Treatment method and treatment system for emulsified liquid

A processing system and a processing method technology, applied in the field of emulsion processing method and processing system, can solve the problems of polluted environment, long reaction time, lack of metal ion removal means, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

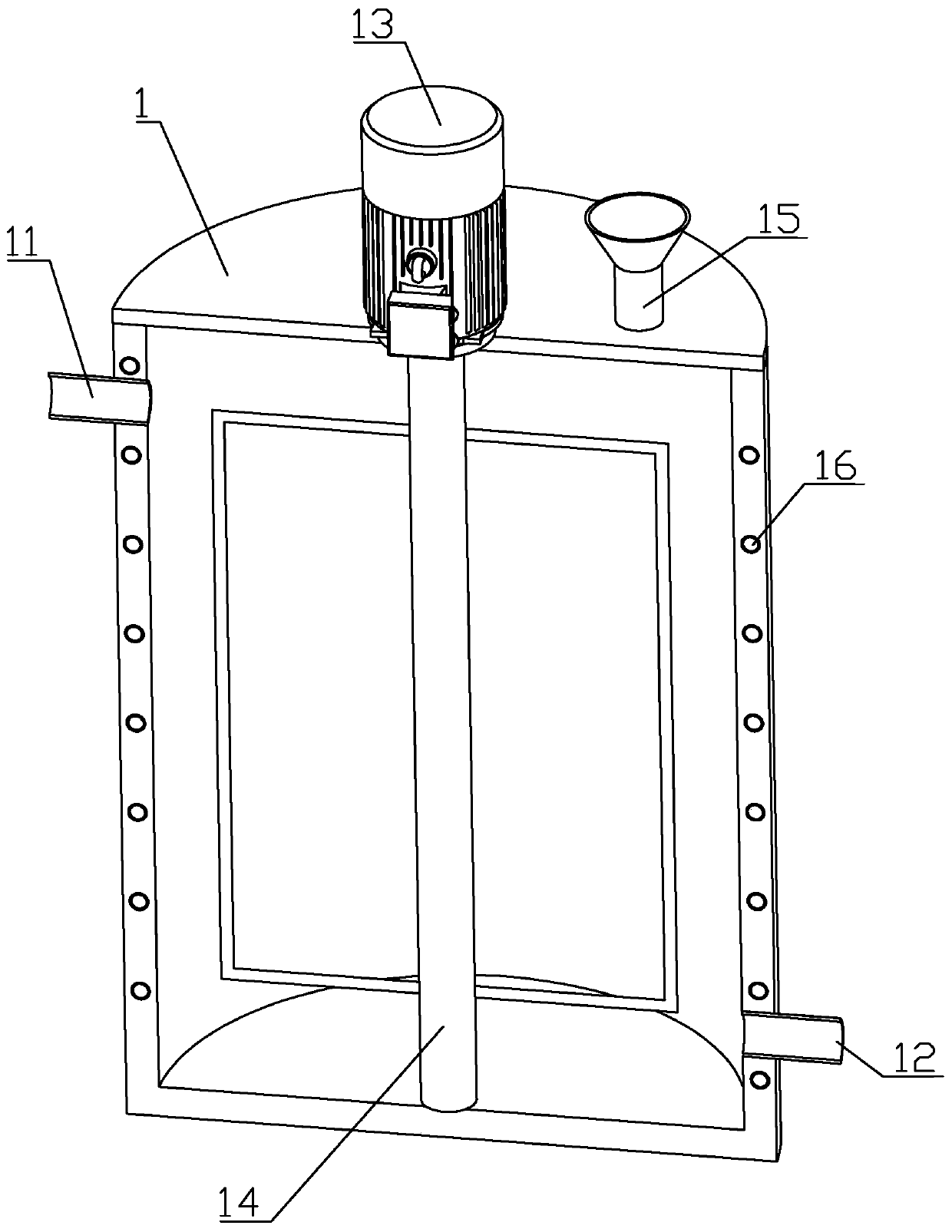

[0042] The present invention will be further described in detail below in conjunction with the drawings.

