An oil boom facility with crude oil recovery function

An oil boom and function technology, which is used in general water supply conservation, open water surface cleaning, construction, etc., can solve the problems of poor crude oil recovery effect, inconvenient use and adjustment, and no crude oil recovery function, and achieve good crude oil recovery function. , Easy to use and adjust, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

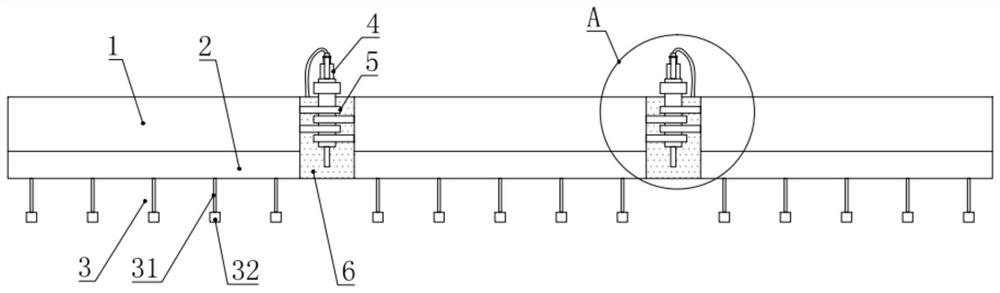

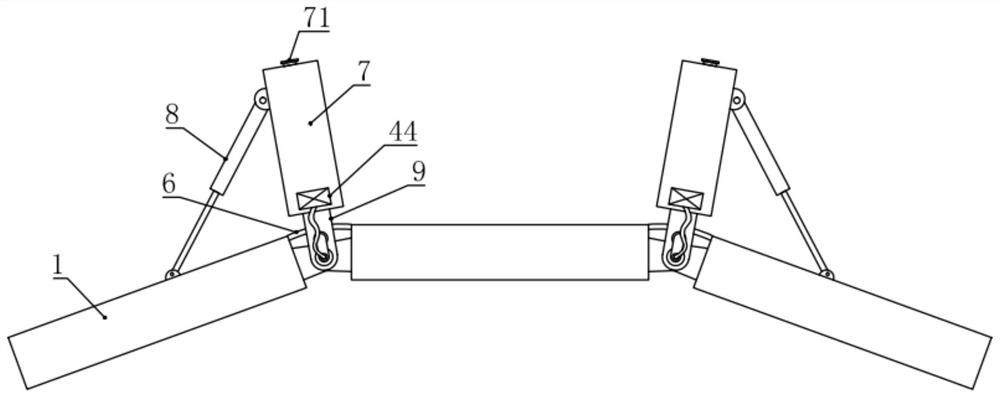

[0031] see figure 1 and 3 , in the embodiment of the present invention, an oil containment boom facility with crude oil recovery function includes three buoys 1, the three buoys 1 are sequentially connected by a hinge assembly 5, and there is a gap between two adjacent buoys 1 An elastic plate 6 is connected, and the oil retaining effect is played through the elastic plate 6. The rear side between two adjacent buoys 1 is also provided with an oil storage buoy 7, and the oil storage buoy 7 is also passed through a fixed plate 9 Connected and fixed with the hinge assembly 5, the oil storage buoy 7 is also equipped with an oil pumping device 4 for extracting crude oil between two adjacent buoys 1, and the rear sides of the two buoys 1 at both ends are A second telescopic cylinder 8 is also hinged, and the other end of the second telescopic cylinder 8 is hinged on the side of the oil storage buoy 7, and the two buoys 1 at both ends can be driven to rotate by the second telescopic...

Embodiment 2

[0036] see Figure 1-7 , the difference between this embodiment and embodiment 1 is:

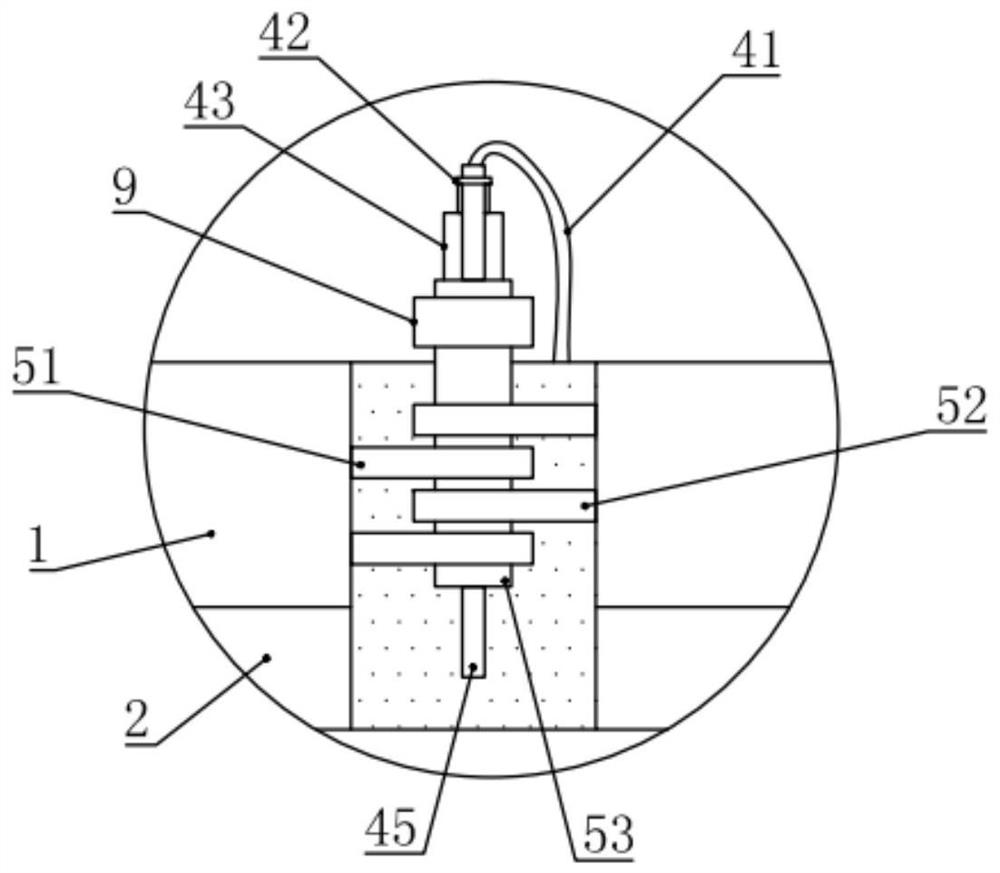

[0037] In this example, if figure 2 As shown, the hinge assembly 5 includes a first hinge plate 51, a second hinge plate 52 and a hinge tube 53, the hinge tube 53 is vertically arranged, and the hinge tube 53 is rotatably connected with two first hinge plates 51 and two hinge tubes. Two second hinged plates 52, and two first hinged plates 51 and two second hinged plates 52 are vertically evenly staggered, and the two first hinged plates 51 are fixed on the buoy 1 on one side of the hinged pipe 53, two The second hinged plate 52 is fixed on the buoy 1 on the other side of the hinged pipe 53; the fixed plate 9 is fixed on the front end of the oil storage float 7, and the fixed plate 9 is fixed to the hinged pipe 53 of the hinged assembly 5 connect.

[0038] In this example, if Figure 4 and 5 As shown, the buoy 1 is a closed cylindrical shell structure, and the inner side of the buoy 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com