Odd taste broad bean deep-frying device

A soy bean oil and strange smell technology is applied to the air treatment device of the oven, oil/fat roasting, roasting and other directions, which can solve the problems such as the inability to discharge the oil fume in time, and the oil is not easy to flow, which is beneficial to the heat preservation effect and prevents the oil from flowing easily. Unstable oil temperature, uniform frying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

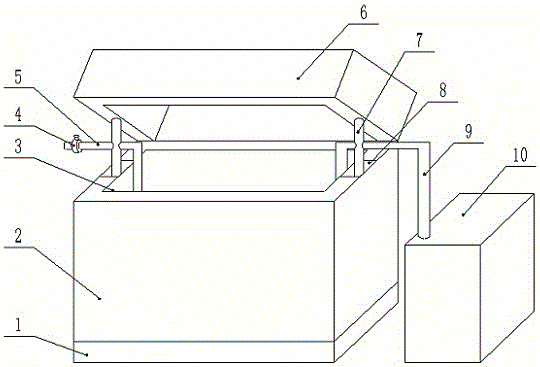

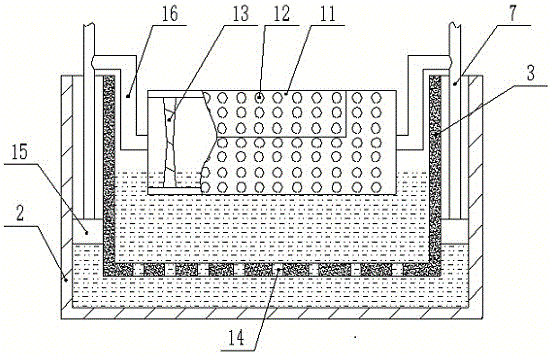

[0013] Description of reference numerals: heater 1, heating tank 2, liner 3, pressure relief valve 4, air intake pipe 5, sealing cover 6, piston rod 7, piston cylinder 8, suction pipe 9, vacuum pump 10, frying cylinder 11 , Oil hole 12, fan blade 13, oil hole 14, piston 15, tube shaft 16.

[0014] Such as figure 1 and figure 2 The shown strange-flavored soybean frying device includes a heater 1 whose fuel is natural gas, a heating tank 2 is placed on the heater 1, a sealing cover 6 is hinged on the heating tank 2, an inner tank 3 is installed in the heating tank 2, and a heating tank 2 A cavity sealed from the top is reserved between the inner tank 3 and eight oil holes 14 communicated with the cavity are evenly distributed on the bottom of the inner tank 3 . The left and right sides of cavity stretch into and are equipped with piston cylinder 8 respectively, and piston cylinder 8 is equipped with piston 15, and piston 15 is hinged with hollow piston rod 7, and the top of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com