Patents

Literature

74results about How to "Reduce churning loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

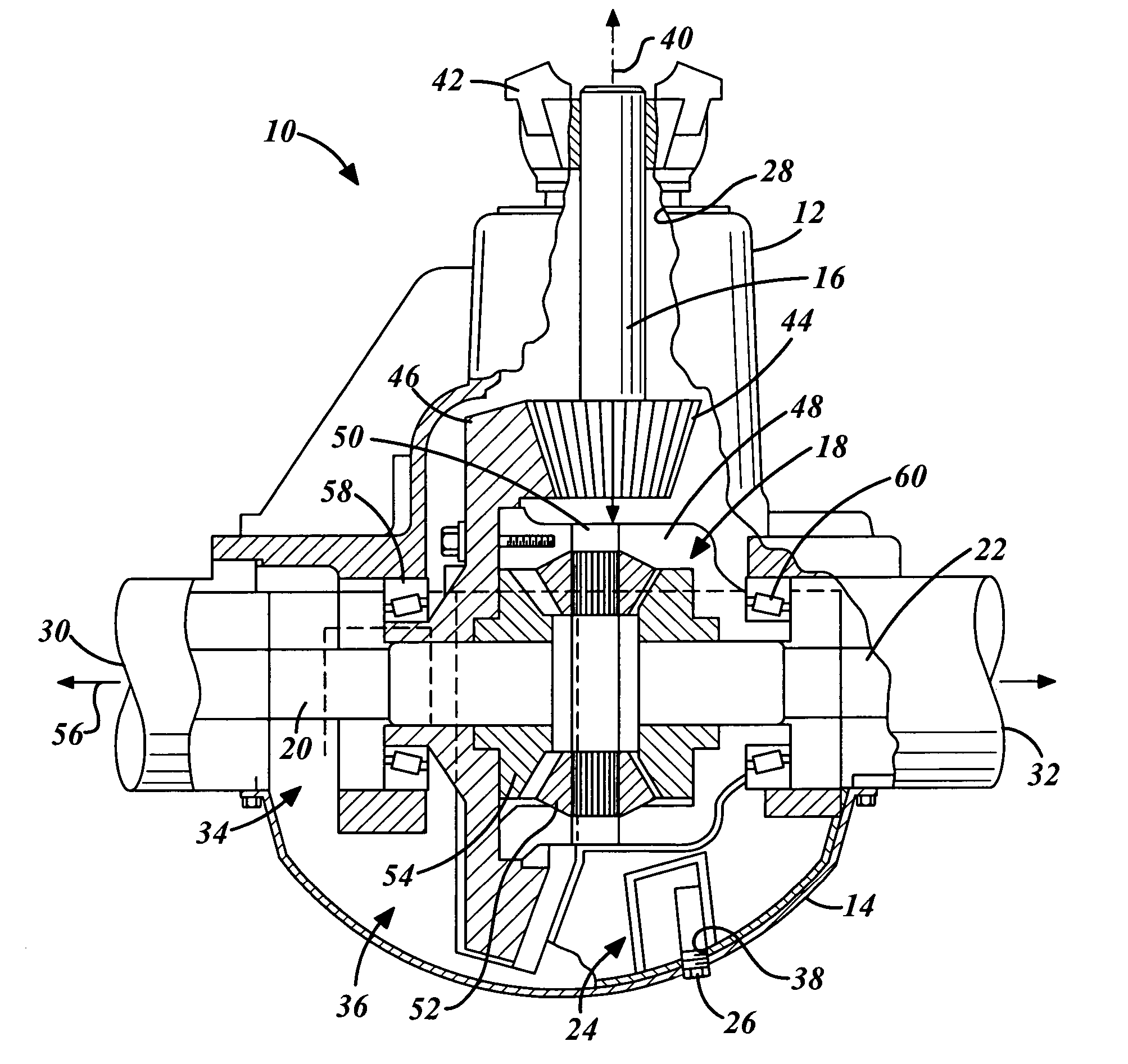

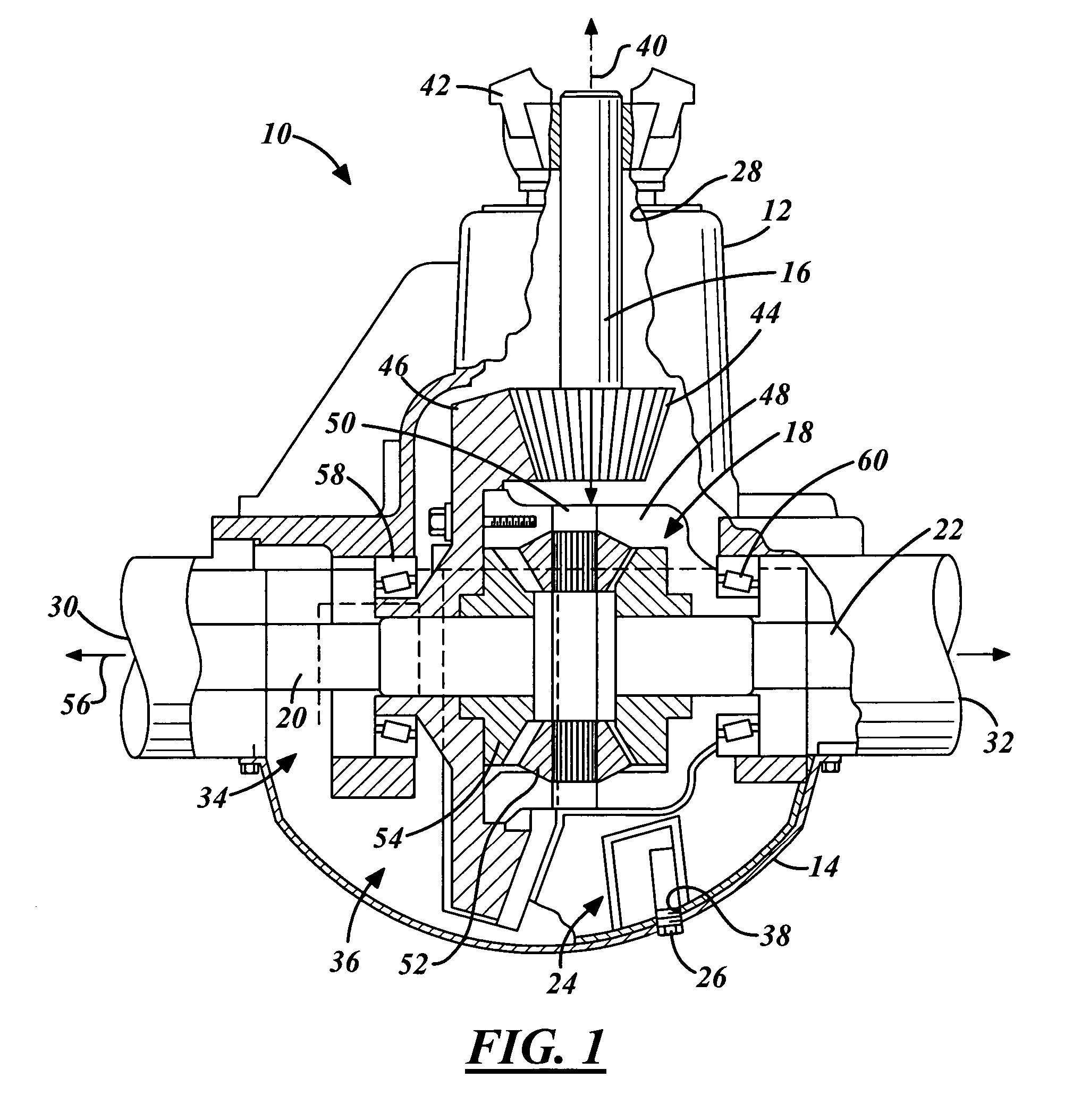

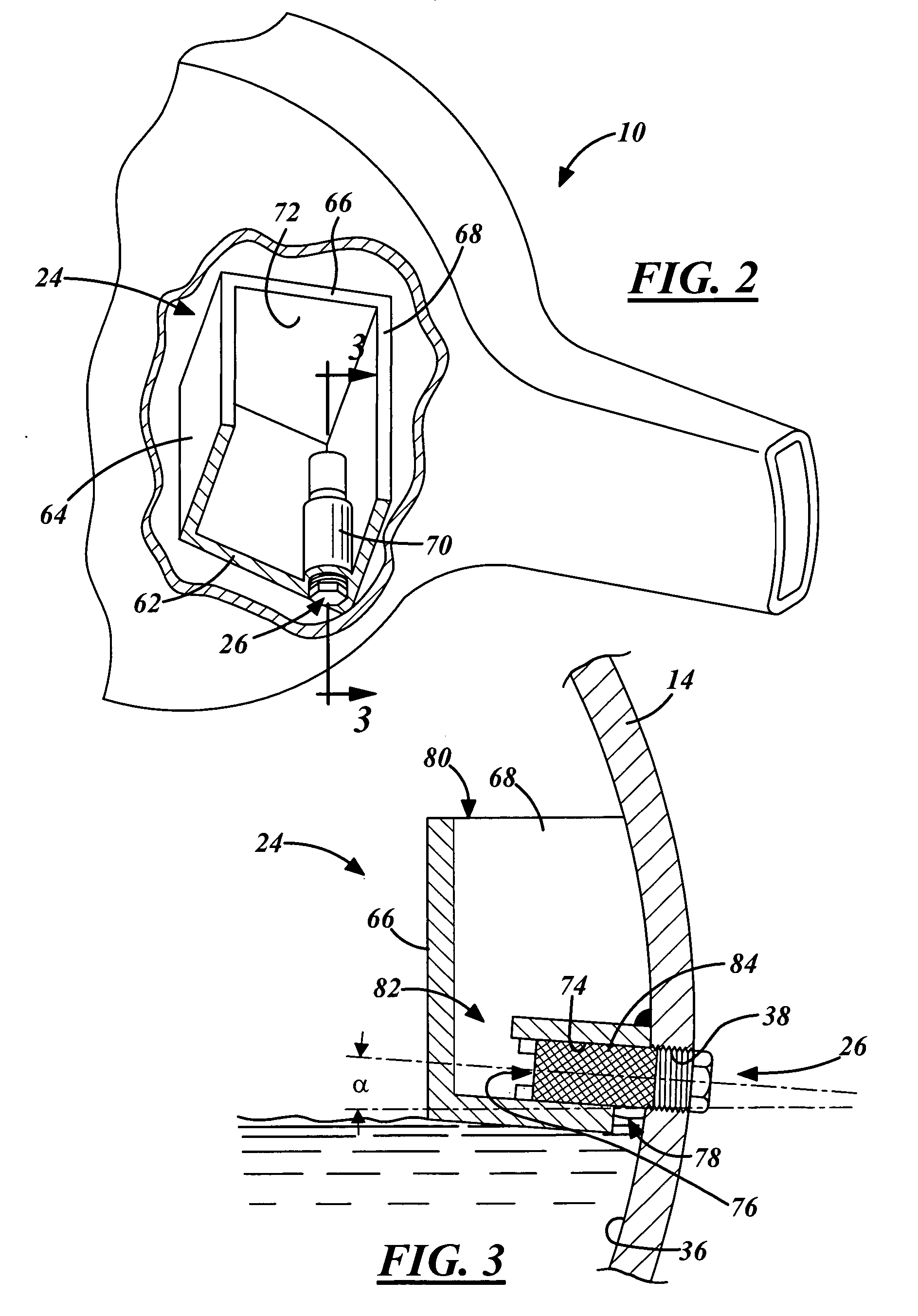

Enhanced lubrication system for drive axle assemblies

ActiveUS20060063633A1Reduce churning lossLowering dynamic lubricant levelGearboxesDrip or splash lubricationTransaxleLubrication

An improved lubrication system for drive axle assemblies is provided that uses a collector in connection with a filter plug to lower the dynamic lubricant level in the drive axle assembly and filter contaminants in the lubricant sump. The collector is affixed to a cover plate attached to the drive axle housing and defines a well and a flow passage proximate the bottom of the well. The flow passage is aligned with an opening through which lubricant is inserted into the housing. A plug with a filter is inserted through the opening in the cover plate and into the flow passage. The invention reduces churning losses by lowering the dynamic lubricant level in the axle assembly without having a negative impact on lubricant life.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

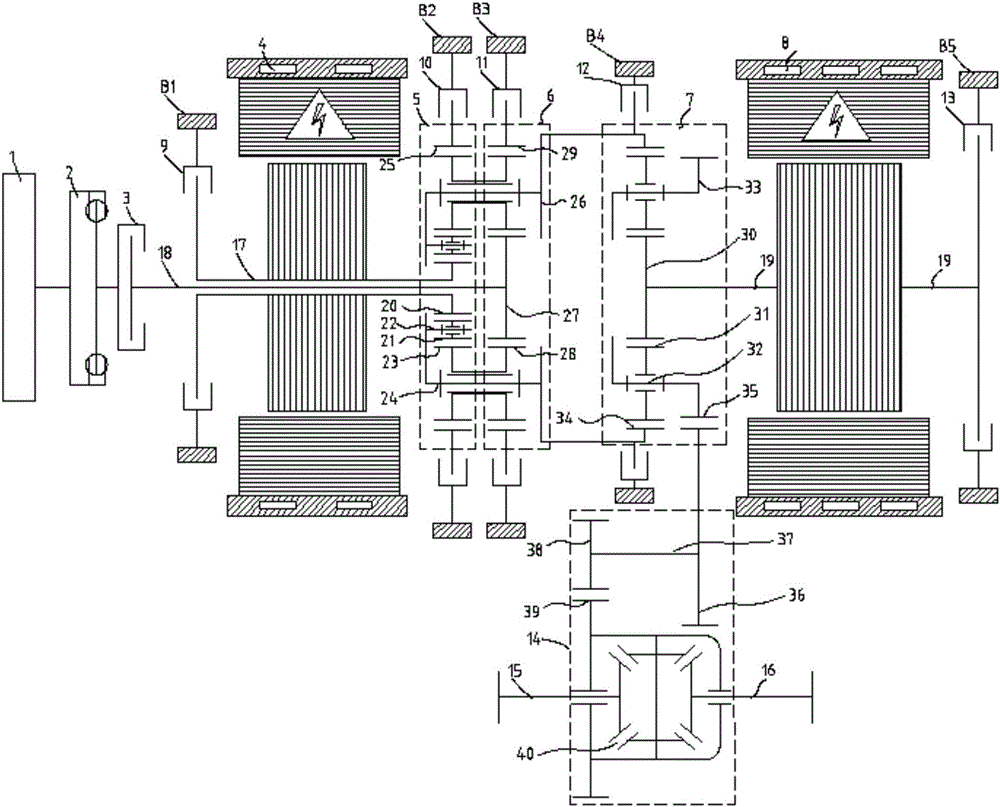

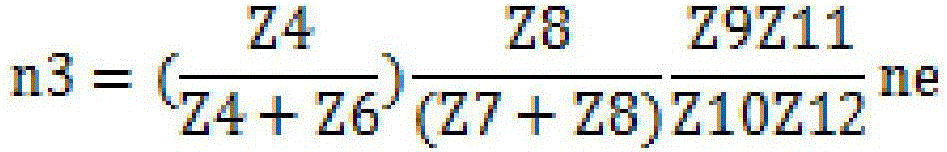

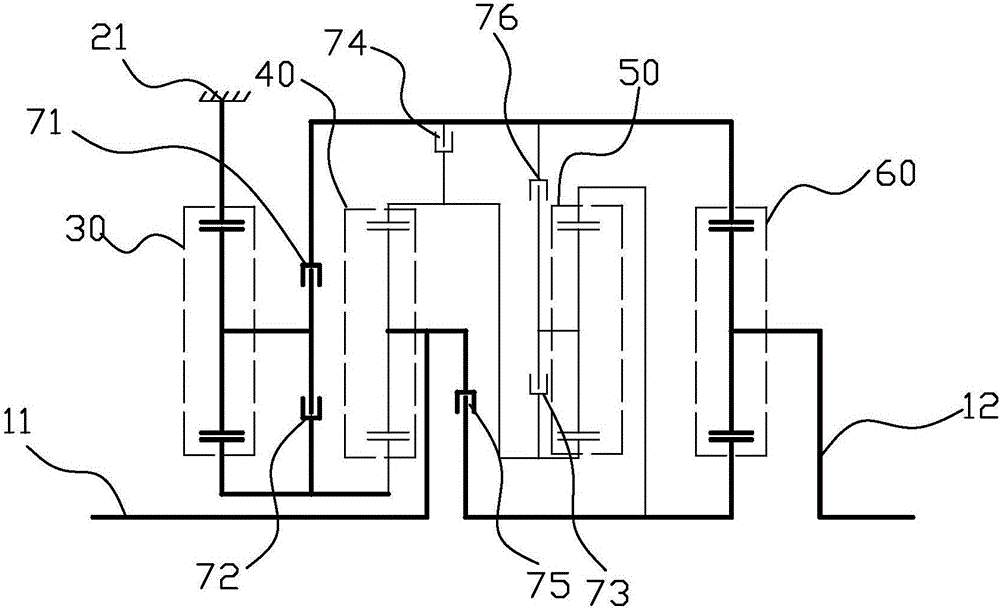

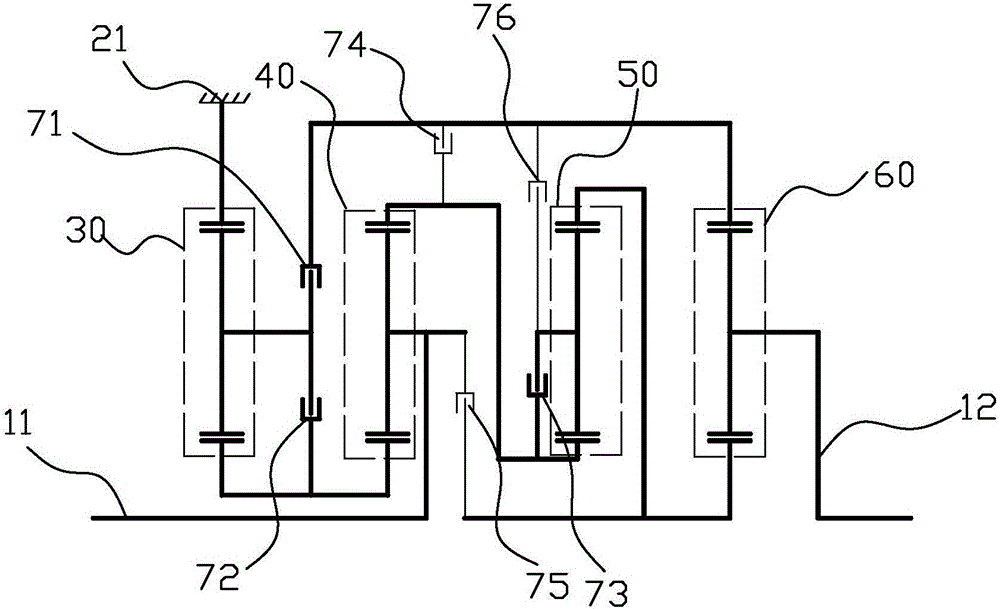

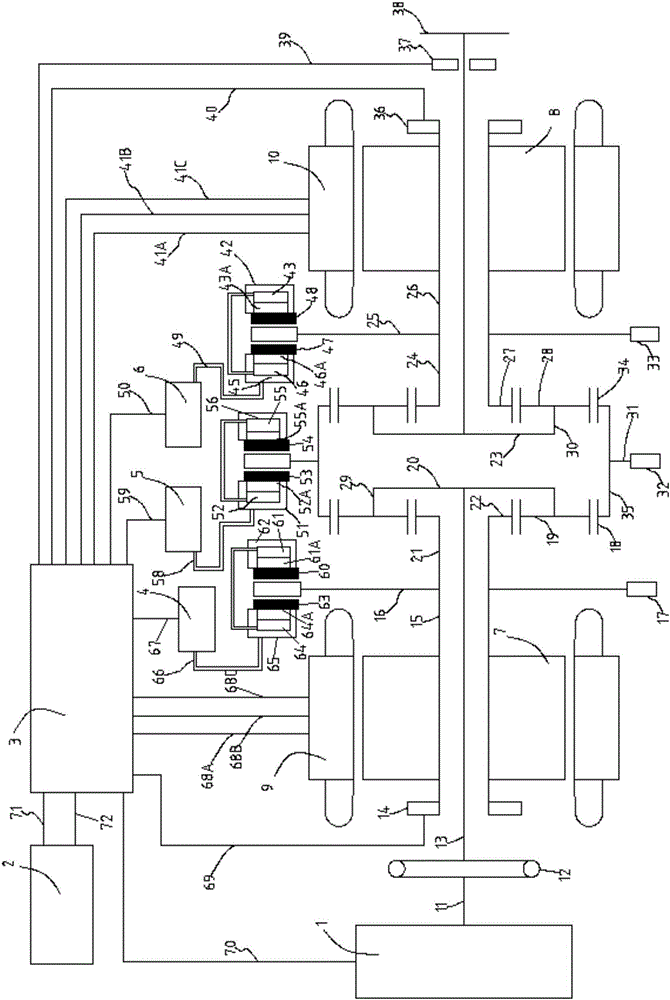

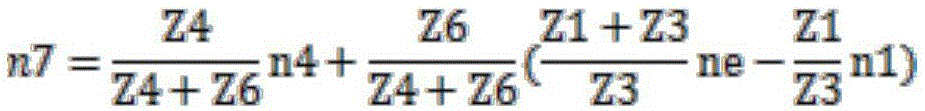

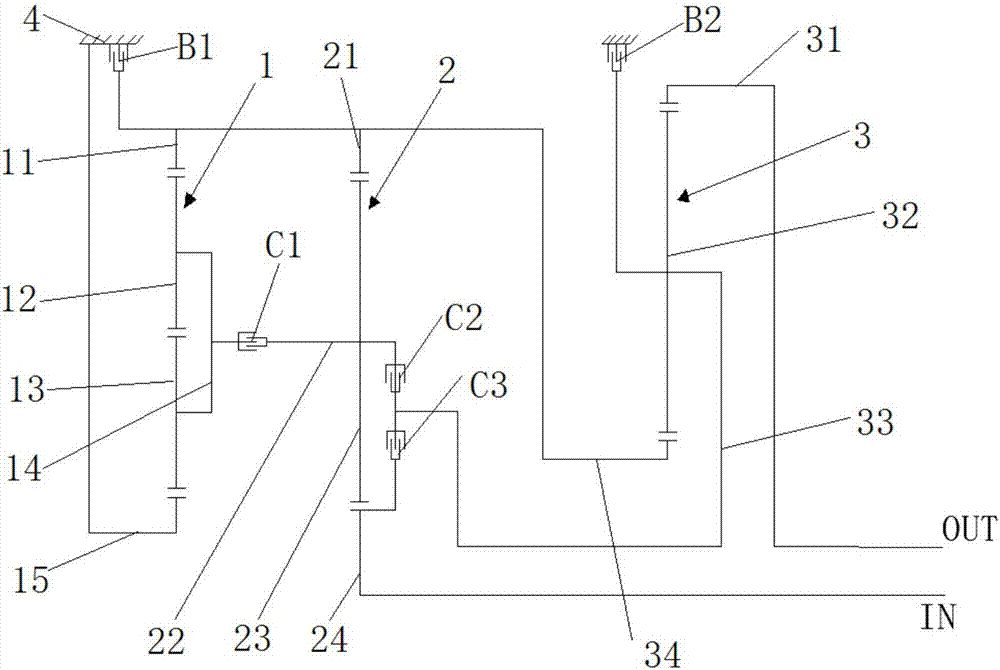

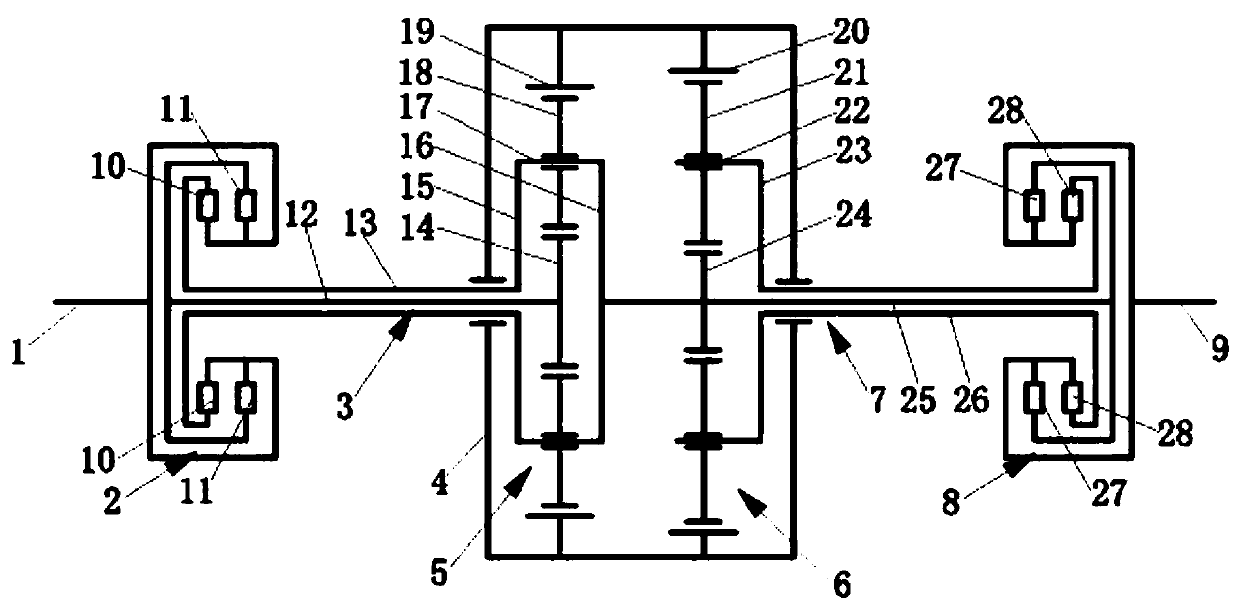

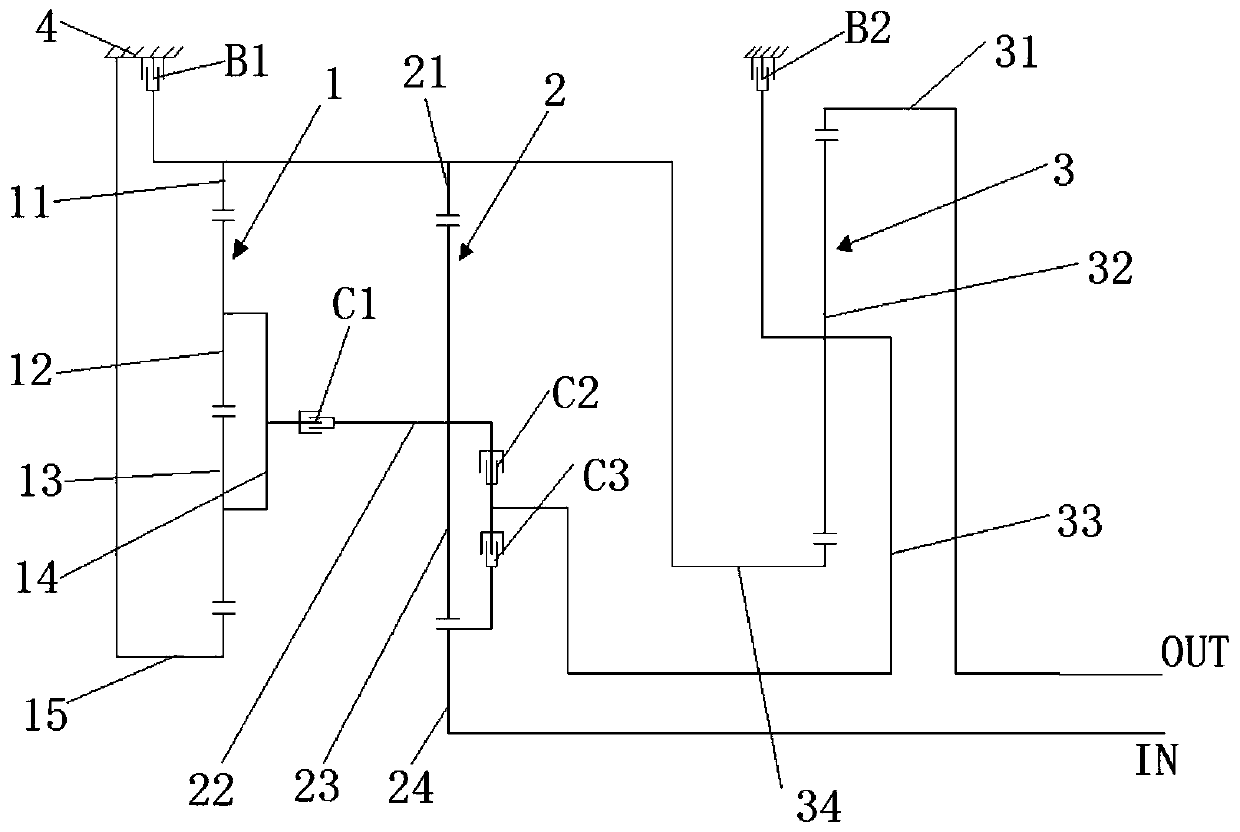

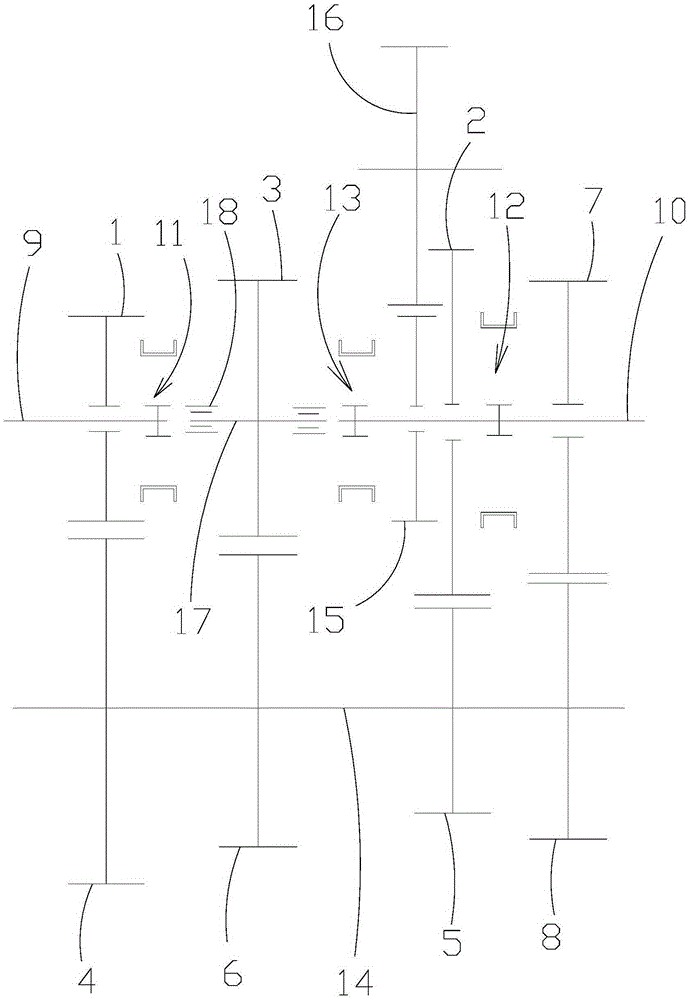

Dual-motor multi-mode composite forerunner plug-in hybrid power system

ActiveCN106560336ALess heat productionReduce churning lossElectric propulsion mountingGas pressure propulsion mountingMotor driveDriving mode

