Gearbox lubricating oil liquid level adjusting and controlling system and adjusting and controlling method thereof

A control system and lubricating oil technology, applied in the direction of gear lubrication/cooling, transmission parts, belt/chain/gear, etc. cost, the effect of improving the overall power transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

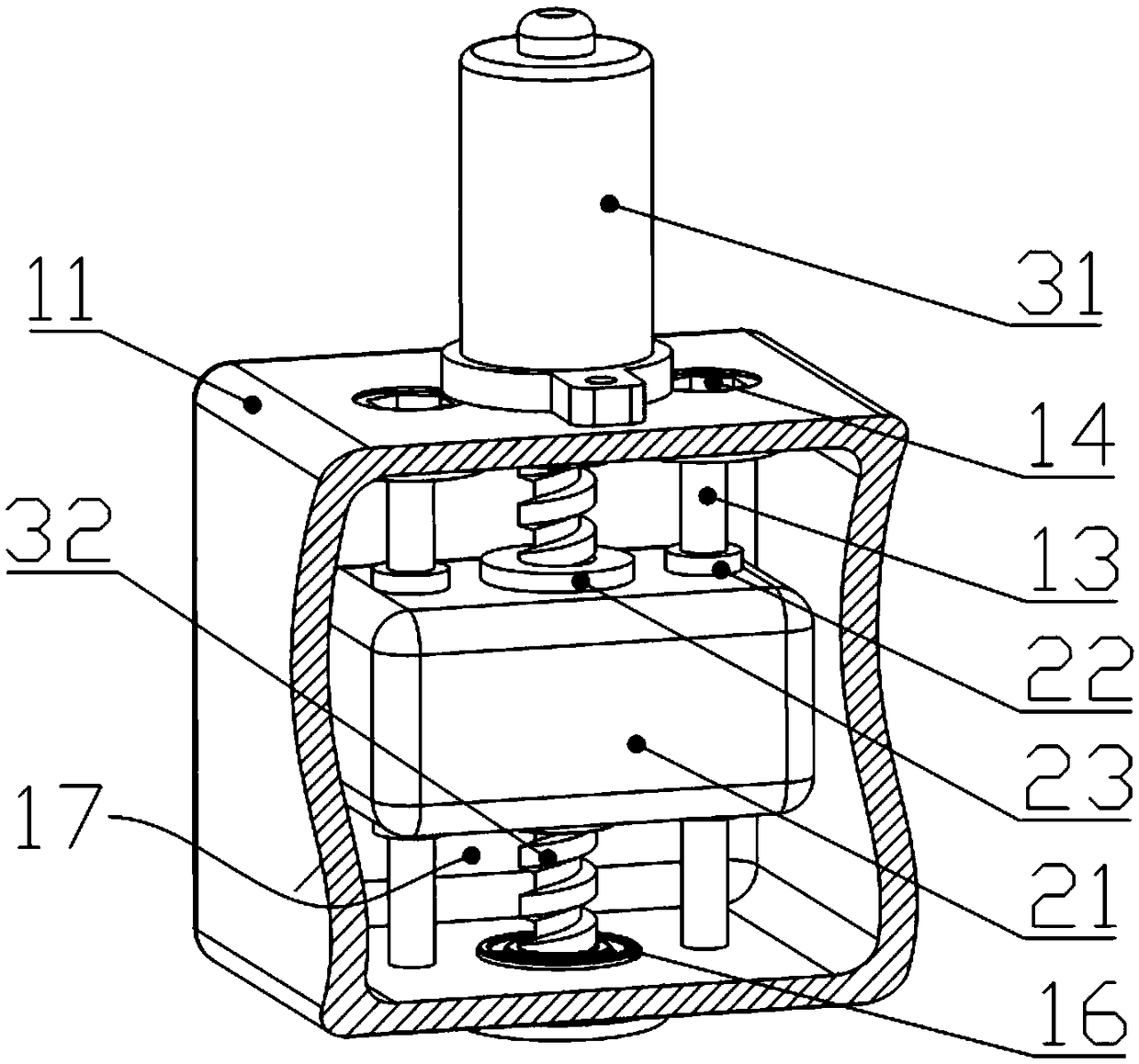

