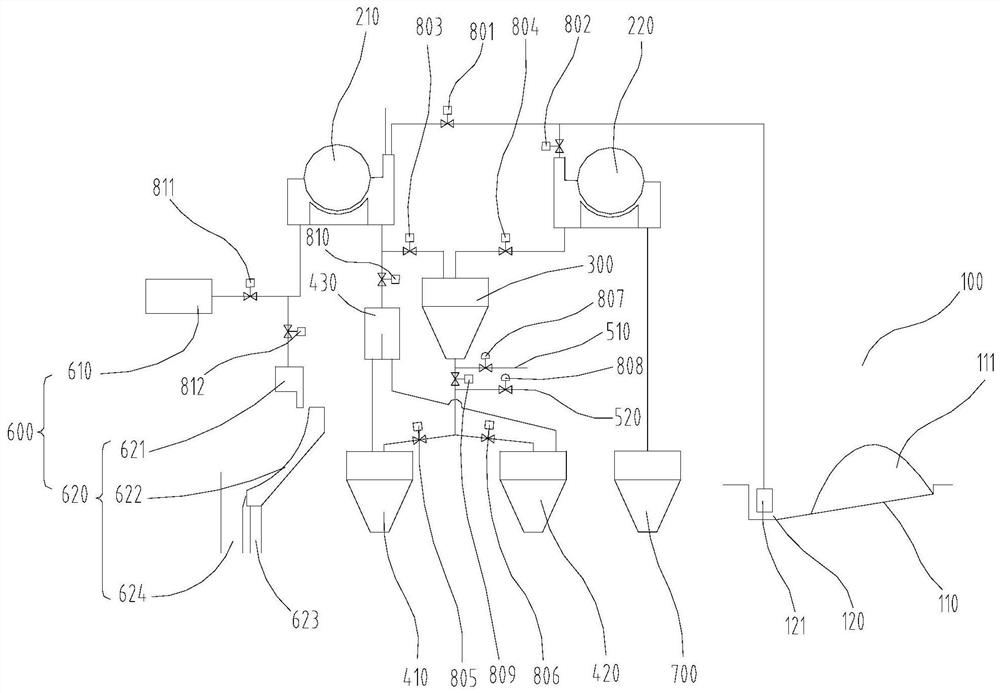

Dense medium density adjusting system for coal dressing

A technology of density adjustment and heavy medium, which is applied in the coal field, can solve the problems of manpower occupation, high labor intensity of manual addition, and lower liquid level and density, so as to reduce density and liquid level, reduce labor intensity, and increase density and liquid bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