The invention discloses a dual-motor multi-mode composite forerunner plug-in hybrid power system; an engine, an elastic damper, a clutch, a first motor, a first planet row, a second planet row, a third planet row and a second motor are coaxially arranged in order; a first brake connecting plate is connected with the output shaft of the first motor; a second brake connecting plate is connected with the first planet row; a third brake connecting plate is connected with the third planet row; a fourth brake connecting plate is respectively connected with the first, second and third planet rows; a fifth brake connecting plate is connected with the output shaft of the second motor; the third planet row is connected with an output gear set; the output gear set is respectively connected with a left output semiaxis and a right output semiaxis. The dual-motor multi-mode composite forerunner plug-in hybrid power system is more reasonable in configuration, more compact in structure, low in loss, high in reliability, and can realize the following work modes: an engine multi-speed ratio separate drive mode, an engine-motor multi-gradient combined ECVT drive mode, and a multi-speed ratio single motor-driven mode.

Owner:GUANGZHOU XINYU POWER TECH CO LTD

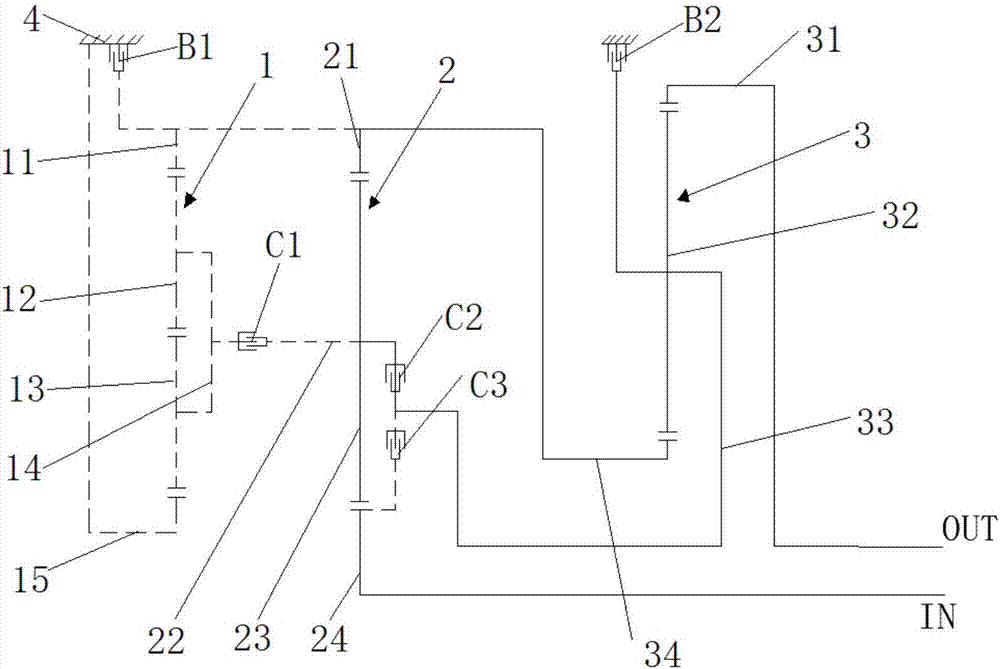

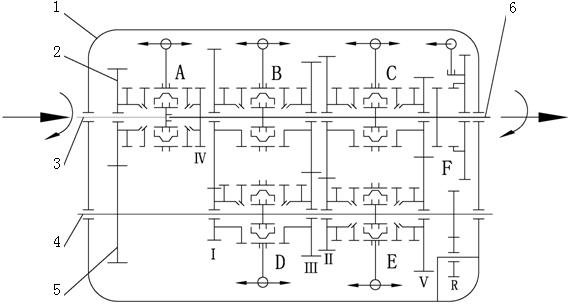

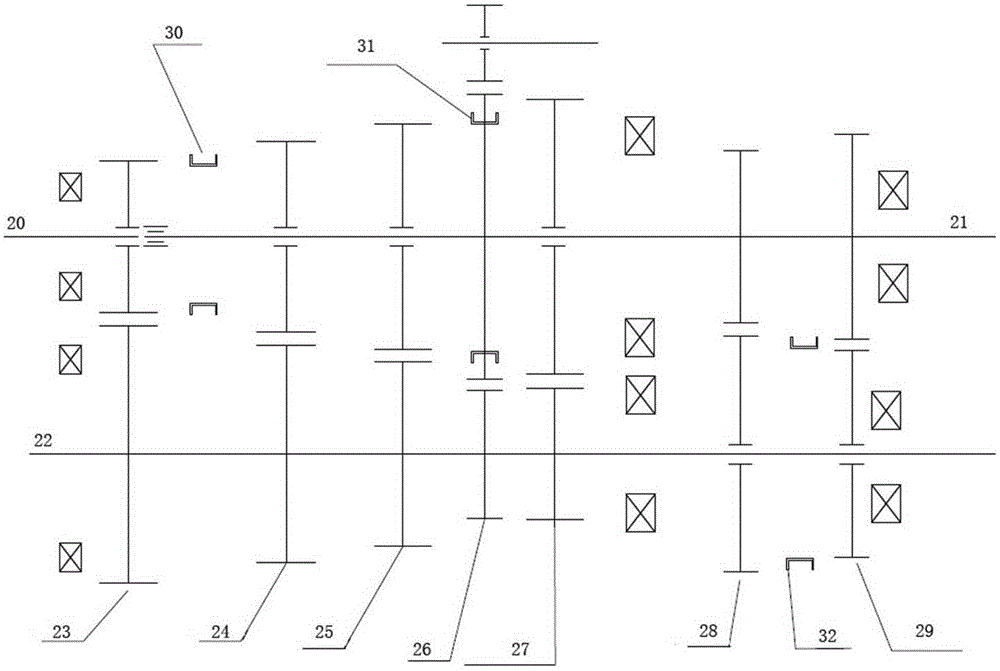

Automatic transmission and vehicle

ActiveCN106594201ACompact structureIncrease the number ofToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to an automatic transmission which has ten forward gears and one reverse gear through reasonable arrangement of four planetary gear sets and six clutches. Through control of three clutches, power transmission under the gear can be guaranteed; on the premise that the transmission efficiency and the planet wheel rotating speed of the automatic transmission are guaranteed, a first gear ring is directly fixed to a box without using a brake; on one hand, the structure of the automatic transmission is more compact; and on the other hand, impact of the brake on the box in the gear shifting process is reduced, and the loading condition of the box is improved. Comparatively speaking, the brake is not used, the number of the clutches is increased, on one hand, the automatic transmission is more compact through the nested arrangement, and on the other hand, the using rate of the clutches can be increased, the idle shortening transmission line is disconnected, idle planetary gear set dragging torque is reduced, drag torque oil stirring losses are reduced, and the transmission efficiency is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

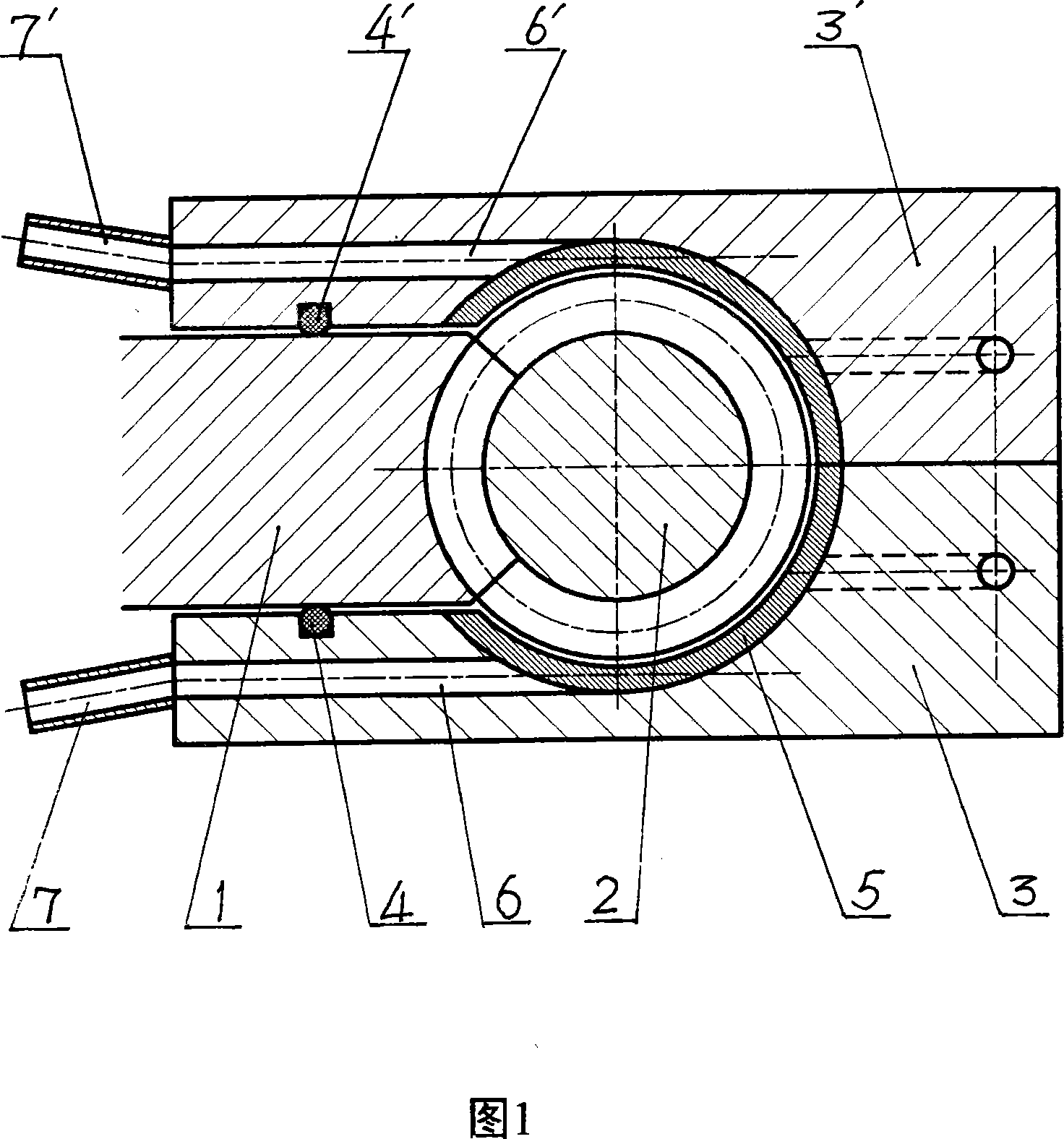

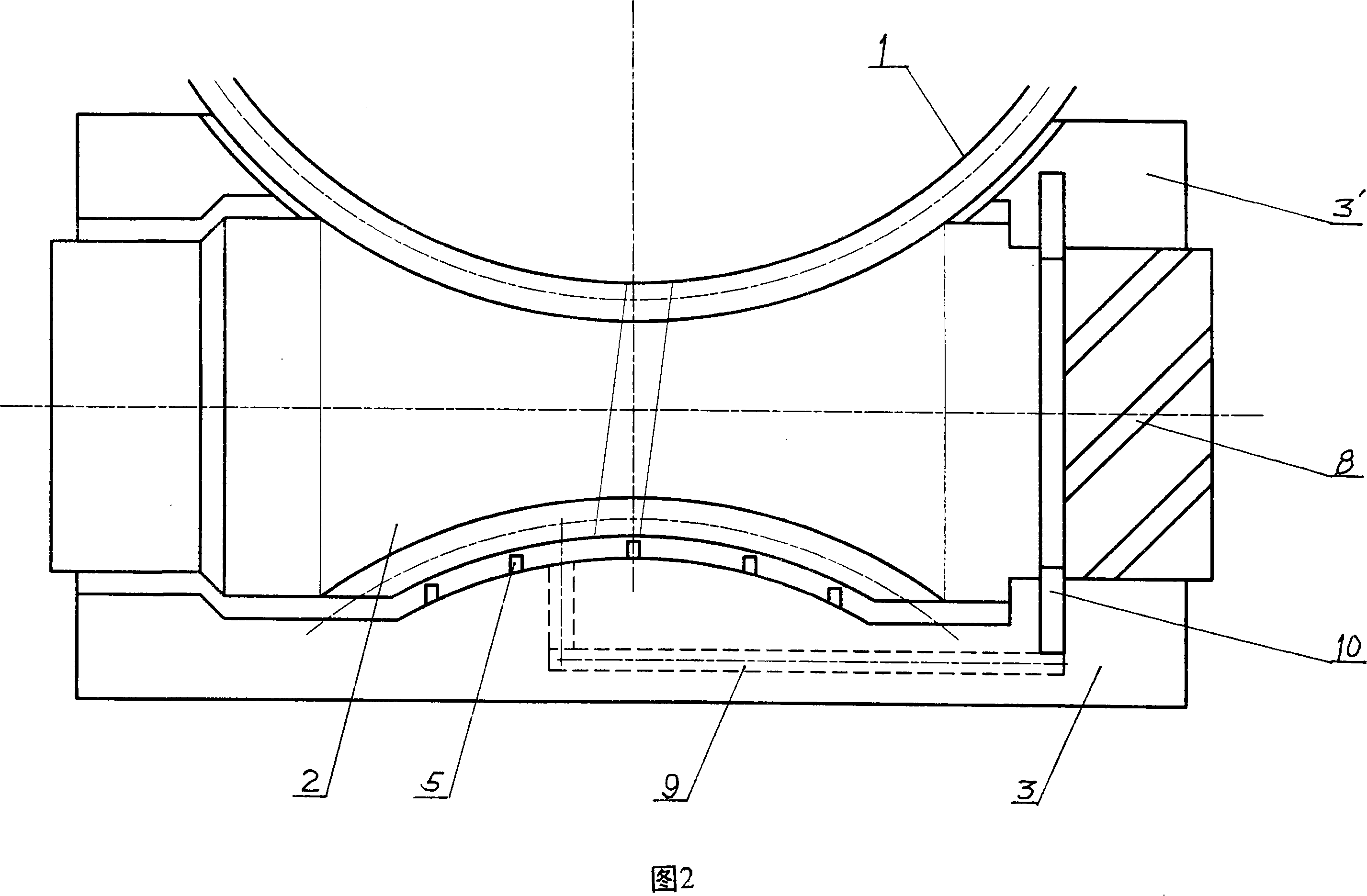

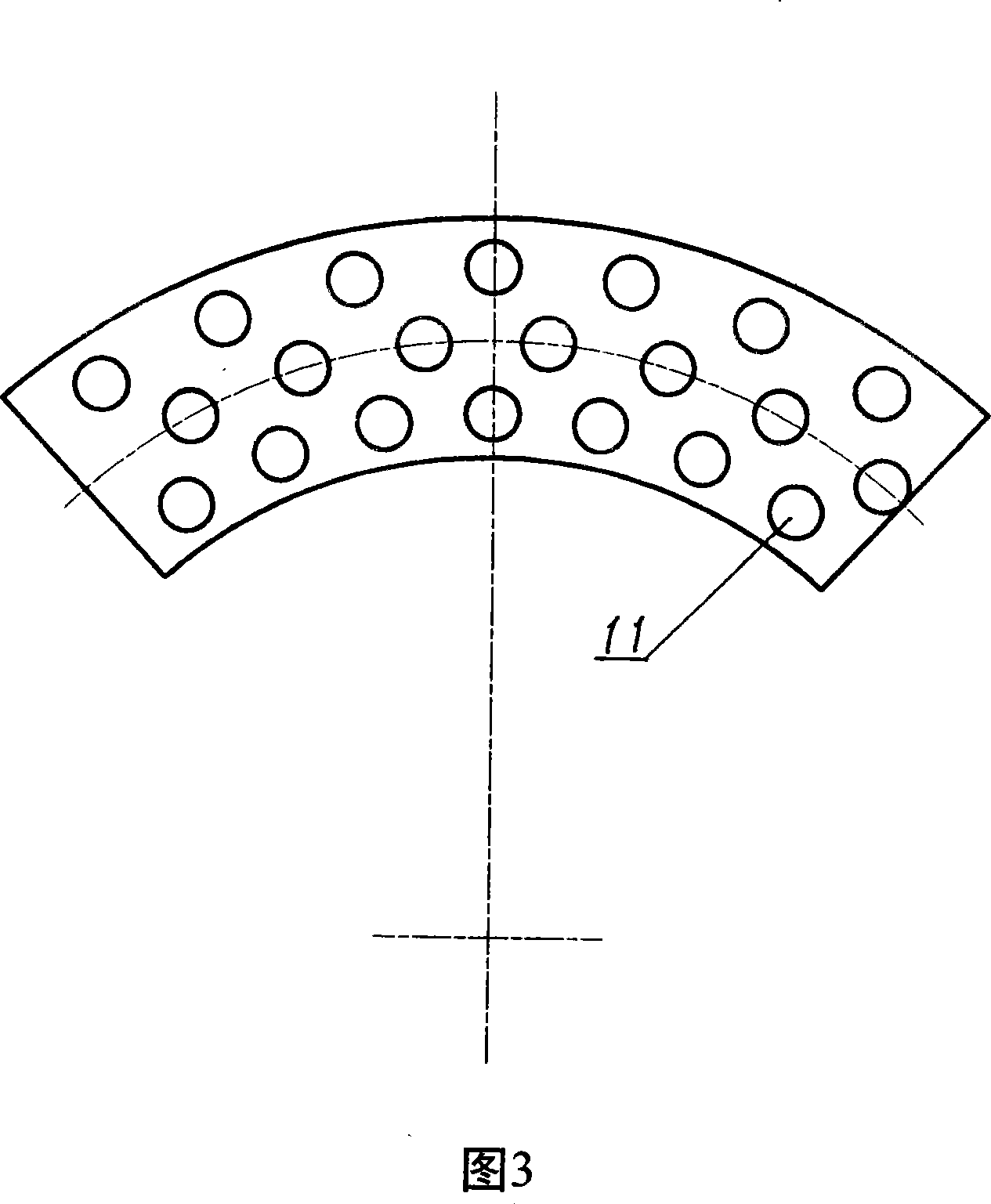

Worm wheel and worm with dynamic and static pressure lubricating at engagement zone

InactiveCN101067437AImprove the lubrication effectReduce churning lossToothed gearingsPortable liftingGear driveGear wheel

The invention discloses the worm and gear with the active and static pressure lubricant used in the mechanically-driven meshing zone. The sealing mass is installed in the out of the meshing zone of the worm and the gear, which contacts with the worm and has the sealing strip. The maze tooth is on the relative surface of the sealing mass and the gear, which is directed to the bear without the oil through the oil pipe from the oil hole opened in the sealing zone formed between the sealing mass hollow and the worm or gear. The screw vanes with the same direction are set on the meshed end of the basal leptospira in gear. The ring oil groove in sealing mass hollow is connected to the sealing zone through the oil hole; on the tooth surface of the worm or gear, the unconnected oil slots are opened. The structure of the invention has improved the lubricant of the worm and gear to improve the loading ability. The driven efficiency has improved by 3%, so it can instead the multilevel gear or planet gear and used in the big speed ratio field.