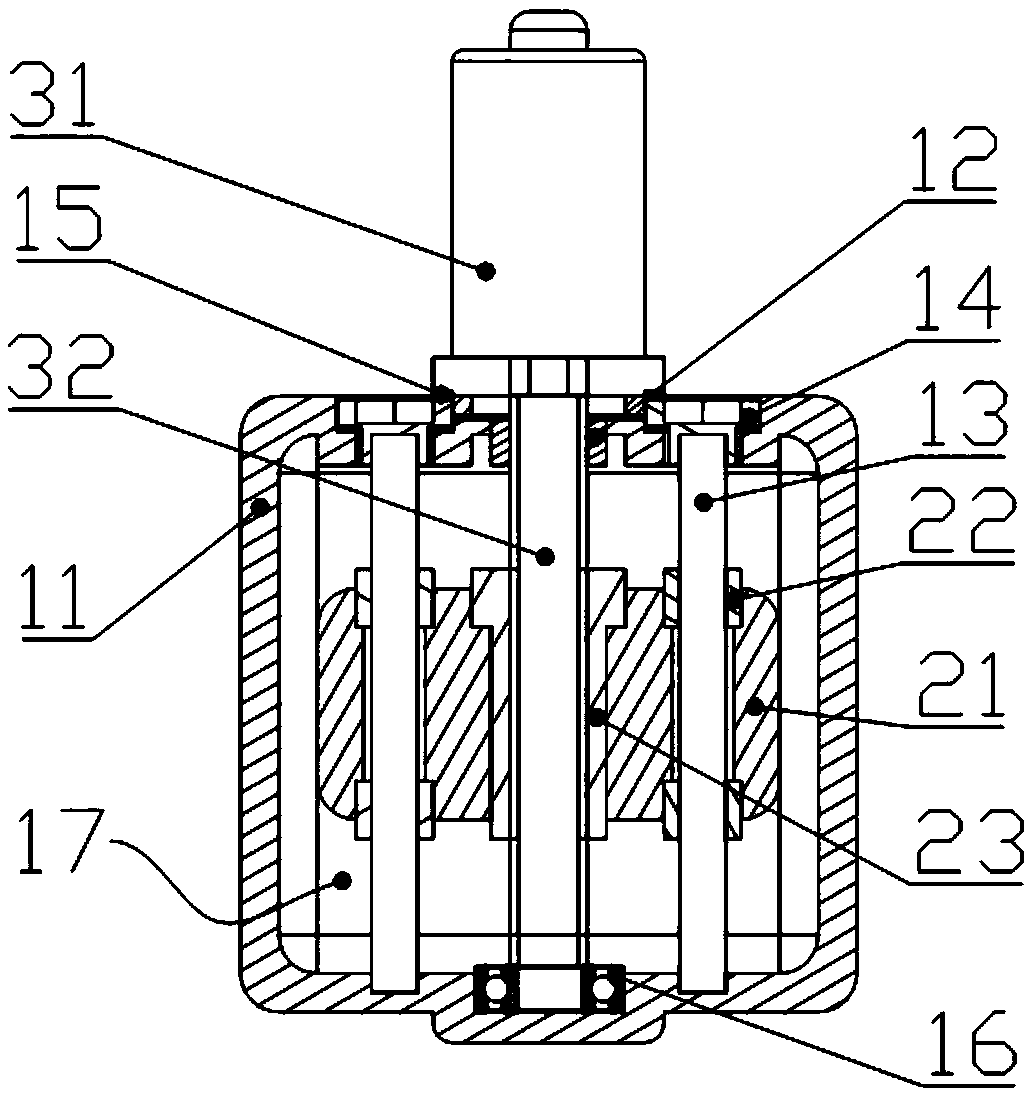

[0035] In order to further illustrate the technical scheme and working process of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0036] The gearbox lubricating oil level control system of the present invention is composed of four parts, namely: a support and guide assembly, an oil drain device, a lifting device and a control assembly.