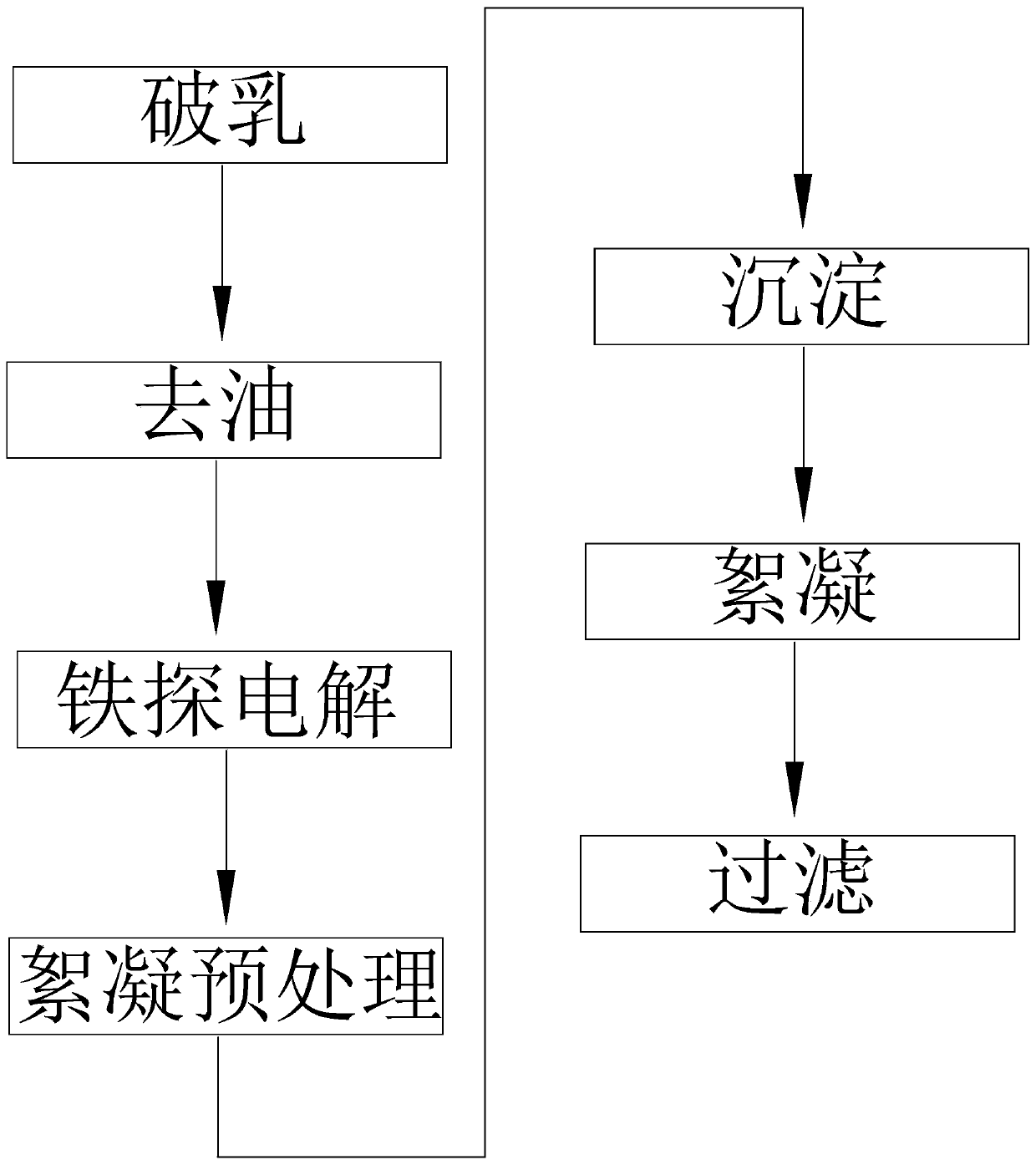

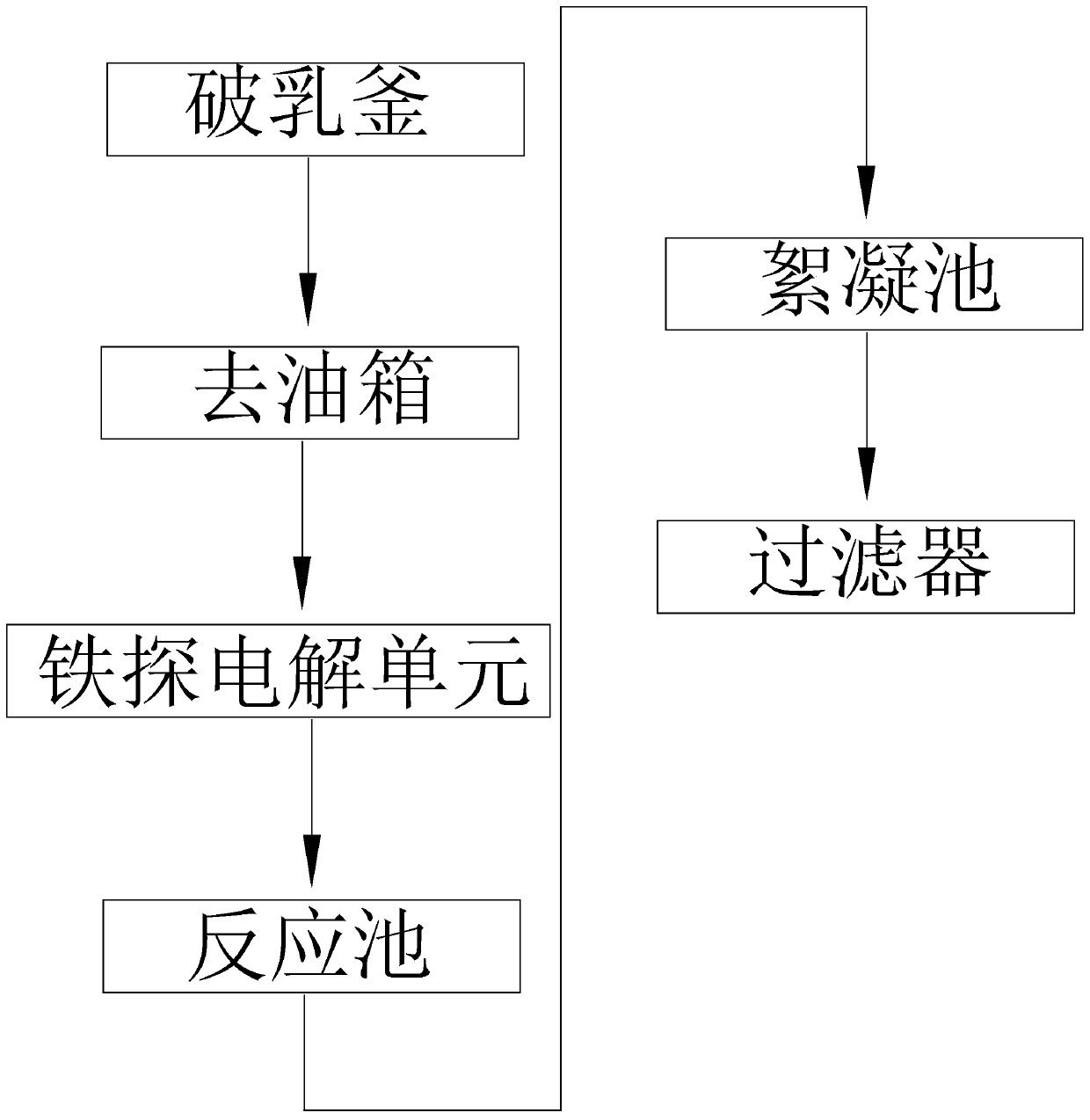

[0043] Reference figure 1 , Is an emulsion processing method disclosed in the present invention, including the following steps:

[0044] a. Demulsification: heat and stir the emulsion, and at the same time add the demulsifier of FeCl2 solution toward the emulsion to separate the oil and water in the emulsion;

[0045] b. Oil removal: remove the slick oil floating on the surface of the emulsion;

[0046] c. Iron-carbon electrolysis: the waste liquid enters the iron-carbon electrolysis unit, adjust the pH value of the waste liquid to 5, electrolyze at room temperature for 28 minutes, and use the electrode reaction product to activate the organic pollutants in the waste liquid and convert them into non-toxic substances. Reduce the COD value and oil content of wastewater;

[0047] d. Flocculation pretreatment: Add FeCl2 solution to the waste liquid to increase the concentration of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com