Owner:刘继清

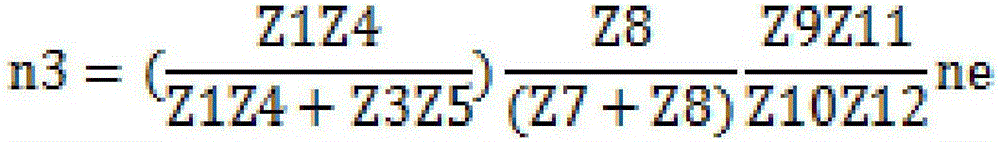

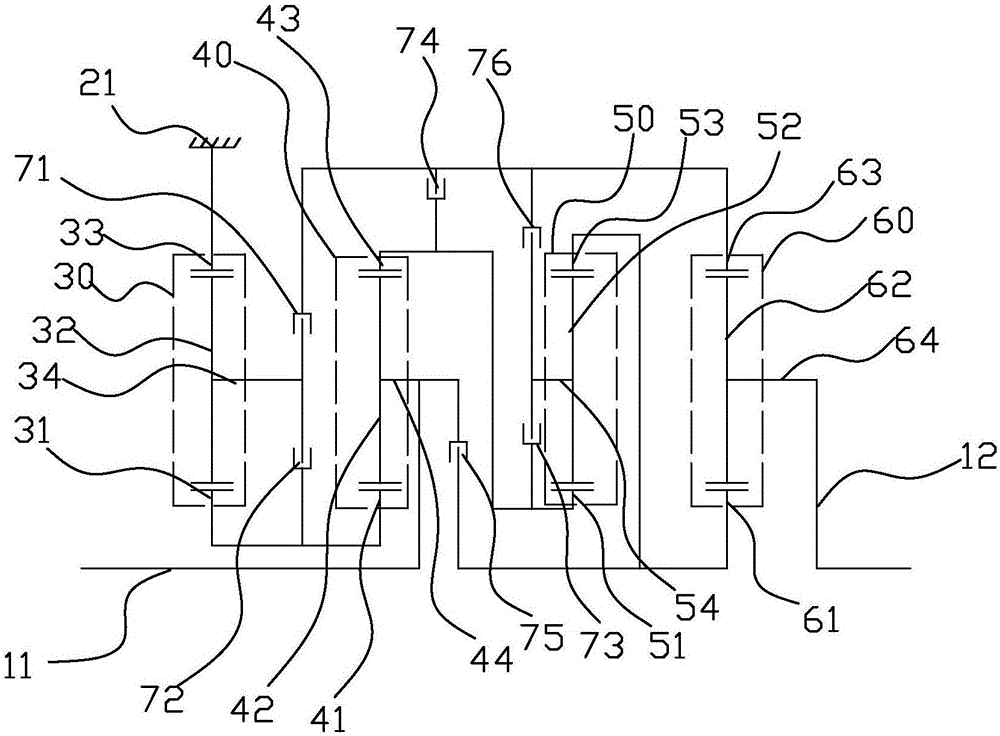

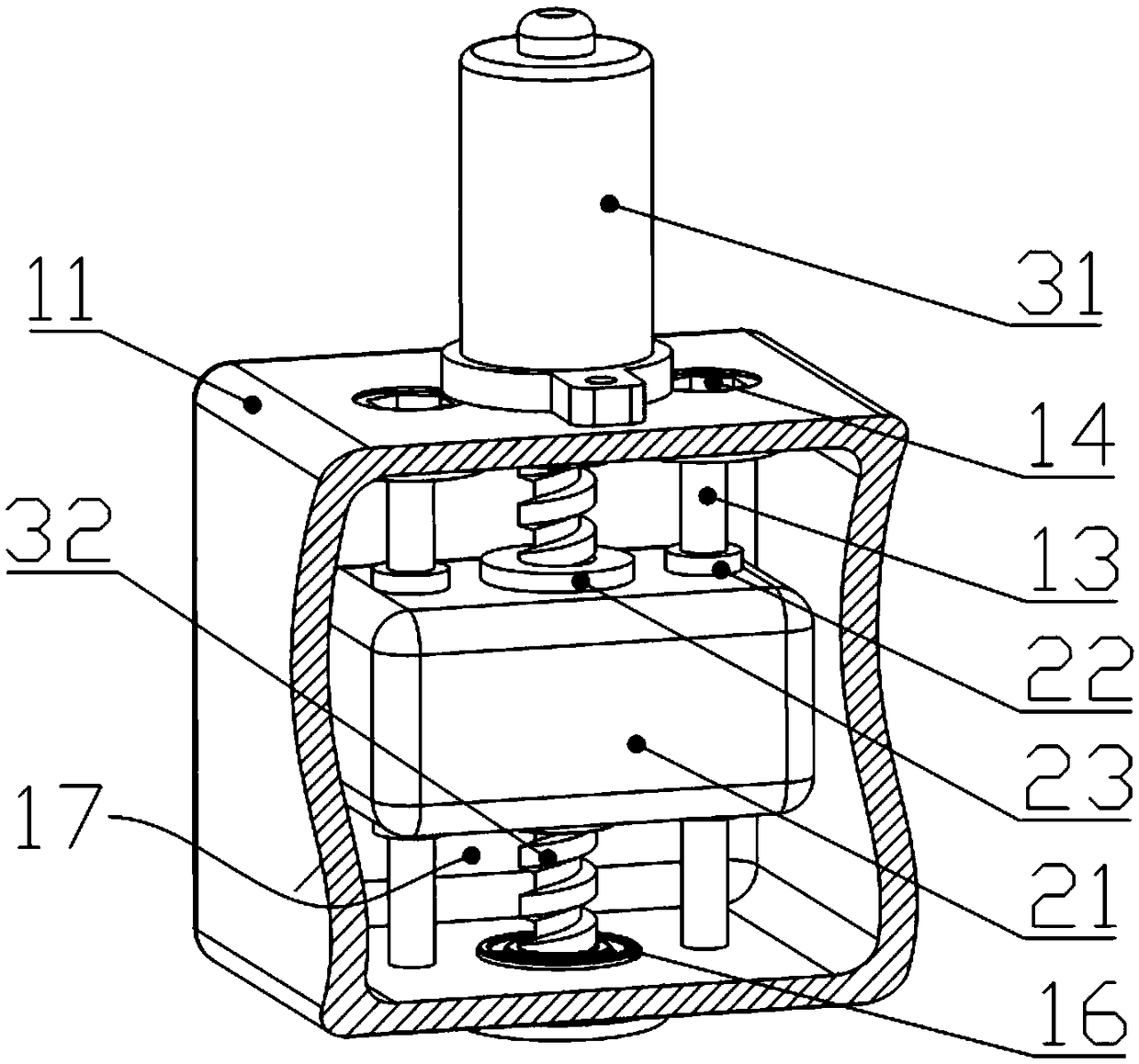

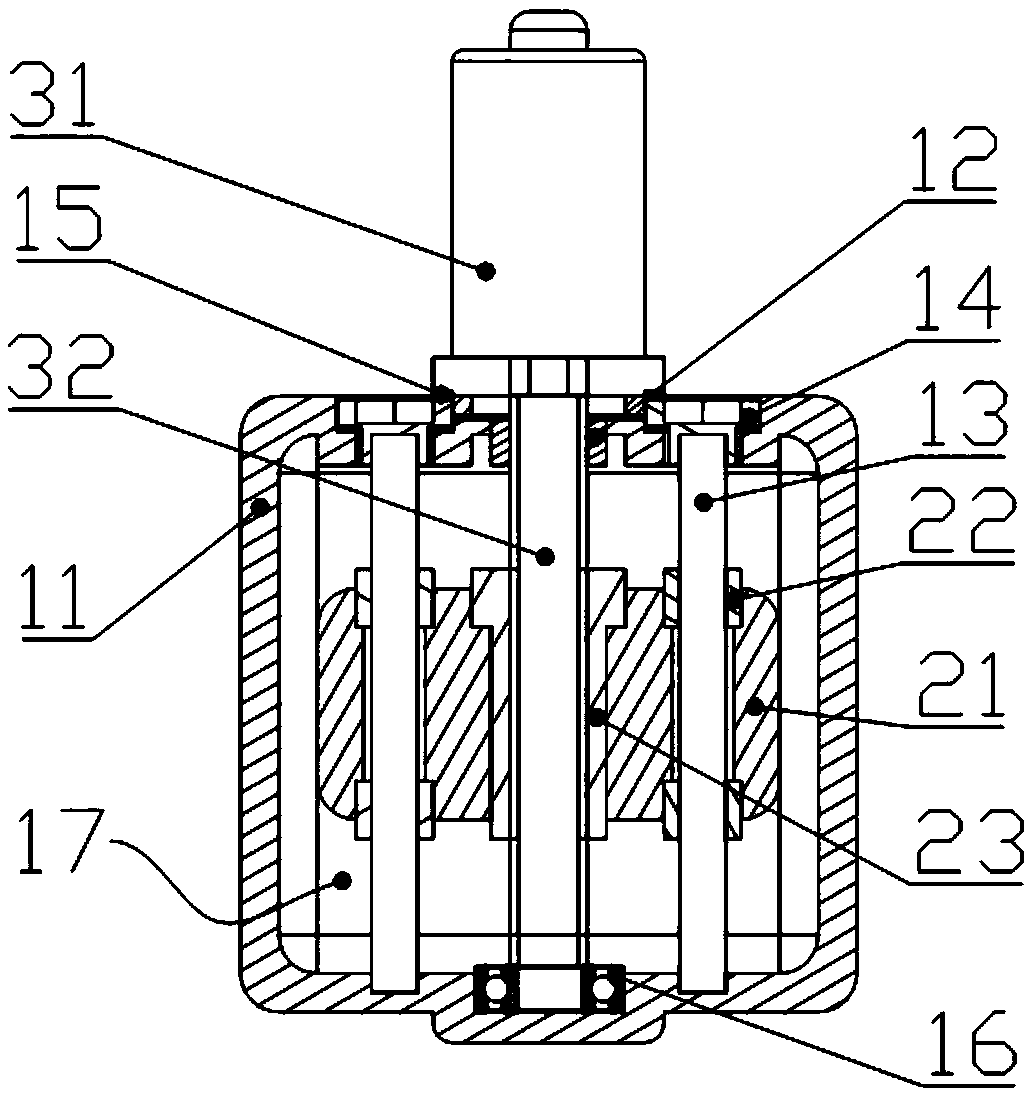

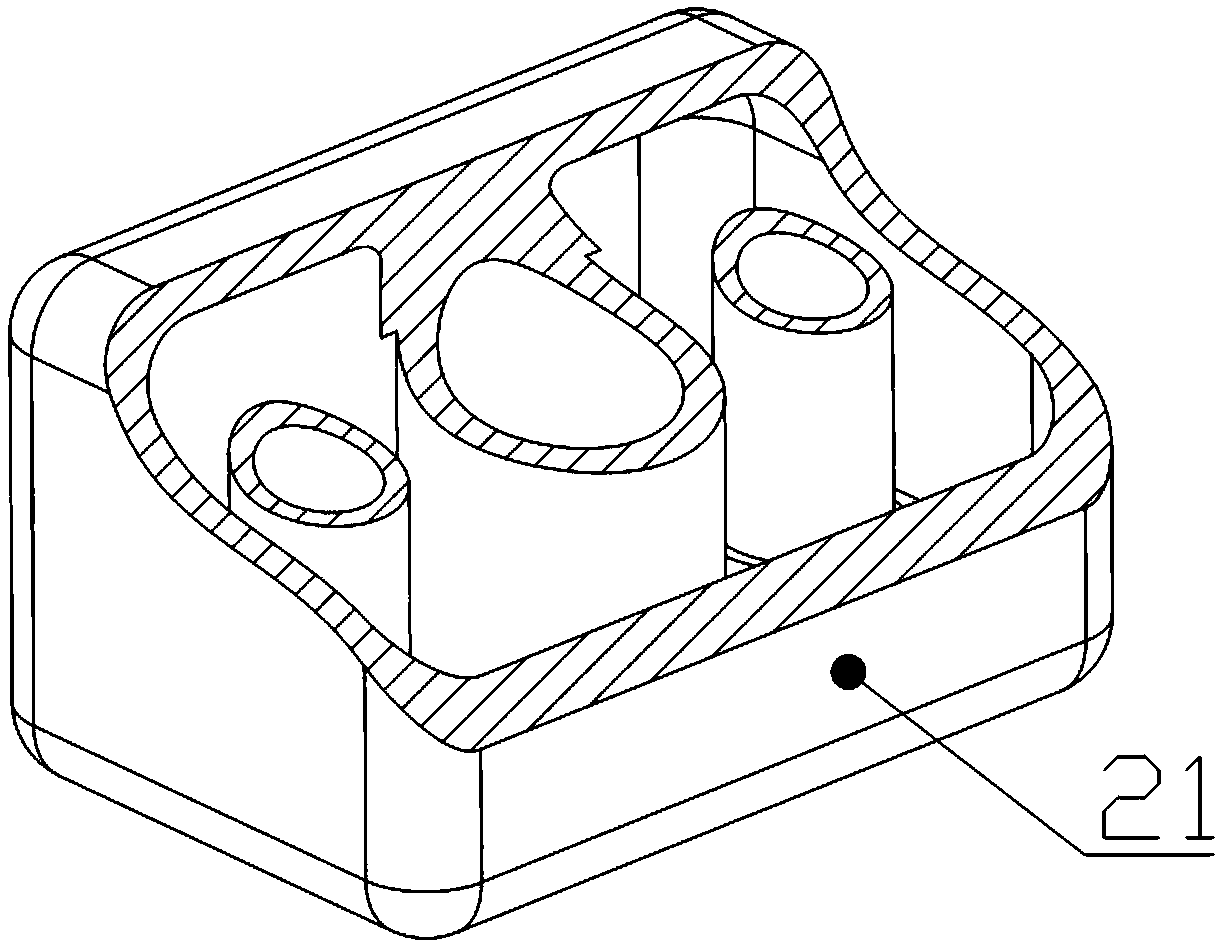

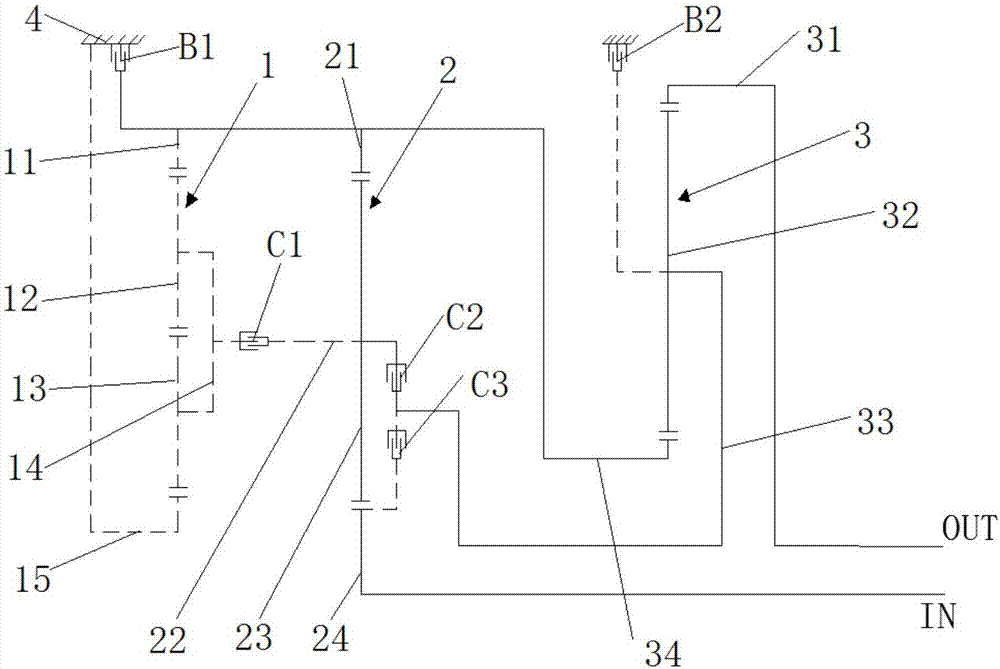

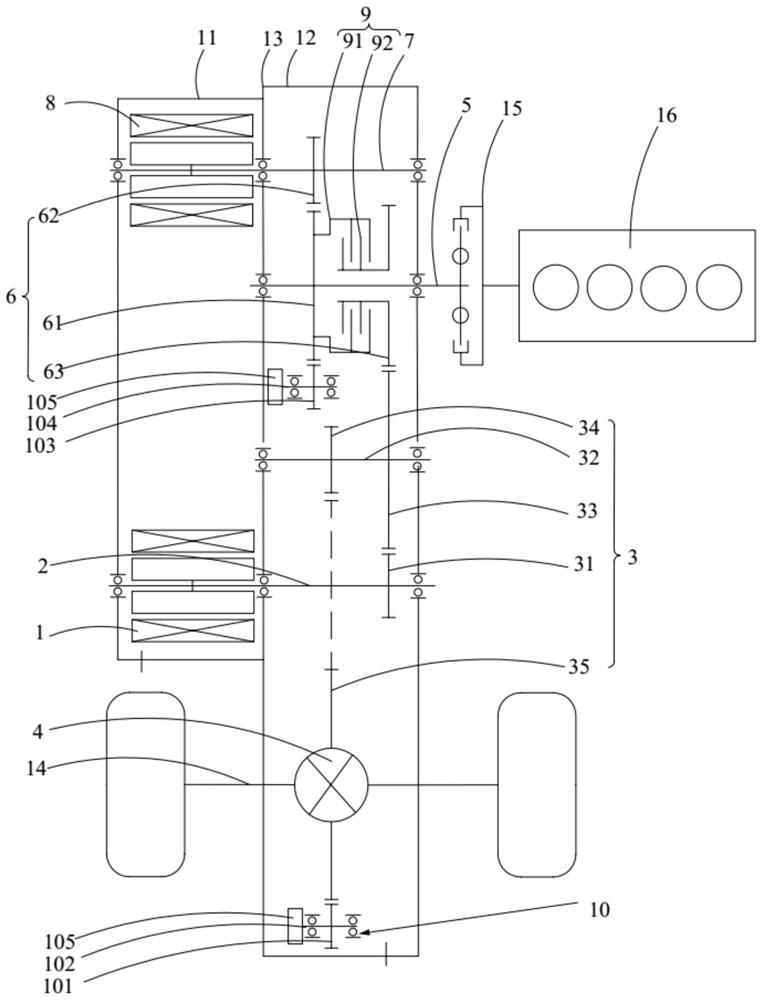

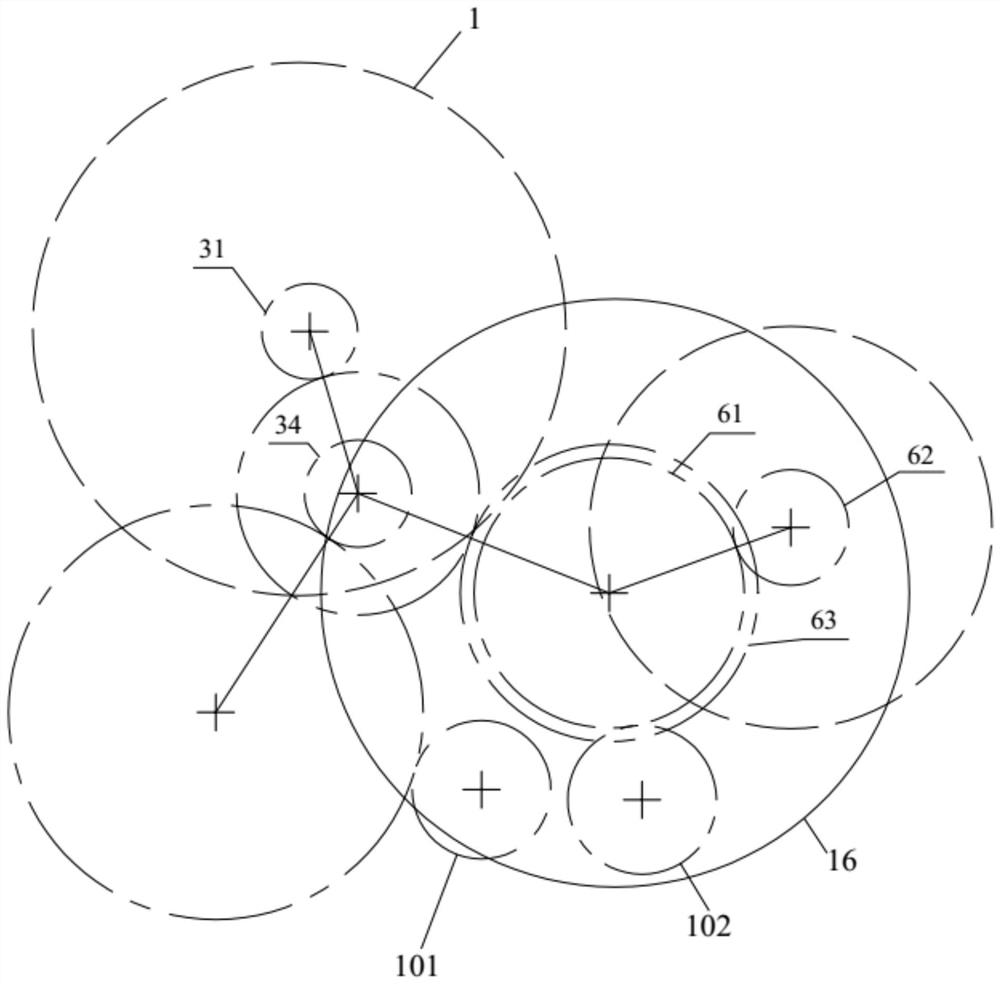

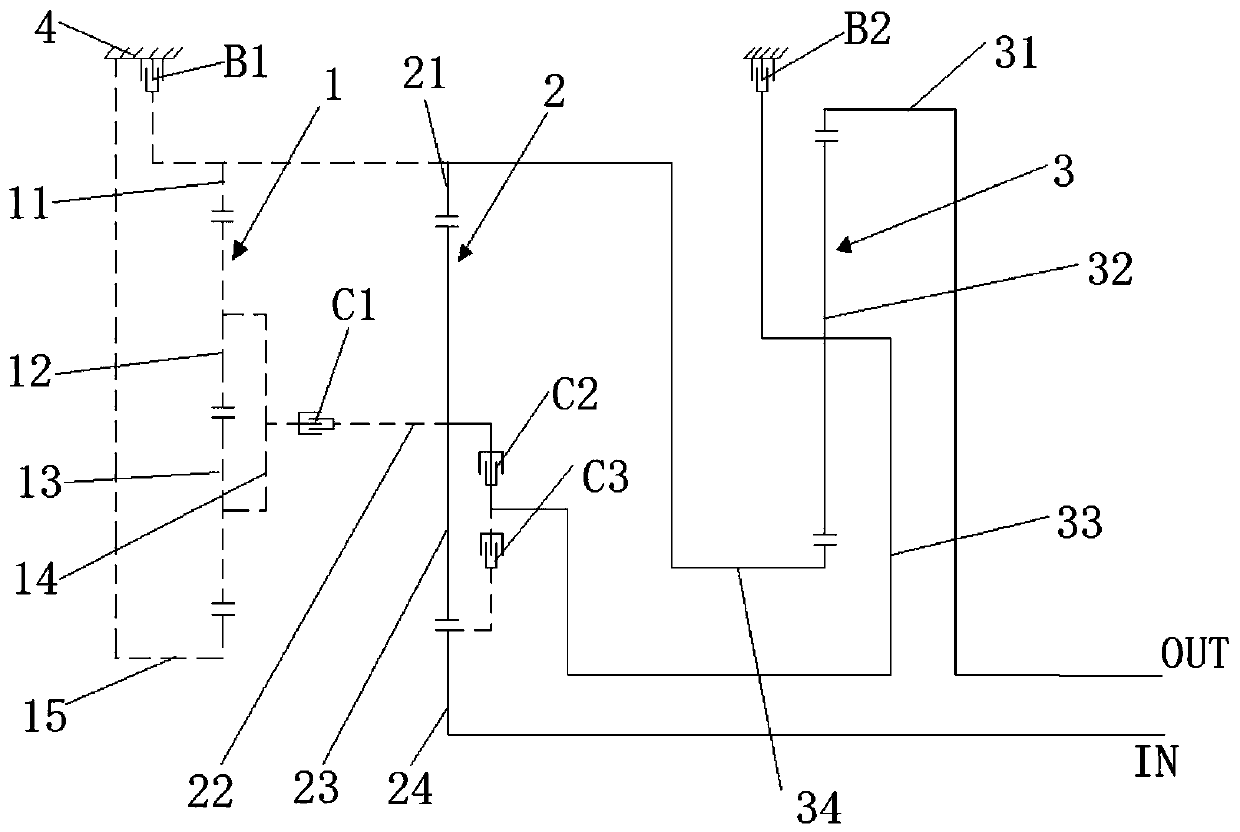

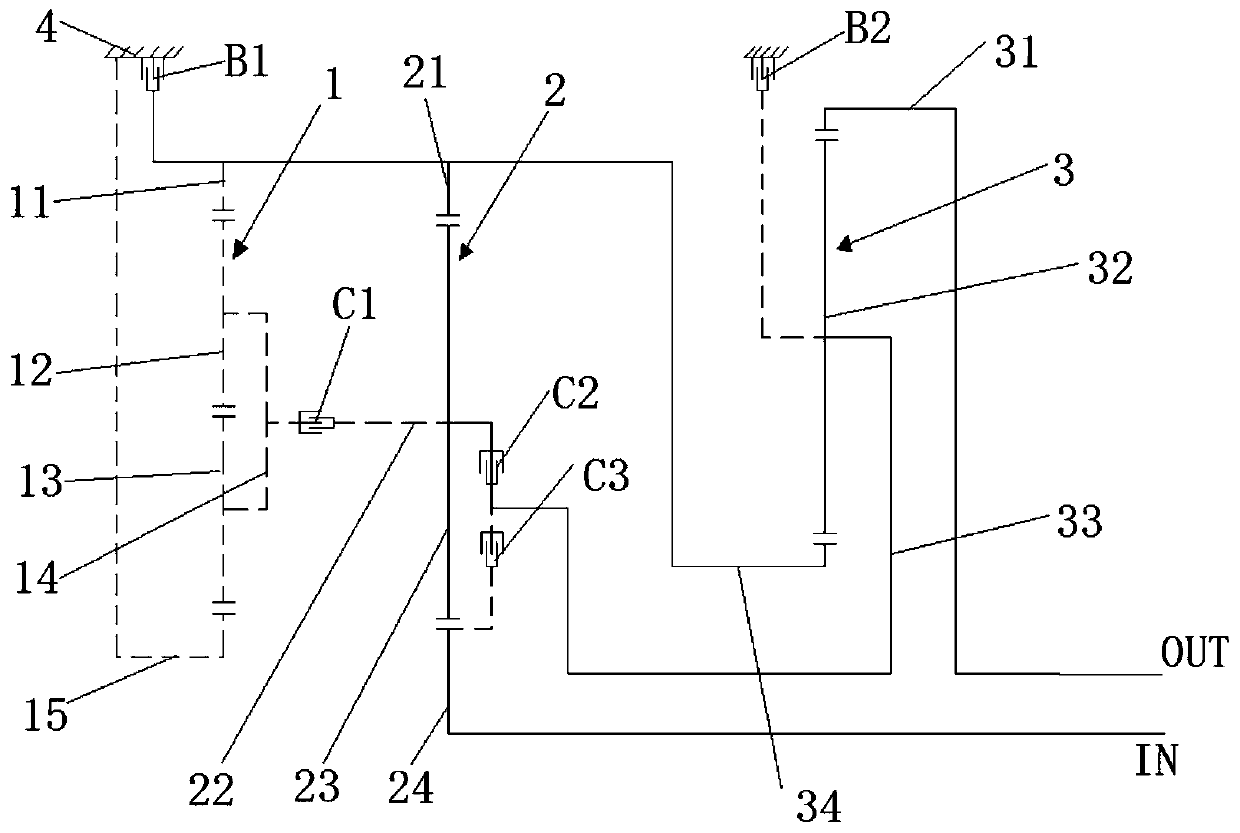

Hybrid power assembly with multimode compound planets

ActiveCN106494215AImprove reliabilityHigh transmission reliabilityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingPowertrainLoad capacity

The invention discloses a hybrid power assembly with multimode compound planets. An engine, an elastic damper, a first motor, a first planetary line, a second planetary line, and a second motor are coaxially and sequentially mounted. An output shaft of the hybrid power assembly is connected to the second planetary line. A first shift brake is connected to the output shaft of the first motor and the first planetary line. A second shift brake is connected to the first planetary line and the second planetary line. A third shift brake is connected to an output shaft of the second planetary line and an output shaft of the second motor. A controller is electrically connected to a storage battery, the engine, the first motor, the first motor, the first shift brake, the second shift brake and the third shift brake. The hybrid power assembly with multimode compound planets has the advantages of being high in transmission efficiency, low in running and production cost, high in reliability, good in load capacity, long in service life and good in cost-performance.