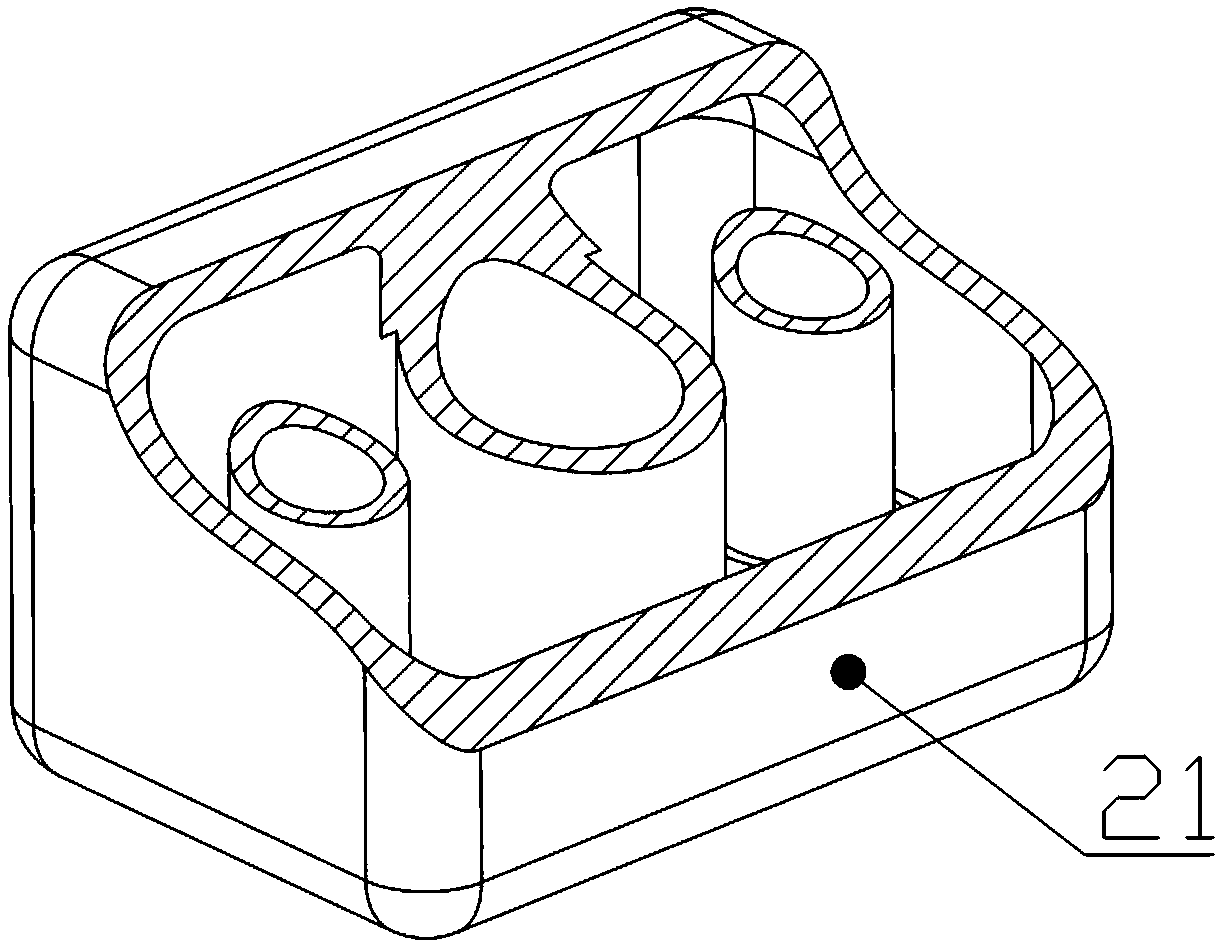

[0037] The support and guide assembly provides a fixed base and support for the gearbox lubricating oil level control system of the present invention. Such as figure 1 with figure 2 As shown, the support and guide assembly is composed of a gearbox housing 11, a support sleeve 12, a guide column 13, a locking bolt 14, a sealing ring 15 and a bearing 16. Among them, such as Figure 4 As shown, the side of the lubricating oil storage bin at the bottom of the gearbox housing 11 is provided with a cavity 17 for installing the gearbox lubricating oil level contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com