Lubricating system of four-stroke engine and tool equipment with four-stroke engine

A four-stroke engine and lubrication system technology, which is applied in the field of lubrication systems, can solve the problems of reduced engine life, poor lubrication effect of the cam, and influence on the lubrication effect of the four-stroke engine, and achieve the effects of stable pressure and wear prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

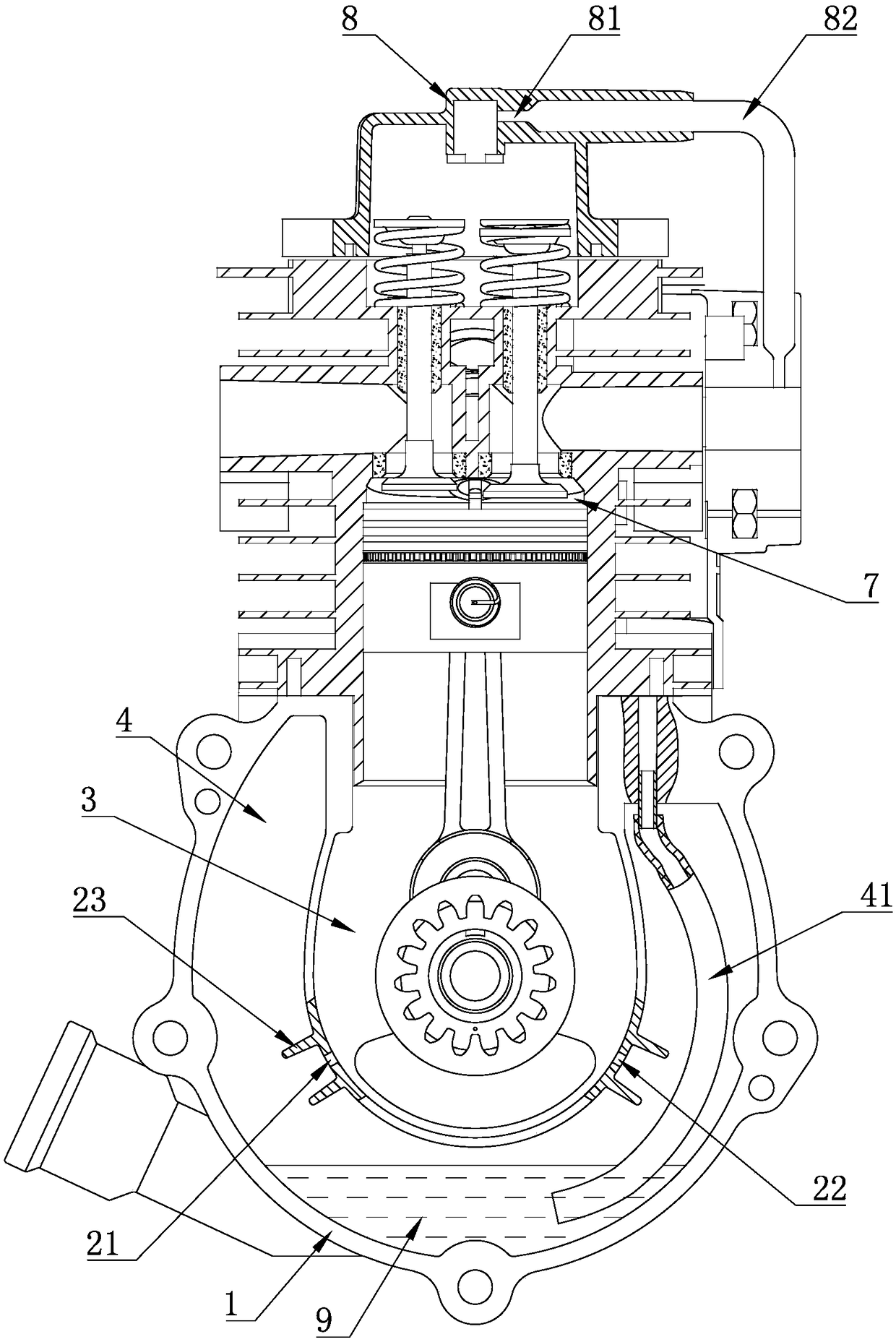

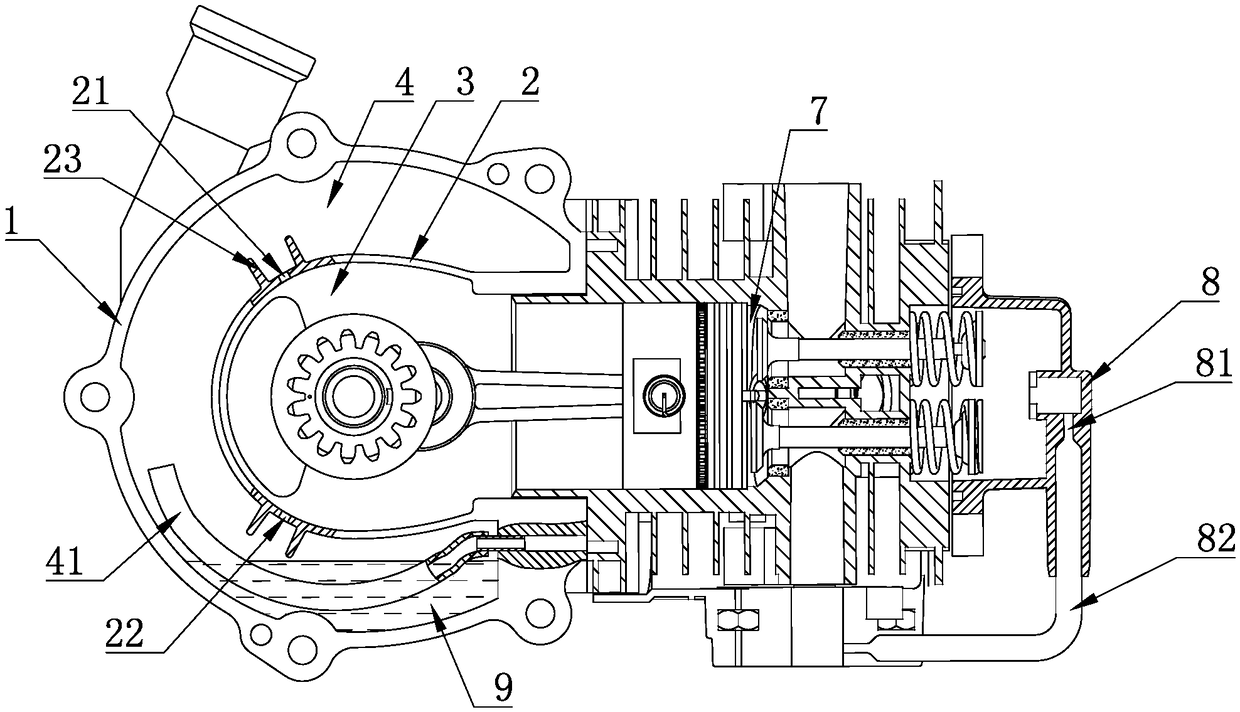

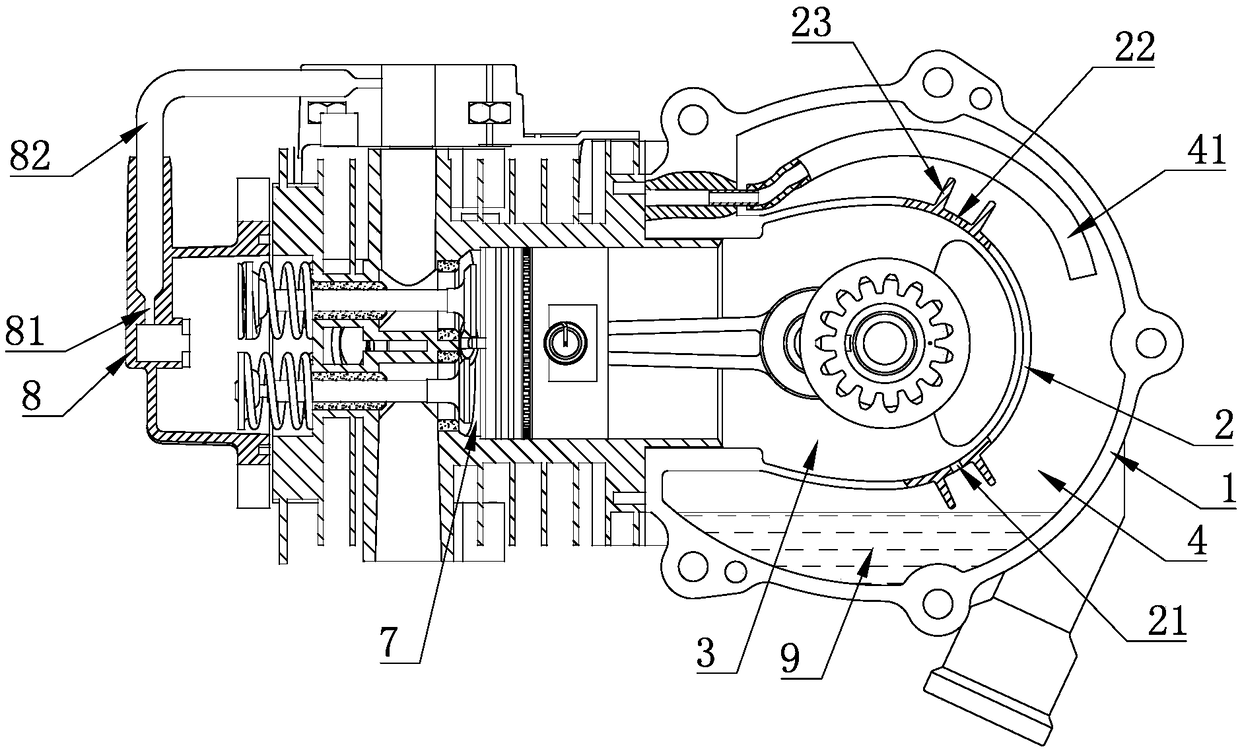

[0038] A lubricating system for a four-stroke engine, comprising a crankcase 2 forming a crank chamber 3, a lubricating oil tank 1 positioned outside the crankcase 2, and a cam chamber 5 accommodating a cam 51, such as figure 1As shown, the four-stroke engine is in a horizontal state, the section of the crankcase 2 is "U"-shaped, the lower part of the crankcase 2 is in a downward convex arc shape, the lubricating oil tank 1 is surrounded by the outside of the crankcase 2, the lubricating oil tank 1 and the crankshaft A "U"-shaped lubricating oil chamber 4 for storing lubricating oil 9 is formed between the boxes 2. The crankcase 2 is provided with a pre-stage oil intake hole connecting the crank chamber 3 and the lubricating oil chamber 4, and the cam chamber 5 and the lubricating oil chamber 4. It communicates with the oil pipe 41, one end of the oil pipe 41 communicates with the cam chamber 5, and the other end extends into the lubricating oil 9, and the oil pipe 41 makes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com