Owner:GUANGZHOU XINYU POWER TECH CO LTD

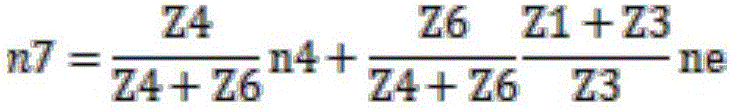

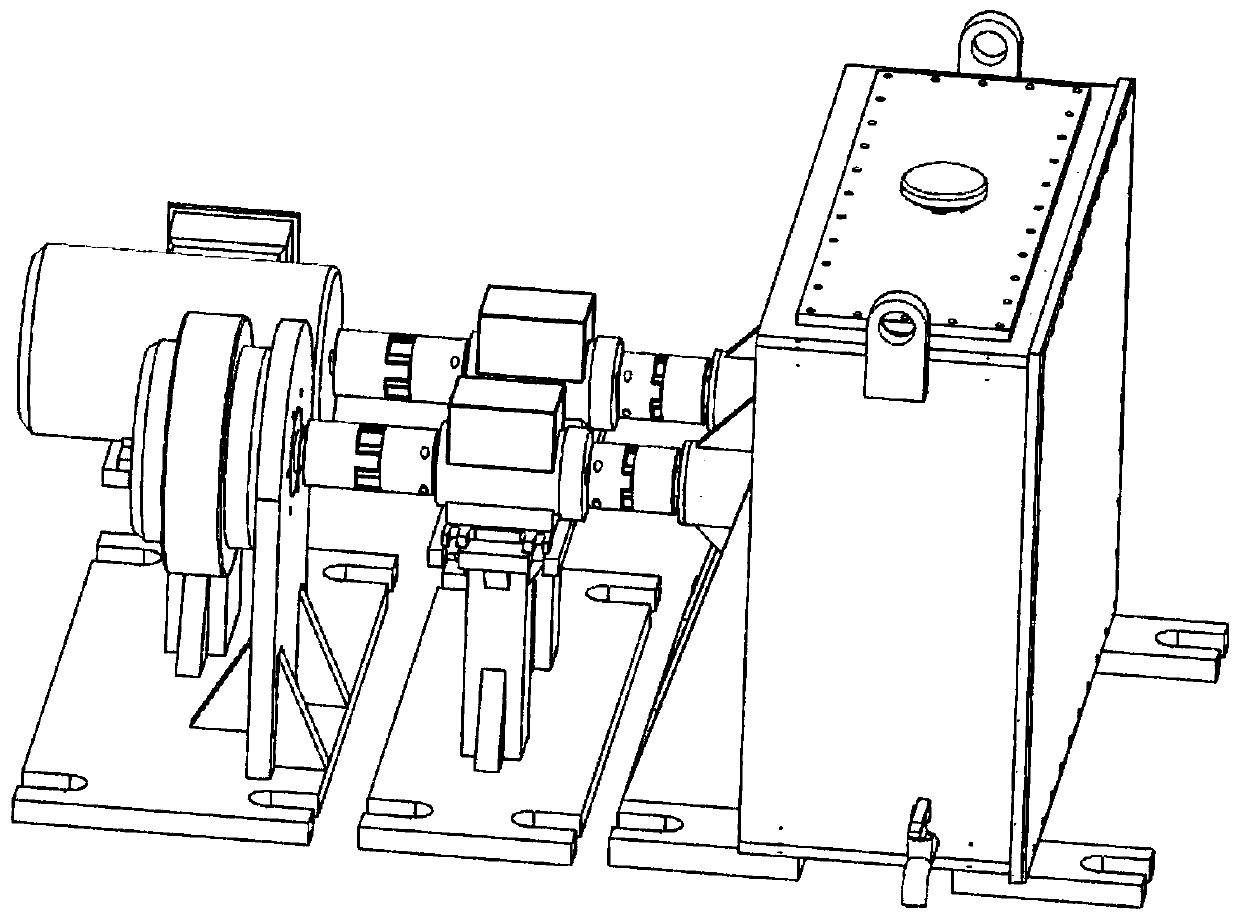

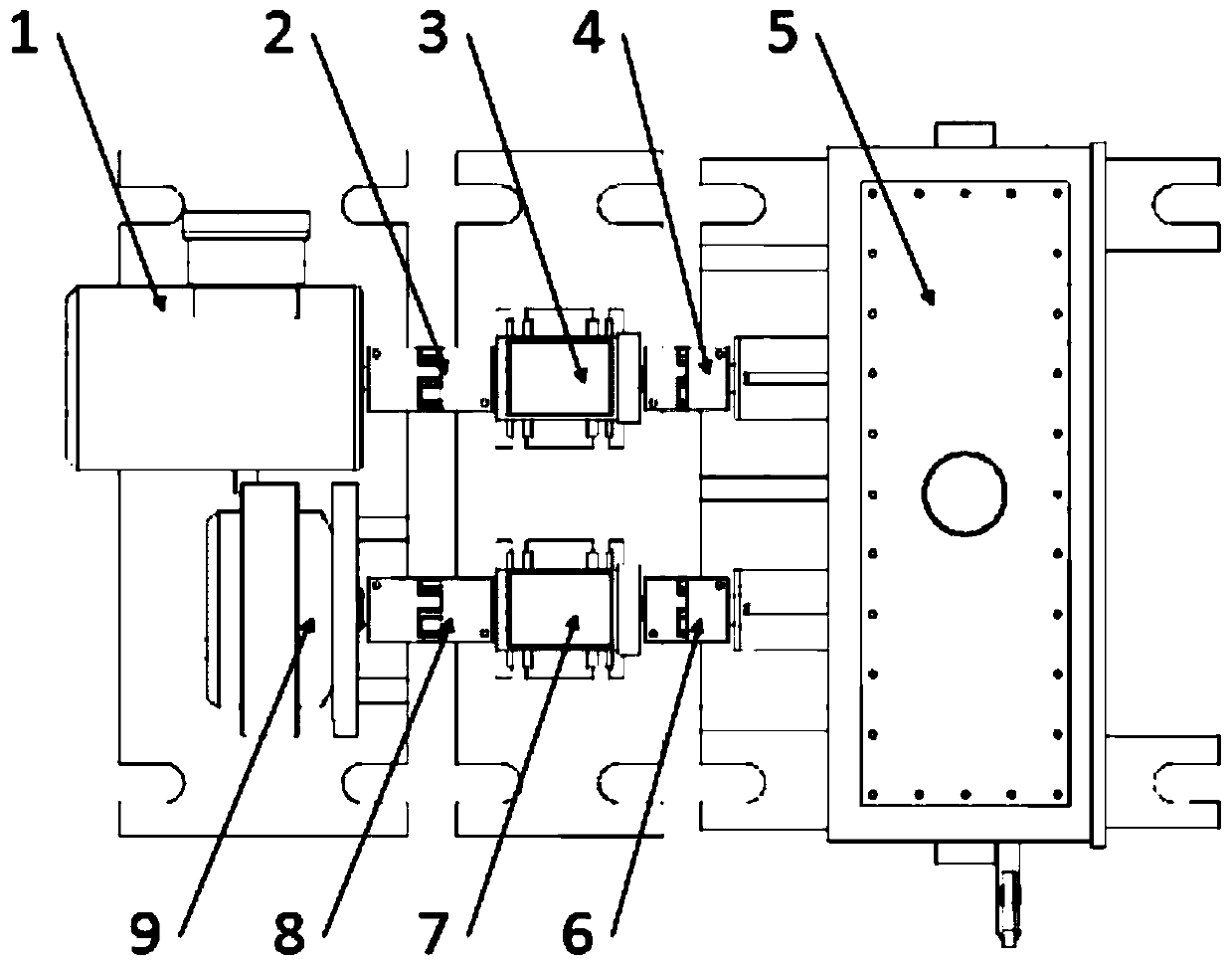

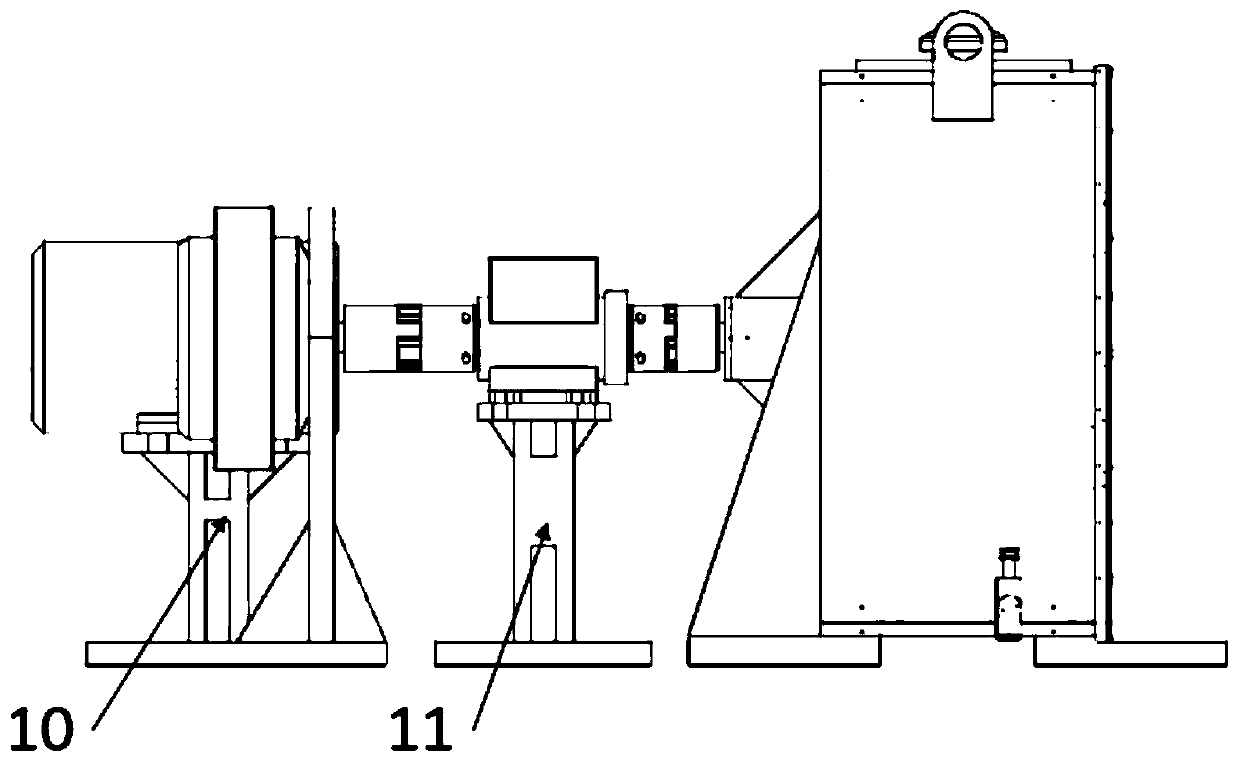

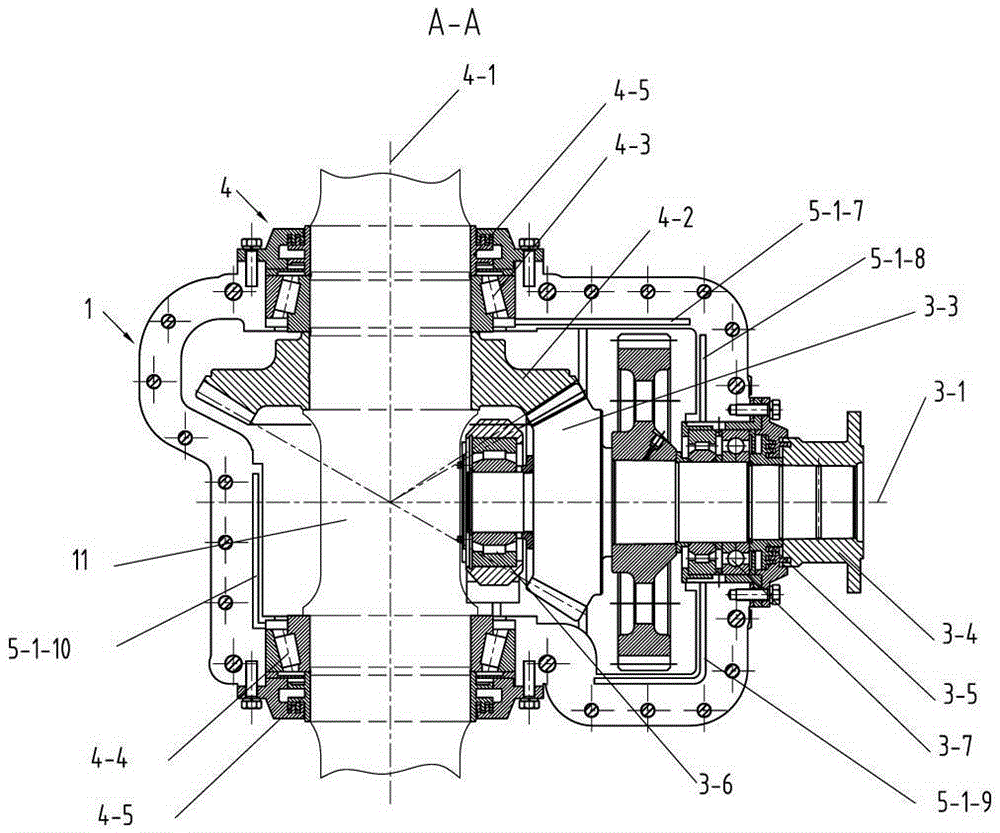

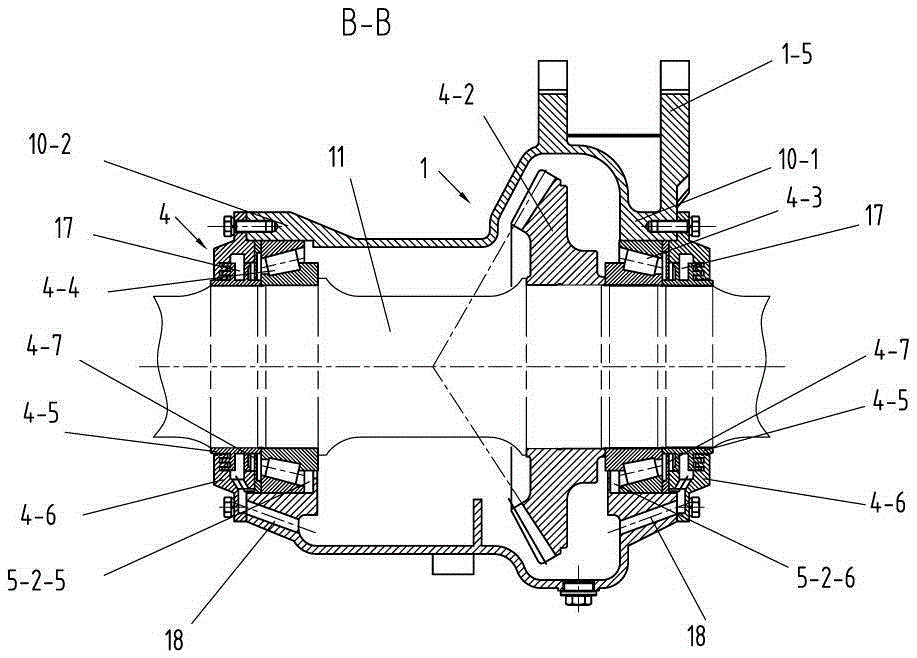

Drive axle for mobile working machine

ActiveCN103863078ALower system temperatureEasy maintenanceAssociation with control/drive circuitsElectric propulsion mountingDrive motorElectric drive

The invention relates to a drive axle (1) for a mobile working machine, especially for a ground conveying machine. The drive axle at least comprises electric drive motors (3a; 3b), power electronic devices (6a; 6b) manipulating the drive motors (3a; 3b), and speed changers (4a; 4b) driven by the drive motors (3a; 3b). The speed changers drive hubs (5a; 5b). A liquid cooling device which is used for the drive motors (3a; 3b), the power electronic device (6a; 6b) and the speed changers (4a; 4b) is equipped with a liquid loop. One or more following parts, a circulating pump (10), a heat exchanger device (11) and a filter (12), of the liquid loop are assembled or attached onto the drive axle (1).

Owner:LINDE MATERIAL HANDLING

Gearbox lubricating oil liquid level adjusting and controlling system and adjusting and controlling method thereof

PendingCN109296741AFlexible adjustment of liquid levelLower the liquid levelGear lubrication/coolingDrive motorEngineering

The invention provides a gearbox lubricating oil liquid level adjusting and controlling system and an adjusting and controlling method thereof. The side face of a bottom lubricating oil storing bin ofa gearbox shell is provided with a communicating containing cavity; the adjusting and controlling system is installed in the containing cavity; a lifting device is formed in a manner that a driving motor and a lead screw are coaxially connected; an oil discharging device is formed in a manner that a floating cavity, a guiding sleeve and a threaded long sleeve are fixedly connected; the floating cavity is in sliding connection with a supporting and guiding assembly through the guiding sleeve, and is in threaded connection with the lifting device through the threaded long sleeve; under drivingby the lifting device, the floating cavity performs lifting movement in the containing cavity along the supporting and guiding assembly, and therefore the liquid level height of lubricating oil in thecontaining cavity is controlled; a control assembly is composed of a controller and a vehicle state sensor in a signal connection manner; and the adjusting and controlling method comprises an adjusting and controlling method for increasing and decreasing the liquid level height of the lubricating oil. According to the gearbox lubricating oil liquid level adjusting and controlling system and the adjusting and controlling method thereof, the amount of the lubricating oil needed by each part is determined according to the specific work state of a gearbox, the liquid level of the lubricating oilis controlled at the position of optimal height, the oil stirring loss is reduced, and the overall transmission efficiency of the gearbox is improved.

Owner:JILIN UNIV

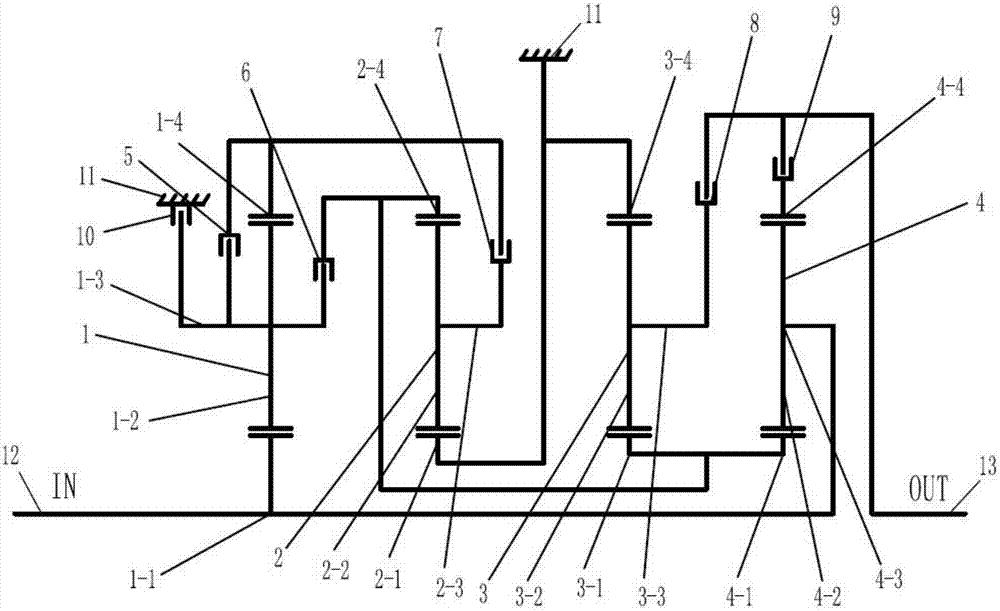

Three-planet-row six-speed automatic transmission and automobile

ActiveCN106884936AIncrease profitMiniaturizationToothed gearingsTransmission elementsAutomatic transmissionTorque transmission

The invention relates to the field of automobiles, and discloses a three-planet-row six-speed automatic transmission and an automobile. The three-planet-row six-gear automatic transmission comprises a first planet row, a second planet row and a third planet row, wherein the first planet row comprises a first gear ring, a first inner planet gear group and a first outer planet gear group which are meshed with each other, a first sun gear and a first planet carrier; the second planet row comprises a second gear ring, a second planet gear group, a second sun gear and a second planet carrier; the third planet row comprises a third gear ring, a third planet gear group, a third sun gear and a third planet carrier; the first gear ring, the second gear ring and the third sun gear are sequentially and fixedly connected into a whole; the first gear ring is connected to the transmission housing through a first brake member; the first planet carrier is connected with the second planet carrier through a first torque transmission member; the second planet carrier is connected with the third planet carrier through a second torque transmission member; the third planet carrier is connected with the second sun gear through a third torque transmission member and further connected to the transmission housing through a second brake member.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Gearbox lubricating test device and measuring device for lubricating oil injection quantity

InactiveCN107687946APlay a lubricating effectOptimal Solution for Filling VolumeMachine gearing/transmission testingCapacity measurement calibrationPetroleum engineeringVariator

Owner:SAIC MOTOR

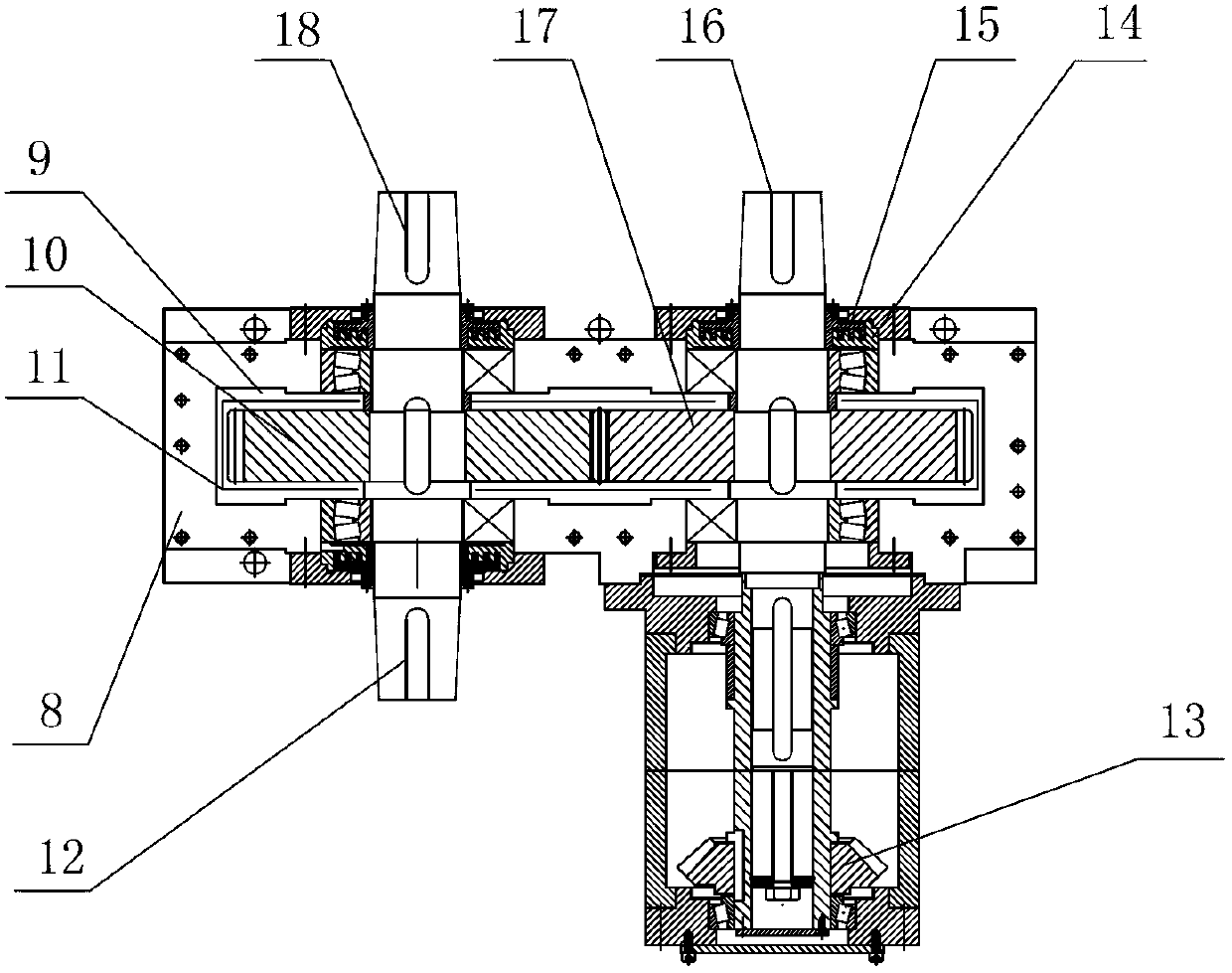

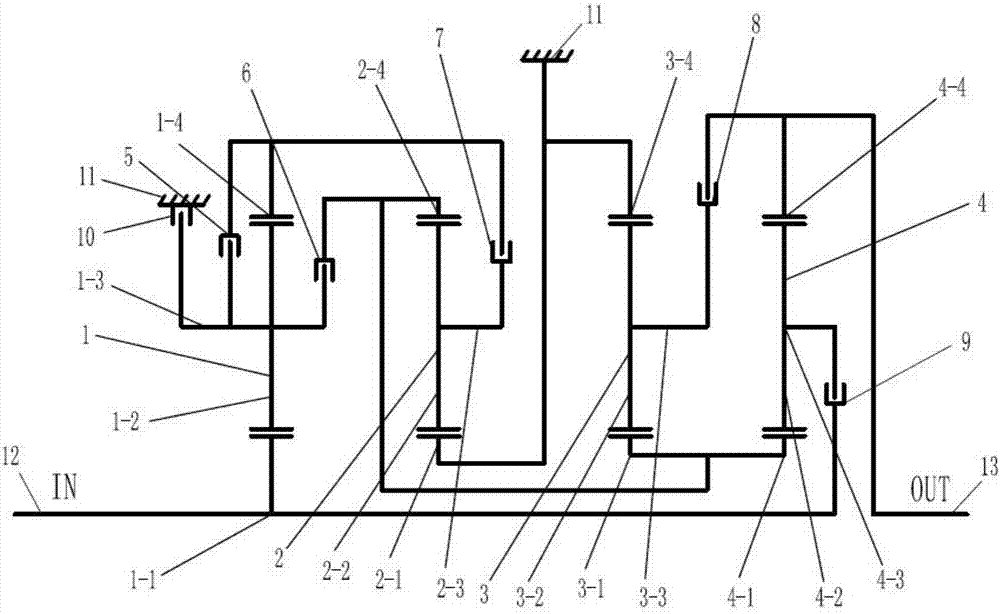

Two-clutch double-row planetary gear four-gear automatic transmission

ActiveCN109737190AReduce churning lossImprove efficiencyToothed gearingsGearing controlAutomatic transmissionEngineering

The invention discloses a two-clutch double-row planetary gear four-gear automatic transmission. The transmission comprises an input shaft, input end double clutches, a front shaft assembly, a box body, a first planetary row, a second planetary row, a rear shaft assembly, output end double clutches and an output shaft, wherein the input end double clutches comprise a first clutch and a second clutch, the front shaft assembly comprise a first sun wheel front shaft and a first front planet carrier front shaft, the first planetary row comprises a first sun gear, a first front planet carrier, a first rear planet carrier, a first planetary gear shaft, a first planetary gear and a first gear ring, the second planetary row comprises a second gear ring, a second planetary gear, a second planetarygear shaft, a second planet carrier and a second sun gear, the rear shaft assembly comprises a second sun gear rear shaft and a second planet carrier rear shaft, and the output end double clutches comprise a third clutch and a fourth clutch. According to the transmission, the clutches are arranged outside the box body, the churning loss of a gearbox is reduced, the efficiency of the planetary geartransmission is very high, the multi-gear adjustment of the transmission is realized, so that the chance that a motor works in a high-efficiency area is increased, the economy of the whole vehicle isimproved, and the driving mileage is increased.

