Balancing weight of rotary compressor and double-cylinder double-stage compressor with balancing weight

A technology of rotating compressors and balance weights, which is applied in the fields of compressors, refrigeration and air conditioning. It can solve the problems of high vibration and noise of compressors, affecting system balance, and increasing mold opening costs. It achieves guaranteed vibration and noise, simple assembly process, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

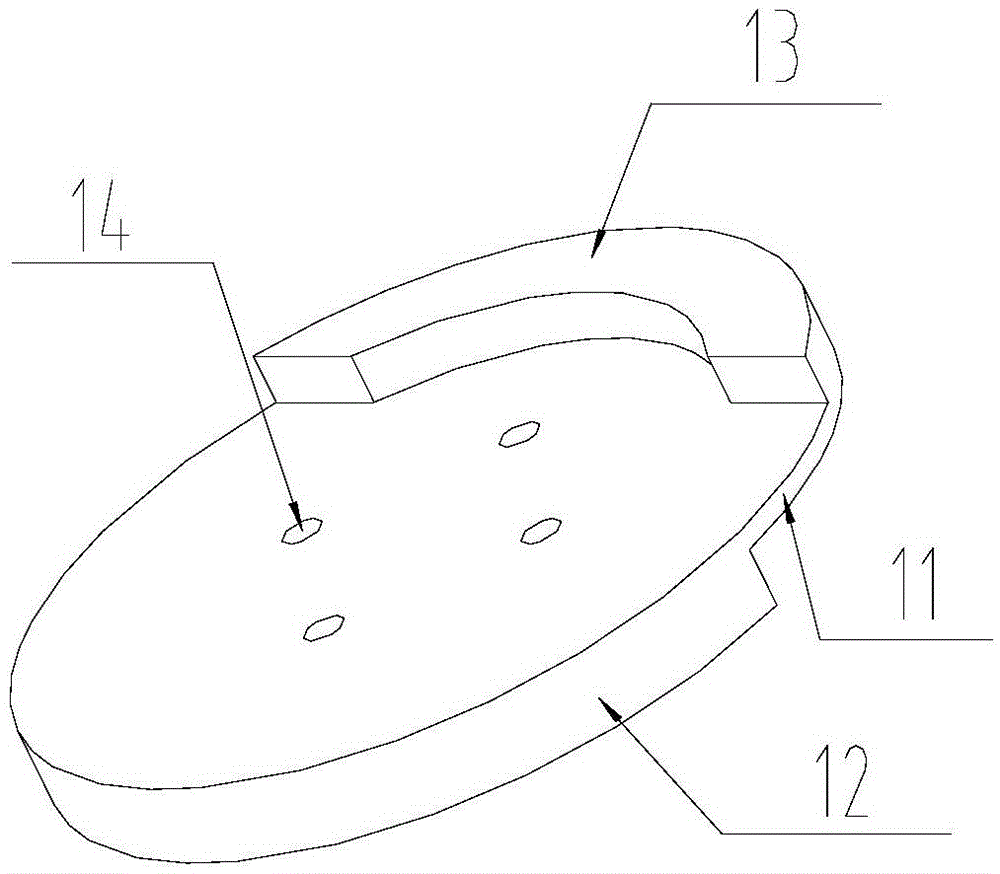

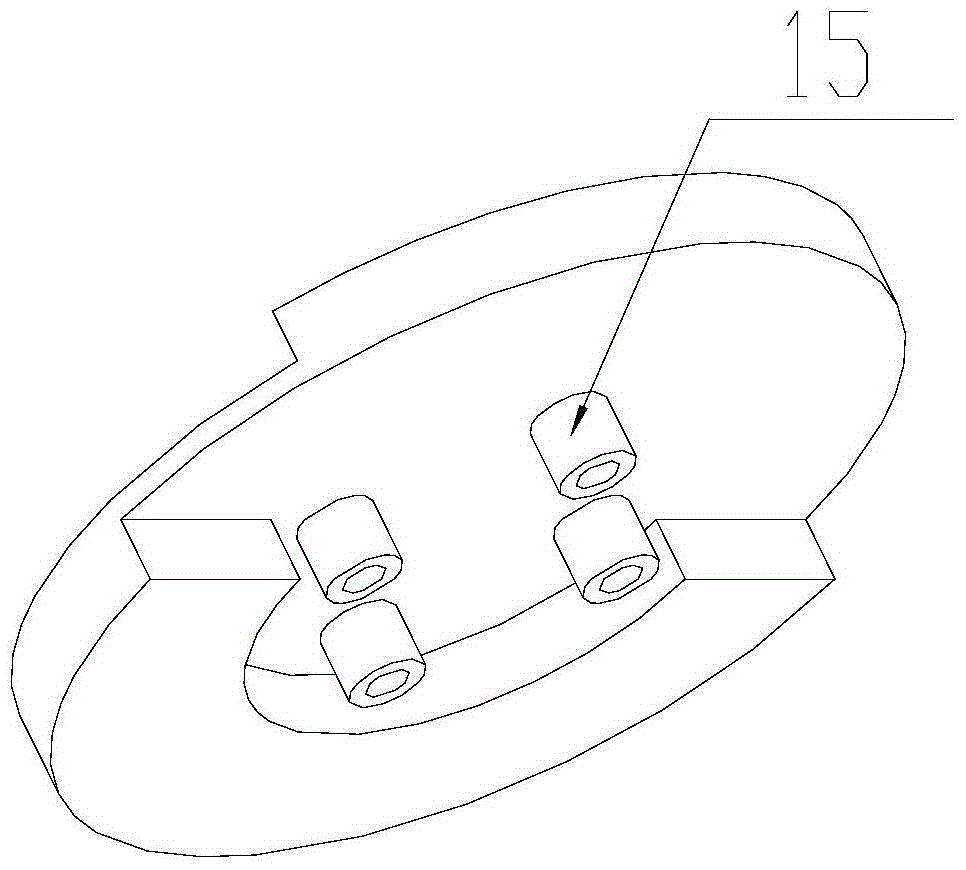

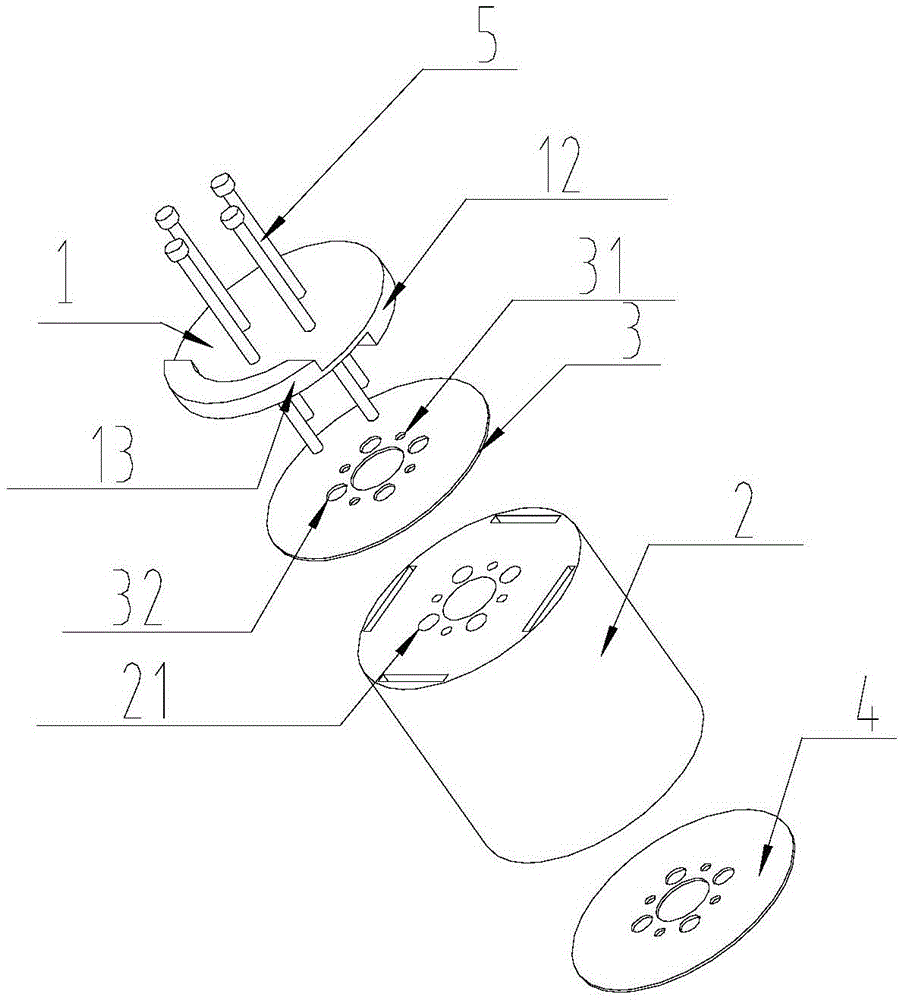

[0028] like Figure 1-2 As shown, the present invention provides a balance weight 1 of a rotary compressor, which includes a balance weight bottom plate 11 in the shape of a flat disk and having upper and lower circular surfaces. The center of circle of the disc-shaped balance weight bottom plate 11 is oppositely arranged (preferably in 180 ° of rotation or arranged symmetrically to the center) of the balance weight main eccentric portion 12 and the balance weight secondary eccentric portion 13 (that is, the balance weight is set on the upper circular surface During the main eccentric part, the balance weight secondary eccentric part is set on the lower circular surface; when the balance weight secondary eccentric part is set on the upper circular surface, the balance weight main eccentric part is set on the lower circular surface), and the balance weight bottom plate 11. The main eccentric portion 12 of the balance weight and the auxiliary eccentric portion 13 of the balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com