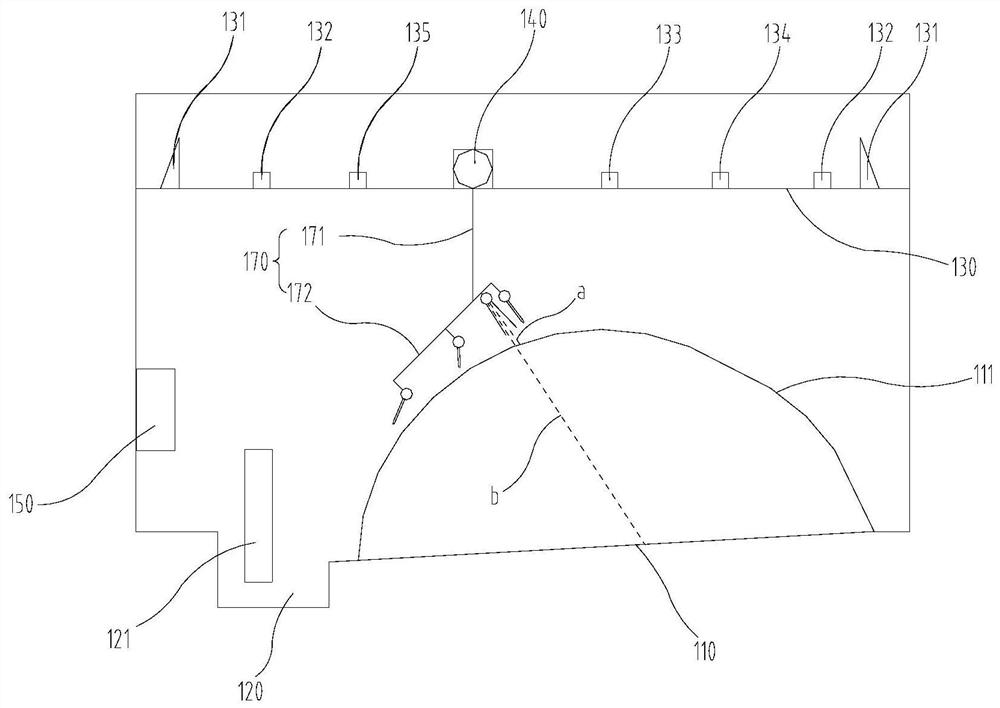

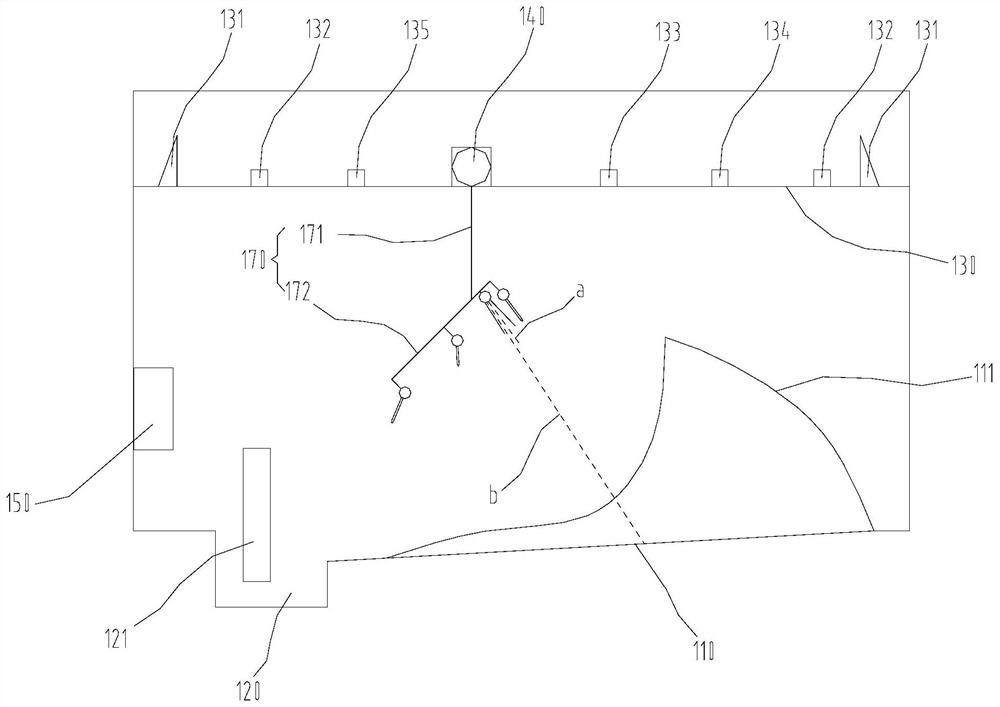

Embodiment Construction

[0034] Next, the technical scheme in the present application embodiment will be clearly described, apparent from the embodiments of the present application, and not all embodiments. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art are the scope of the protection of the present application.

[0035] The term "first", "second", "second", or the like in the specification of the present application and the like are used to distinguish a similar object, and is not intended to describe a particular order or ahead order. It should be understood that the data such as use can be interchanged in appropriate, so that the embodiments of the present application can be implemented in the order other than those illustrated or described herein, and "first", "second", etc. Objects are usually a class, and the number of objects is not limited, such as one of the first object, or multiple.

[0036] DRAWINGS, through specific em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com