Owner:开沃新能源汽车集团股份有限公司

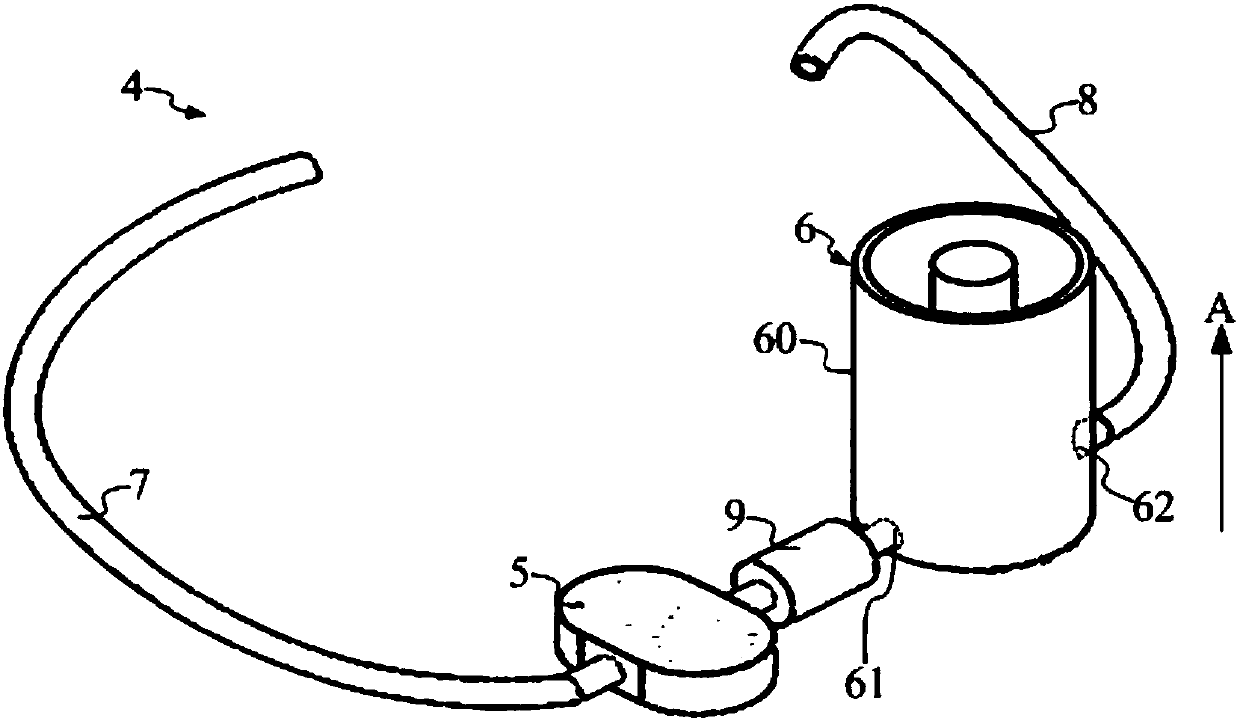

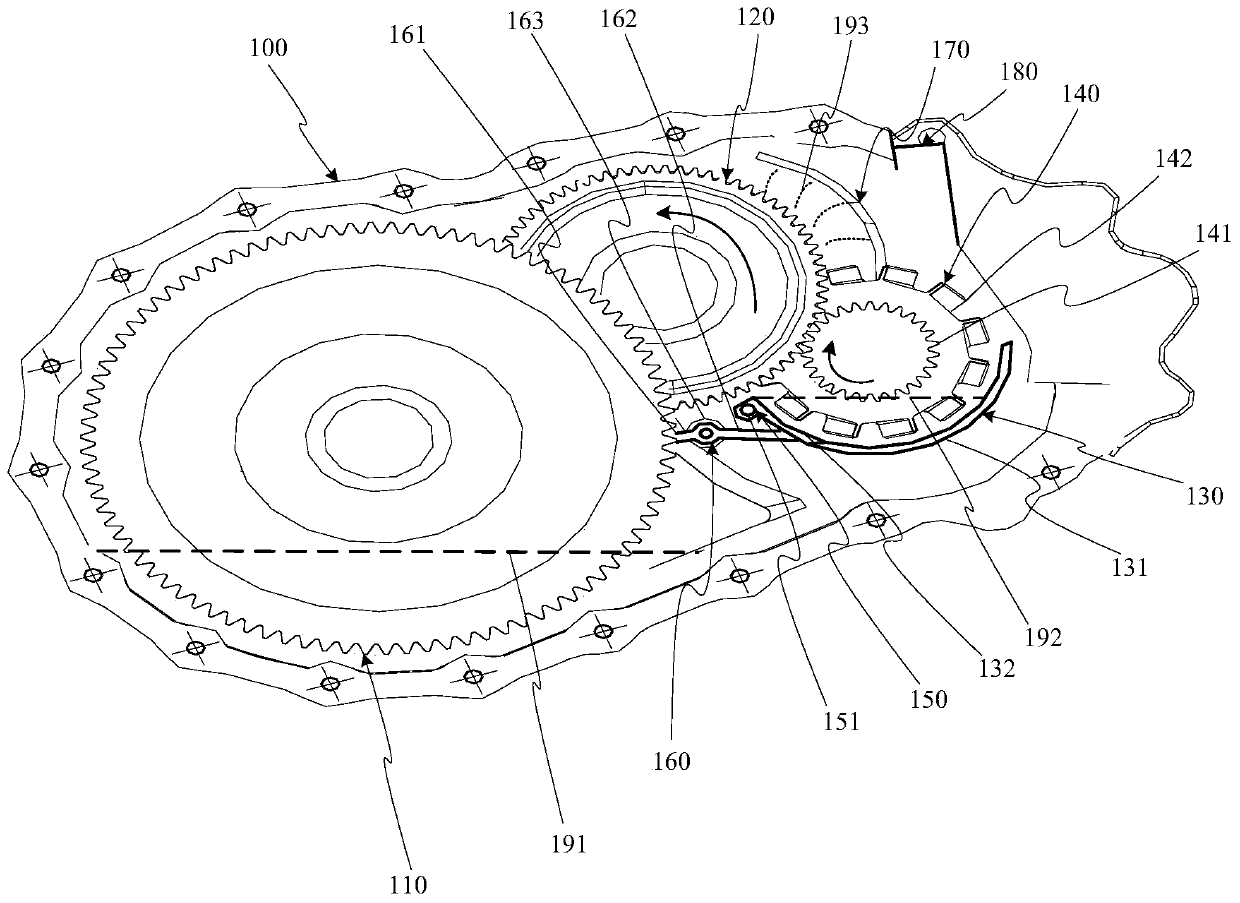

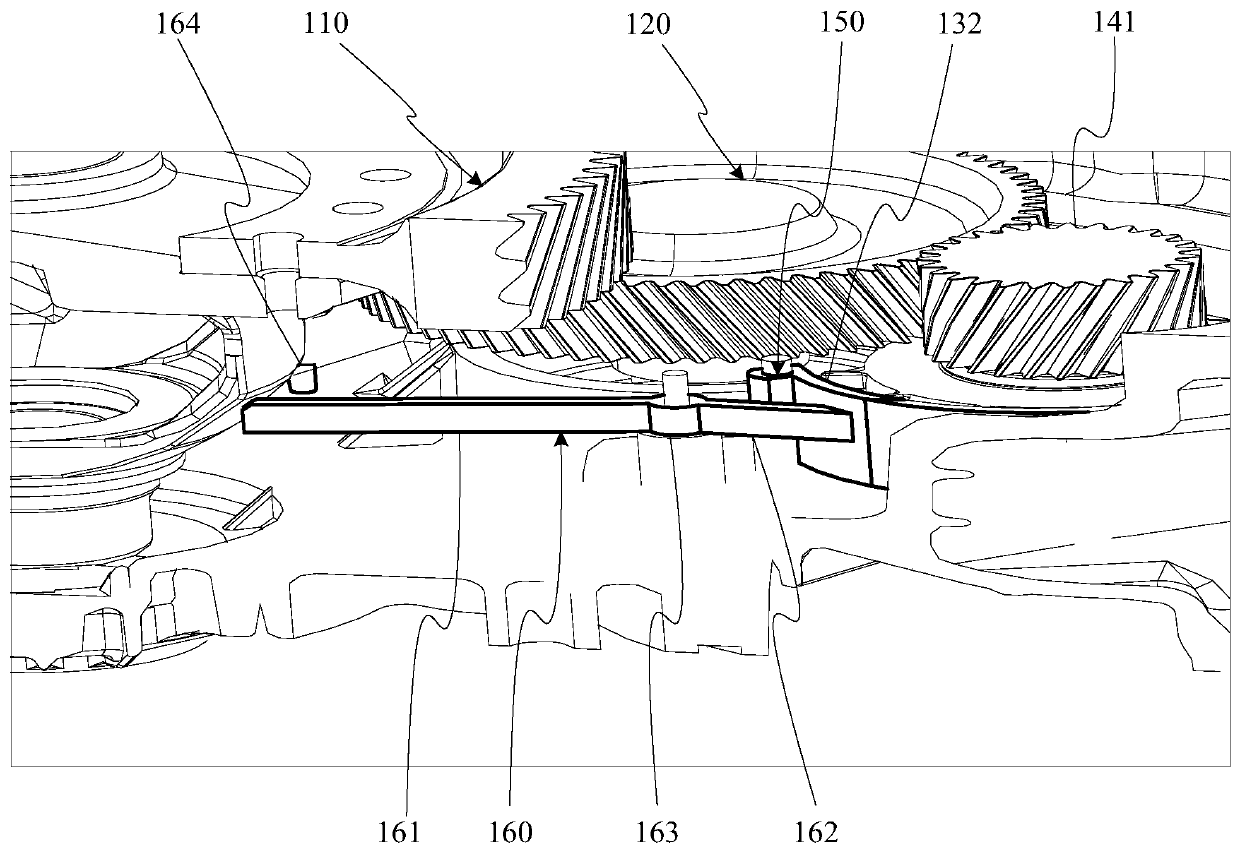

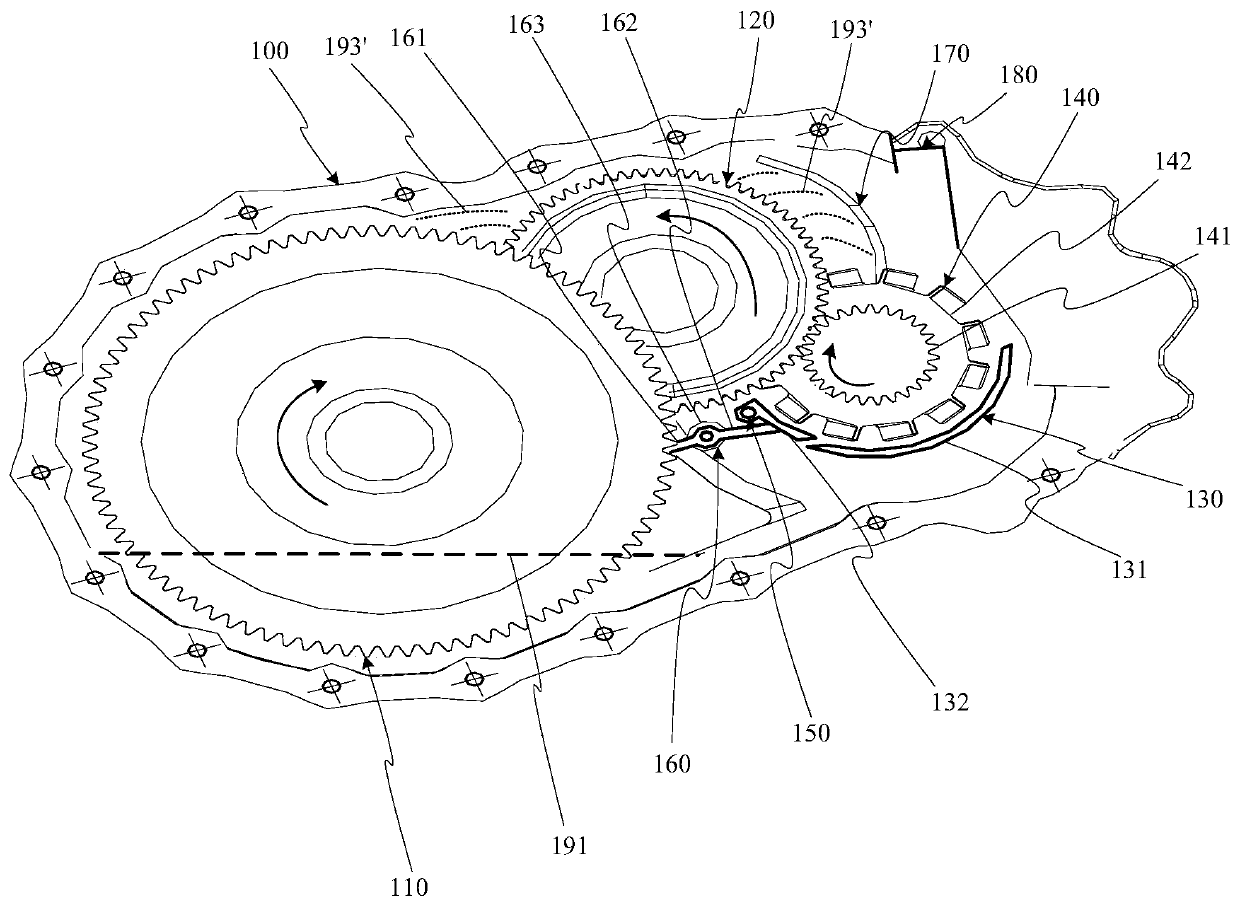

Experimental device and method for measuring gear oil stirring loss in oil immersion lubrication state

ActiveCN111458138AGuaranteed lubrication effectReduce churning lossMachine part testingGear lubrication/coolingGear wheelEngineering

The invention provides an experimental device for measuring gear oil stirring loss in an oil immersion lubrication state. A plurality of transverse partition plates, longitudinal partition plates andclamping grooves are arranged in a box body; the transverse partition plates or the longitudinal partition plates are independently inserted into the corresponding clamping grooves according to requirements in an experiment process, and therefore a lubricating oil cavity is divided into the multiple cavities. Therefore, the lubricating effect of a reduction gearbox is guaranteed, and power loss caused by the turbulence, laminar flow and splashing of lubricating oil is reduced. The invention further provides an experimental method for measuring gear oil stirring loss in an oil immersion lubrication state.

Owner:合肥九州龙腾科技成果转化有限公司

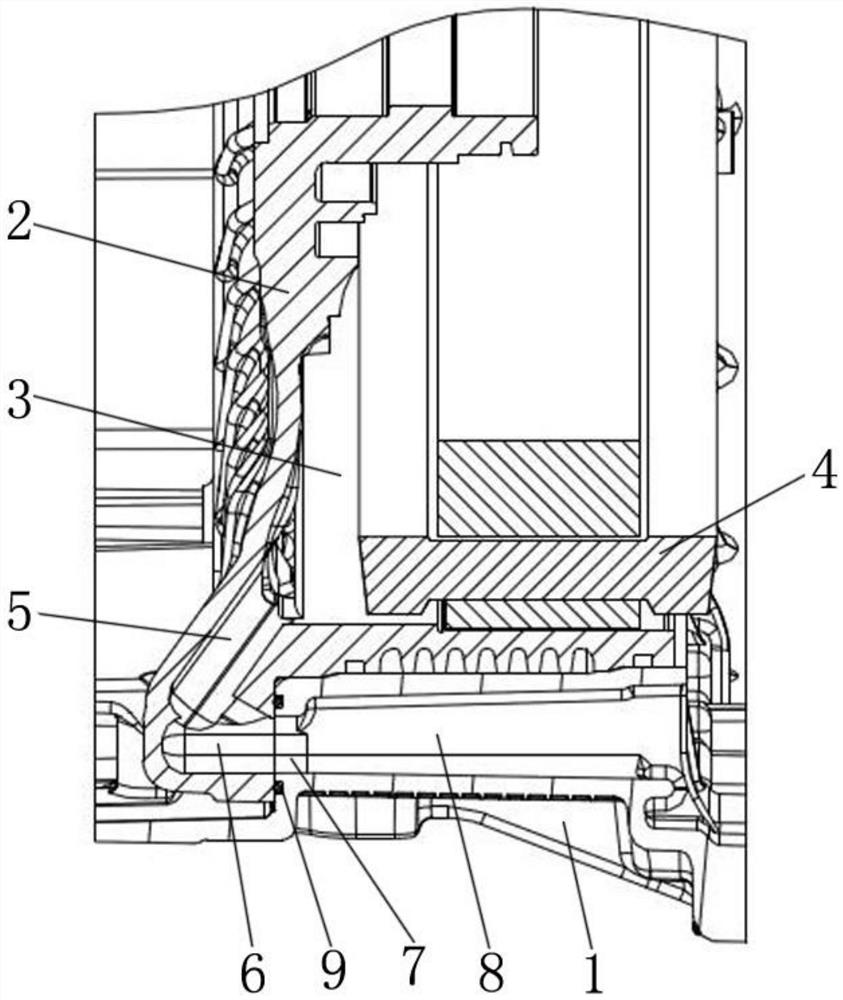

Bearing lubricating mechanism of transmission and transmission

InactiveCN109944928AImprove the lubrication effectReduce failureGearboxesGear lubrication/coolingEngineeringLubrication

The invention discloses a bearing lubricating mechanism of a transmission and a transmission. The bearing lubricating mechanism of the transmission comprises a transmission shell, an input shaft bearing, a differential gear, an input shaft gear, an oil collecting tank and an oil stirring gear, the oil collecting tank has an oil storage state and an oil discharging state, therefore, the oil stirring gear can stir lubricating oil in the oil collecting tank to carry out splashing lubrication on the input shaft bearing, due to the fact that the rotation of the oil stirring gear is directly associated with an input shaft and does not depend on the differential gear, so that even splashing lubrication based on the differential gear is failed due to the fact that a vehicle is parked or idling fora long time, the oil stirring gear can also perform splashing lubrication on the input shaft bearing by utilizing the lubricating oil in the oil collecting tank in response to the rotation of the input shaft, in running process of the differential gear, the oil collecting tank can continuously discharge lubricating oil collected in the period of effective splashing lubrication effect based on thedifferential gear so as to reduce unnecessary oil-stirring loss of the oil stirring gear during the period.

