Upper input and lower output type speed reduction gear box

A technology of gear reduction box and large gear, which is applied in gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems of liquid lubricating oil thrown to the top of the box, increased equipment cost, and fast gear wear. , to achieve the effects of reducing oil churning loss, good cooling and lubrication, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

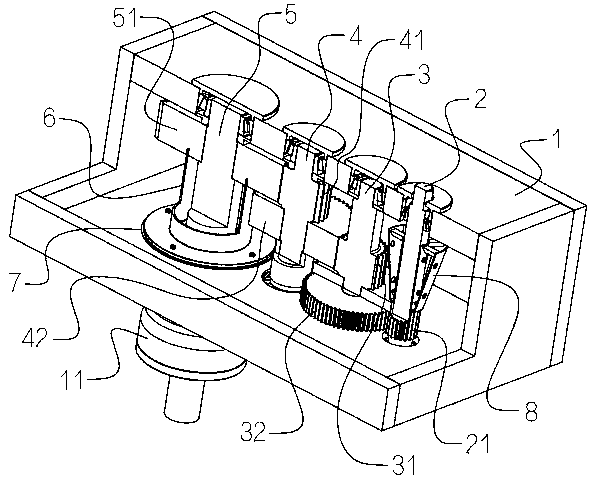

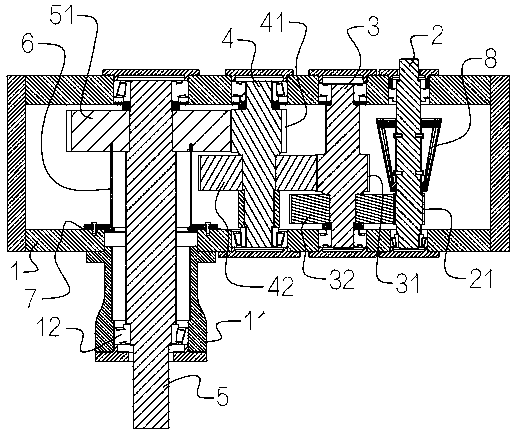

[0034] Embodiment one: if figure 1 and figure 2 As shown, a gear reduction box with upper input and lower output includes a rectangular box 1, and the box 1 is rotatably connected with a first-stage rotating shaft 2, a second-stage rotating shaft 3, and a third-stage rotating shaft 4, all of which are vertically arranged through bearings. Four-stage rotating shaft 5. The upper end of the first-stage rotating shaft 2 protrudes from the upper wall of the box body 1 , and the second-stage rotating shaft 3 and the third-stage rotating shaft 4 are located in the box body 1 . The outer side of the lower wall of the box body 1 is sealed and welded with an output extension sleeve 11, and the lower end of the fourth-stage rotating shaft 5 protrudes from the lower end of the extension sleeve 11. The extension sleeve 11 is provided with a tapered roller bearing 12 for rotationally connecting and supporting the fourth-stage rotating shaft 5. The tapered roller bearing 12 here is prefer...

Embodiment 2

[0045] Embodiment 2: This embodiment is a technical solution obtained through further improvement on the basis of Embodiment 1.

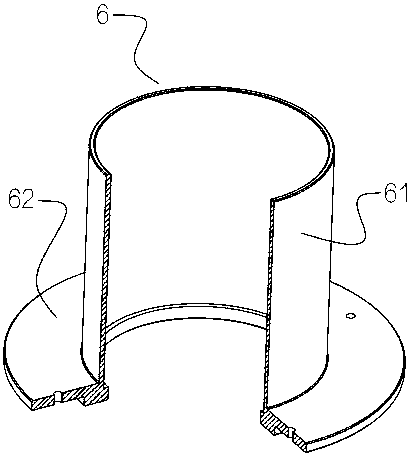

[0046] The difference between this embodiment and Embodiment 1 is that, as Figure 6 , Figure 7 and Figure 8 As shown, the lower end of the three-stage bull gear 51 is also coaxially provided with a second circular groove 512 with a rectangular cross-section, and the second circular groove 512 is outside the first circular groove 511 .

[0047] Such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the outer side of the cylindrical side wall 61 is coaxially sleeved with an annular piece 63, and the annular piece 63 is coaxially provided with an annular oil retaining cylinder 64, and the oil retaining cylinder 64 extends into the second annular groove 512 Inside, and there are gaps on the wall surfaces of the oil deflecting cylinder 64 and the second annular groove 512 .

[0048] An annular oil groove 65 is coaxially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com