Rotor assembly, compressor and air conditioner

A component and rotor technology, applied in the field of gas compression devices, can solve the problems of increased windward area of the main balance weight, enhanced exhaust slapping effect, and increased oil discharge rate of the compressor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

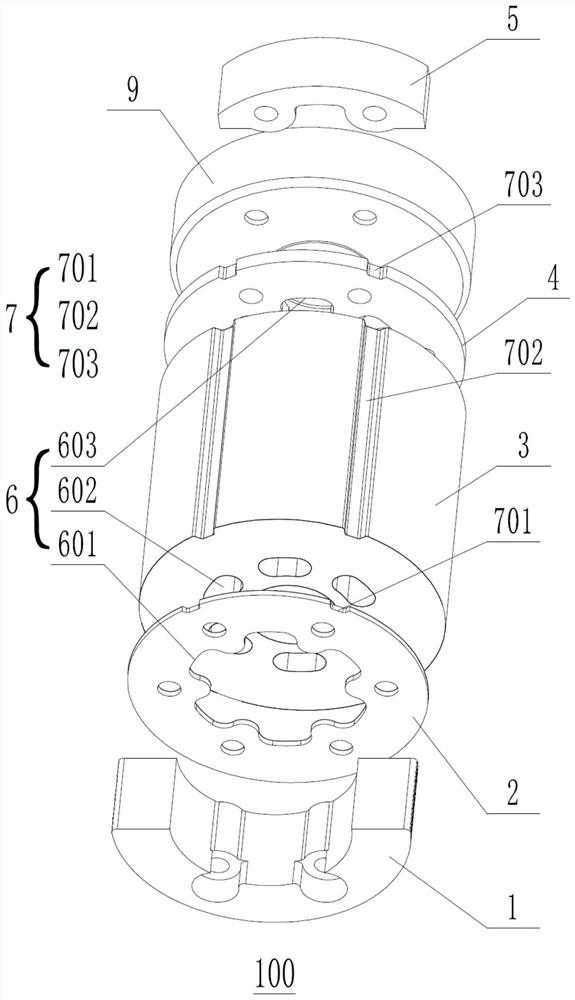

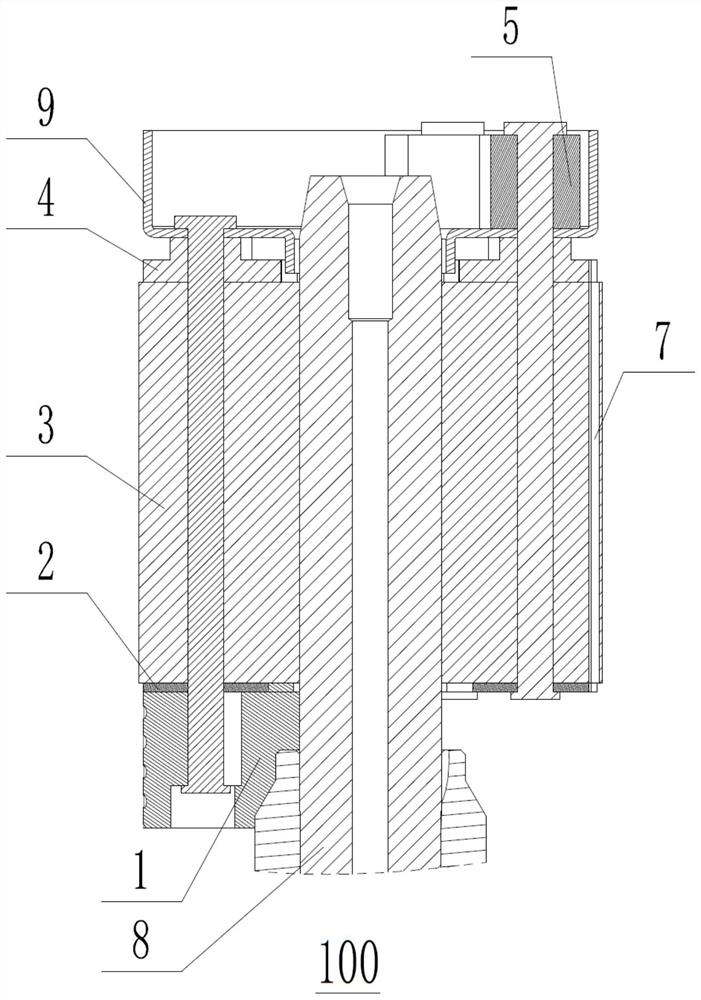

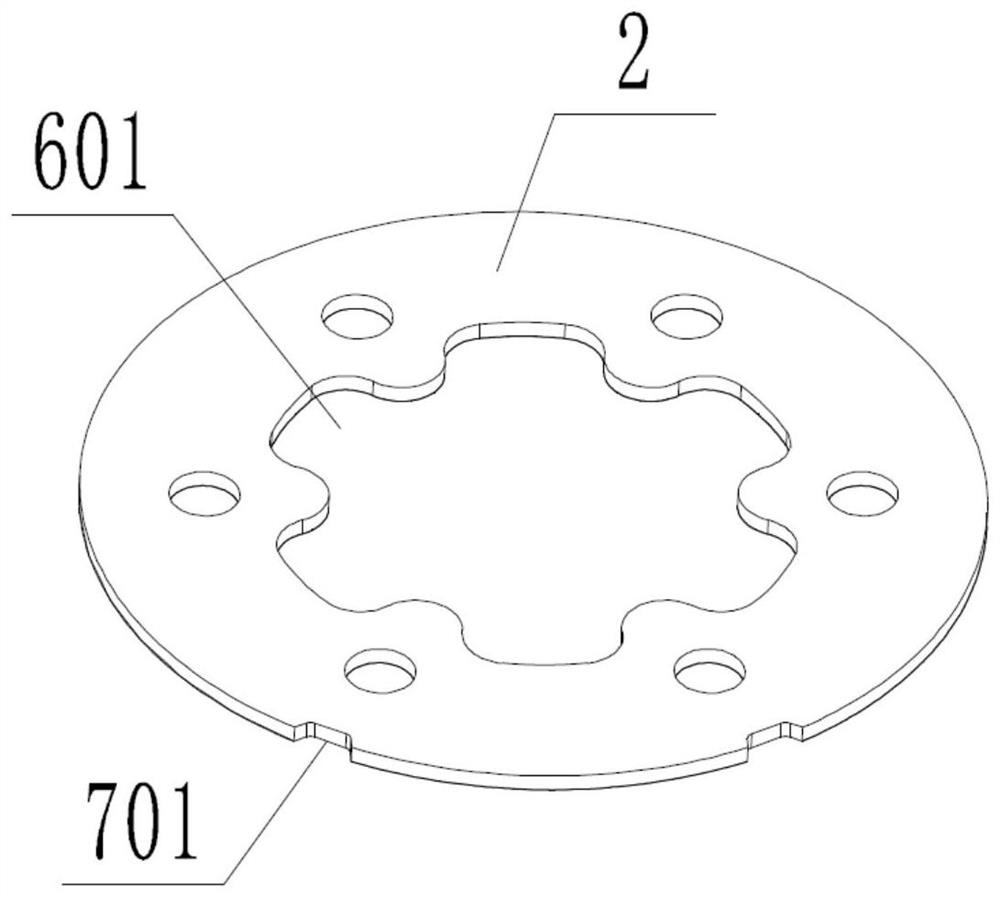

[0047] Such as figure 1 with 2As shown, the embodiment of the present invention provides a rotor assembly 100, which is applied to a single-cylinder rolling rotor compressor. The rotor assembly 100 includes a main balance weight 1, a first magnetic shield 2, a rotor Iron core 3, second magnetic shielding plate 4, oil shielding cap 9 and auxiliary balance weight 5, the inside of the first magnetic shielding plate 2, rotor core 3 and second magnetic shielding plate 4 are uniformly arranged with several main poles around the central axis. The circulation passage 6, the first magnetic shielding plate 2, the rotor core 3 and the second magnetic shielding plate 4 are formed with a secondary circulation passage 7 penetrating in the axial direction, and the main balance weight 1 is located on the rotor core 3 On one side of the central axis, the secondary flow channel 7 and the secondary balance weight 5 are located on the other side of the central axis of the rotor core 3 . During ...

Embodiment 2

[0080] Such as figure 1 , 2 As shown in and 10-12, the embodiment of the present invention provides a rotor assembly 100, which is applied to a single-cylinder rolling rotor compressor. The rotor assembly 100 includes a main balance weight 1, a first magnetic stop Plate 2, rotor core 3, second magnetic shielding plate 4, oil shielding cap 9 and auxiliary balance weight 5, the inside of the first magnetic shielding plate 2, rotor core 3 and second magnetic shielding plate 4 is uniform around the central axis Several main flow channels 6 are provided, the main balance weight 1 is located on one side of the central axis of the rotor core 3 , and the auxiliary balance weight 5 is located on the other side of the central axis of the rotor core 3 . During the specific use of the rotor assembly, the central axis of the rotor assembly 100 is set vertically, the main balance weight 1 is located at the lower end of the rotor assembly, the auxiliary balance weight 5 is located at the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com