Owner:CH AUTO TECH CORP CO LTD

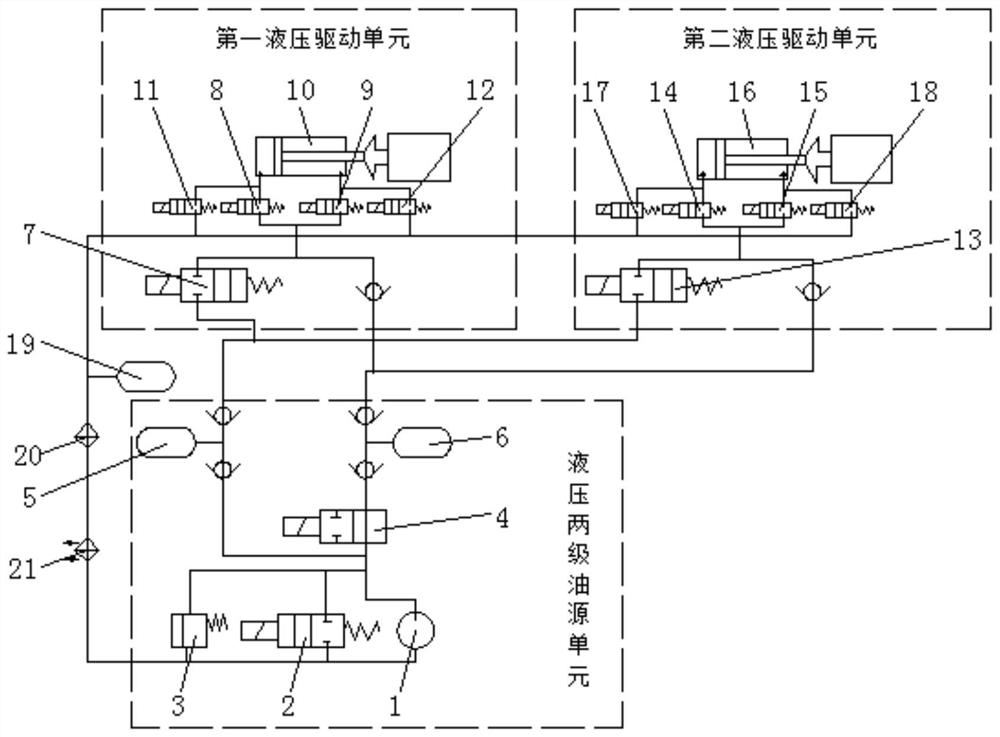

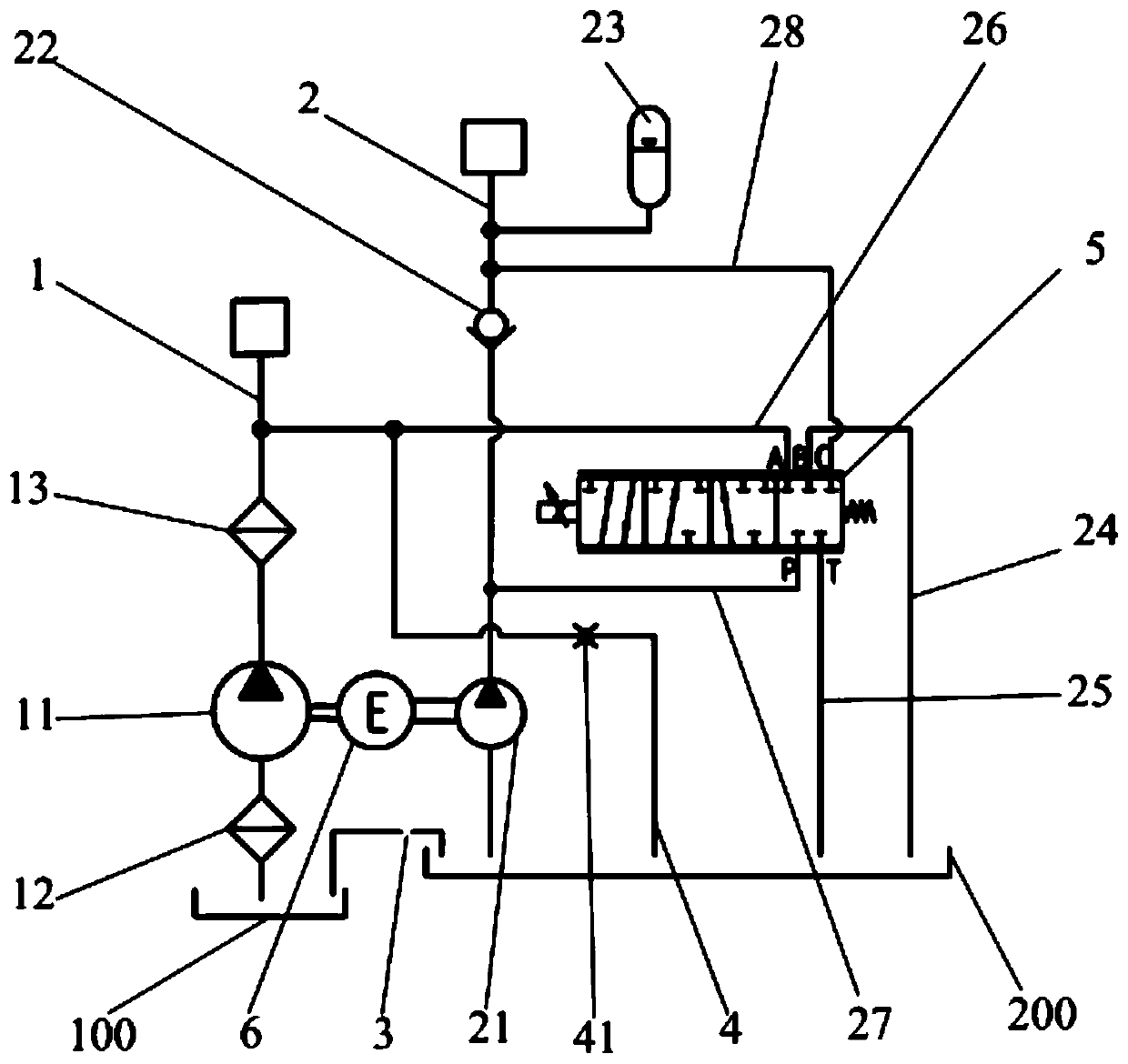

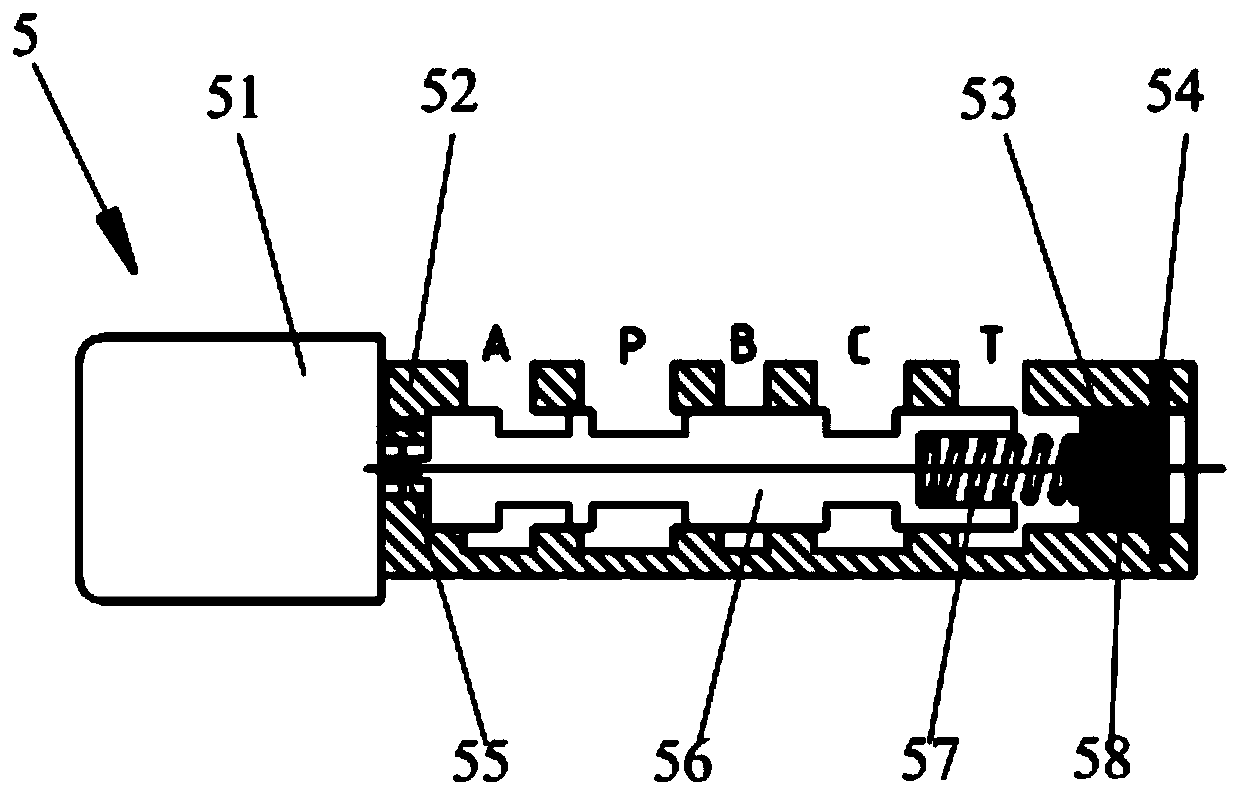

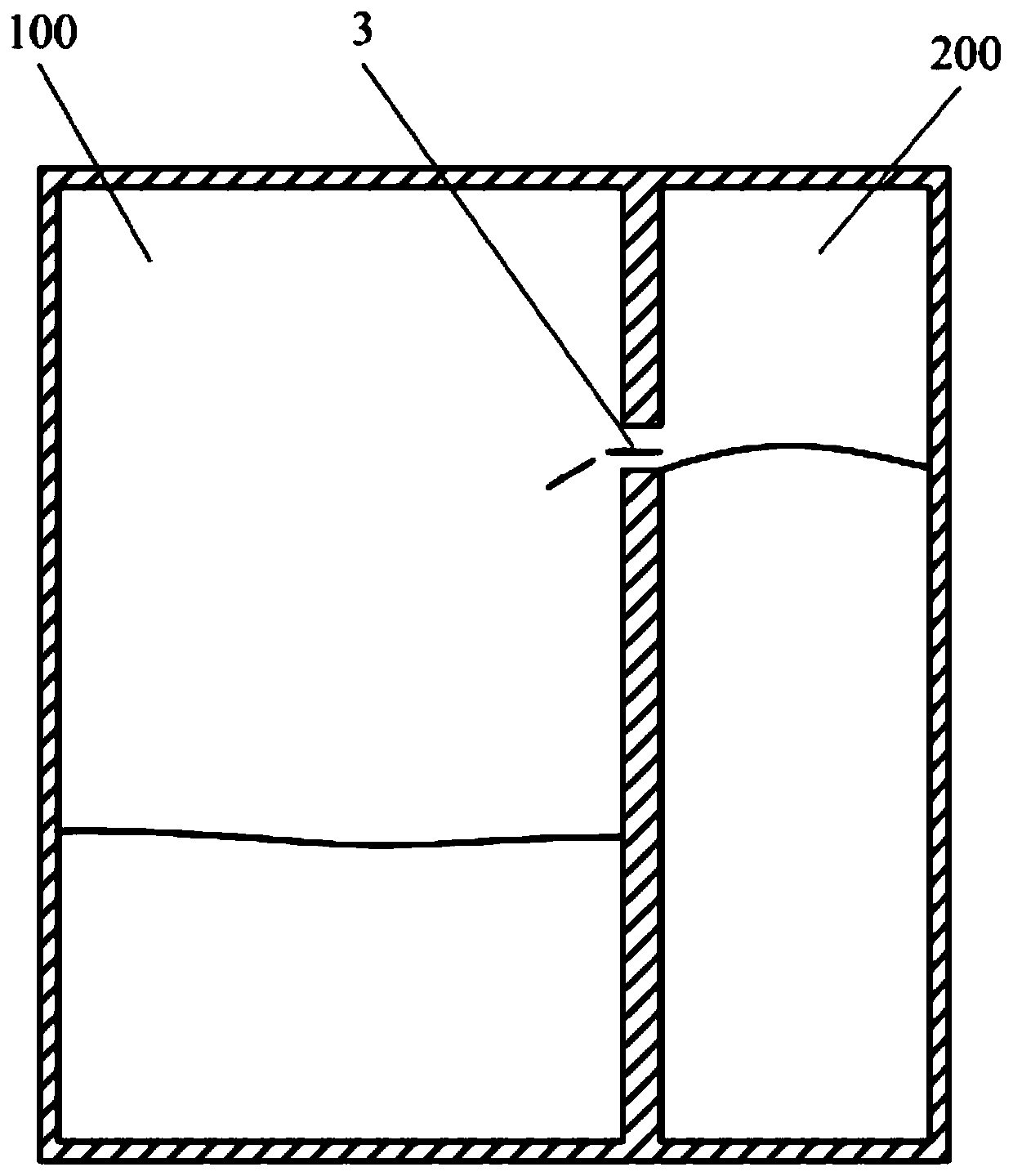

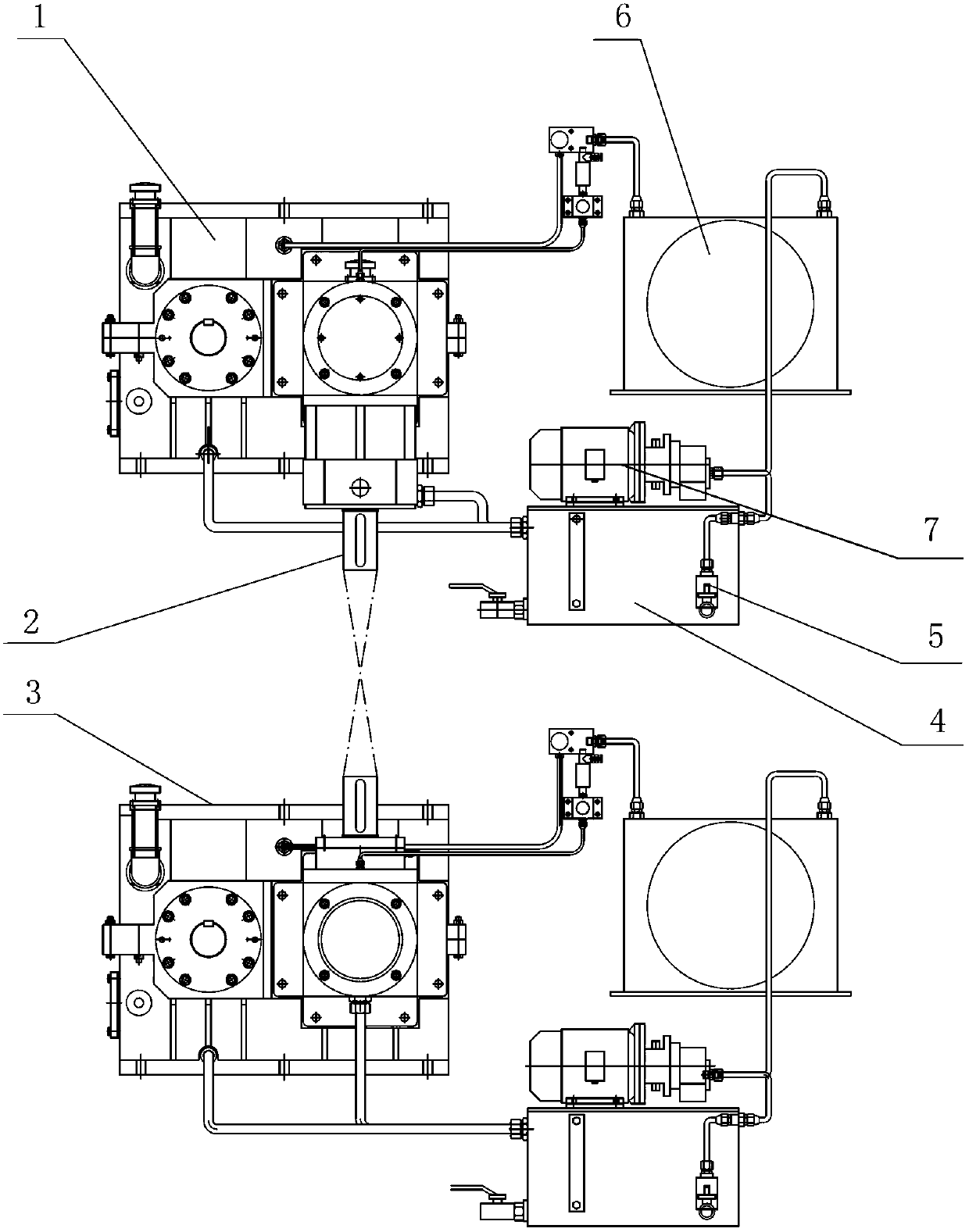

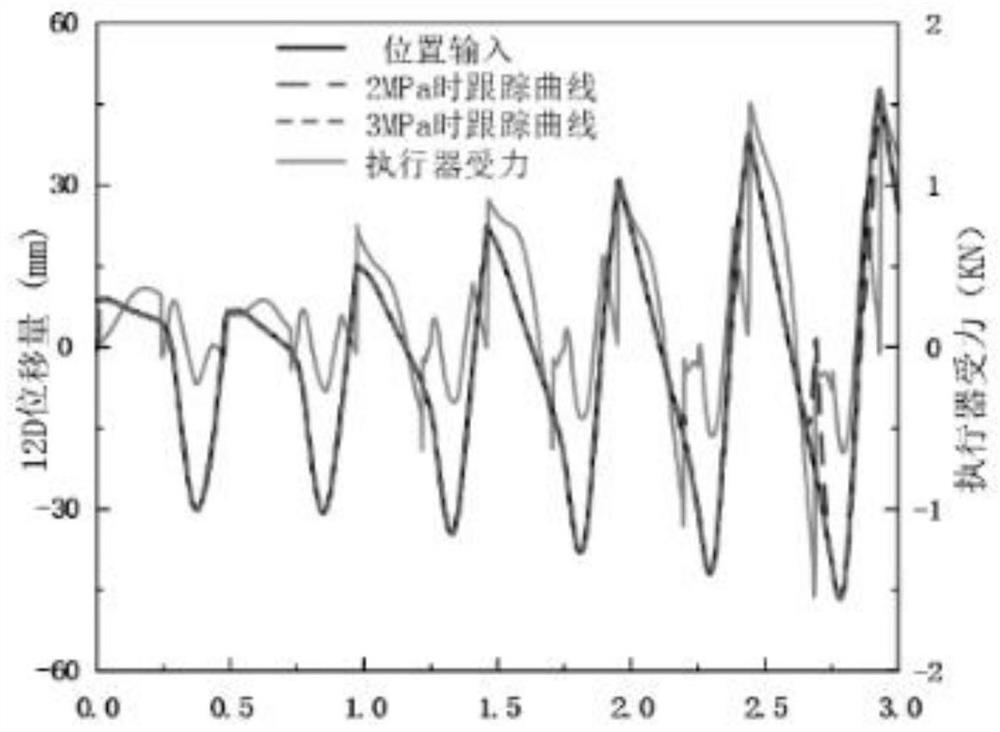

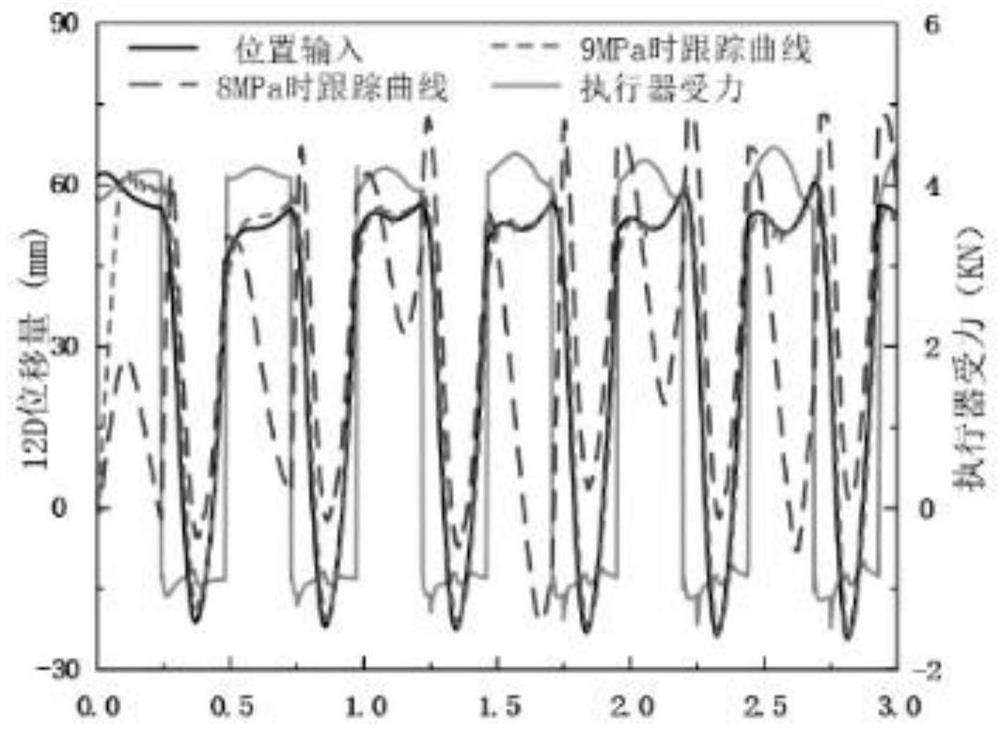

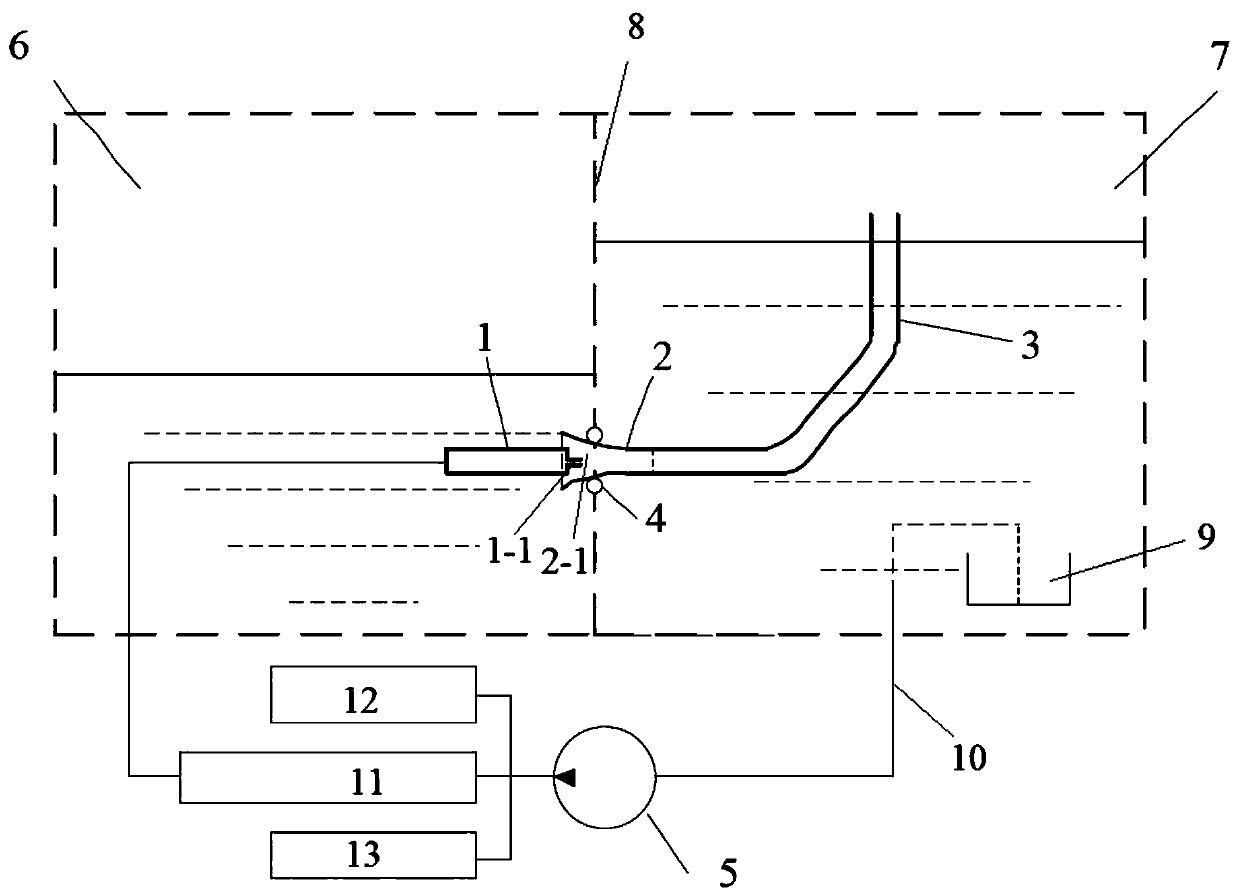

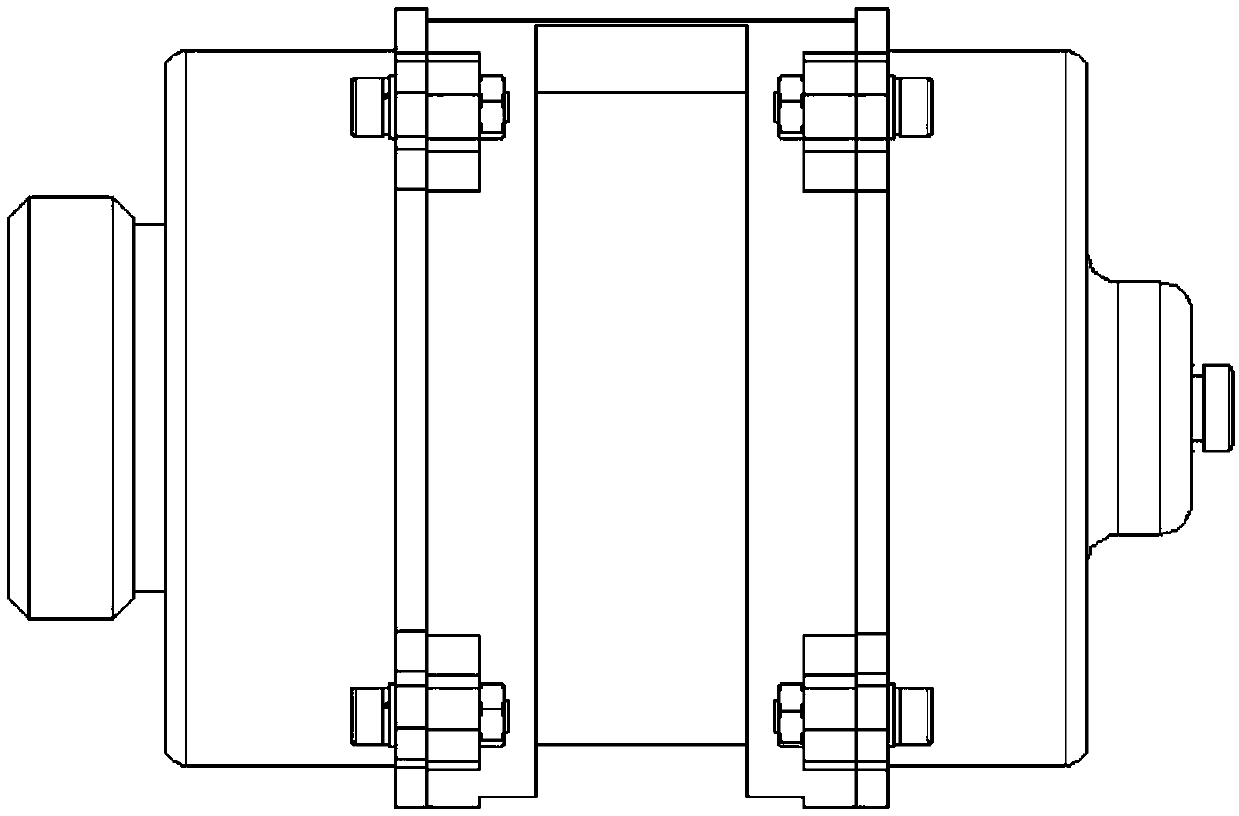

Quadruped robot hydraulic system based on two-stage energy supply and loading opening independent valve control

ActiveCN111828410AImprove efficiencyReduce energy consumptionServomotor componentsAccumulator installationsControl engineeringEnergy supply

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +2

Transmission hydraulic control system and vehicle

ActiveCN110469663AIncrease profitEnsure adequate lubricationGear lubrication/coolingGearing controlControl systemHigh pressure

The invention relates to the technical field of vehicle hydraulic control systems and discloses a transmission hydraulic control system and a vehicle including the same. The transmission hydraulic control system comprises a low-pressure oil path communicating with a first oil cavity, a high-pressure oil path communicating with a second oil cavity, an oil quantity balance hole arranged between thefirst oil cavity and the second oil cavity, an oil supplementing branch arranged between the low-pressure oil path and the second oil cavity and a pressure regulating valve arranged on the high-pressure oil path. Hydraulic oil in the second oil cavity can enter the first oil cavity through the oil quantity balance hole, hydraulic oil in the low-pressure oil path can enter the second oil cavity through the oil supplementing branch, and the pressure of the high-pressure oil path can be regulated by a plurality of stations of the pressure regulating valve. According to the transmission hydrauliccontrol system and the vehicle, the pressure in the high-pressure oil path can be adjusted according to different working conditions, and the utilization rate of the hydraulic oil is high; and the quantity of the hydraulic oil in the low-pressure oil path can not only ensure sufficient lubrication to a transmission, but also avoid the excessive oil stirring loss, and therefore the transmission efficiency is high.

Owner:CHINA FIRST AUTOMOBILE

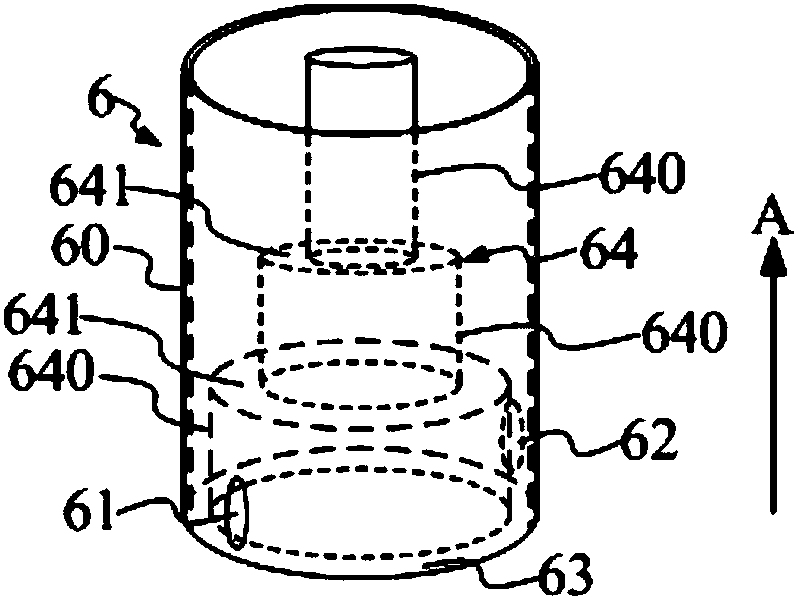

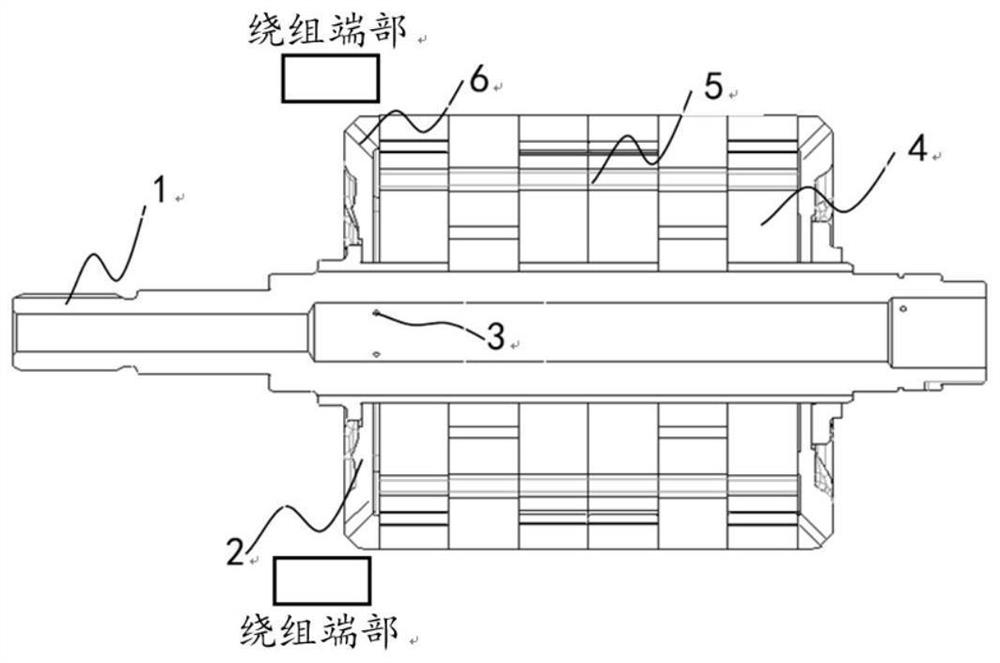

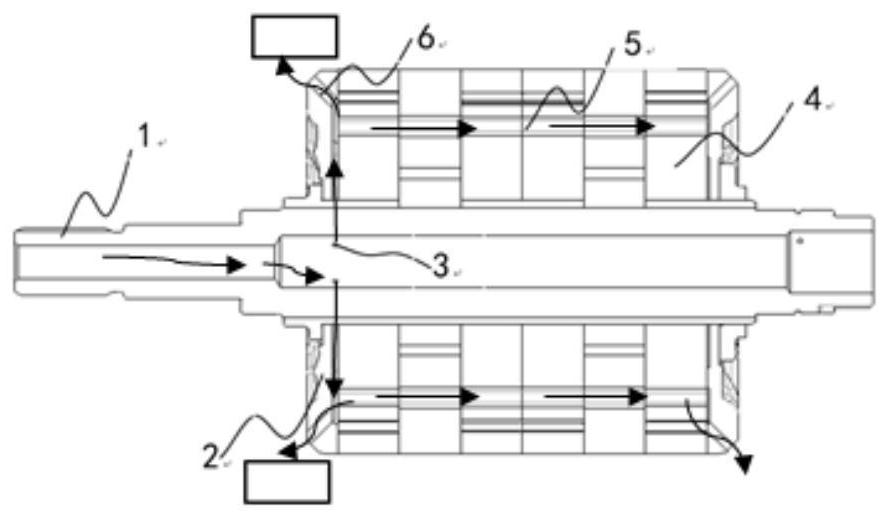

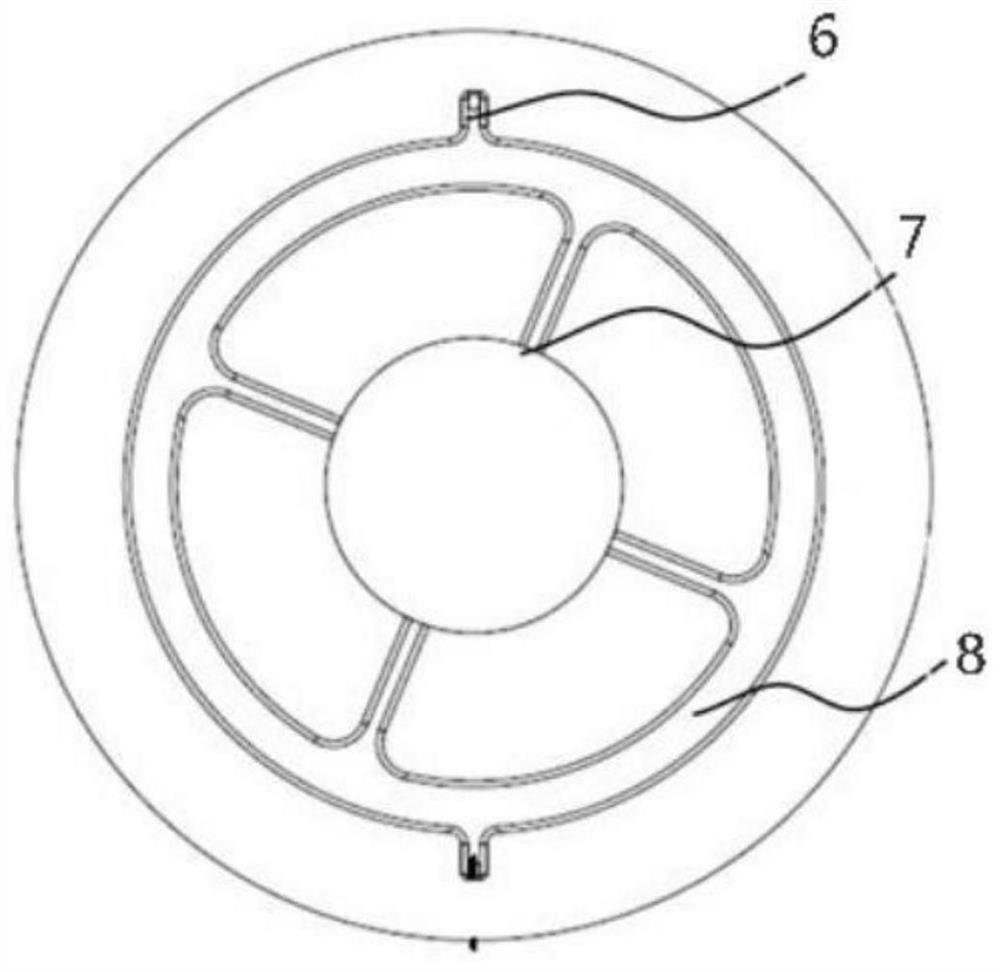

Direct cooling system applied to rotor and winding of high-speed permanent magnet motor

PendingCN113364184AReduce direct coolingReduce output efficiencyMagnetic circuit rotating partsElectric machinesElectric machinePermanent magnet motor

The invention relates to a direct cooling system applied to a rotor and a winding of a high-speed permanent magnet motor. Cooling liquid enters from a hollow cavity of a rotating shaft, passes through a rotating shaft guide hole under the rotating centrifugal effect of the rotor and flows into an area formed by the end face of the end plate and a rotor core; the area formed by the end face and the rotor core is communicated with a rotor de-weight hole and an end plate guide hole; one part of the cooling liquid is thrown out from the end plate guide hole and is in contact with the inner end face of the winding for heat exchange, and winding cooling is completed; and the other part of the cooling liquid passes through the rotor de-weight hole communicated with the rotor core, so that the cross flow in the axial direction is completed, and the rotor iron core is cooled. According to the invention, the hollow shaft, the end plates, the rotor core, the permanent magnet magnetic isolation bridges and other structures are fully utilized to set the cooling flow channels, so that the influence of the cooling flow channels on electromagnetic performance is reduced; through a rotor encapsulation process, the change of a cooling flow channel structure is realized, and the flow demand and the temperature rise demand are balanced. and the rotation inertia is reduced, the oil stirring loss is reduced, and the motor performance output and the system efficiency are improved.

Owner:CHINA FIRST AUTOMOBILE

Double-side needling machine speed reducing system

ActiveCN103133661AReduce noiseIncrease the effective meshing areaGear lubrication/coolingNeedling machinesDrive shaftUniversal joint

The invention discloses a double-side needling machine speed reducing system and belongs to the field of double-side needling machine speed reducers. The double-side needling machine speed reducing system comprises an upper reducer and a lower reducer which are oppositely arranged and identical in structure. The double-side needling machine speed reducing system is characterized in that transmission shafts of spiral bevel gears of the upper reducer and the lower reducer are perpendicularly arranged, transmission shafts of the upper reducer and the lower reducer are vertically opposite, connected via a universal joint and identical in rotating direction, output shafts of the upper reducer and the lower reducer are identical in phase position, and oil-stir preventing devices are respectively arranged in gear boxes of the upper reducer and the lower reducer. The upper reducer and the lower reducer are integrally connected via the universal joint, phase positions of the output shafts are kept consistent during power transmission process, each oil-stir preventing device separates lubricating oil in each gear box into two parts, only the lubricating oil in the oil-stir preventing devices is stirred when gears rotate at high speed, oil stirred by the gears is low in amount, so that heating is low, and oil stirring loss is greatly reduced. The double-side needling machine speed reducing system is efficient, energy-saving, compact in structure, strong in stability, convenient to maintain, good in lubricating and sealing effects, normal in warming, and low in noise.

Owner:山东安吉富传动设备股份有限公司

Transmission device for improving transmission efficiency of intermediate shaft type gear box

InactiveCN102606715AReduce the totalReduce in quantityGear lubrication/coolingToothed gearingsEngineeringGear train

The invention discloses a transmission device for improving transmission efficiency of an intermediate shaft type gear box, wherein the front end of an input shaft of the gear box is supported on a gear box body by a bearing, the tail end of the input shaft of the gear box is connected with a splined hub of a synchronizer by a spline, a first-level transmission driving gear is sleeved on the input shaft, and a first-level transmission driven gear is fixedly connected on an intermediate shaft; the front end of an output shaft of the gear box is supported in a tail end hole of the input shaft and is fixedly connected with a direct-gear jointed gear ring, and the other end of the output shaft of the gear box is supported on the gear box body; the two ends of the intermediate shaft of the gear box are supported on the gear box body by a bearing; except direct gear shifting and gear reversing, all gears of the gear box are sleeved on the shaft by corresponding to the transmission wheels, and due to the adoption of the synchronizer for gear shifting, when a certain gear works, other gears do not rotate and keep in a static state. The transmission device has the advantages that the overall transmission efficiency of the gear box is effectively increased, the temperature rise of the gear box is improved, and the service life of the gear box is prolonged.

