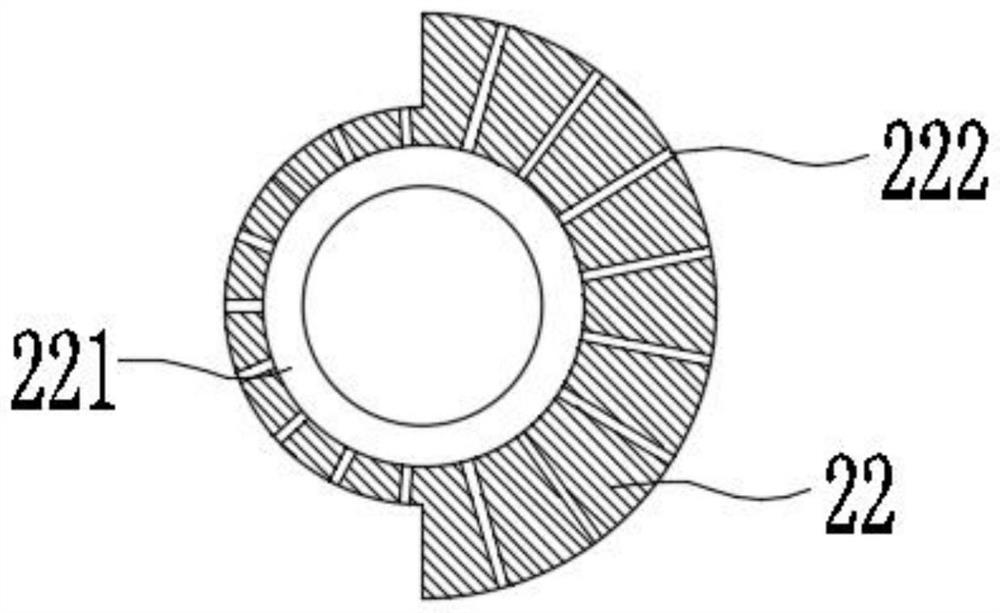

[0034] see in conjunction Figure 1-8 As shown, a compressor includes a pump body assembly 1 and a shaft assembly 2, the pump body assembly includes a compression structure 11, and the compression structure 11 has an exhaust port; the shaft assembly 2 is provided with a separation chamber 221, and the exhaust port is connected to the separation Cavity 221. The separation cavity 221 is used to separate oil and gas from the fluid discharged from the exhaust port. The separation chamber 221 is arranged inside the rotating shaft assembly 2. When the rotating shaft assembly 2 rotates, it can effectively separate oil and gas from the fluid discharged from the compression structure 11 under the action of centrifugal force, which can enhance the oil separation capacity of the compressor and reduce the oil discharge rate of the compressor. The application can effectively reduce the oil discharge rate of the compressor. The compressor of this application includes a pump body assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com