Owner:TONGJI UNIV

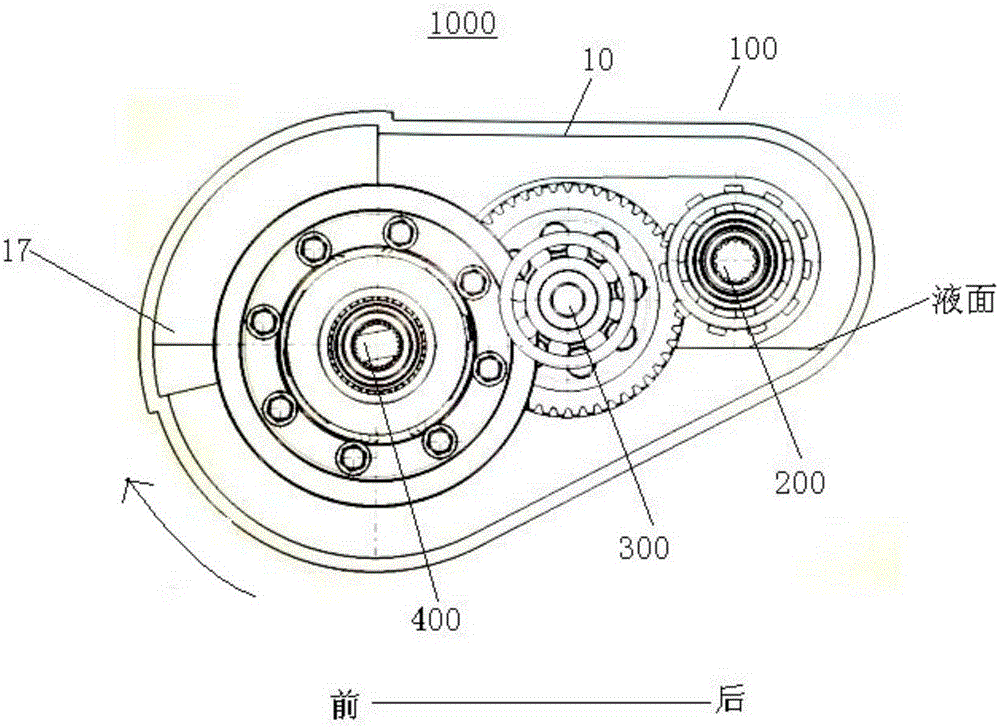

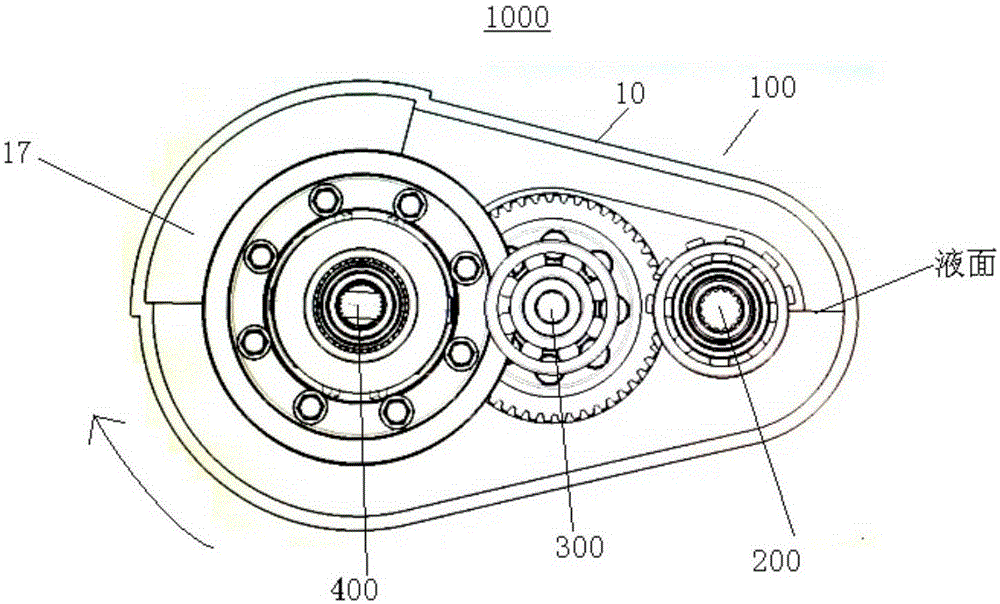

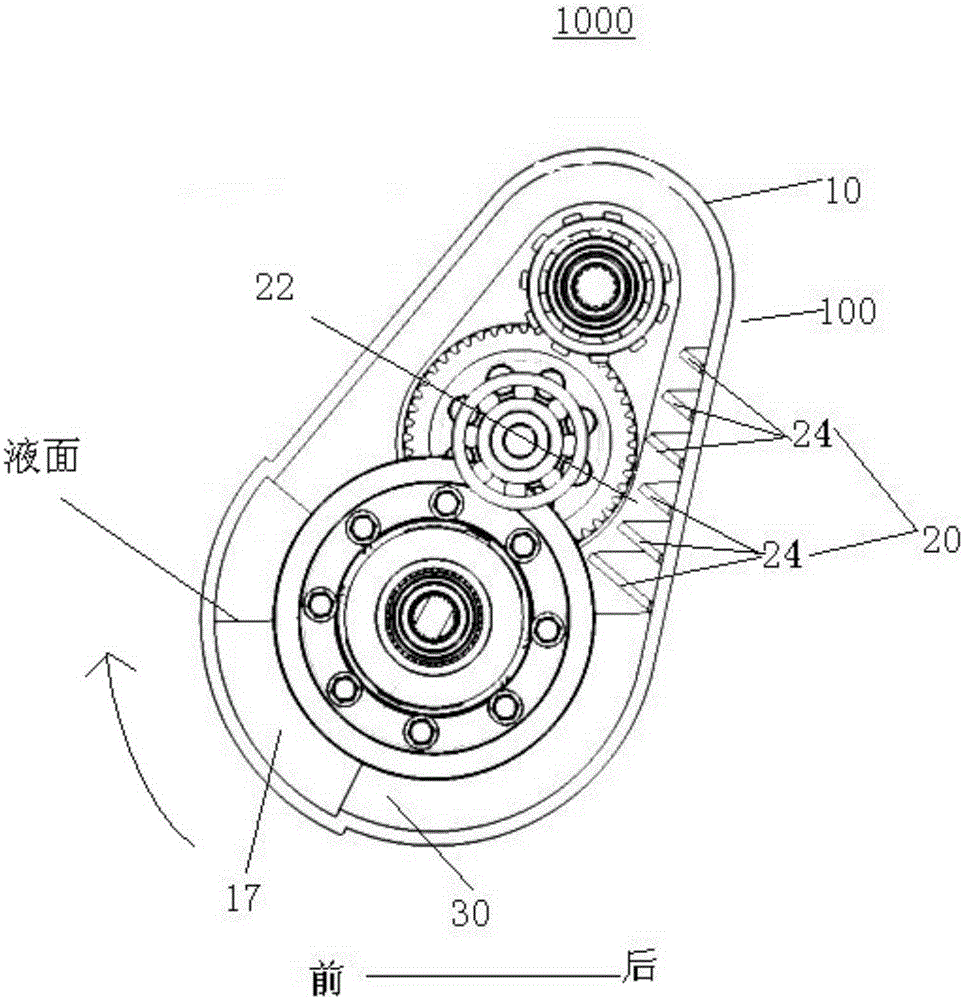

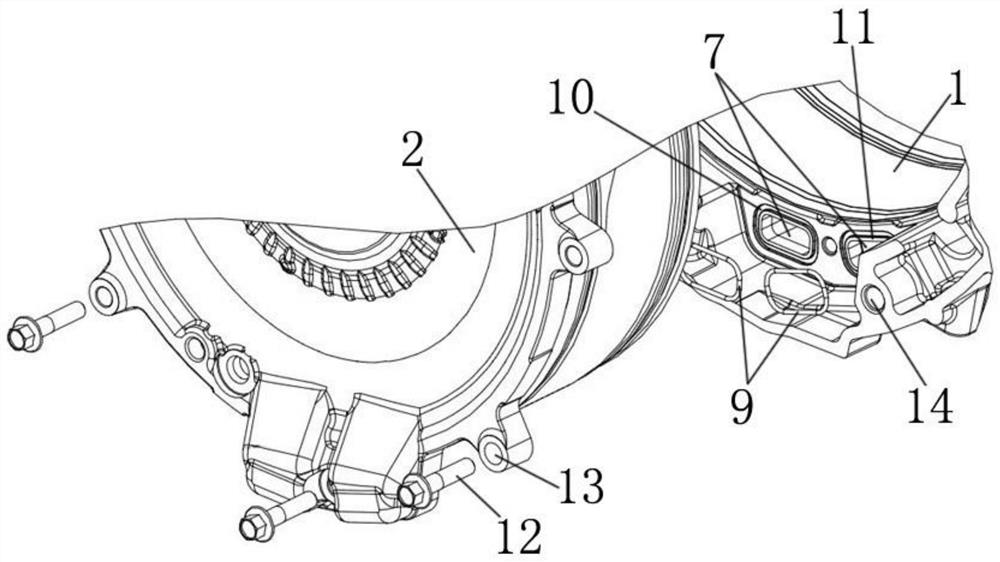

Speed reducer and shell thereof

ActiveCN105179650AReduce churning lossImprove work efficiencyGearboxesGear lubrication/coolingReduction driveReducer

The invention discloses a speed reducer and a shell thereof. The shell of the speed reducer comprises a shell body and an isolating device. The shell body is provided with a cavity. An output shaft hole, an intermediate shaft hole and an input shaft hole which are sequentially arranged from the front portion of the shell body to the rear portion of the shell body are formed in the shell body. The isolating device is arranged below the intermediate shaft hole and / or the input shaft hole, so that a dynamic oil storage area is formed in the cavity. The dynamic oil storage area is provided with a circulating oil inlet end and a circulating oil outlet end. The circulating oil inlet end and the circulating oil outlet end are communicated with the cavity, and the circulating oil inlet end is located above the circulating oil outlet end. At least part of the area, located in front of the isolating device, of the cavity is a static oil storage area. By arranging the isolating device, oil stirring loss of the speed reducer can be reduced, and the working efficiency of the speed reducer can be improved.

Owner:BEIJING ELECTRIC VEHICLE

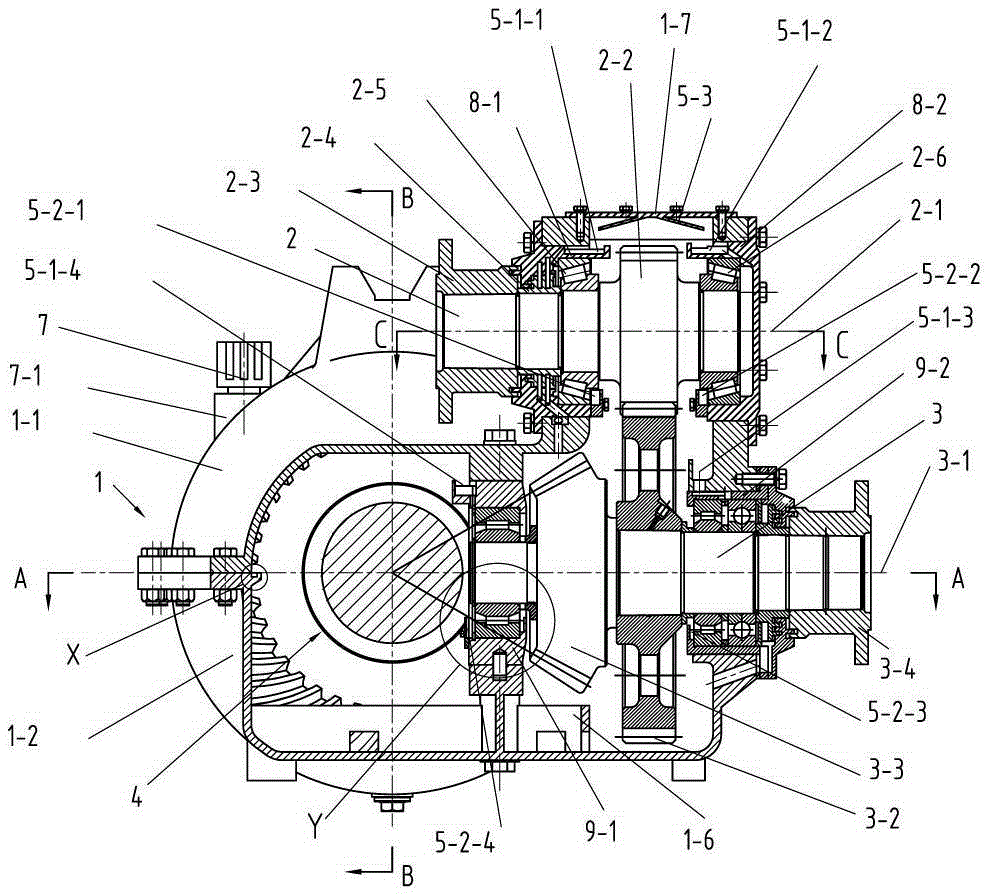

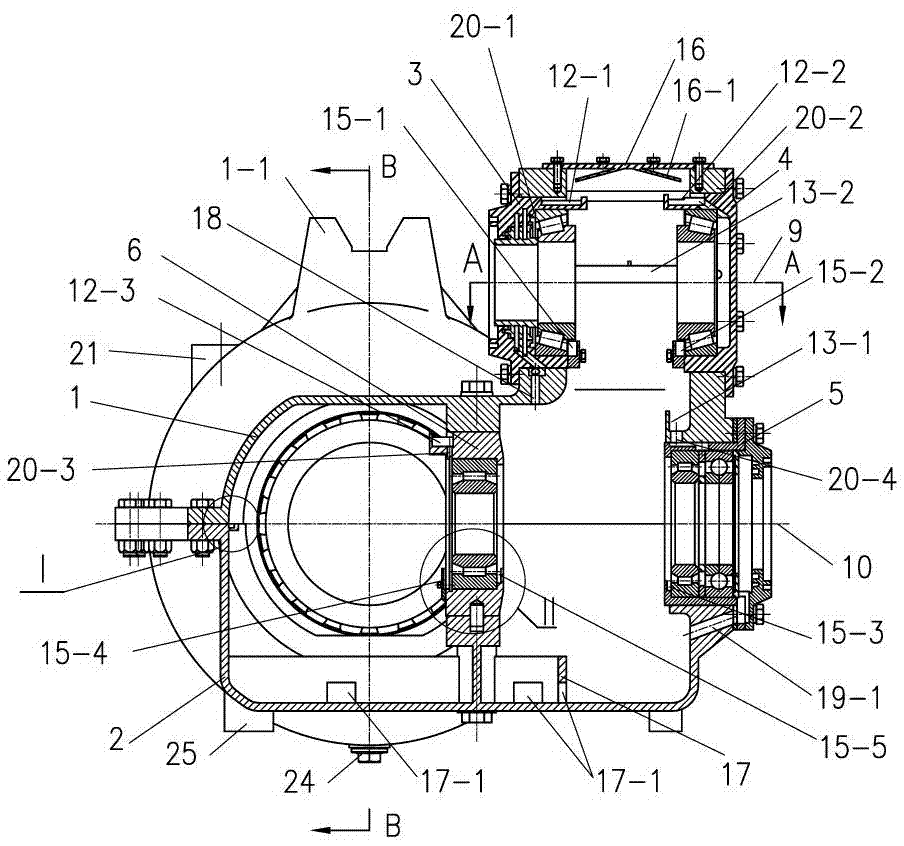

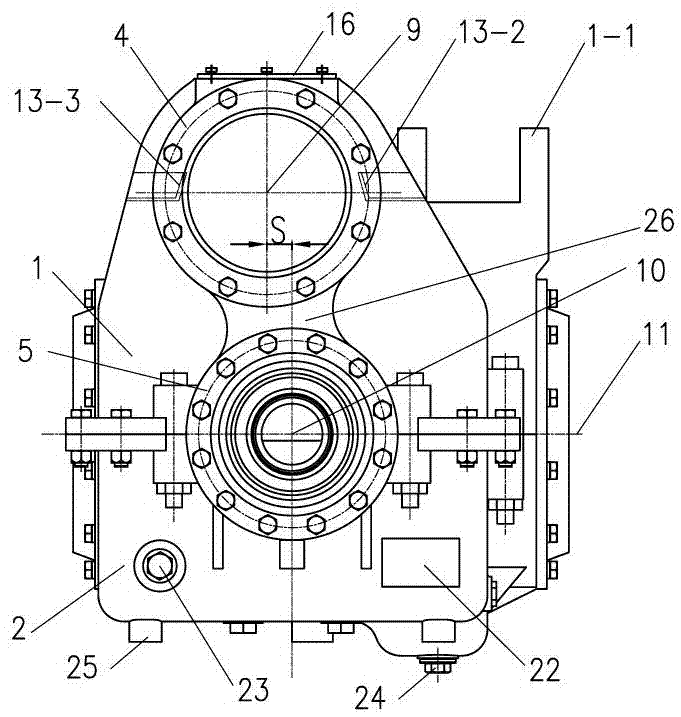

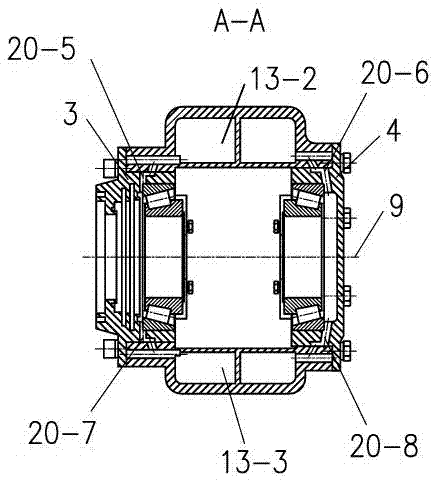

Hydraulic transmission axle gearbox

ActiveCN105402386ASimple structureSimplified weightGear lubrication/coolingGear wheelAgricultural engineering

The invention discloses a hydraulic transmission axle gearbox for a railway vehicle. The hydraulic transmission axle gearbox comprises a box body assembly, an input shaft assembly, a middle shaft assembly, an output shaft assembly and a ventilator, wherein the gear outer diameter of an input gear shaft of the input shaft assembly is less than the diameter of a hole of each input shaft integrated bearing seat; corresponding first oil collection grooves are arranged in the input shaft integrated bearing seats and middle shaft bearing seats, second oil collection grooves are arranged in an upper box body, third oil collection grooves are arranged in a lower box body, corresponding oil storage bins are arranged on the input shaft integrated bearing seats, the middle shaft bearing seats and output shaft bearing seats, and an oil guide plate is arranged on an observation window of the upper box body; each oil collection groove is communicated with the corresponding bearing, and a side-retaining height of each oil storage bin is at least greater than 1 / 3-1 / 2 of the height of a roller at the lowest part of the corresponding bearing; and a sealing structure is arranged at an input end rotary penetrating part of the input shaft assembly, an output end rotary penetrating part of the middle shaft assembly, and a rotary penetrating part of the output shaft assembly respectively. The hydraulic transmission axle gearbox disclosed by the invention is compact in structure, reasonable in layout, and reliable in lubrication.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Hybrid power system

InactiveCN111993880AAchieve independent distributionReduce consumptionHybrid vehiclesGas pressure propulsion mountingDrive shaftElectric machinery

The invention belongs to the technical field of automobiles, and discloses a hybrid power system. A first input shaft is arranged at an output end of a driving motor of the hybrid power system and isin transmission connection with a differential mechanism through a first transmission assembly, and the differential mechanism is in transmission connection with transmission shafts of wheels; a second input shaft is arranged at the output end of the engine and is in transmission connection with a power generation output shaft through a second transmission assembly, and the power generation outputshaft is in transmission connection with the input end of the generator; a clutch sleeves the second input shaft; and a hydraulic mechanism is configured to drive the clutch to be combined and separated so that the second transmission assembly is selectively connected to the first transmission assembly in a transmission mode through the clutch, and the hydraulic mechanism is configured to be selectively connected to the first transmission assembly and the second transmission assembly in a transmission mode and can be connected with the clutch, the driving motor and the generator. According tothe hybrid power system, driving of the driving motor is achieved, engine driving is completely decoupled, and economical efficiency and power performance are guaranteed.

Owner:CHINA FIRST AUTOMOBILE

Hydraulic transmission axle gear box body

ActiveCN105443732AGuaranteed heightGuaranteed churning lossGearboxesGear lubrication/coolingOil storageEngineering

The invention discloses a hydraulic transmission axle gear box body of a rail vehicle, which comprises an upper box body and a lower box body, wherein corresponding first oil collecting grooves are formed in a first input shaft bearing support and a second input shaft bearing support; a second oil collecting groove is formed in a second intermediate shaft bearing support; a third oil collecting groove and a fourth oil collecting groove are formed in the upper box body; an inward extending boss is arranged on the box dividing surface of the lower box body; a plurality of fifth oil collecting grooves are formed in the inward extending boss; corresponding oil storage bins are arranged on the first input shaft bearing support, the second input shaft bearing support, a first intermediate shaft bearing support, the second intermediate shaft bearing support, a first output shaft bearing support and a second output shaft bearing support respectively; the heights of retaining edges of the oil storage bins are at least higher than 1 / 3-1 / 2 of the heights of the lowers rollers of corresponding bearings; an observation window is arranged on the upper box body; oil guide plates are arranged on the observation window; the lower edges of the oil guide plates are located above the first oil collecting grooves; and oil return holes are formed in the upper box body and the lower box body. The hydraulic transmission axle gear box body is compact in structure and reasonable in layout.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

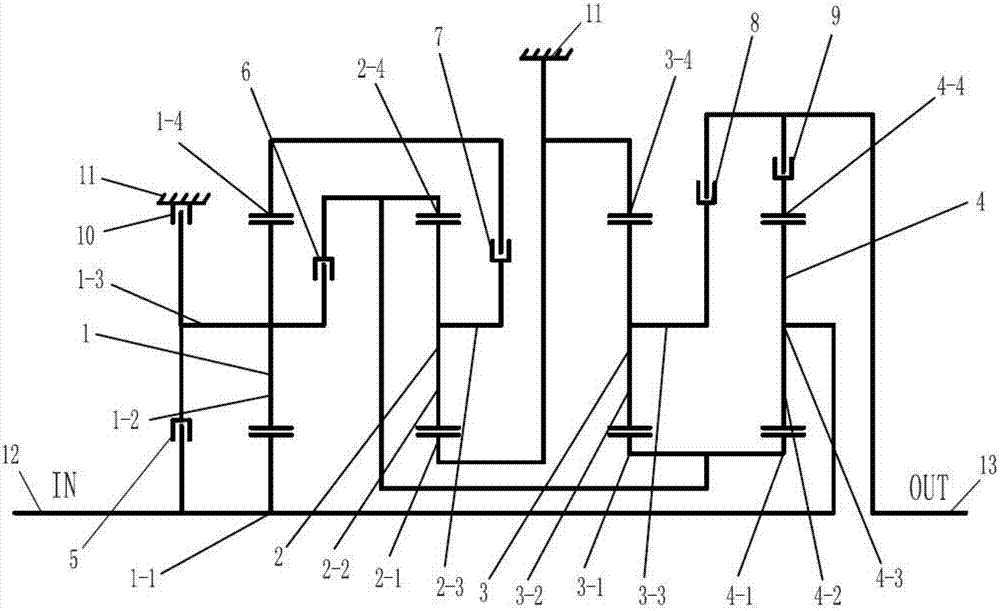

Three planetary six-speed automatic transmission and car

ActiveCN106884936BIncrease profitMiniaturizationToothed gearingsTransmission elementsAutomatic transmissionTorque transmission

The invention relates to the field of automobiles, and discloses a three-planet-row six-speed automatic transmission and an automobile. The three-planet-row six-gear automatic transmission comprises a first planet row, a second planet row and a third planet row, wherein the first planet row comprises a first gear ring, a first inner planet gear group and a first outer planet gear group which are meshed with each other, a first sun gear and a first planet carrier; the second planet row comprises a second gear ring, a second planet gear group, a second sun gear and a second planet carrier; the third planet row comprises a third gear ring, a third planet gear group, a third sun gear and a third planet carrier; the first gear ring, the second gear ring and the third sun gear are sequentially and fixedly connected into a whole; the first gear ring is connected to the transmission housing through a first brake member; the first planet carrier is connected with the second planet carrier through a first torque transmission member; the second planet carrier is connected with the third planet carrier through a second torque transmission member; the third planet carrier is connected with the second sun gear through a third torque transmission member and further connected to the transmission housing through a second brake member.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Automatic transmission

PendingCN107269780AReduce manufacturing difficultyCompactToothed gearingsTransmission elementsPhysicsDrag torque

The invention relates to the field of transmissions and discloses a nine-speed automatic transmission. The transmission is combined by four planet rows and six gear shift operating elements (comprising five clutches and one brake) so as to realize nine forward gears and one reverse gear; compared with a transmission with gear shift operating elements (six) of the same amount, the automatic transmission has the advantages that due to the reduction of the amount of the brake, the production difficulty of a box body is lowered, and the light weight of the whole transmission is favorably realized; due to the adoption of a relatively large number of clutches (five), the nested design of the clutches is favorably realized, so that the whole mechanism is more compact; the larger clutch number (five) is beneficial to the cutting-off of a connecting relationship among the planet rows under a specific gear, and the redundant planet rows are made not to take part in rotation, so that the drag torque and the drag churning loss are reduced, and the efficiency is increased; in addition, due to the adoption of the more clutches, the expansion of more speed gears by increment of the planet rows or more operating elements in future is favorably realized.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Speed change gear structure, transmission and vehicle

InactiveCN106555840ALow costReduce the number of runsToothed gearingsGearing detailsGear transmissionVariator

The invention relates to the field of speed change gears, and provides a speed change gear structure, a transmission and a vehicle. The speed change gear structure comprises an input rotation shaft, an output rotation shaft and a middle rotation shaft; the input rotation shaft is provided with a first gear rotating relatively; the output rotation shaft is provided with a second gear rotating relatively; a third gear is arranged between the input rotation shaft and the output rotation shaft; the middle rotation shaft is provided with a fourth gear meshing with the first gear, a fifth gear meshing with the second gear and a sixth gear meshing with the third gear; the input rotation shaft is provided with a first synchronizer combined with the first gear and the third gear; and the output rotation shaft is provided with a second synchronizer combined with the second gear and a third synchronizer combined with the third gear. Multi-gear output is realized through a few gear transmission pairs, the function of each gear is maximized, the weight of the transmission is lowered, the cost of the transmission is lowered, the size is optimized, and the number of the rotating gears is reduced at idle so that the churning loss of idling can be reduced and abnormal sounds of idling can be lowered.

Owner:GREAT WALL MOTOR CO LTD

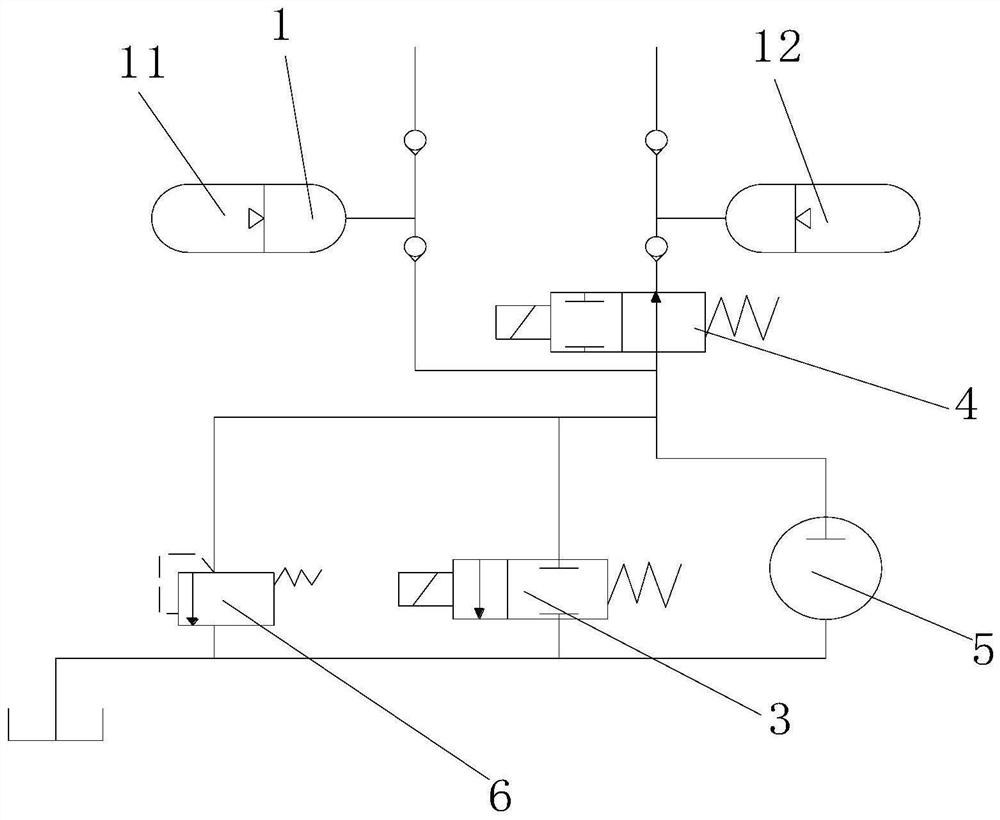

Hydraulic two-stage oil source for supplying energy through two-stage energy accumulator

InactiveCN111810461AAvoid overflow lossReduce churning lossAccumulator installationsServometer circuitsWork cycleEngineering

The invention relates to the technical field of robots, and discloses a hydraulic two-stage oil source for supplying energy through a two-stage energy accumulator. The hydraulic two-stage oil source comprises the energy accumulator, a switching valve A, a switching valve B, a constant displacement pump and an overflow valve. The energy accumulator comprises a high-pressure energy accumulator bodyand a low-pressure energy accumulator body. Through the arrangement of the high-pressure energy accumulator body and the low-pressure energy accumulator body, the degrees that gas is compressed in theoil charge process and the oil drainage process are different, and the oil pressure in the energy accumulator changes constantly; when the working cycle of the energy accumulator is smaller than 3 min, it can be considered that the energy accumulator works under the adiabatic condition; when the energy accumulator serves as an auxiliary power source, the inflation pressure should be lower than 90% of the lowest work pressure and higher than 25% of the highest work pressure, at this moment, the pressure change range in the energy accumulator does not exceed 20% of the work pressure, and the energy supply requirement of a hydraulic drive unit is met; and in the process that the energy accumulator stores and releases energy, less energy is lost, the requirement of a quadruped robot hydraulicsystem for energy consumption is completely met, and reasonable parameter selection is achieved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +2

Transmission oil pumping device and using method

PendingCN110594390AMinor changesLow costGearboxesGear lubrication/coolingPetroleum engineeringNozzle

The invention discloses a transmission oil pumping device and a using method. According to the device, a nozzle, a throat pipe and a spray pipe are arranged in two transmission cavities, pressure oiltransmitted by an oil pump is sprayed out through the nozzle, an oil outlet of the nozzle partially form a vacuum, liquid oil in the first transmission cavity is sucked into the second transmission cavity through the throat pipe and the spray pipe, when the transmission is operated and the the nozzle is submerged in the liquid oil in the first transmission cavity, the liquid oil at the bottom shell of the first transmission cavity is sucked into the second transmission cavity through the nozzle, so that the liquid level of the first transmission cavity is always lower than the liquid level ofthe second transmission cavity, the oil adding amount of the transmission can be reduced, the weight and cost of the transmission are reduced, the oil stirring loss can be reduced, the transmission efficiency is improved, and the device can be widely applied to various transmissions. The device has the beneficial effects that the oil adding amount of the transmission can be reduced, the transmission efficiency can be improved, and the device is suitable for the transmission with a pressure oil circuit and a plurality of cavities (or the like).

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

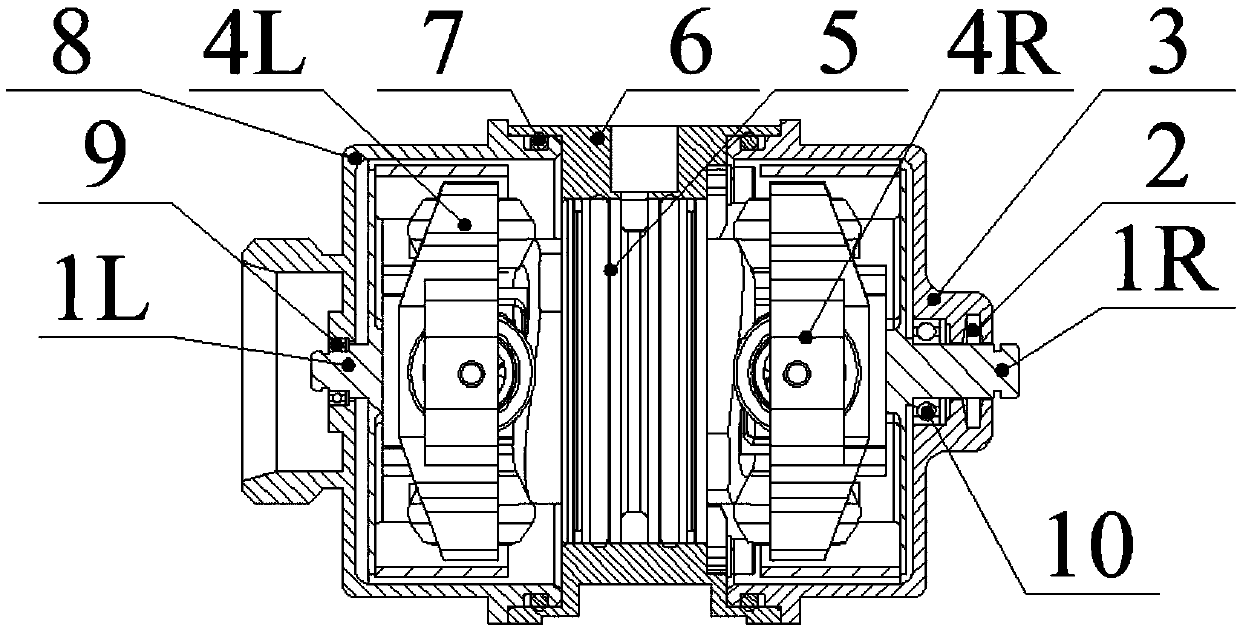

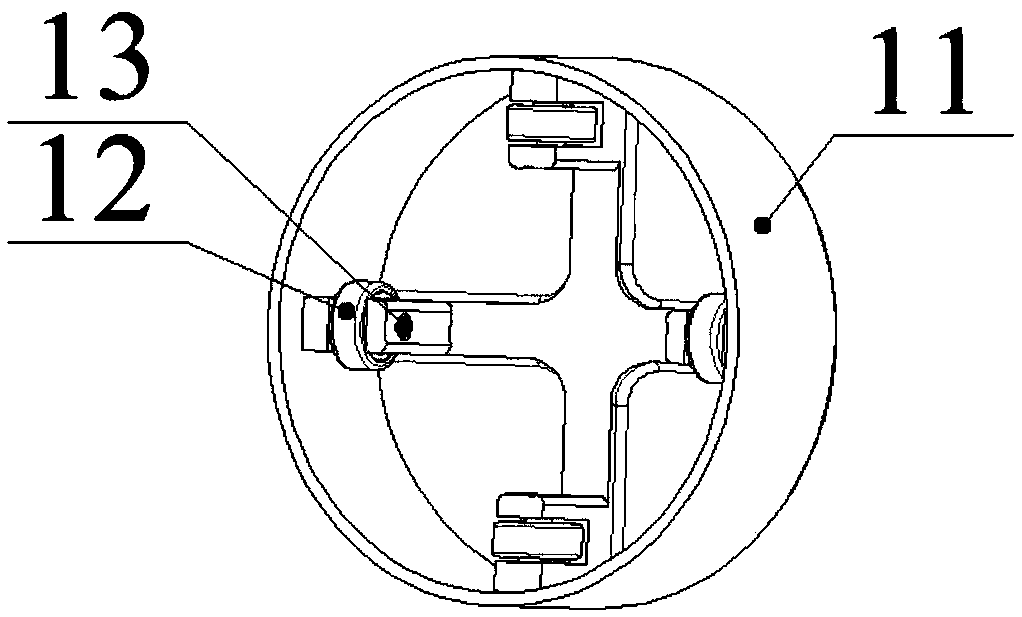

Roller type force balancing unit pump

PendingCN111502951AReduce stressSave spacePositive displacement pump componentsPiston pumpsRolling-element bearingDrive shaft

Disclosed is a roller type force balancing unit pump. A rolling bearing is mounted between a right coupling and a right roller assembly. Left and right cams are symmetrically distributed on both sidesof a pump core assembly with the phase difference of 90 DEG. A roller assembly rolls on the cam surfaces. Four conical rollers are distributed on the single side. Every two conical rollers are fixedto a C-shaped roller support as a group through a pin shaft. A copper sleeve of a pump core assembly and a cylinder body are respectively provided with two pairs of rectangular high pressure and low pressure oil holes uniformly distributed in the circumferential direction. The rectangular high pressure and low pressure oil holes correspondingly make contact with first and second flow distributiongrooves in the upper portions of a piston to suck and discharge oil. The cylinder body is provided with an annular oil groove communicating with the high-pressure oil holes, and oil liquid flowing outof the two high-pressure oil holes is collected together. The mass of a rotor which is composed of a first roller support assembly, a third roller support assembly, a transmission shaft and left andright concentric rings should be equal to the sum of the mass of a rotor which is composed of a second roller set, a fourth roller support assembly and the piston. First high pressure and low pressurecavities in a pump core communicate with the first flow distribution groove of the piston all the time. Second high pressure and low pressure cavities communicate with the second flow distribution groove of the piston all the time.

Owner:ZHEJIANG UNIV OF TECH

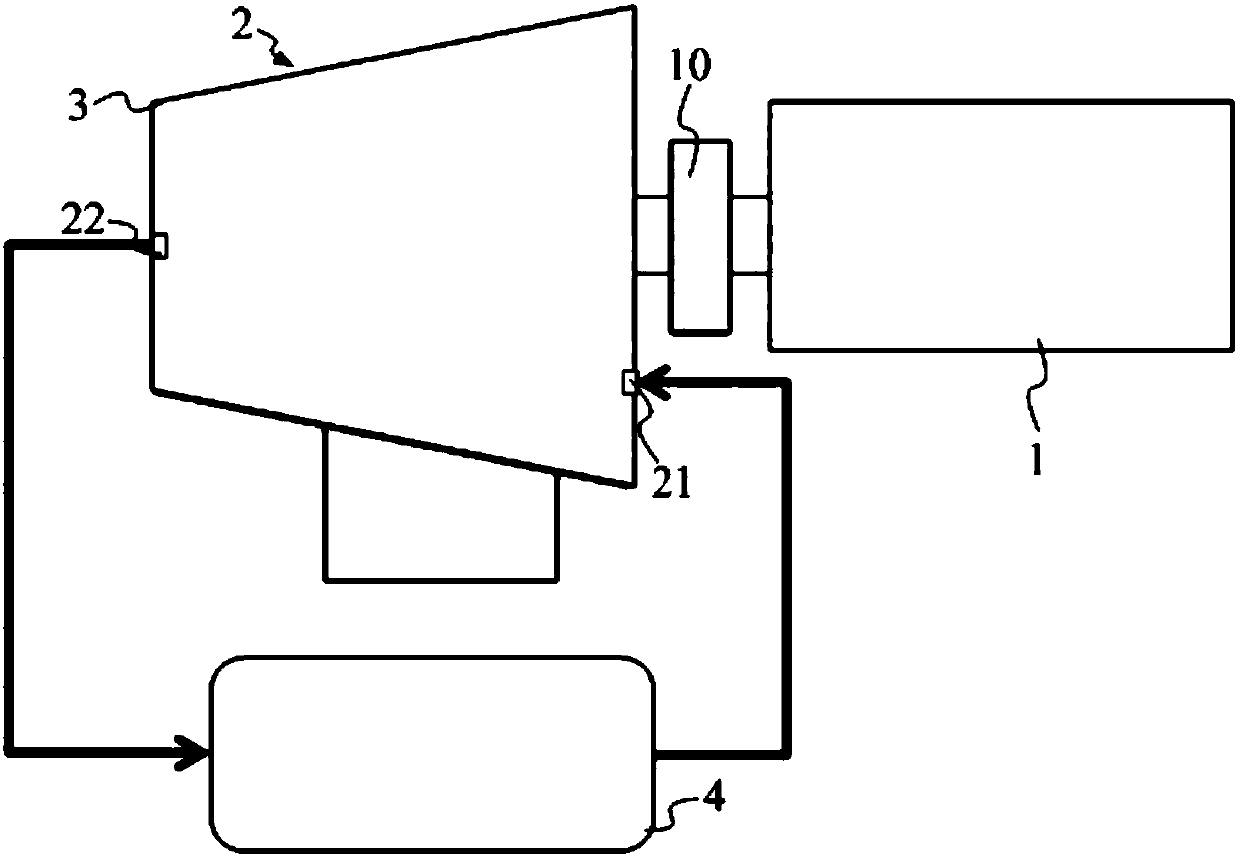

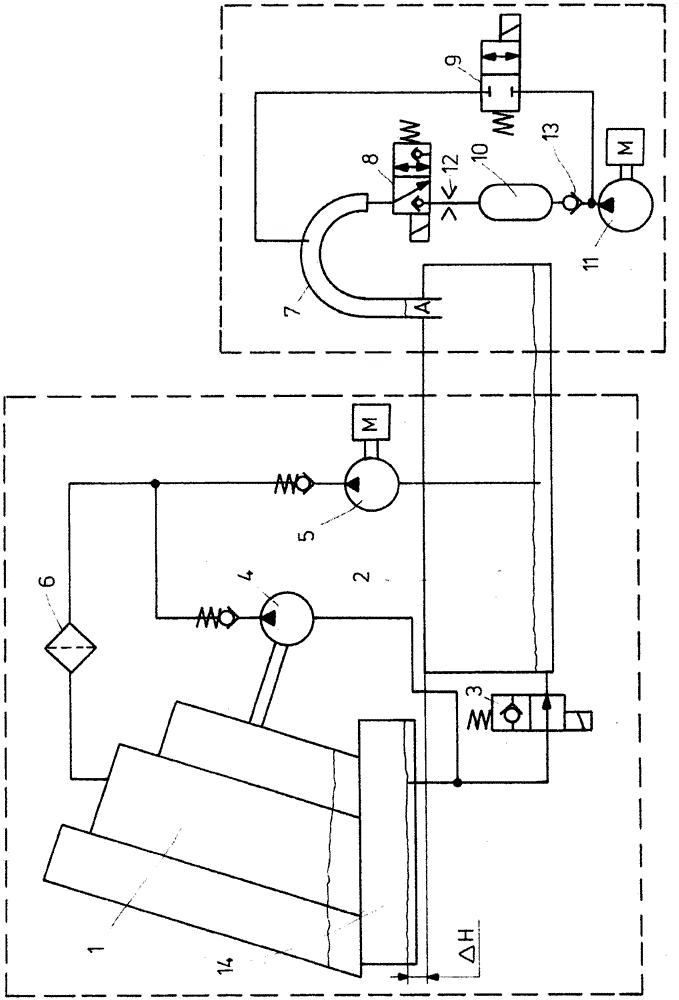

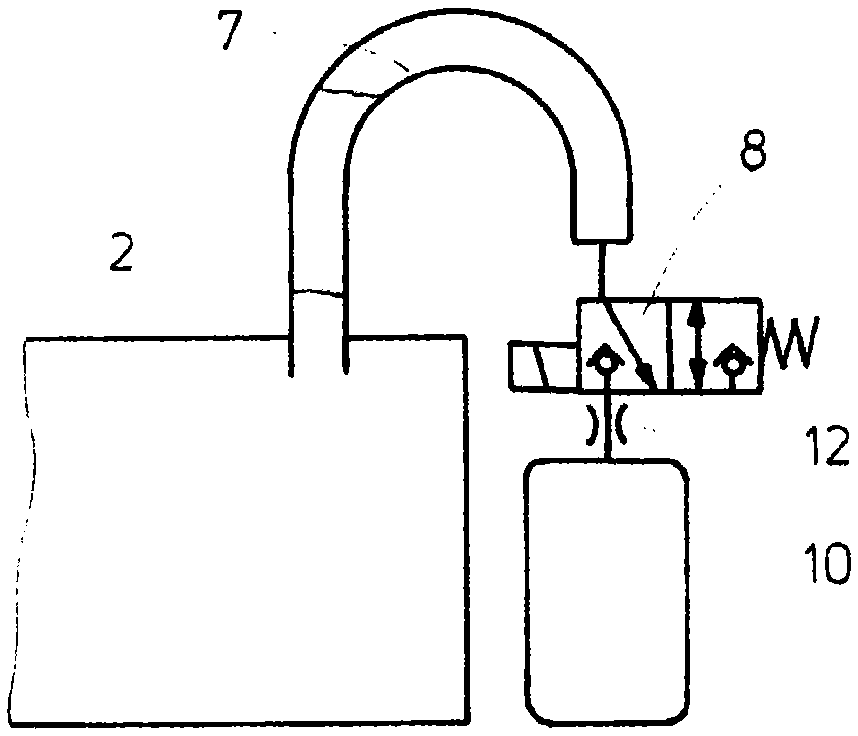

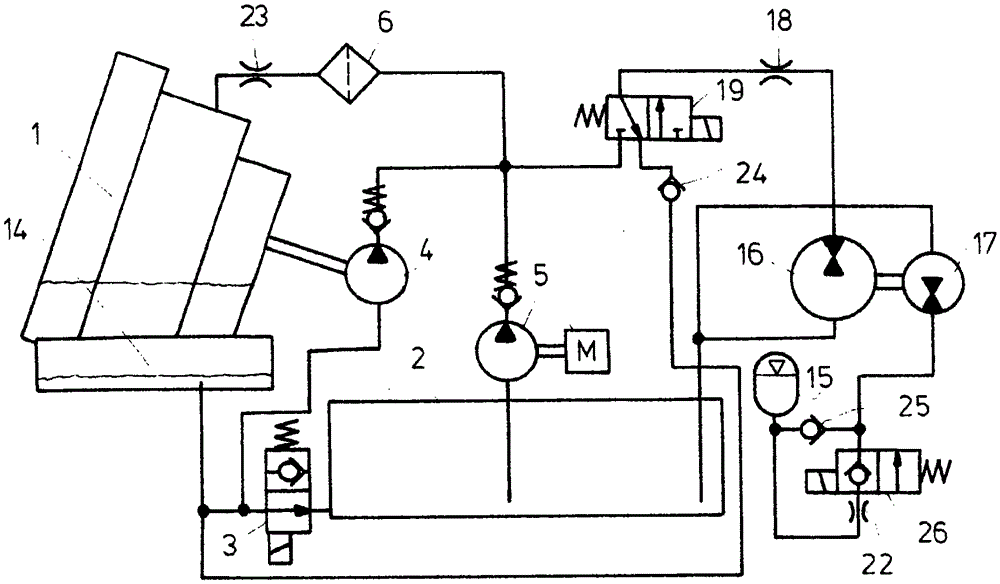

Supply system, in particular for gear mechanisms and generators

InactiveCN105431658AIncrease flexibilityOptimum Lubricant LevelEngine fuctionsGear lubrication/coolingWet sumpEngineering

A lubricating system has been disclosed for gear mechanisms (1) or generators, in particular for gear mechanisms (1) of wind power plants, which lubricating system permits a switchover between dry sump lubrication and wet sump lubrication. This takes place by way of a delivery device which increases the pressure in a lubricant tank (2) selectively or in an emergency, for example a power outage, and presses a lubricant back into an oil sump (14) in the gear mechanism (1), whereupon a lubricant level is increased there and wet sump lubrication is realized. The delivery device can have a compressor (11). Said compressor (11) can charge a pressure accumulator (10) via a non-return valve (9) or can increase the pressure in the lubricant tank (2) directly (not shown here). The delivery device can consist of hydraulic, pneumatic or else electrical components. If it is pneumatic, it can be separated from the hydraulic lubricating system via an elbow (7).

Owner:ROBERT BOSCH GMBH

Hybrid transmission box body oil return path structure

ActiveCN112815077AReduce risk of oil seepageImprove efficiencyGear lubrication/coolingBodies oilElectric machinery

The invention relates to a hybrid transmission box body oil return path structure. The structure comprises a transmission box body and a motor shell which are fixedly connected together, wherein a transmission cavity is formed in the transmission box body, and a motor cavity is formed in the motor shell. An oil return channel is arranged between the motor cavity and the transmission cavity and comprises a motor shell oil channel formed in the motor shell in a casting and machining mode and a transmission box body oil channel formed in the transmission box body in a casting mode. An oil inlet of the motor shell oil channel is formed in the cavity wall of the lower portion of the motor cavity, an oil outlet of the motor shell oil channel is communicated with an oil inlet of the transmission box body oil channel, and an oil outlet of the transmission box body oil channel is communicated with the transmission cavity. Lubricating oil at the bottom of the motor cavity is discharged through the oil return channel, the oil stirring loss of a clutch and a motor rotor can be reduced, and the efficiency of a transmission is improved by 2%-3%.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

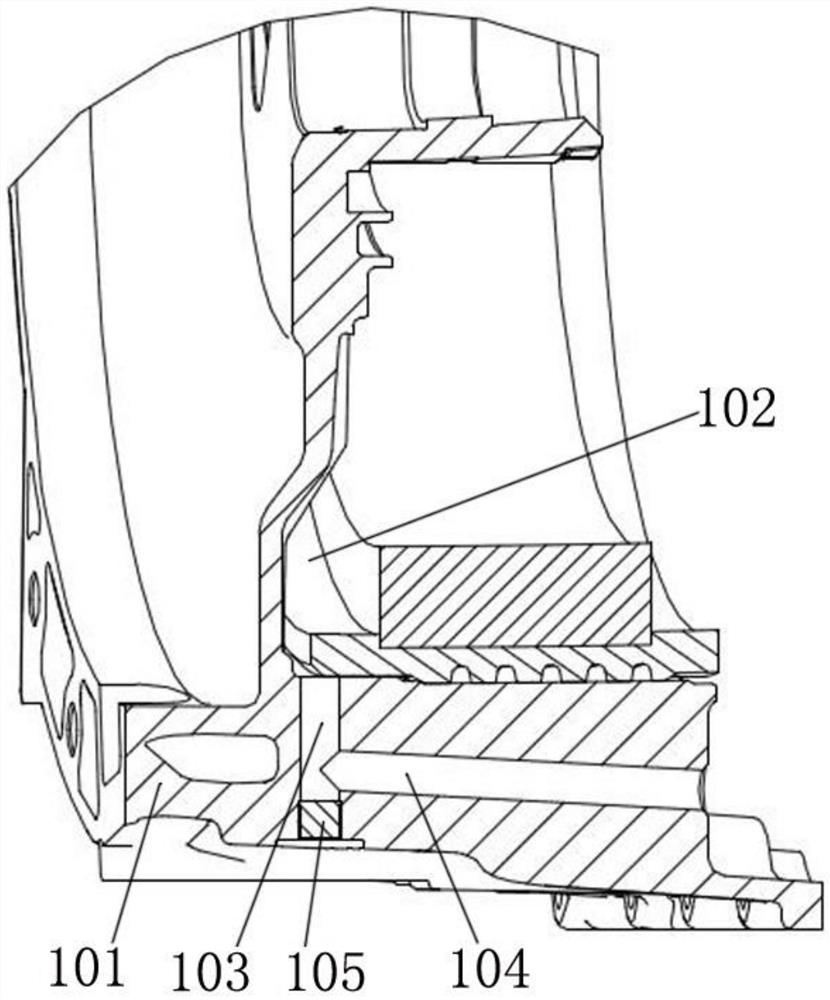

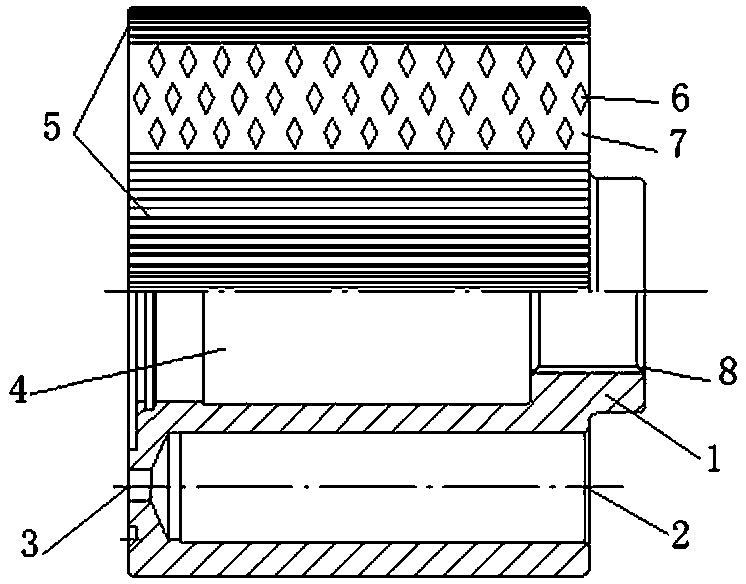

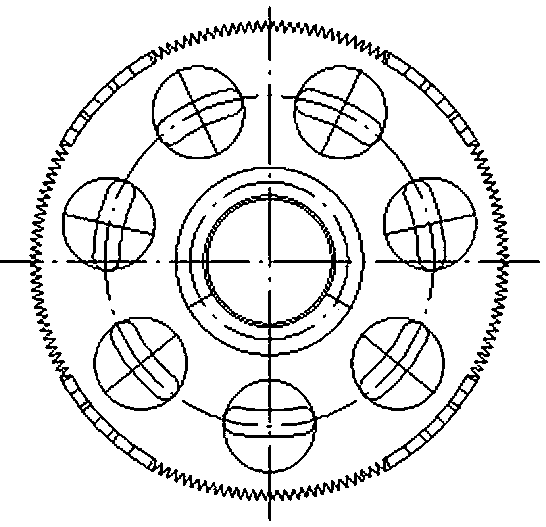

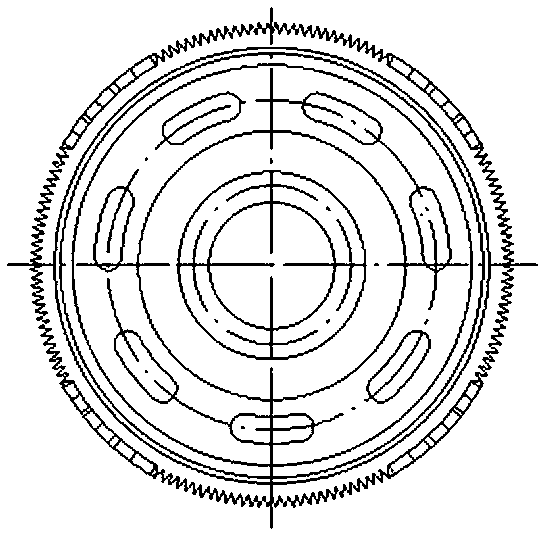

Surface resistance reducing type hydraulic plunger pump/motor cylinder block

ActiveCN108799096AReduce friction lossReduce churning lossPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpCylinder block

The invention relates to a surface resistance reducing type hydraulic plunger pump / motor cylinder block which aims to reduce stirring losses generated by the cylinder body in the plunger pump / motor running process and improve the efficiency of the hydraulic plunger pump / motor. The cylinder block comprises a main cylinder block (1), plunger holes (2), oil through holes (3), a shaft hole (4) and a spline (8), and a resistance reducing groove (5), a protrusion (6) and an oleophobic coating (7) are arranged on the surface of the outer circle of the main cylinder block (1); the shaft hole (4) is formed in the center of the main cylinder block (1), the plunger holes (2) are evenly distributed around the shaft hole (4) of the main cylinder block (1) and communicates with the oil through holes (3)in the bottom of the main cylinder block (1), and the spline (8) is arranged at the head of the shaft hole (4). The resistance reducing groove is formed in the outer circle of the cylinder block, a secondary vortex is formed in the resistance reducing groove when the cylinder body rotates, it like the condition that a row of rolling columns are clamped between the wall face and coming flow, the effect like that of a roller bearing is achieved, sliding friction of the liquid flow and the wall face becomes rolling friction, and the aim of resistance reducing is achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com